Содержание

- 2. © 2010 Wiley Learning Objectives Define product design and explain its strategic impact on organizations Describe

- 3. © 2010 Wiley Learning Objectives – con’t Understand how to use a process flowchart Understand how

- 4. © 2010 Wiley Product Design & Process Selection - defined Product design – the process of

- 5. © 2010 Wiley Design of Services versus Goods Service design is unique in that the service

- 6. © 2010 Wiley The Product Design Process Idea development: all products begin with an idea whether

- 7. © 2010 Wiley Product Design Process Idea developments selection affects Product quality Product cost Customer satisfaction

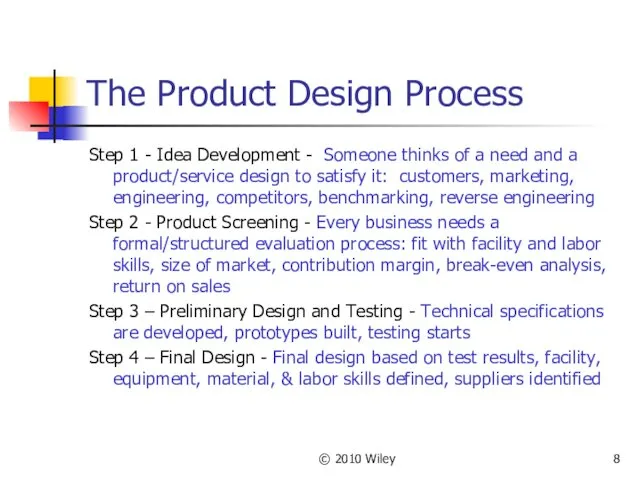

- 8. © 2010 Wiley The Product Design Process Step 1 - Idea Development - Someone thinks of

- 9. © 2010 Wiley Product Screening Tool – Break-Even Analysis Computes the quantity of goods company needs

- 10. © 2010 Wiley Product Screening Tool – Break-Even Analysis con’t Break-even analysis also includes calculating Total

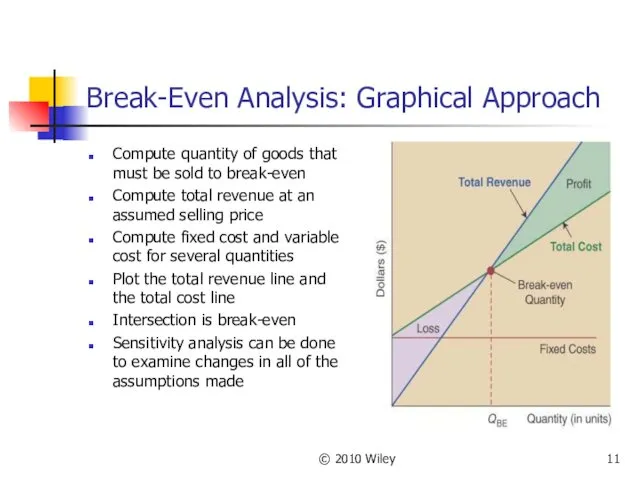

- 11. © 2010 Wiley Break-Even Analysis: Graphical Approach Compute quantity of goods that must be sold to

- 12. © 2010 Wiley Break-Even Example: A company is planning to establish a chain of movie theaters.

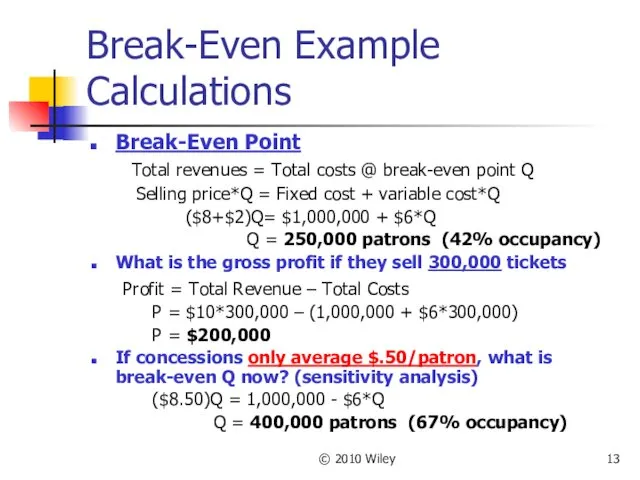

- 13. © 2010 Wiley Break-Even Example Calculations Break-Even Point Total revenues = Total costs @ break-even point

