Содержание

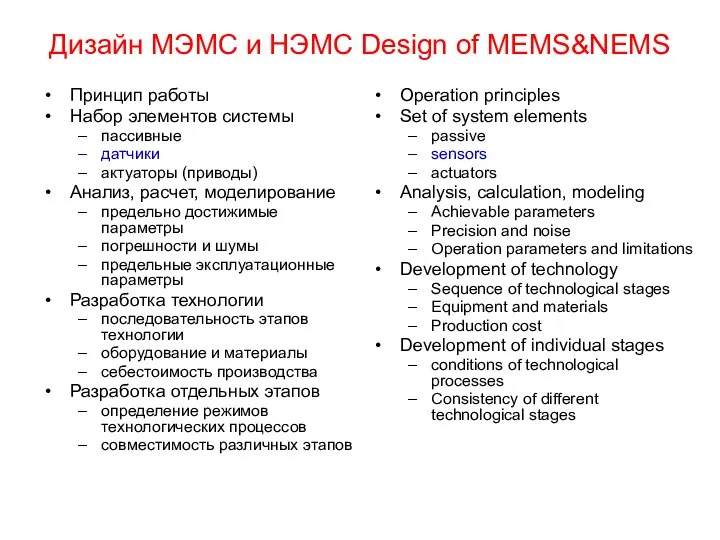

- 2. Дизайн МЭМС и НЭМС Design of MEMS&NEMS Принцип работы Набор элементов системы пассивные датчики актуаторы (приводы)

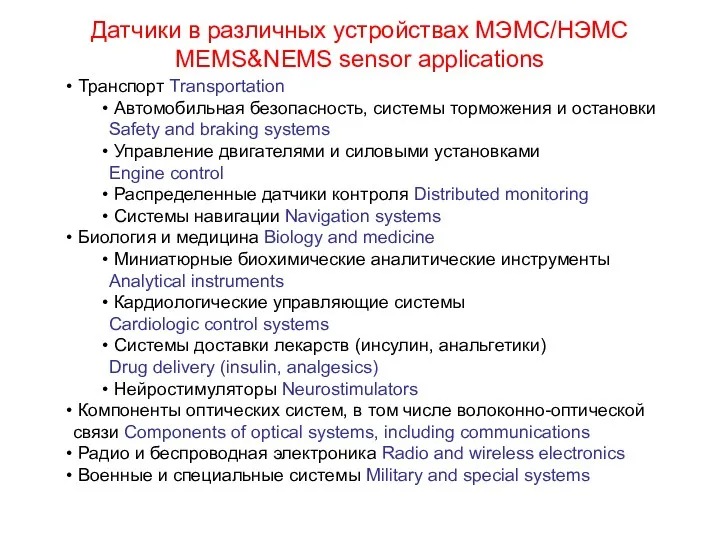

- 3. Датчики в различных устройствах МЭМС/НЭМС MEMS&NEMS sensor applications Транспорт Transportation Автомобильная безопасность, системы торможения и остановки

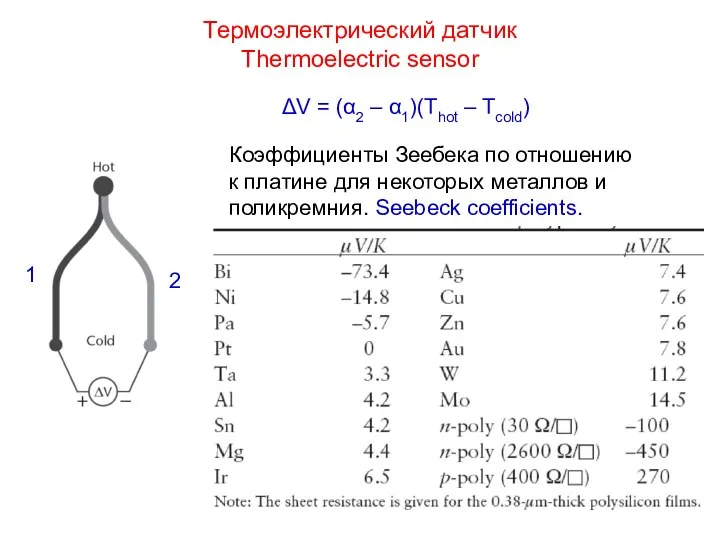

- 4. Термоэлектрический датчик Thermoelectric sensor Коэффициенты Зеебека по отношению к платине для некоторых металлов и поликремния. Seebeck

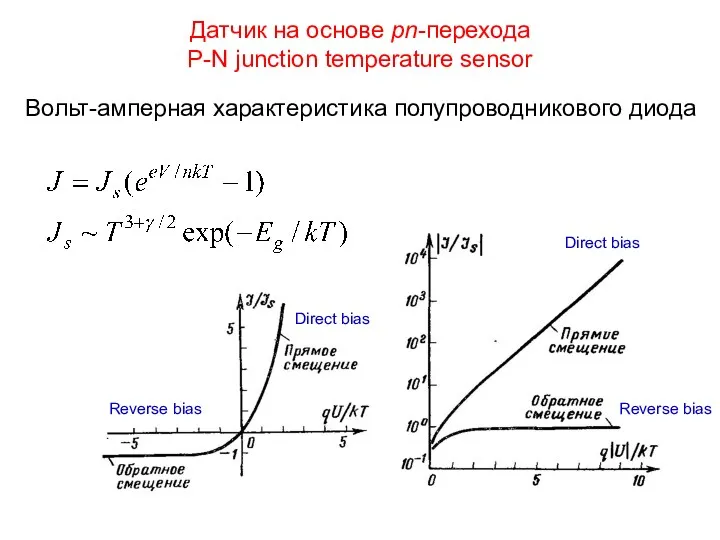

- 5. Датчик на основе pn-перехода P-N junction temperature sensor Вольт-амперная характеристика полупроводникового диода Direct bias Direct bias

