Содержание

- 2. КЛАССИЧЕСКОЕ ФЕРМЕНТНОЕ РЕШЕНИЕ САМОЕ ЭФФЕКТИВНОЕ ВСЕ-В-ОДНОМ Brewers Compass® Пивоварение с ячменем Февраль 2020, Алматы Константин Кляритский

- 3. Пивоварение с ячменем. Экономии и снижение влияния пива на CO2 -выбросы В среднем: 55% ячменя В

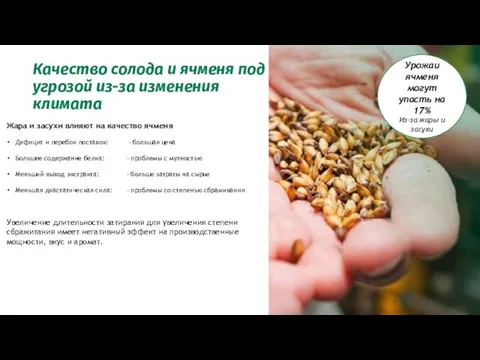

- 4. Качество солода и ячменя под угрозой из-за изменения климата Жара и засухи влияют на качество ячменя

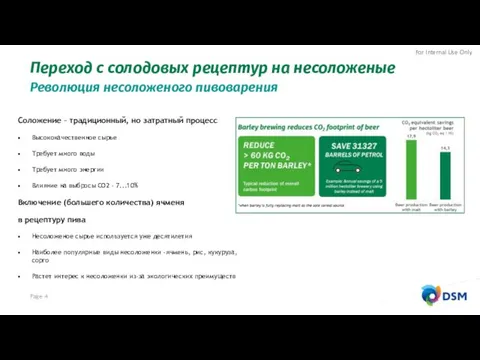

- 5. Соложение – традиционный, но затратный процесс Высококачественное сырье Требует много воды Требует много энергии Влияние на

- 6. DSM помогает преодолеть вызовы пивоварения с несоложеным сырьем Page Вызовы пивоварения с несоложеным сырьем Недостаток диастатической

- 7. Brewers Compass® Самое эффективное, классическое ферментное решение для ячменного пивоварения. Все-в одном.

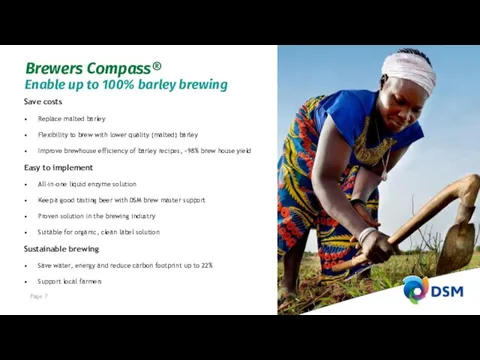

- 8. Page Save costs Replace malted barley Flexibility to brew with lower quality (malted) barley Improve brewhouse

- 9. The best performing all-in-one classical enzyme solution Experiences with Brewers Compass® Mash profile was optimized for

- 10. Page

- 11. Рассчитайте ваши экономии Calculate my costs savings

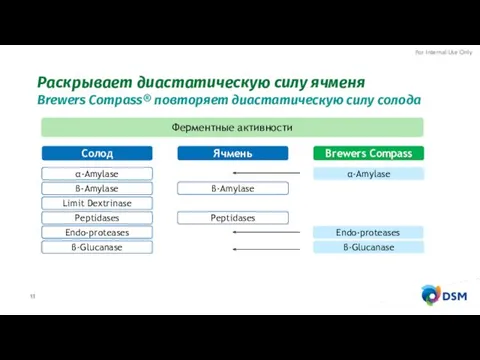

- 12. Brewers Compass® повторяет диастатическую силу солода Солод Brewers Compass Ячмень α-Amylase β-Amylase Limit Dextrinase Peptidases Endo-proteases

- 13. Добавляется в начале затирания Brewers Compass®

- 14. Проверить параметры сусла науровень FAN Профиль сахаров Вязкость Бета глюканы Page Пивовары DSM поддержат Сохранить тот

- 15. Тест с местным сырьем в лаборатории Tepral filtration Тест в промышленном масштабе. Page Пивовары DSM поддержат