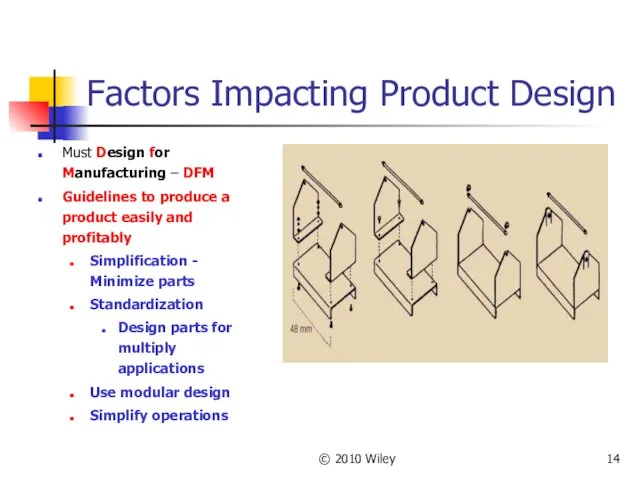

- 14. © 2010 Wiley Factors Impacting Product Design Must Design for Manufacturing – DFM Guidelines to produce

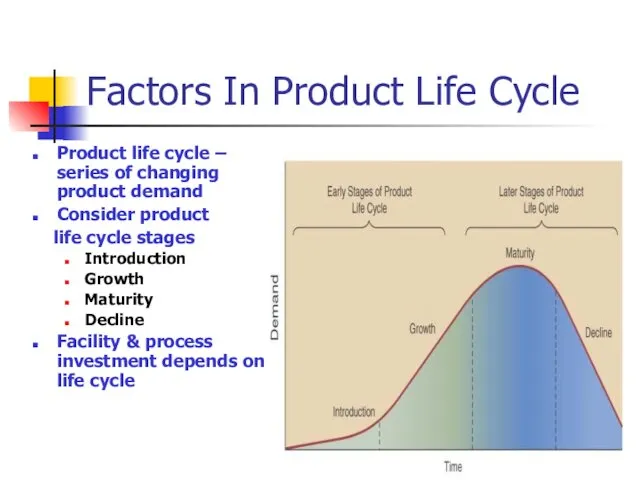

- 15. © 2010 Wiley Factors In Product Life Cycle Product life cycle – series of changing product

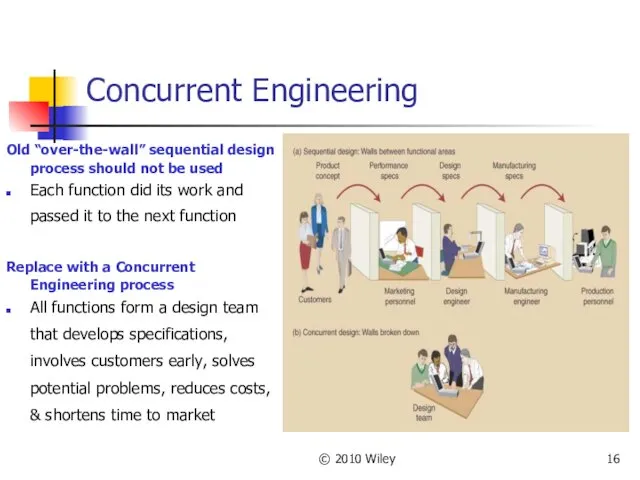

- 16. © 2010 Wiley Concurrent Engineering Old “over-the-wall” sequential design process should not be used Each function