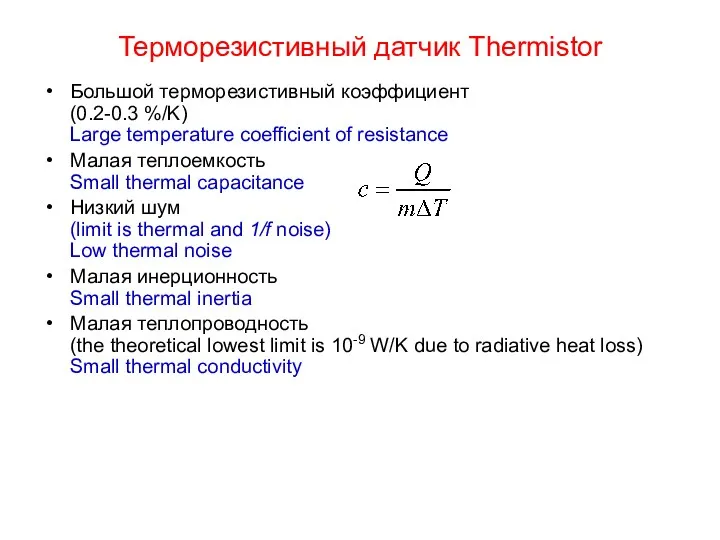

- 6. Терморезистивный датчик Thermistor Большой терморезистивный коэффициент (0.2-0.3 %/K) Large temperature coefficient of resistance Малая теплоемкость Small

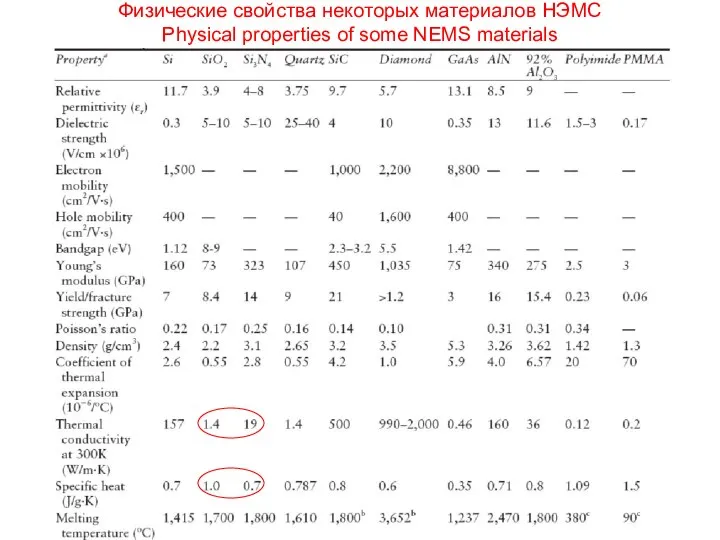

- 7. Физические свойства некоторых материалов НЭМС Physical properties of some NEMS materials

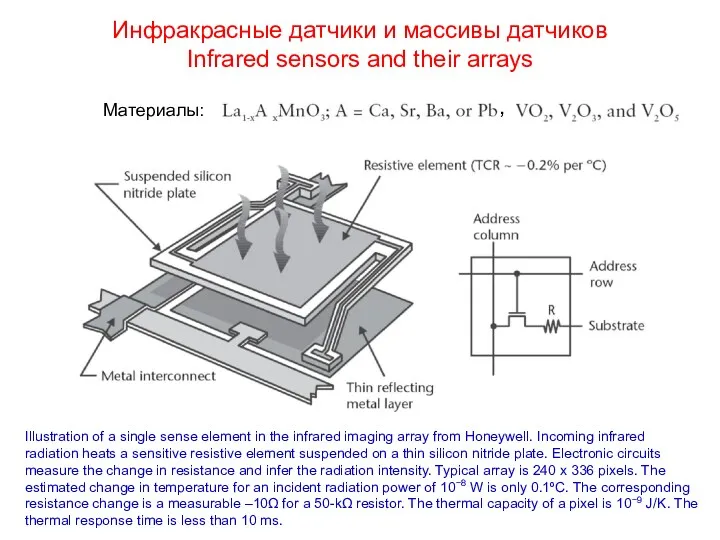

- 8. Инфракрасные датчики и массивы датчиков Infrared sensors and their arrays Illustration of a single sense element

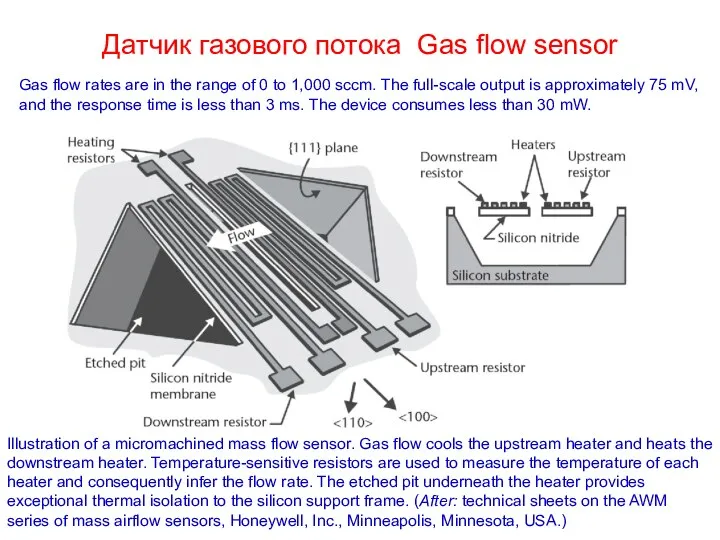

- 9. Датчик газового потока Gas flow sensor Illustration of a micromachined mass flow sensor. Gas flow cools