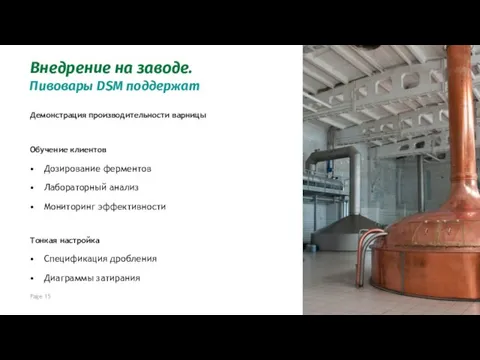

- 16. Демонстрация производительности варницы Обучение клиентов Дозирование ферментов Лабораторный анализ Мониторинг эффективности Тонкая настройка Спецификация дробления Диаграммы

- 17. Пивоваренные лаборатории , Delft (NL) и Shanghai Служба технологической поддержки клиентов Фокус на Затирание и фильтрацию

- 18. Команда пивоваров по всему миру DSM Food Specialties – DSM Brewing Как мы это делаем... МЕСТНЫЕ

- 19. ПОРТФЕЛЬ ФЕРМЕНТОВ DSM ДЛЯ НЕСОЛОЖОНОГО ПИВОВАРЕНИЯ

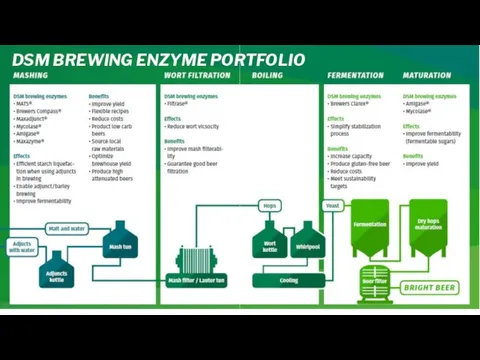

- 20. DSM BREWING ENZYME PORTFOLIO

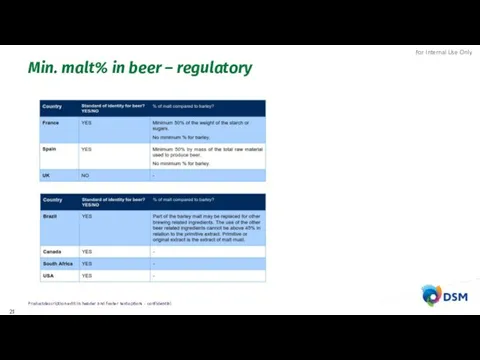

- 22. Min. malt% in beer – regulatory Productdescription edit in header and footer textoptions - confidential

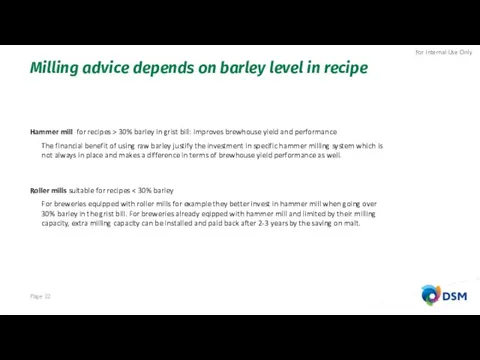

- 23. Hammer mill for recipes > 30% barley in grist bill: improves brewhouse yield and performance The

- 24. Assumptions CO2 reduction adjunct brewing Malting = 15-20% of total beer carbon footprint Agriculture = 15

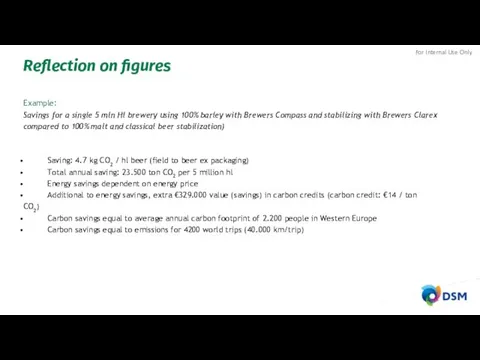

- 25. Reflection on figures Saving: 4.7 kg CO2 / hl beer (field to beer ex packaging) Total

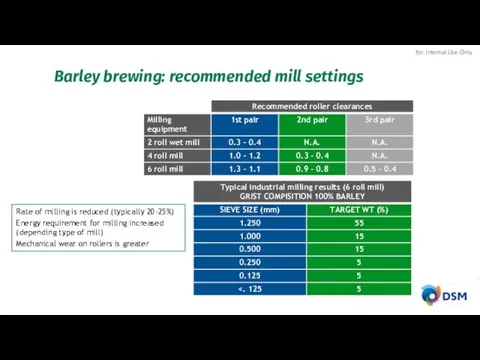

- 26. Barley brewing: recommended mill settings Rate of milling is reduced (typically 20-25%) Energy requirement for milling