- 17. © 2010 Wiley Remanufacturing Uses components of old products in the production of new ones and

- 18. © 2010 Wiley Types of Processes Intermittent processes: Processes used to produce a variety of products

- 19. © 2010 Wiley Process Selection Product design considerations must include the process Differences between Intermittent &

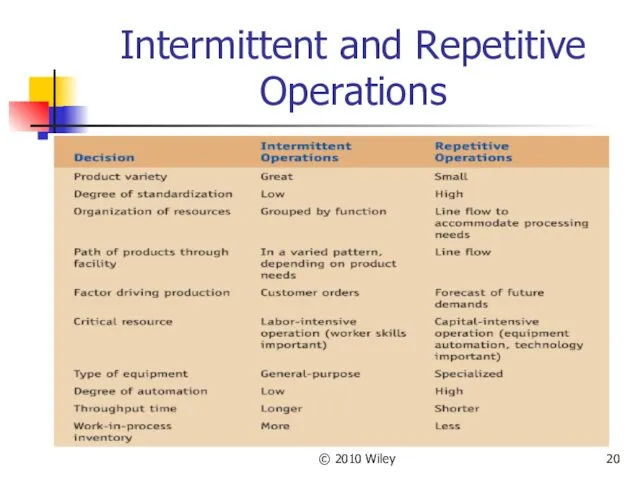

- 20. © 2010 Wiley Intermittent and Repetitive Operations

- 21. © 2010 Wiley Process Selection Types Process types can be: Project process – make a one-at-a-time

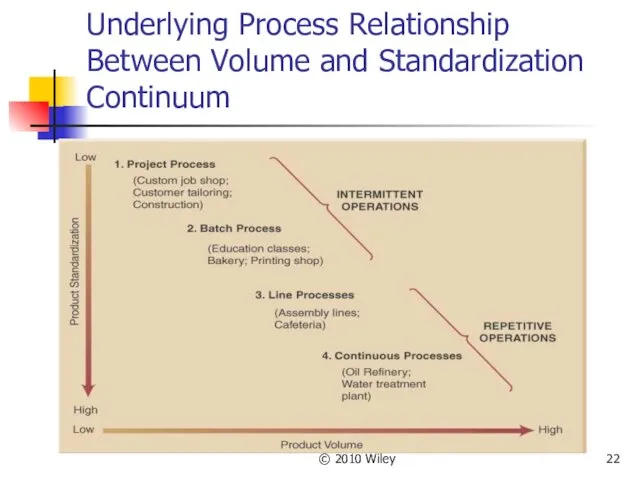

- 22. © 2010 Wiley Underlying Process Relationship Between Volume and Standardization Continuum

- 23. © 2010 Wiley Process Selection Considerations Process selection is based on five considerations Type of process;

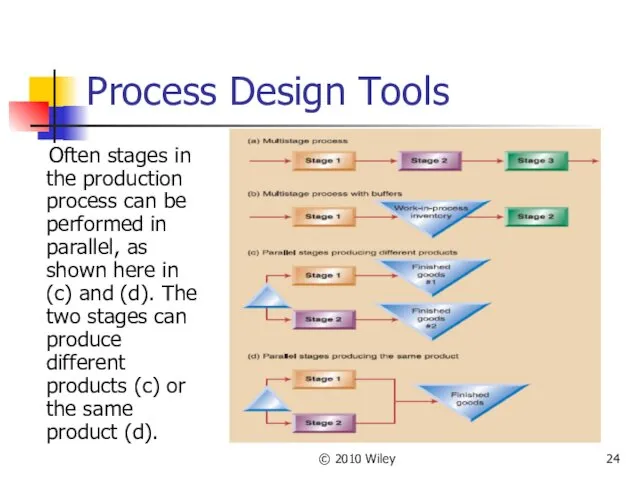

- 24. © 2010 Wiley Process Design Tools Often stages in the production process can be performed in

- 25. © 2010 Wiley Designing Processes Process design tools include Process flow analysis Process flowchart Design considerations