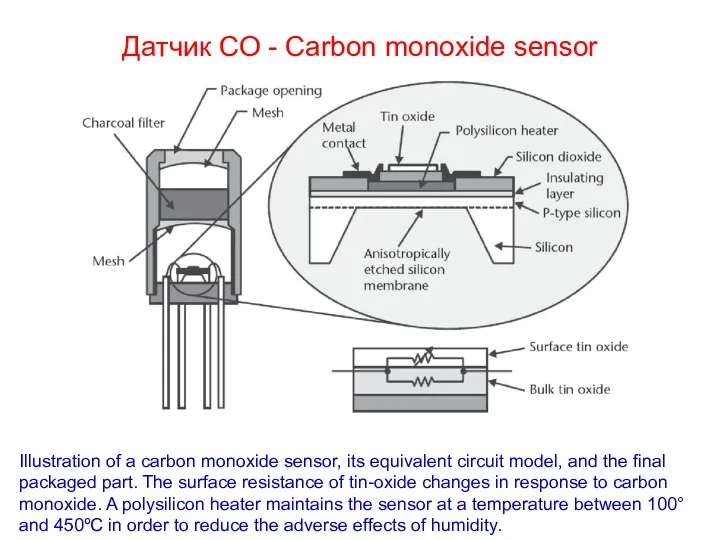

- 10. Датчик СО - Carbon monoxide sensor Illustration of a carbon monoxide sensor, its equivalent circuit model,

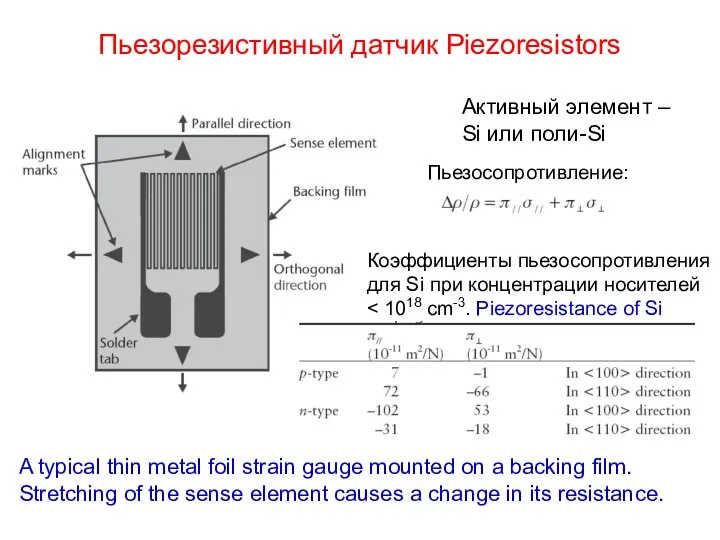

- 11. Пьезорезистивный датчик Piezoresistors A typical thin metal foil strain gauge mounted on a backing film. Stretching

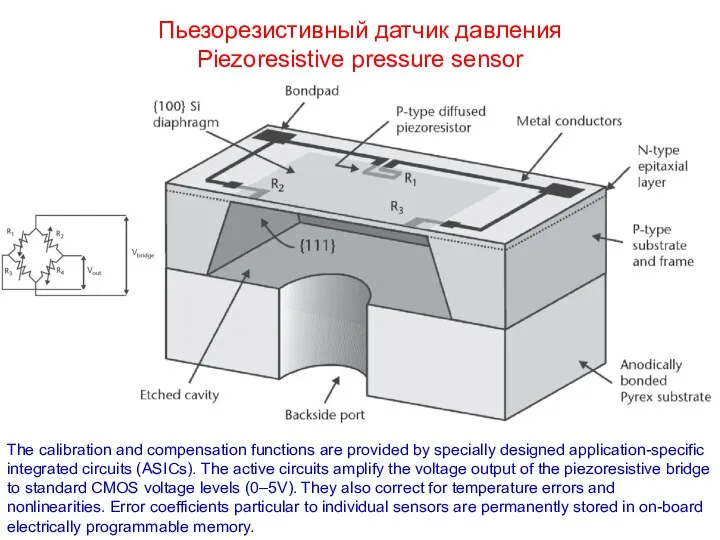

- 12. Пьезорезистивный датчик давления Piezoresistive pressure sensor The calibration and compensation functions are provided by specially designed

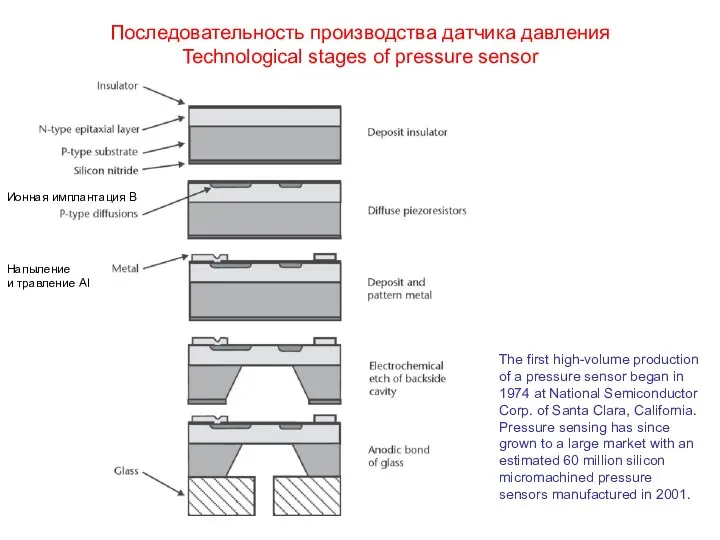

- 13. Последовательность производства датчика давления Technological stages of pressure sensor The first high-volume production of a pressure

