Содержание

- 2. Content Fundamentals on grinding Different types of ball mills Vertical mills Roller press Horomill

- 3. Content Fundamentals on grinding Different types of ball mills Vertical mills Roller press Horomill

- 4. Why do we grind in the cement business? To create surface area for good chemical reactions

- 5. Where do we grind in the overall cement manufacturing process

- 6. What are the main challenges for cement production Reduce power consumption Maximize production Optimize and improve

- 7. Grinding costs money Grinding uses approx. 60% of plant electricity Cheap power is no longer true

- 9. Grinding costs money Costs of wear parts increasing Joint visits between process and maintenance departments upgrade

- 10. The different types of mill Three different mill types with specific purposes Raw mills (for slag,

- 11. Technologies and arrangements Different mill technologies Ball mills Air swept mill = materials released by ventilation

- 12. Origin of a current workshop Existing workshop design depends on Material feed specifications Feed size Moisture

- 13. Content Fundamentals on grinding Different types of ball mills Vertical mills Roller press Horomill

- 14. The Ball Mill

- 15. The Ball Mill Compound with two compartments

- 16. The ball mill in open circuit Dust Collector Mill Fresh Feed Finished Product Fan gas material

- 17. The ball mill in open circuit Advantages Moderate investment costs Simple operation Simple maintenance Highest reliability

- 18. The ball mill in closed circuit

- 19. The ball mill in closed circuit General description Better regularity thanks to a real control of

- 20. The Bi-rotator Mill

- 21. The Bi-rotator Mill

- 22. The Bi-rotator Mill in closed circuit

- 23. Advantages High ventilation capacity for drying materials Disadvantages False air The Bi-rotator Mill

- 24. The Air-Swept Mill

- 25. The Air-Swept Mill in closed circuit

- 26. Advantages High ventilation capacity to dry materials Disadvantages High specific power consumption due to swept solution

- 27. Content Fundamentals on grinding Different types of ball mills Vertical mills Roller press Horomill

- 28. The Vertical Mill

- 29. The Vertical Mill in closed circuit

- 30. The Vertical Mill Advantages Good efficiency factor High drying capacity Combined grinder, separator and dryer in

- 31. Content Fundamentals on grinding Different types of ball mills Vertical mills Roller press Horomill

- 32. Roller Press

- 33. Roller Press Pneumatic slide choke plates on both sides of feed hopper needed to control intake

- 34. Roller Press Advantages High efficiency factor Compact installation High production increase when used as pregrinding Disadvantages

- 35. Pregrinding with Roller Press Basic pregrinding Preground material could feed into an intermediate bin Approx. 30%

- 36. Pregrinding with Roller Press Hybrid pregrinding Separator rejects are split (partly to ball mill and pregrinder)

- 37. Pregrinding with Roller Press Combined pregrinding (series) Each grinding machine has its own separator Up to

- 38. Content Fundamentals on grinding Different types of ball mills Vertical mills Roller press Horomill

- 39. Horomill General description Horizontal mill Single roller inside a motorized tube shell Slide shoe (thrust pad)

- 40. Horomill

- 41. Horomill

- 42. Horomill Patented device to control retention time RPM > V critical Internal recirculation results in low

- 44. Скачать презентацию

Налоговая система РФ

Налоговая система РФ День Великомучениці Катерини

День Великомучениці Катерини Ревматоидный артрит с позиций доказательной медицины (рандомизированное клиническое исследование )

Ревматоидный артрит с позиций доказательной медицины (рандомизированное клиническое исследование ) Зеленые страницы Новосибирска

Зеленые страницы Новосибирска Презентация к уроку по теме Химические свойства кислот

Презентация к уроку по теме Химические свойства кислот Вред и утилизация батареек

Вред и утилизация батареек Шаблон Факультет

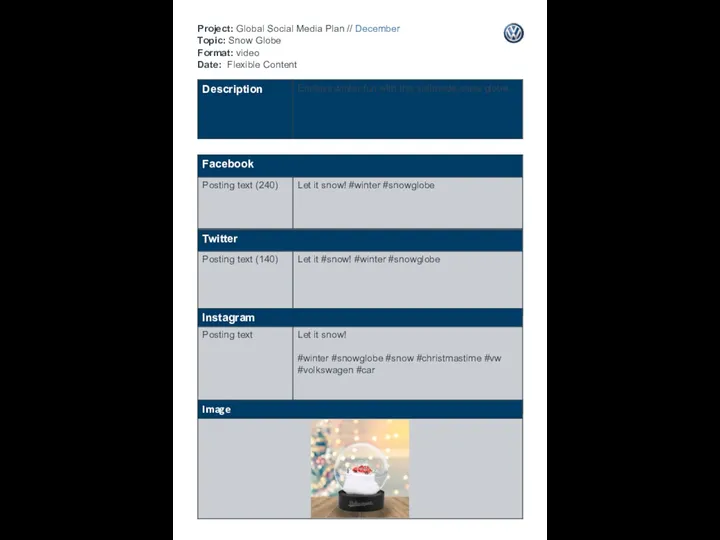

Шаблон Факультет Snow Globe

Snow Globe Мир древности далекий и близкий

Мир древности далекий и близкий Картофельные продукты

Картофельные продукты Оформление классного уголка

Оформление классного уголка Классный час Солдат для первоклассников

Классный час Солдат для первоклассников Презентация Дорогою добра к классному часу Дорогою добра

Презентация Дорогою добра к классному часу Дорогою добра Проект Летопись родного края.

Проект Летопись родного края. Развитие связной речи у детей дошкольного возраста

Развитие связной речи у детей дошкольного возраста Презентация к празднику День защитника Отечества

Презентация к празднику День защитника Отечества Общероссийский конкурс Мой бизнес- моя Россия. Веревочный парк Rope Jungle

Общероссийский конкурс Мой бизнес- моя Россия. Веревочный парк Rope Jungle Четырехугольники. Решение задач

Четырехугольники. Решение задач Интернет-магазин спортивного питания Apollon Market

Интернет-магазин спортивного питания Apollon Market Личностный подход к современной психотерапии зависимостей

Личностный подход к современной психотерапии зависимостей Творчество Мариуса Ивановича Петипа

Творчество Мариуса Ивановича Петипа Reported speech

Reported speech Физико-химия полимеров и их растворов

Физико-химия полимеров и их растворов Рождение протестантизма православия

Рождение протестантизма православия Моя Россия

Моя Россия Лучевая диагностика органов грудной клетки

Лучевая диагностика органов грудной клетки 920752

920752 Цифровая схемотехника. Классификация регистров

Цифровая схемотехника. Классификация регистров