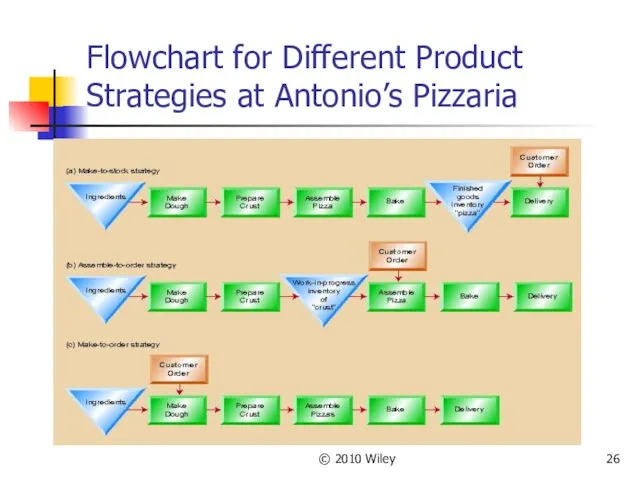

- 26. © 2010 Wiley Flowchart for Different Product Strategies at Antonio’s Pizzaria

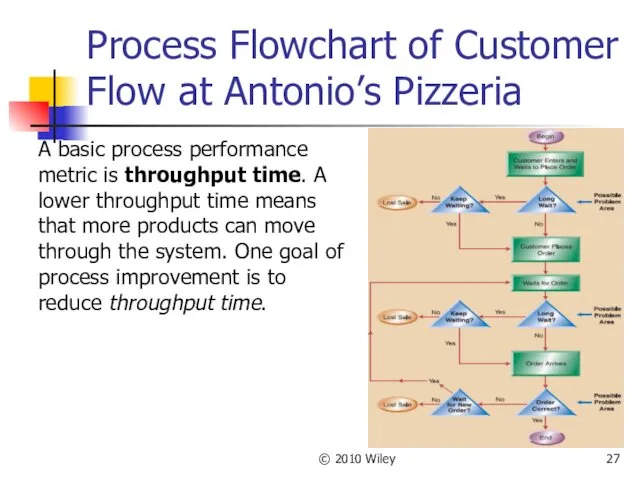

- 27. © 2010 Wiley Process Flowchart of Customer Flow at Antonio’s Pizzeria A basic process performance metric

- 28. © 2010 Wiley Process Performance Metrics Process performance metrics – defined: Measurement of different process characteristics

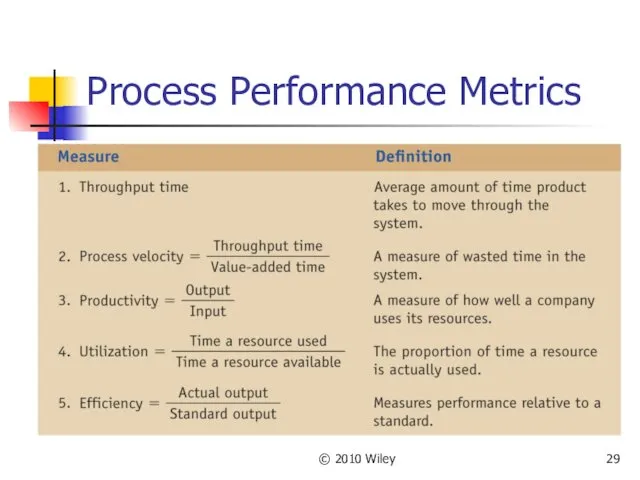

- 29. © 2010 Wiley Process Performance Metrics

- 30. © 2010 Wiley Linking Product Design & Process Selection Product design and process selection are directly