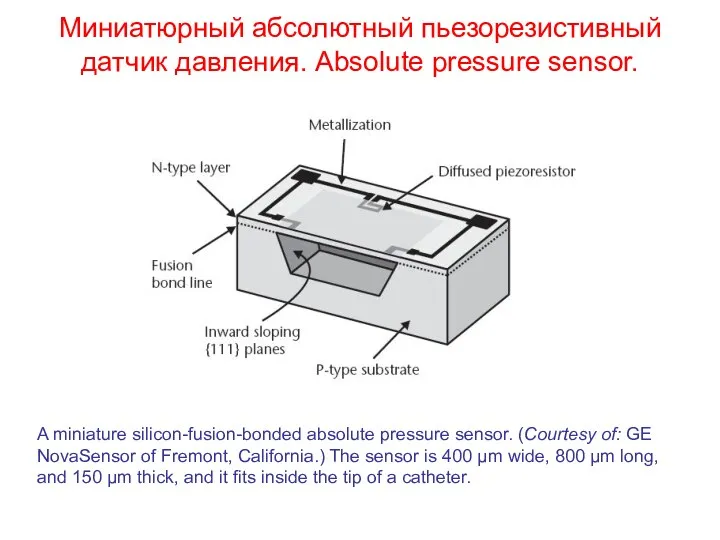

- 14. Миниатюрный абсолютный пьезорезистивный датчик давления. Absolute pressure sensor. A miniature silicon-fusion-bonded absolute pressure sensor. (Courtesy of:

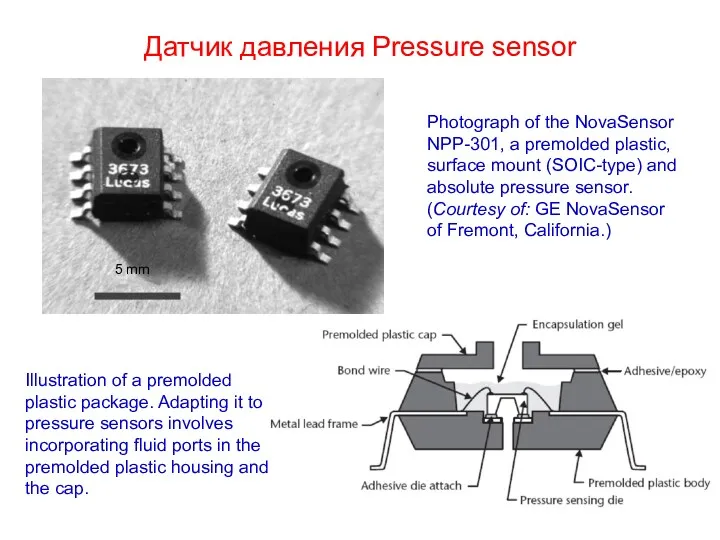

- 15. Photograph of the NovaSensor NPP-301, a premolded plastic, surface mount (SOIC-type) and absolute pressure sensor. (Courtesy

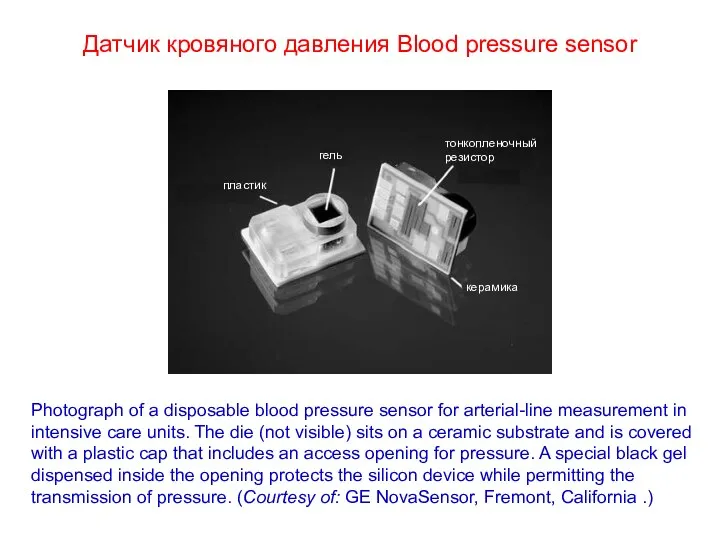

- 16. Photograph of a disposable blood pressure sensor for arterial-line measurement in intensive care units. The die

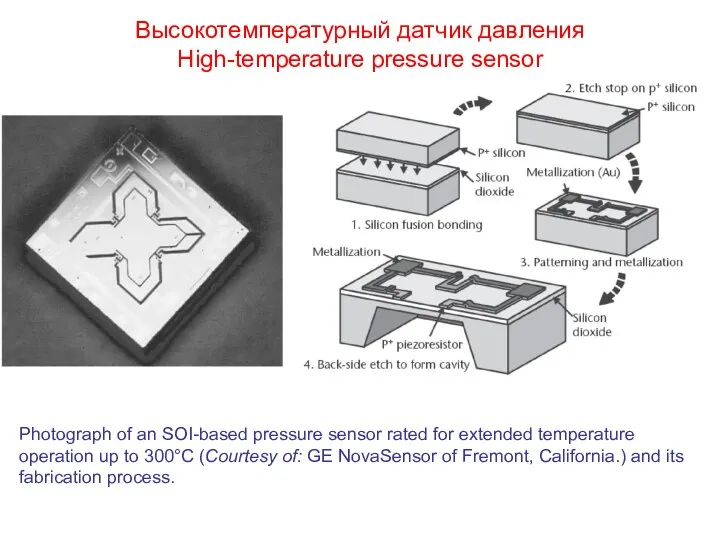

- 17. Высокотемпературный датчик давления High-temperature pressure sensor Photograph of an SOI-based pressure sensor rated for extended temperature

