Слайд 2

3D Simulation

The wire-frame 3D simulation allows to display on the

PC the real machining process, therefore detecting and correcting the possible mistakes beforehand

Approximate calculation of machining time

Possibility of displaying the real tool shape

Availability of rotation and zoom functions

Слайд 3

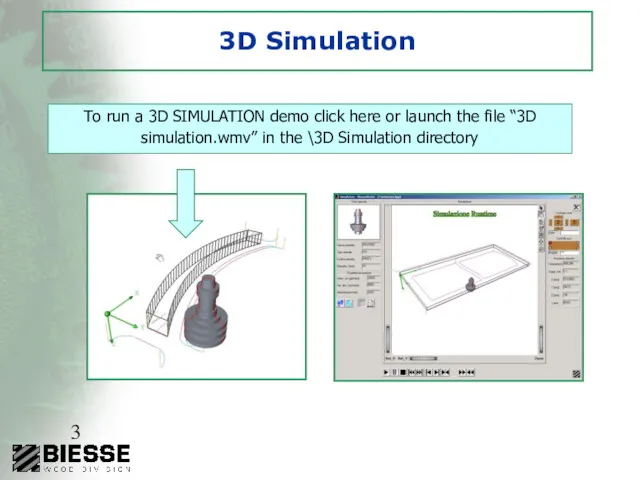

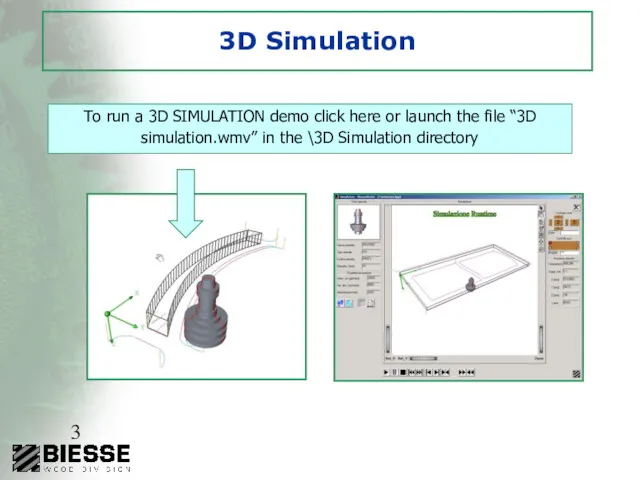

3D Simulation

To run a 3D SIMULATION demo click here or launch

the file “3D simulation.wmv” in the \3D Simulation directory

Слайд 4

Pocketing and text engraving

Automatic calculation of the tool routes necessary

for the performance of automatic pocketing operations of any geometrical shape with a single tool

Possibility of leaving islands in relief at different depths

Pocketing can be performed with concentric or parallel runs or cuts and it is possible to provide an edge-finishing pass