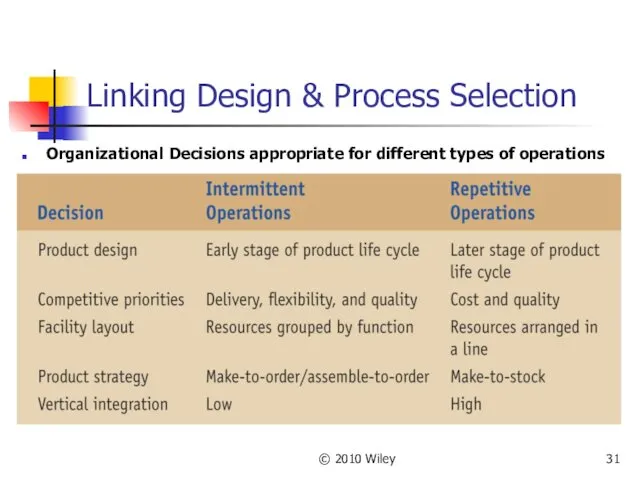

- 31. © 2010 Wiley Linking Design & Process Selection Organizational Decisions appropriate for different types of operations

- 32. © 2010 Wiley Linking Product Design & Process Selection con’t Product Design Decisions: Intermittent and repetitive

- 33. © 2010 Wiley Linking Product Design & Process Selection, con’t Competitive Priorities: decisions of how a

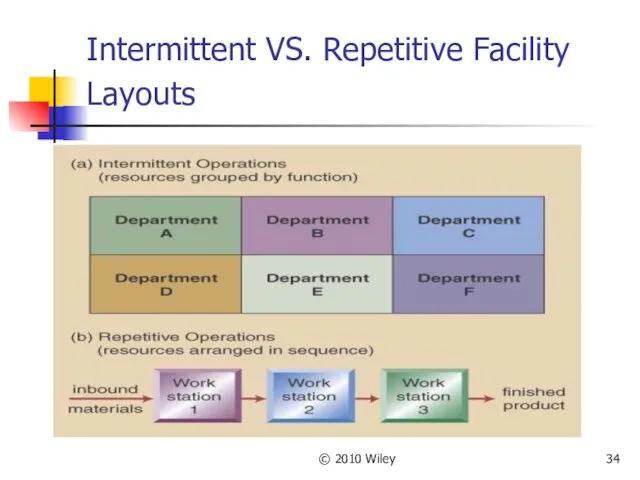

- 34. © 2010 Wiley Intermittent VS. Repetitive Facility Layouts

- 35. © 2010 Wiley Product and Service Strategy Type of operation is directly related to product and

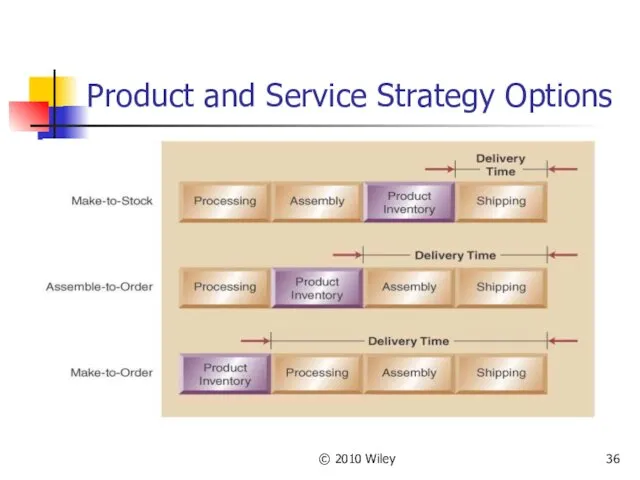

- 36. © 2010 Wiley Product and Service Strategy Options

- 37. © 2010 Wiley Degrees of Vertical Integration & Make or Buy Vertical integration refers to the

- 38. © 2010 Wiley Technology Decisions Information Technology Simplify first then apply appropriate technology ERP, GPS, RFID

- 39. © 2010 Wiley E-manufacturing Web-based environment creates numerous business opportunities to include; Product design collaboration Process

- 40. © 2010 Wiley Designing Services: How do they Differ from Manufacturing? Services are different from manufacturing