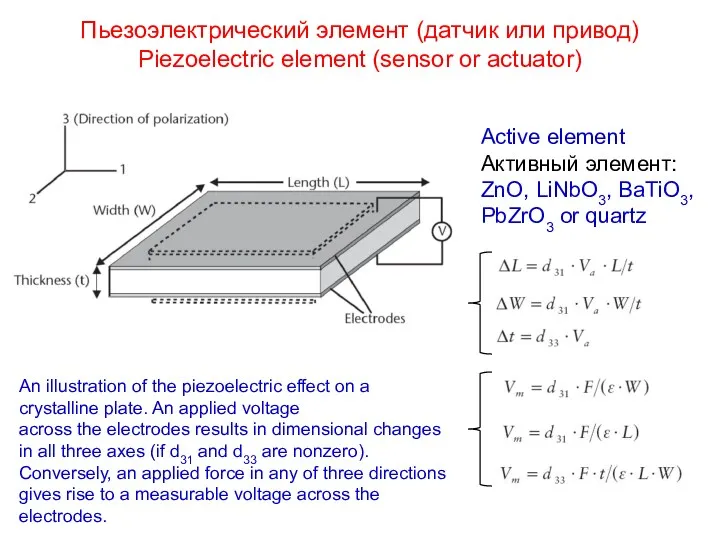

- 18. Пьезоэлектрический элемент (датчик или привод) Piezoelectric element (sensor or actuator) An illustration of the piezoelectric effect

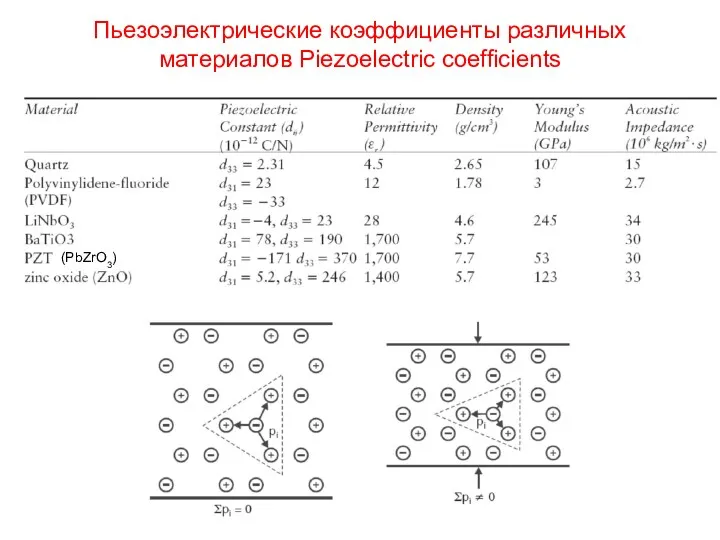

- 19. Пьезоэлектрические коэффициенты различных материалов Piezoelectric coefficients (PbZrO3)

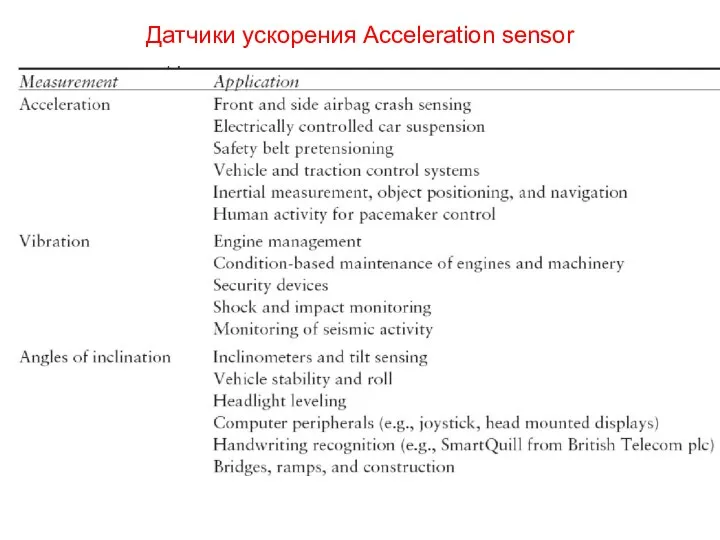

- 20. Датчики ускорения Acceleration sensor

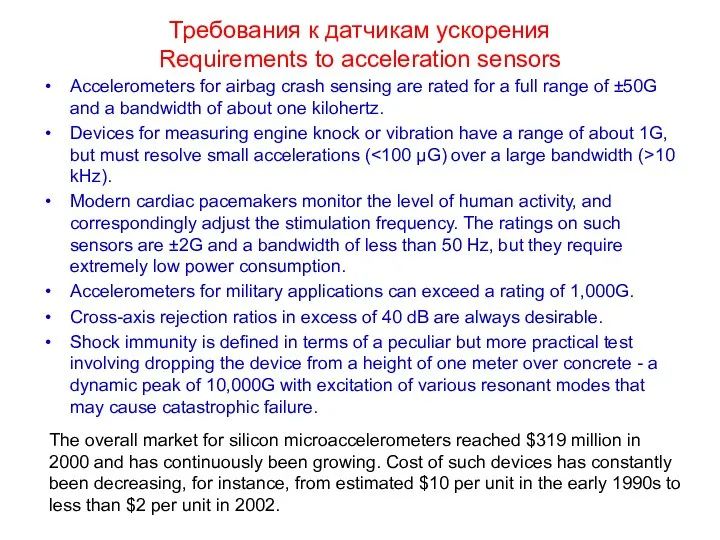

- 21. Требования к датчикам ускорения Requirements to acceleration sensors Accelerometers for airbag crash sensing are rated for

- 22. Базовая структура датчика ускорения Base structure of acceleration sensor The basic structure of an accelerometer, consisting