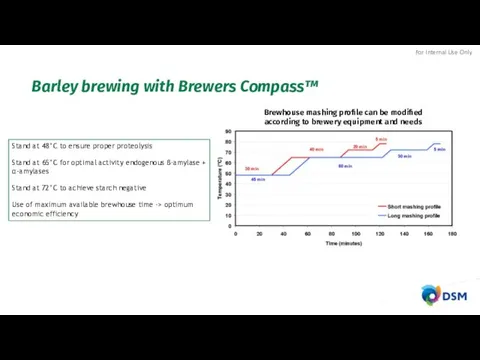

- 27. Stand at 48°C to ensure proper proteolysis Stand at 65°C for optimal activity endogenous β-amylase +

- 28. Brewers Compass™ is a natural mix of enzyme activities, complementing and working synergistically with barley enzymes

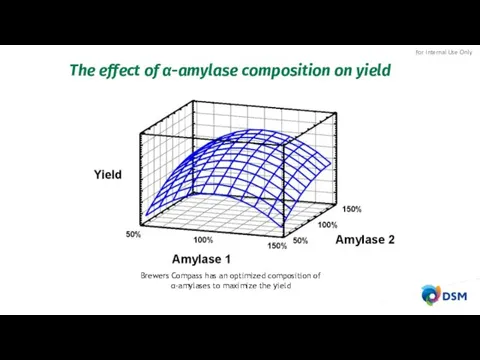

- 29. The effect of α-amylase composition on yield Brewers Compass has an optimized composition of α-amylases to

- 30. Data were generated at commercial scale 10 Ton brewhouse Fermentation vessels 2000 Hl Cereal fraction =

- 31. Brewers Compass: industrial results Particle size distribution after hammer milling

- 32. In this case a 175 minute mash scheme was used (2 mash vessels supplied one mash

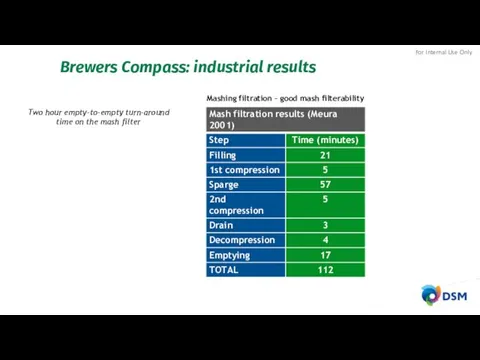

- 33. Two hour empty-to-empty turn-around time on the mash filter Brewers Compass: industrial results Mashing filtration –

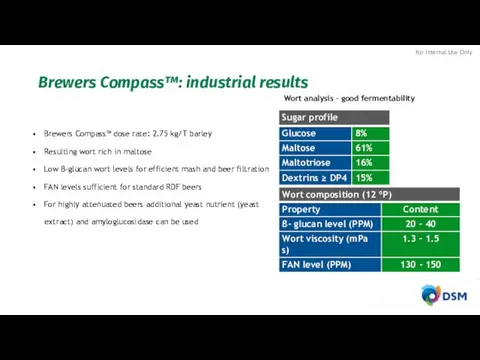

- 34. Brewers Compass™ dose rate: 2.75 kg/T barley Resulting wort rich in maltose Low β-glucan wort levels

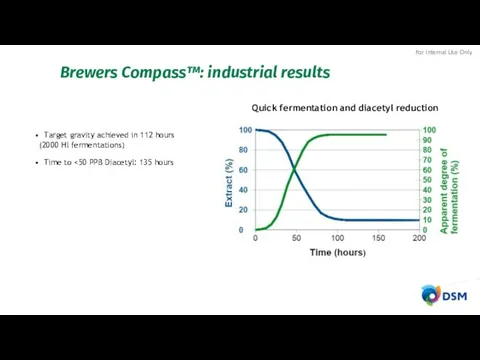

- 35. Target gravity achieved in 112 hours (2000 Hl fermentations) Time to Quick fermentation and diacetyl reduction

