Содержание

- 2. INTRODUCTION plastic waste - hazard to the environment. plastics waste - construction of flexible pavement. Plastic

- 3. What is plastic?? A material that contains one or more organic polymers of large molecular weight,

- 4. NATURAL RESINS solids or semi solid materials light yellow to darkbrown in colour carbon, hydrogen and

- 5. SYNTHETIC RESINS derived primarily from petroleum. polystyrene, polyesters and acrylics used in the manufacture of varnishes,

- 6. Various Resins Of Plastic Polyethylene terephthalate (PET,PETE) Density polyethylene(HDPE) Vinyl(Poly vinyl chloride or PVC) Low Density

- 7. BASIC PROCESSES Segregation . Cleaning process . Shredding process . Collection process .

- 8. 1.SEGREGATION plastic waste collected from various sources must be separated from other waste. Maximum thickness of

- 9. 2 cleaning process Plastic waste get cleaned and dried. cleaning process

- 10. 3 Shredding process will be shredded or cut into small piece. the different types of plastic

- 11. 4 Collection process the plastic waste retaining in 2.36 mm is collected. collected plastic

- 12. FIELD TRIALS There are two type of field trials 1.Dry process 2.Wet process

- 13. 1.DRY PROCESS The aggregate is heated to 170°C in the Mini hot Mix Plant . Heated

- 14. the shredded plastic waste is added in equal proportion. Adding shredded plastic

- 15. Aggregate-plastic- Bitumen Mix The mixture is transferred to the road and the road is laid. Immediately

- 16. 2.Wet Process Waste plastics by direct mixing with hot bitumen at 160°C Mechanical stirrer is needed

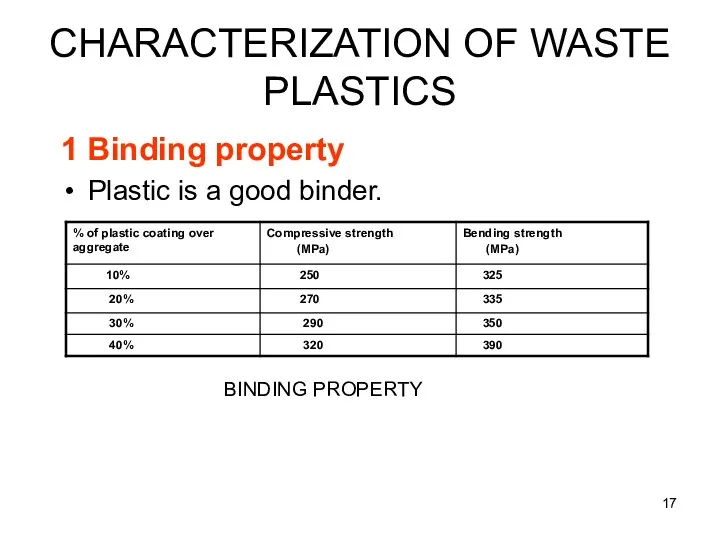

- 17. CHARACTERIZATION OF WASTE PLASTICS 1 Binding property Plastic is a good binder. BINDING PROPERTY

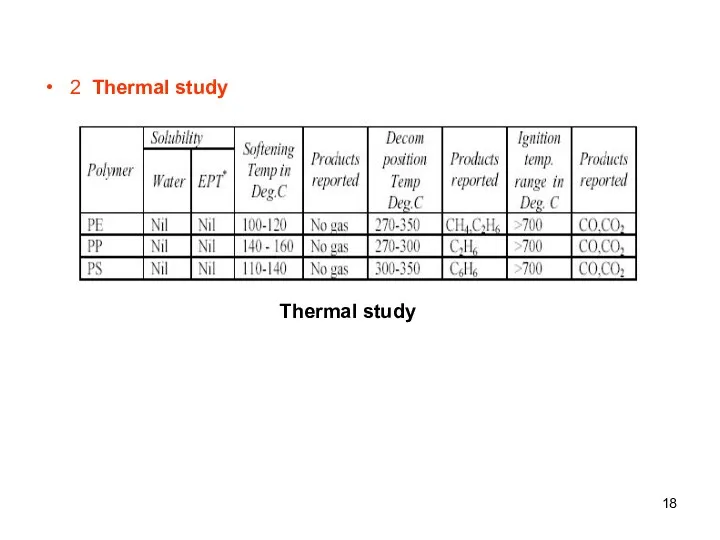

- 18. 2 Thermal study Thermal study

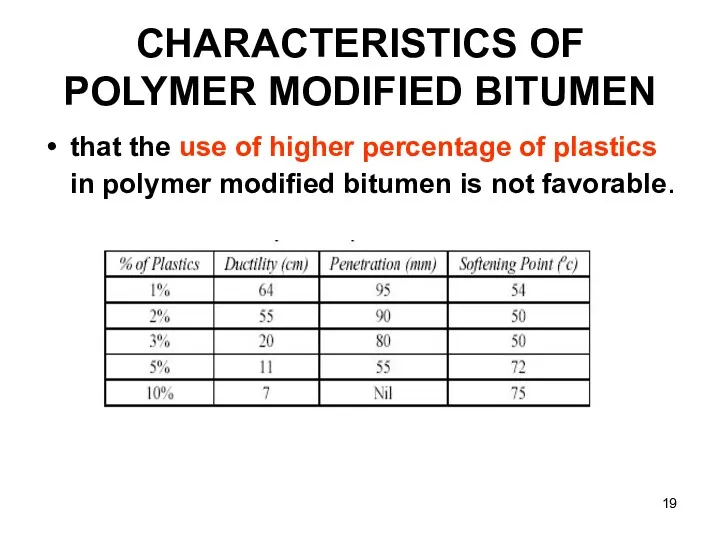

- 19. CHARACTERISTICS OF POLYMER MODIFIED BITUMEN that the use of higher percentage of plastics in polymer modified