Bidimensional engraving of text using Windows True Type Fonts

Possibility of tilting the text or positioning it on a circumference

Слайд 5

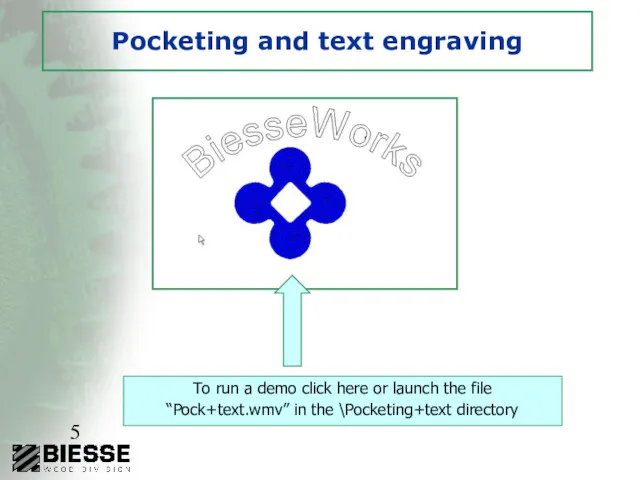

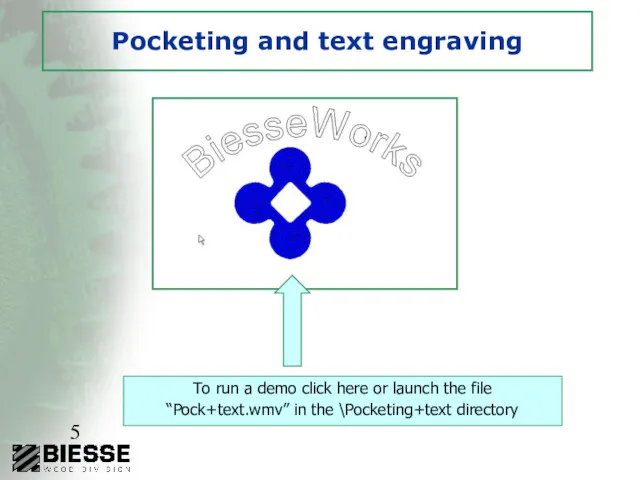

Pocketing and text engraving

To run a demo click here or launch

the file “Pock+text.wmv” in the \Pocketing+text directory

Слайд 6

Sides defined by the operator

Creation of linear and circular sides

defined by the operator in addition to the 6 standard panel sides

The linear and circular sides defined by the operator are considered by BiesseWorks as new sides in every respect and are displayed next to the panel

On the new sides it is therefore possible to define the workings in an extremely simple way, by using local reference points and making the software perform all the necessary calculations

Programming sides defined by the operator is therefore absolutely similar to programming the standard panel sides

Слайд 7

Sides defined by the operator

To run a demo click here or

launch the file “Sides.wmv” in the \Custom sides directory

Слайд 8

Parametric Work Table Tooling

Creation of parametric rules for the

positioning of locking devices, so that the positioning measures are automatically re-calculated for different panel dimensions or other parameters

By changing the parameters the programs automatically adjust both the workings and the positioning of the elements on the work area