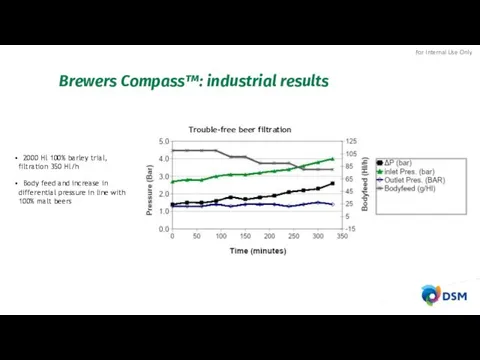

- 36. 2000 Hl 100% barley trial, filtration 350 Hl/h Body feed and increase in differential pressure in

- 37. Fresh and force aged beers produced using 100% barley and Brewers Compass™ subjected to chemical and

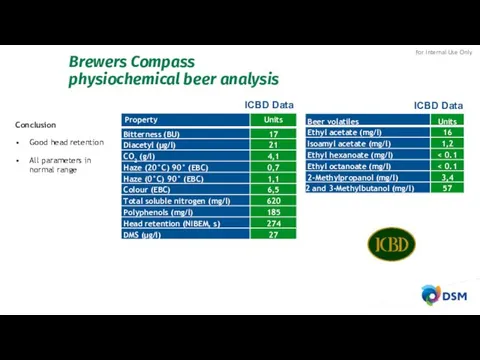

- 38. Conclusion Good head retention All parameters in normal range Brewers Compass physiochemical beer analysis ICBD Data

- 39. Good flavor stability with Brewers Compass (100% barley) Low ageing aldehydes after forcing 28 days at

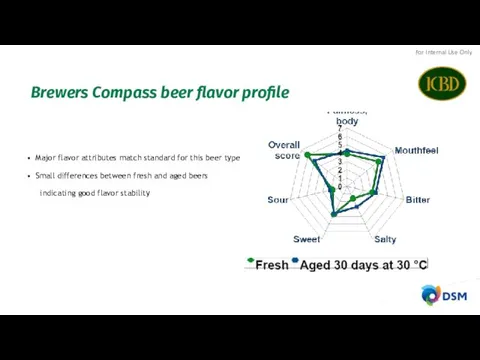

- 40. Major flavor attributes match standard for this beer type Small differences between fresh and aged beers

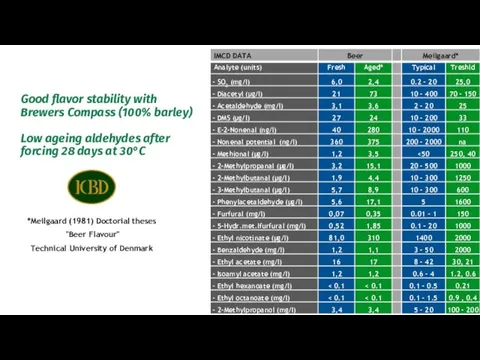

- 41. With Brewers Compass™: Mash profile was optimized for brewhouse time available Wort high in fermentable sugars,

- 42. Scope of the LCA Study Use of an Brewers Compass together with unmalted barley Use of

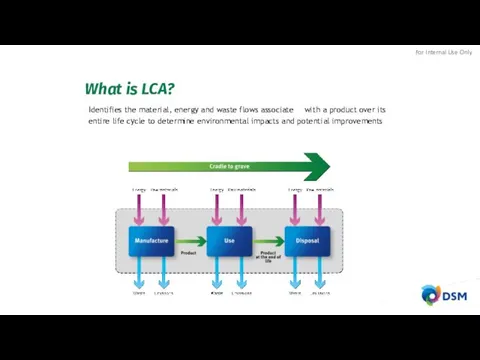

- 43. What is LCA? Identifies the material, energy and waste flows associate with a product over its

- 44. Summary of LCA methodology 2 Methods used for standard assessments: IPCC GWP 100a Eco-indicator 99 SigmaPro

- 45. LCA’s prepared for 4 cases Beer produced with 100 % malt and stabilised with a combination