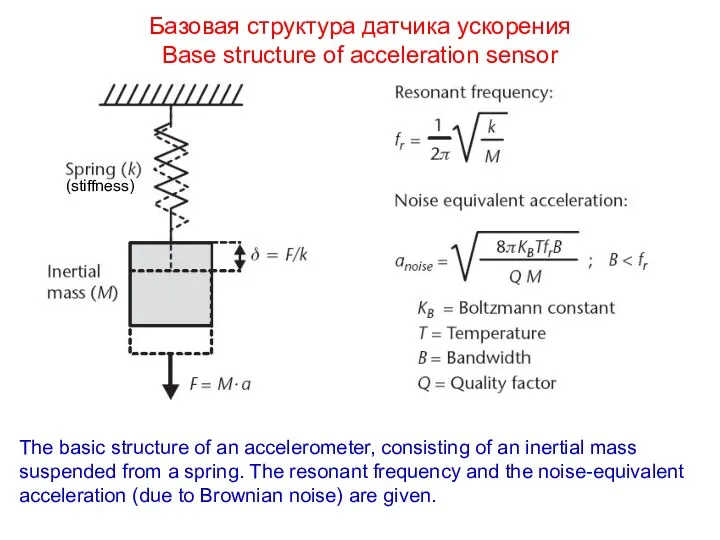

- 23. Пьезорезистивный датчик ускорения Piezoresistive acceleration sensor Illustration of a piezoresistive accelerometer from Endevco Corp., fabricated using

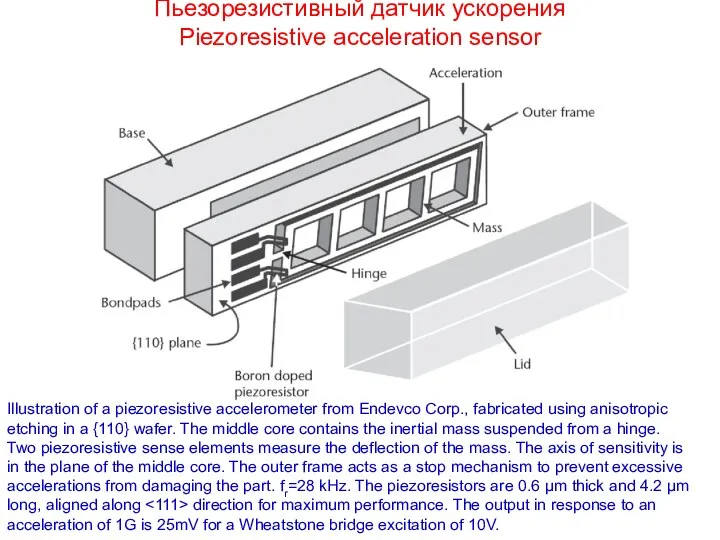

- 24. Емкостной датчик Capacitor sensor Поперечная конфигурация Продольная конфигурация x0 Δx Δy ly

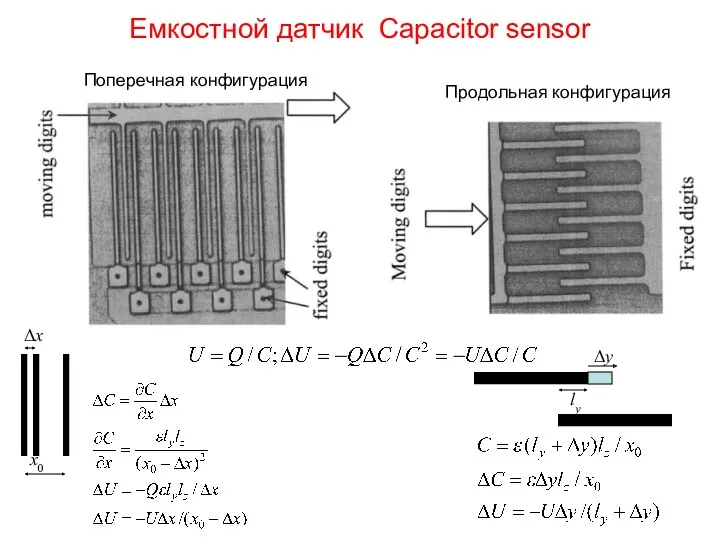

- 25. Емкостной датчик ускорения. Capacitive accelerometer. Illustration of a bulk micromachined capacitive accelerometer. The inertial mass in

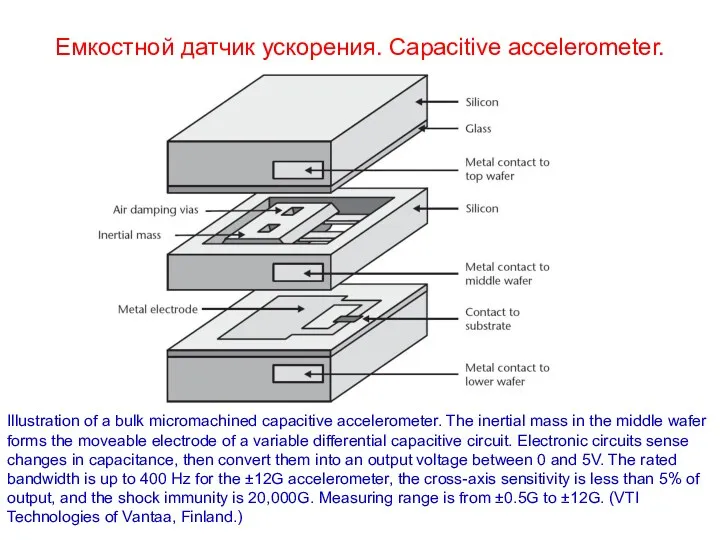

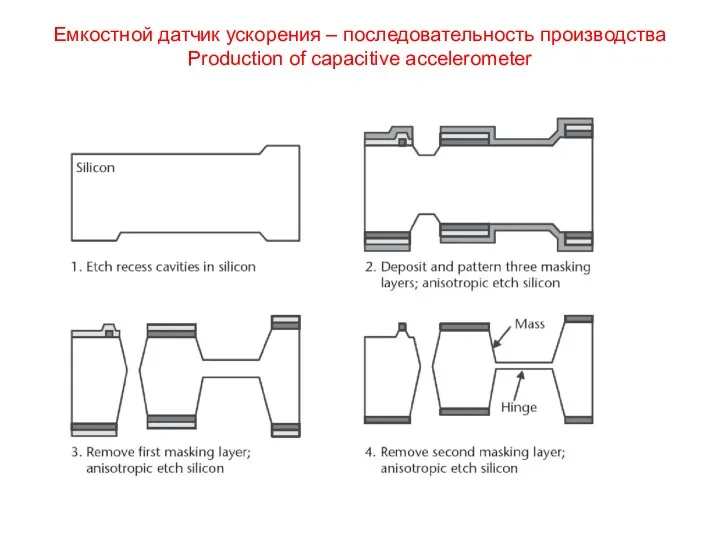

- 26. Емкостной датчик ускорения – последовательность производства Production of capacitive accelerometer