Слайд 9

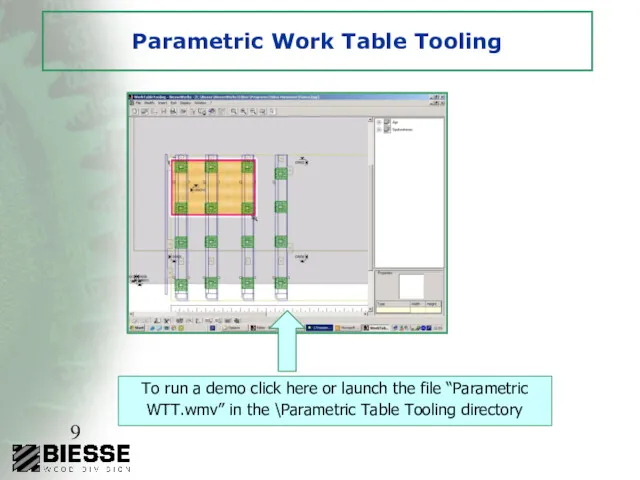

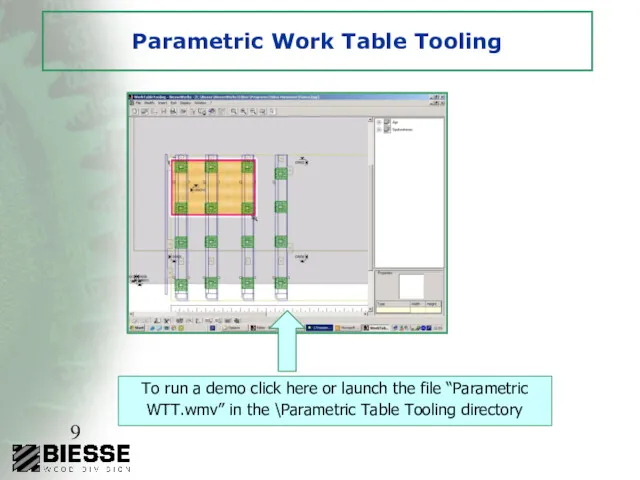

Parametric Work Table Tooling

To run a demo click here or launch

the file “Parametric WTT.wmv” in the \Parametric Table Tooling directory

Слайд 10

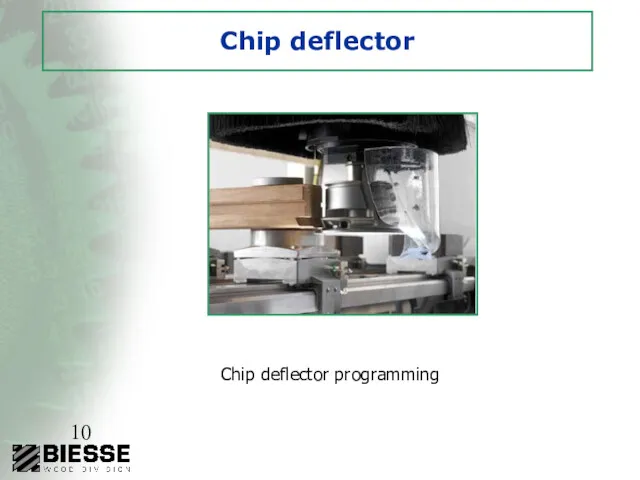

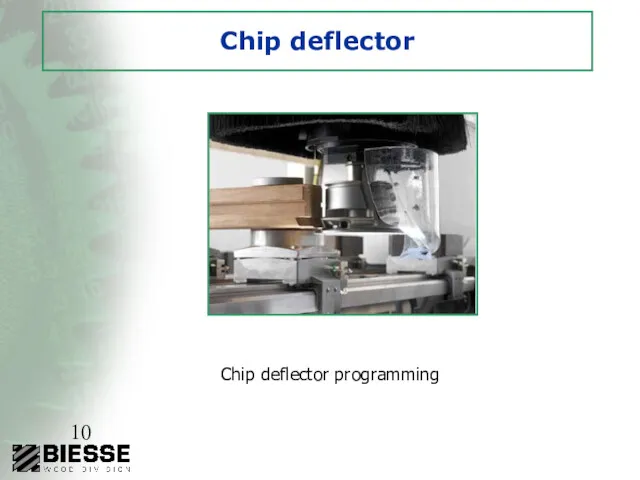

Chip deflector

Chip deflector programming

Слайд 11

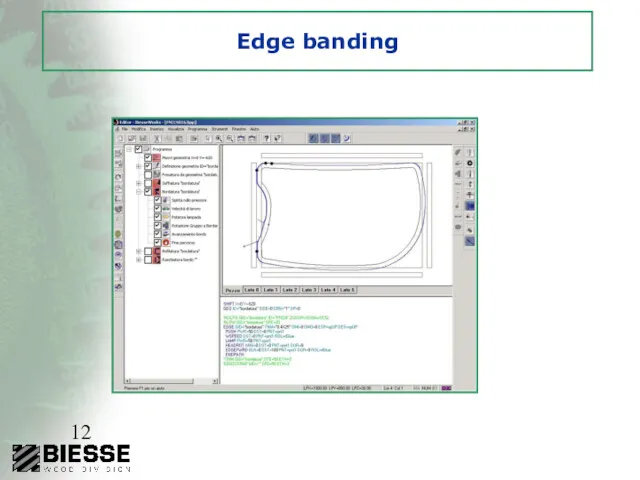

Edge banding

Easy and friendly programming for the edge banding and

finishing process

Tools for the modification of process parameters on every point of the profile (speed, pressure, etc), used for machining particular materials or profiles

Machining simulation and collision djnamic control to grant a safe work table set up

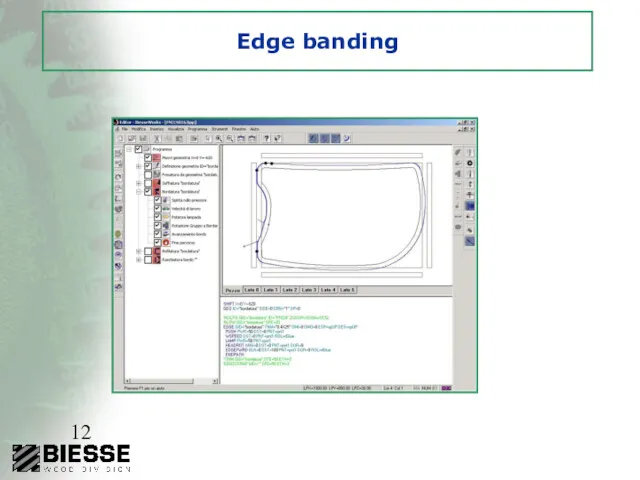

Слайд 12

Электронный информационный объект. Сборочный чертеж

Электронный информационный объект. Сборочный чертеж Шрифты в архитектурной графике

Шрифты в архитектурной графике Autodesk inventor файл-шаблон чертежа. Модуль поддержка ЕСКД. Базовый вид. Проекционный вид. Слои. Свойство ассоциативности

Autodesk inventor файл-шаблон чертежа. Модуль поддержка ЕСКД. Базовый вид. Проекционный вид. Слои. Свойство ассоциативности Подготовка к контрольной работе по начертательной геометрии

Подготовка к контрольной работе по начертательной геометрии Угловая перспектива

Угловая перспектива Нарезание наружной и внутренней резьбы

Нарезание наружной и внутренней резьбы Зображення об’єктів на технічних креслениках. Види. Лекція 2