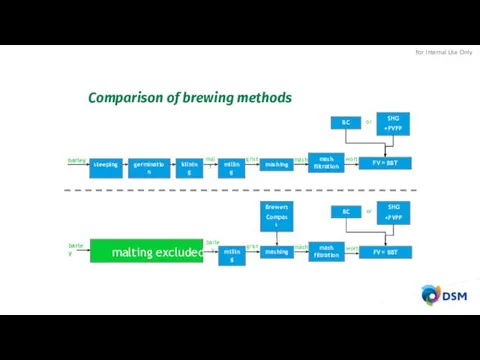

- 46. Comparison of brewing methods barley steeping kilning milling mashing malt grist mash mash filtration wort FV

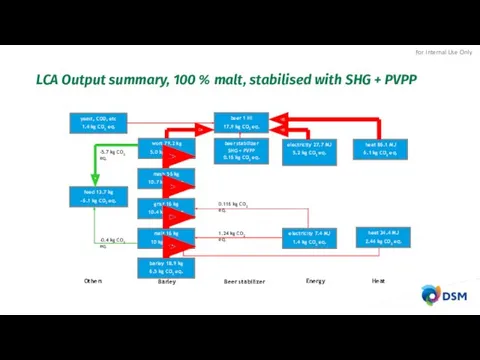

- 47. LCA Output summary, 100 % malt, stabilised with SHG + PVPP barley 18.9 kg 6.5 kg

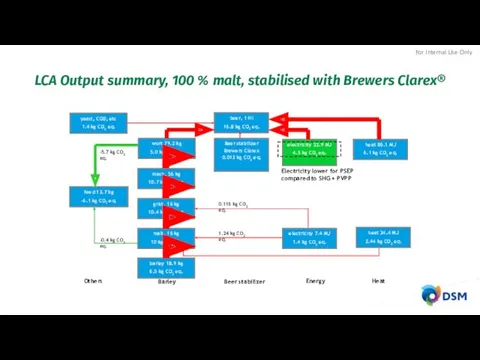

- 48. LCA Output summary, 100 % malt, stabilised with Brewers Clarex® barley 18.9 kg 6.5 kg CO2

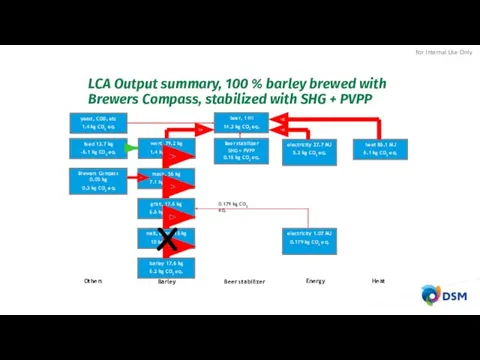

- 49. LCA Output summary, 100 % barley brewed with Brewers Compass, stabilized with SHG + PVPP barley

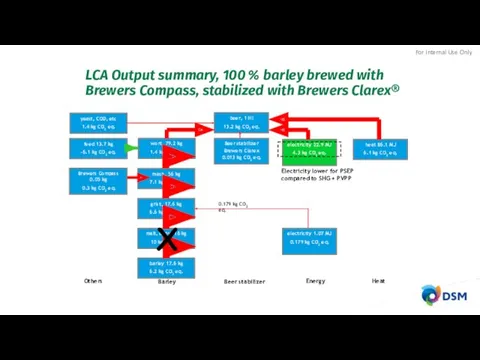

- 50. LCA Output summary, 100 % barley brewed with Brewers Compass, stabilized with Brewers Clarex® barley 17.6

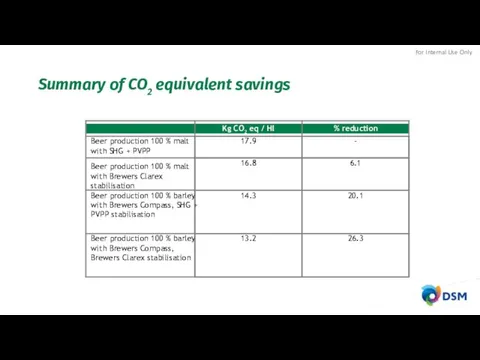

- 51. Summary of CO2 equivalent savings

- 52. Summary of LCA results kg CO2 equivalent

- 53. Reflection on figures Saving: 4.7 kg CO2 / hl beer (field to beer ex packaging) Total