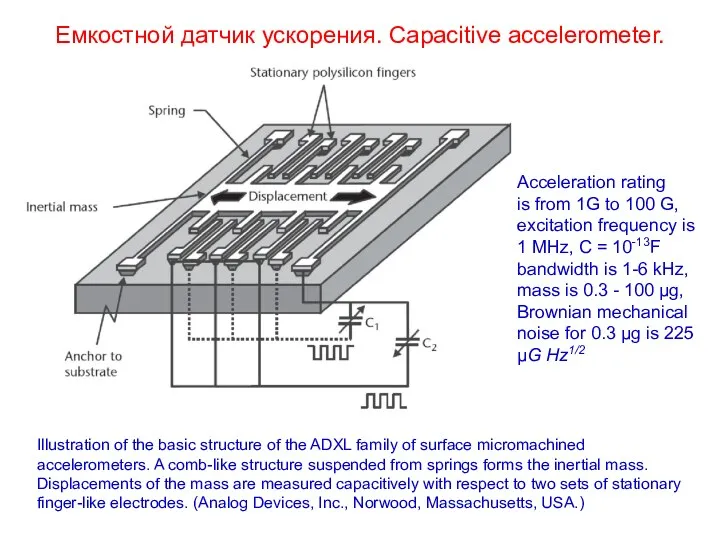

- 27. Емкостной датчик ускорения. Capacitive accelerometer. Illustration of the basic structure of the ADXL family of surface

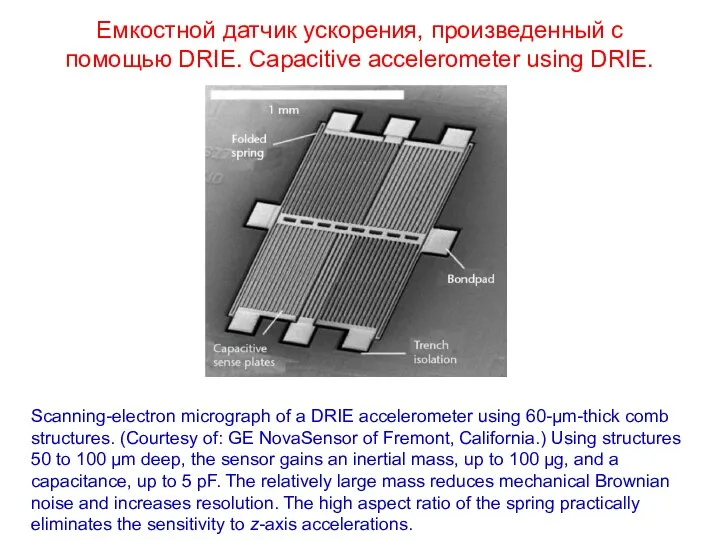

- 28. Емкостной датчик ускорения, произведенный с помощью DRIE. Capacitive accelerometer using DRIE. Scanning-electron micrograph of a DRIE

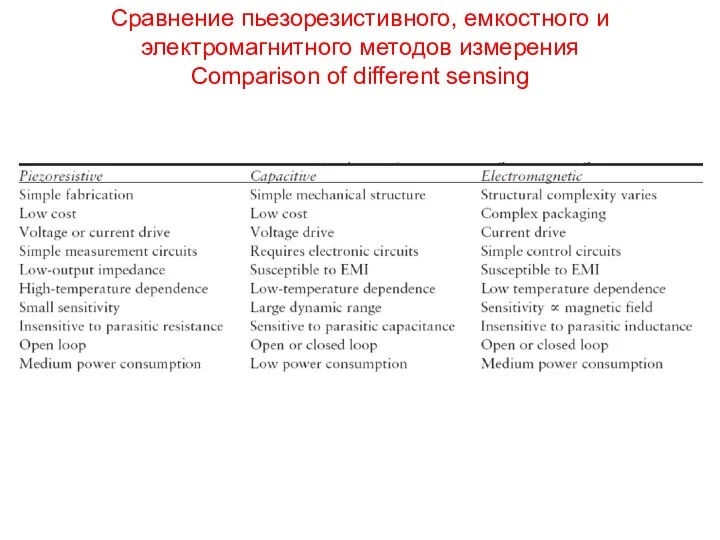

- 29. Сравнение пьезорезистивного, емкостного и электромагнитного методов измерения Comparison of different sensing

- 30. To be continued

- 32. Скачать презентацию

Значение влажности в жизни человека

Значение влажности в жизни человека 26e1e5eed06e9616d6b0b1a82d75cb58

26e1e5eed06e9616d6b0b1a82d75cb58 Area, size and mass

Area, size and mass Постоянные магниты (8 класс)

Постоянные магниты (8 класс) Инфракрасное, ультрафиолетовое и рентгеновское излучения. Их свойства и применение

Инфракрасное, ультрафиолетовое и рентгеновское излучения. Их свойства и применение Физика и техника

Физика и техника Проект Инженерный класс в московской школе. Практические ситуационные задачи и теоретические задачи

Проект Инженерный класс в московской школе. Практические ситуационные задачи и теоретические задачи Законы постоянного тока

Законы постоянного тока Основні уявлення та рівняння

Основні уявлення та рівняння Баяндама Альберт Эйнштейн

Баяндама Альберт Эйнштейн Векторный анализ и синтез сигналов. Программа “Вектор”

Векторный анализ и синтез сигналов. Программа “Вектор” Подготовка к ОГЭ по физике на уроке. Решение задач по физике различного типа и уровня сложности