- 20. CHARACTERISTICS OF PLASTIC COATED AGGREGATE 1 .Aggregate impact value plastics improves aggregate impact value. helps to

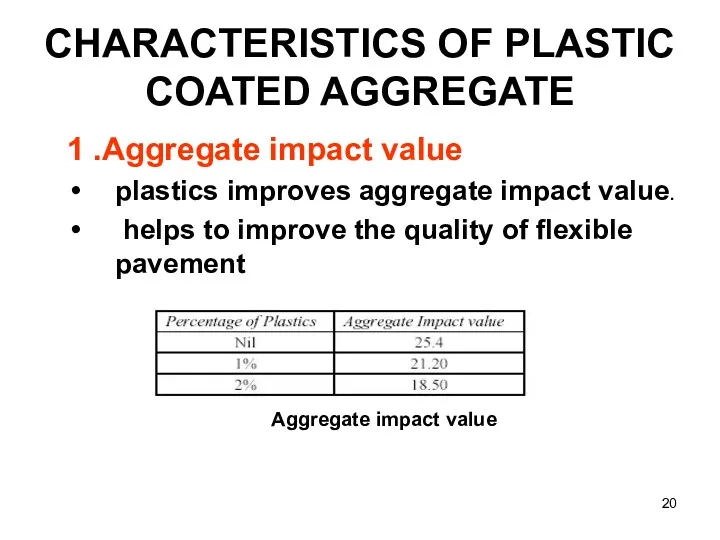

- 21. 2.Los Angel’s Abrasion Test wear and tear values of plastic coated aggregate is found to be

- 22. ADVANTAGES OF PLASTIC ROAD Use higher percentage of plastic waste. Reduce the need of bitumen by

- 23. DISADVANTAGES OF PLASTIC ROADS 1. Cleaning process Toxics present in the co-mingled plastic waste would d

- 24. 3.After the road laying The components of the road, once it has been laid, are not

- 25. CONCLUSION Plastic will increase the melting point of the bitumen use of the innovative technology not

- 26. REFERENCES Vasudevan .R, utilization of waste plastics for flexible pavement, Indian High Ways (Indian Road Congress),

- 28. Скачать презентацию

Экологические принципы рационального использования природных ресурсов

Экологические принципы рационального использования природных ресурсов Экологическая безопасность производства

Экологическая безопасность производства Дидактические игры по экологии

Дидактические игры по экологии Красная книга Тюменской области

Красная книга Тюменской области Табиғи ресурстар және табиғатты қолдану-тұрақты дамудың бір аспектісі

Табиғи ресурстар және табиғатты қолдану-тұрақты дамудың бір аспектісі Экология жилища

Экология жилища Основные направления международного сотрудничества России в области безопасности жизнедеятельности

Основные направления международного сотрудничества России в области безопасности жизнедеятельности Sustainable transportation

Sustainable transportation Қазақстанның экологиялық аймақтары

Қазақстанның экологиялық аймақтары Школа-территория экологического комфорта

Школа-территория экологического комфорта Высокотоксичные соединения в атмосфере

Высокотоксичные соединения в атмосфере Глобальное потепление: домыслы и факты

Глобальное потепление: домыслы и факты Забруднення атмосфери. Негативний вплив на здоров”я людини

Забруднення атмосфери. Негативний вплив на здоров”я людини Співіснування людського суспільства і природи

Співіснування людського суспільства і природи Экология и обеспечение качества воздушного бассейна. Проблемы использования и охраны водных ресурсов

Экология и обеспечение качества воздушного бассейна. Проблемы использования и охраны водных ресурсов Загальні питання моделювання екологічних систем і моделей

Загальні питання моделювання екологічних систем і моделей Мусор и его вторая жизнь

Мусор и его вторая жизнь Экологический проект. Загрязнение природы

Экологический проект. Загрязнение природы Причины возникновения лесных пожаров. 3 класс

Причины возникновения лесных пожаров. 3 класс Экологическая экспертиза

Экологическая экспертиза Городская среда. Урок 9

Городская среда. Урок 9 Учение о биосфере (1)

Учение о биосфере (1) Презентация к уроку по экологии Загрязнение окружающей среды и экологические проблемы

Презентация к уроку по экологии Загрязнение окружающей среды и экологические проблемы Экология

Экология Экологический турнир Кладовая солнца. Пал травы

Экологический турнир Кладовая солнца. Пал травы Римский клуб

Римский клуб Экологические продукты. Регулируемая газовая среда

Экологические продукты. Регулируемая газовая среда 11 января - День заповедников и национальных парков

11 января - День заповедников и национальных парков