Зображення об’єктів на технічних креслениках. Види. Лекція 2 Построение геометрических тел. Сопряжения

Построение геометрических тел. Сопряжения Проекции плоскости (Лекция 3)

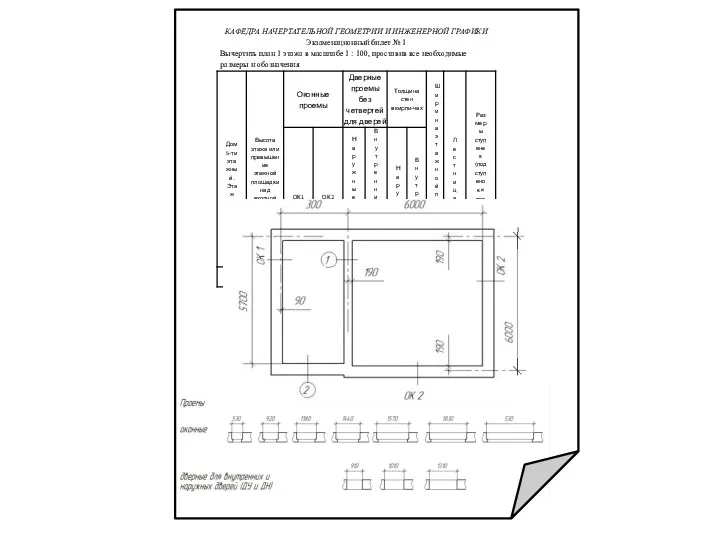

Проекции плоскости (Лекция 3) Строительное черчение. План этажа

Строительное черчение. План этажа Разрезы и сеченя в чертежах сложных деталей

Разрезы и сеченя в чертежах сложных деталей Свойства ортогонального проецирования. Комплексный чертеж. (Лекция 1)

Свойства ортогонального проецирования. Комплексный чертеж. (Лекция 1) Начертательная геометрия, инженерная и компьютерная графика. Курсовой проект

Начертательная геометрия, инженерная и компьютерная графика. Курсовой проект Труба для канализаций

Труба для канализаций Desen tehnic. Dispunerea proiectiilor

Desen tehnic. Dispunerea proiectiilor Резьба. Классификация резьбы. Изображение и обозначение резьбы на чертежах

Резьба. Классификация резьбы. Изображение и обозначение резьбы на чертежах Загальні правила оформлення креслеників

Загальні правила оформлення креслеників Соединения разъёмные

Соединения разъёмные Единая система конструкторской документации

Единая система конструкторской документации Фронтальная перспектива в архитектуре

Фронтальная перспектива в архитектуре Фронтальная перспектива интерьера

Фронтальная перспектива интерьера Рекомендации по выполнению контрольной работы по инженерной графике

Рекомендации по выполнению контрольной работы по инженерной графике Резьбовые соединения

Резьбовые соединения МДК 01.01., 20.03.2021, ПР 1

МДК 01.01., 20.03.2021, ПР 1 Дисциплина:Современное проектирование зданий и сооружений. Основные параметры

Дисциплина:Современное проектирование зданий и сооружений. Основные параметры Нарезание резьбы

Нарезание резьбы Линии чертежа

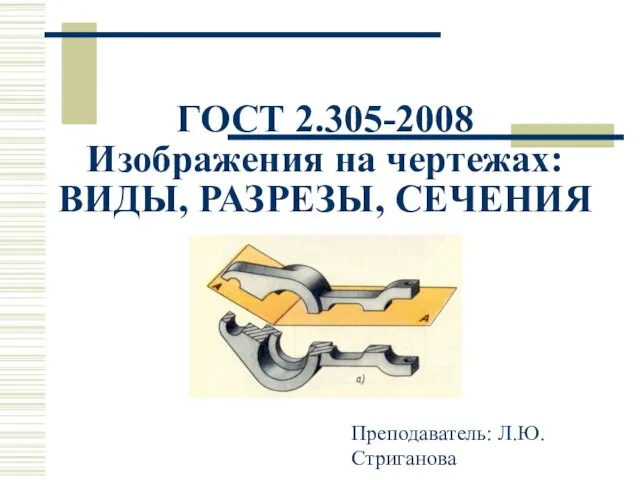

Линии чертежа ГОСТ 2.305-2008. Изображения на чертежах: виды, разрезы, сечения

ГОСТ 2.305-2008. Изображения на чертежах: виды, разрезы, сечения