Слайд 2Plan

Good manufacturing practice

High-level details

High-level details

Слайд 3Good manufacturing practices (GMP) are the practices required in order to conform to the

guidelines recommended by agencies that control authorization and licensing for manufacture and sale of food, drug products, and active pharmaceutical products. These guidelines provide minimum requirements that a pharmaceutical or a food product manufacturer must meet to assure that the products are of high quality and do not pose any risk to the consumer or public.

Слайд 4High-level details

Good manufacturing practice guidelines provide guidance for manufacturing, testing, and quality assurance

in order to ensure that a food or drug product is safe for human consumption. Many countries have legislated that food and pharmaceutical and medical device manufacturers follow GMP procedures and create their own GMP guidelines that correspond with their legislation.

Слайд 5All guidelines follow a few basic principles:

Manufacturing facilities must maintain a clean and

hygienic manufacturing area.

Controlled environmental conditions in order to prevent cross contamination of food or drug product from adulterants that may render the product unsafe for human consumption.

Слайд 6Manufacturing processes are clearly defined and controlled. All critical processes are validated to ensure consistency

and compliance with specifications.

Manufacturing processes are controlled, and any changes to the process are evaluated. Changes that affect the quality of the drug are validated as necessary.

Слайд 7Instructions and procedures are written in clear and unambiguous language. (Good Documentation Practices)

Operators

are trained to carry out and document procedures.

Cross contamination with unlabelled major allergens is prevented.

Records are made, manually or by instruments, during manufacture that demonstrate that all the steps required by the defined procedures and instructions were in fact taken and that the quantity and quality of the food or drug was as expected. Deviations are investigated and documented.

Слайд 8Records of manufacture (including distribution) that enable the complete history of a batch

to be traced are retained in a comprehensible and accessible form.

The distribution of the food or drugs minimizes any risk to their quality.

Слайд 9A system is available for recalling any batch from sale or supply.

Complaints about

marketed products are examined, the causes of quality defects are investigated, and appropriate measures are taken with respect to the defective products and to prevent recurrence.

Слайд 10Guideline versions

GMPs are enforced in the United States by the U.S. Food and Drug

Administration (FDA), under Title 21 CFR. The regulations use the phrase "current good manufacturing practices" (cGMP) to describe these guidelines. Courts may theoretically hold that a product is adulterated even if there is no specific regulatory requirement that was violated as long as the process was not performed according to industry standards.[citation needed] Since June 2010, a different set of cGMP requirements have applied to all manufacturers of dietary supplements.[

Глистные заболевания, причины возникновения, профилактика

Глистные заболевания, причины возникновения, профилактика Введение в онкологию. Канцерогенез

Введение в онкологию. Канцерогенез Система высшего медицинского образования

Система высшего медицинского образования Пренатальная психология

Пренатальная психология Гемолитические анемии

Гемолитические анемии Стандартизация лекарственного растительного сырь

Стандартизация лекарственного растительного сырь Туберкулез костей и суставов

Туберкулез костей и суставов Нефротикалық синдромның емдеу

Нефротикалық синдромның емдеу Антимикробные химиотерапевтические препараты. Механизмы действия. Осложнения антимикробной терапии

Антимикробные химиотерапевтические препараты. Механизмы действия. Осложнения антимикробной терапии Вирустық гепатит қоздырғыштары

Вирустық гепатит қоздырғыштары Осложнения лапароскопических операций

Осложнения лапароскопических операций Предметы и средства гигиены полости рта

Предметы и средства гигиены полости рта Летаргический сон

Летаргический сон Кариес зубов. Причины и механизм образования. Основные теории и гипотезы кариеса (Миллер, Лукомский, Энтин, Шарпенак, Боровский)

Кариес зубов. Причины и механизм образования. Основные теории и гипотезы кариеса (Миллер, Лукомский, Энтин, Шарпенак, Боровский) Неорганические лекарственные средства. Соединения элементов V и VI группы периодической системы

Неорганические лекарственные средства. Соединения элементов V и VI группы периодической системы Иондық сәулелену және оның ағзаға әсері. Дозиметрлік құралдар

Иондық сәулелену және оның ағзаға әсері. Дозиметрлік құралдар Нервно-психическое развитие детей разного возраста. Критерии оценки нервно-психического развития. Семиотика поражения ЦНС

Нервно-психическое развитие детей разного возраста. Критерии оценки нервно-психического развития. Семиотика поражения ЦНС Modal verbs

Modal verbs Биохимия минерализованных тканей

Биохимия минерализованных тканей Формирование правильной осанки

Формирование правильной осанки Вирусные инфекции. Задачи

Вирусные инфекции. Задачи Цирроз печени

Цирроз печени Художественное творчество больных шизофренией и эпилепсией

Художественное творчество больных шизофренией и эпилепсией Сахарный диабет типа I

Сахарный диабет типа I Трансплантация почки

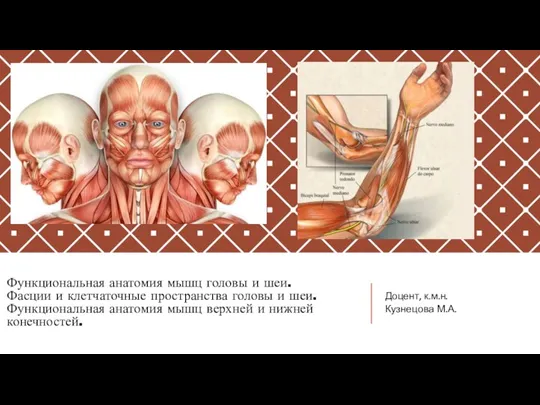

Трансплантация почки Функциональная анатомия мышц головы и шеи. Фасции и клетчаточные пространства головы и шеи. Анатомия мышц конечностей

Функциональная анатомия мышц головы и шеи. Фасции и клетчаточные пространства головы и шеи. Анатомия мышц конечностей Расщелина неба

Расщелина неба Медициналық құралдардың қауіпсіздігі мен сенімділігі

Медициналық құралдардың қауіпсіздігі мен сенімділігі