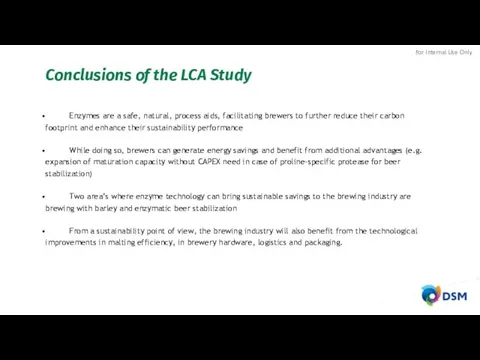

- 54. Conclusions of the LCA Study Enzymes are a safe, natural, process aids, facilitating brewers to further

- 56. Скачать презентацию

Методы оценки источников загрязнения окружающей среды

Методы оценки источников загрязнения окружающей среды Самарская Лука-жемчужина русской равнины

Самарская Лука-жемчужина русской равнины Причины устоичивости и смены экосистем

Причины устоичивости и смены экосистем Корпорация по атомной энергии Росатом. Методы и средства очистки воздуха от радиоактивных и токсичных примесей

Корпорация по атомной энергии Росатом. Методы и средства очистки воздуха от радиоактивных и токсичных примесей Проблема переработки отходов в России

Проблема переработки отходов в России Экологическая доктрина Российской Федерации. Стратегия и механизмы обеспечения устойчивого развития России

Экологическая доктрина Российской Федерации. Стратегия и механизмы обеспечения устойчивого развития России Памятник природы Ива белая

Памятник природы Ива белая Промышленность и окружающая среда

Промышленность и окружающая среда Технології переробки побутових відходів

Технології переробки побутових відходів Класифікація екосистем . Ландшафтна,провінційна і субстратна екосистеми

Класифікація екосистем . Ландшафтна,провінційна і субстратна екосистеми Проект Красная книга

Проект Красная книга Переработка отходов из пластика с использованием микроорганизмов

Переработка отходов из пластика с использованием микроорганизмов Международное сотрудничество в целях охраны природы

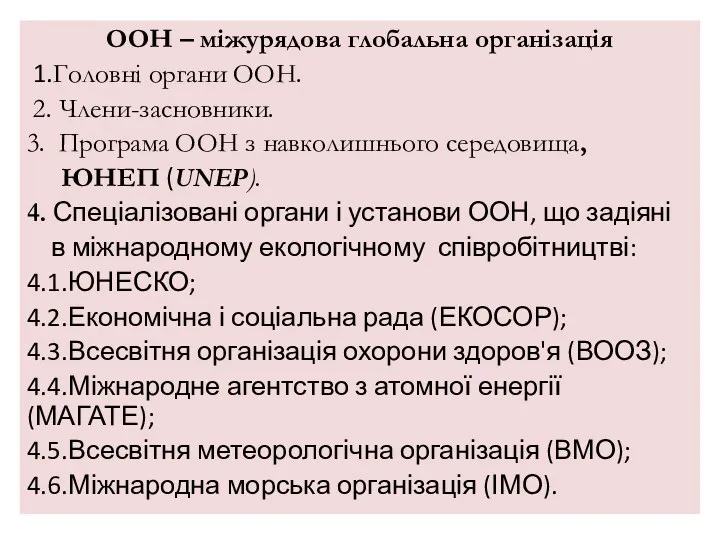

Международное сотрудничество в целях охраны природы ООН – міжурядова глобальна організація

ООН – міжурядова глобальна організація Экология и культура – будущее России. Всероссийский открытый урок по охране окружающей среды

Экология и культура – будущее России. Всероссийский открытый урок по охране окружающей среды Повторное использование пластика. Мастер-класс

Повторное использование пластика. Мастер-класс Ландшафтный дизайн. ЭКОГРАД

Ландшафтный дизайн. ЭКОГРАД Глобальные проблемы человечества

Глобальные проблемы человечества Экологическое хозяйство

Экологическое хозяйство Нормирование качества природной среды

Нормирование качества природной среды Как решить проблему мусора

Как решить проблему мусора Природные и антропогенные источники загрязнения атмосферы

Природные и антропогенные источники загрязнения атмосферы Вторая жизнь мусора

Вторая жизнь мусора Сделаем вместе. Урок Свобода от отходов

Сделаем вместе. Урок Свобода от отходов Земля наш общий дом

Земля наш общий дом Загрязнение воды: причины и последствия

Загрязнение воды: причины и последствия Обеспечение безопасности при неблагоприятной экологической обстановке

Обеспечение безопасности при неблагоприятной экологической обстановке Влияние человека на биосферу Земли

Влияние человека на биосферу Земли