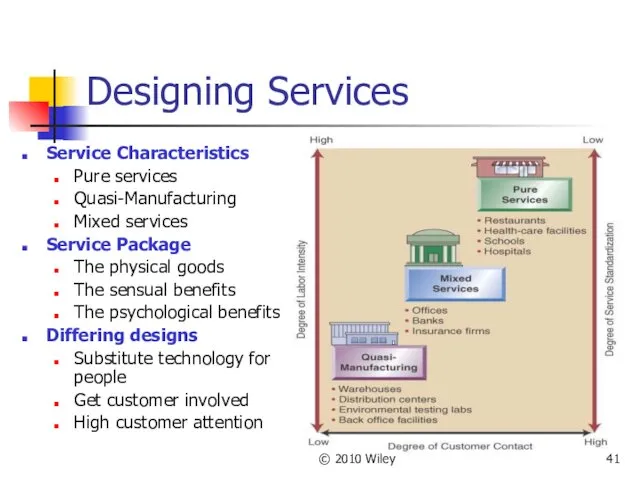

- 41. © 2010 Wiley Designing Services Service Characteristics Pure services Quasi-Manufacturing Mixed services Service Package The physical

- 42. © 2010 Wiley Product Design and Process Selection Across the Organization Strategic and financial of product

- 43. © 2010 Wiley Product Design and Process Selection Across the Organization – con’t Strategic and financial

- 44. © 2010 Wiley Chapter 3 Highlights Product design is the process of deciding on the unique

- 45. © 2010 Wiley Chapter 3 Highlights con’t Product design and process selection decisions are linked Process

- 47. Скачать презентацию

Меры поддержки для малого и среднего бизнеса

Меры поддержки для малого и среднего бизнеса Поддержка социальных предпринимателей

Поддержка социальных предпринимателей Социальный проект ДекАРТоника

Социальный проект ДекАРТоника Разработка бизнес-плана

Разработка бизнес-плана Бизнес-курс. Начало. Этапы прохождения курса

Бизнес-курс. Начало. Этапы прохождения курса Экологический туризм

Экологический туризм Туризм Ашхабаду

Туризм Ашхабаду Антикафе. Критерии оценки бизнес-идеи

Антикафе. Критерии оценки бизнес-идеи Отель Holiday Inn Samara

Отель Holiday Inn Samara Переработка сырья сельского хозяйства. Бизнес-план

Переработка сырья сельского хозяйства. Бизнес-план Основные этапы подготовки внешнеторговых сделок

Основные этапы подготовки внешнеторговых сделок DoubleTree by Hilton tyumen, Russia

DoubleTree by Hilton tyumen, Russia Содействие малому и среднему бизнесу. Главные деятели

Содействие малому и среднему бизнесу. Главные деятели Бизнес-жоспар Туристік компания

Бизнес-жоспар Туристік компания ООО Велес. Реализация концепции комплексной системы безопасности, систем связи и слаботочных систем

ООО Велес. Реализация концепции комплексной системы безопасности, систем связи и слаботочных систем Компания АО Третий парк

Компания АО Третий парк LOTTE. Отель 5*

LOTTE. Отель 5* Организация деловых туров

Организация деловых туров Хостел Библиотека Лиговский

Хостел Библиотека Лиговский Продажи – сердце бизнеса

Продажи – сердце бизнеса Оформление и обработка заказа клиента по подбору пакетного тура. Команда № 3

Оформление и обработка заказа клиента по подбору пакетного тура. Команда № 3 Проект Маникюрный кабинет

Проект Маникюрный кабинет Владимирская дверная компания. Итоги 2017 года

Владимирская дверная компания. Итоги 2017 года ООО Санта Ритейл

ООО Санта Ритейл О создании на территории Московской области центров оказания услуг для бизнеса

О создании на территории Московской области центров оказания услуг для бизнеса Бизнес-план открытия тюнинг-ателье Permtuning

Бизнес-план открытия тюнинг-ателье Permtuning Шаблон проекта

Шаблон проекта 7 найменших готелів світу

7 найменших готелів світу