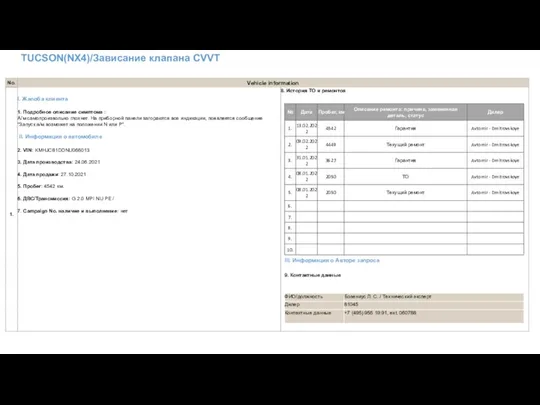

Подготовка к ОГЭ по физике на уроке. Решение задач по физике различного типа и уровня сложности Tucson (NX 4). Зависание клапана CVVT

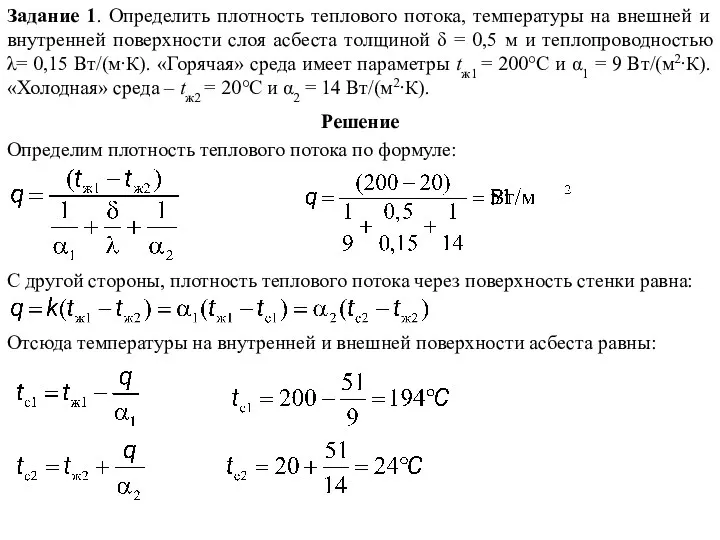

Tucson (NX 4). Зависание клапана CVVT Теплопередача. Задачи

Теплопередача. Задачи Физика атома и атомных явлений

Физика атома и атомных явлений Сила. Явление тяготения. Сила тяжести

Сила. Явление тяготения. Сила тяжести История развития нанотехнологий

История развития нанотехнологий Алгоритмы решения физических задач

Алгоритмы решения физических задач Unusual modes pf transport

Unusual modes pf transport Виды теплопередачи ( презентация к уроку)- 8 класс

Виды теплопередачи ( презентация к уроку)- 8 класс Получение и передача переменного электрического тока. Трансформатор

Получение и передача переменного электрического тока. Трансформатор Состав систем космического аппарата. Проведение литературного обзора

Состав систем космического аппарата. Проведение литературного обзора Основы машиноведения

Основы машиноведения Викторина по физике

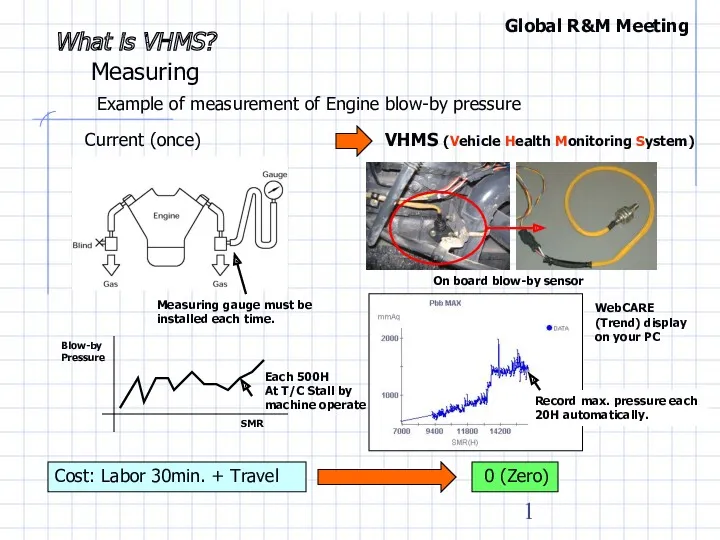

Викторина по физике Summary of effective use 6

Summary of effective use 6 Основы квантовой физики. Лазеры

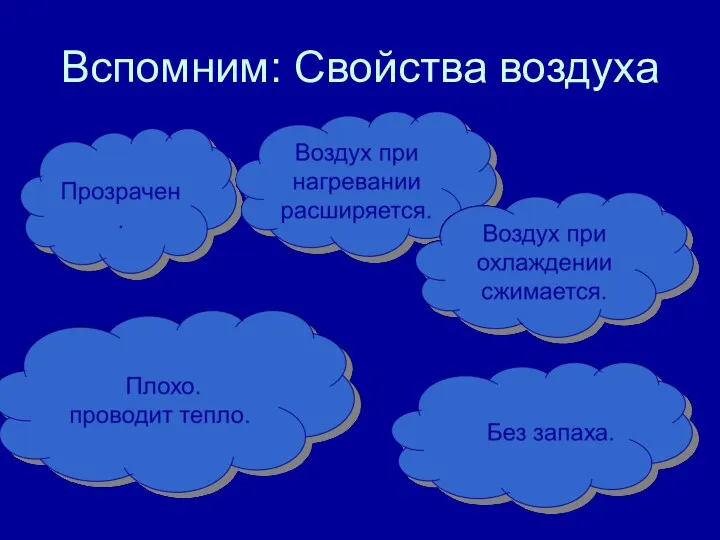

Основы квантовой физики. Лазеры Свойства воздуха

Свойства воздуха Система питания двигателя от впрыска топлива

Система питания двигателя от впрыска топлива