Содержание

- 2. Learning objectives Provide a formal Management Process Reservoir Management tools Review some examples of Management Strategy

- 3. “The purpose of reservoir management is to control operations to obtain the maximum possible economic recovery

- 4. “The marshalling of all appropriate business, technical and operating resources to exploit a reservoir optimally from

- 5. “There are probably as many different definitions as there are perceptions of the process” “Integrated approach...key

- 6. What is reservoir management? - Summary Integrated approach: to control operations to maximise benefits/profits (value) from

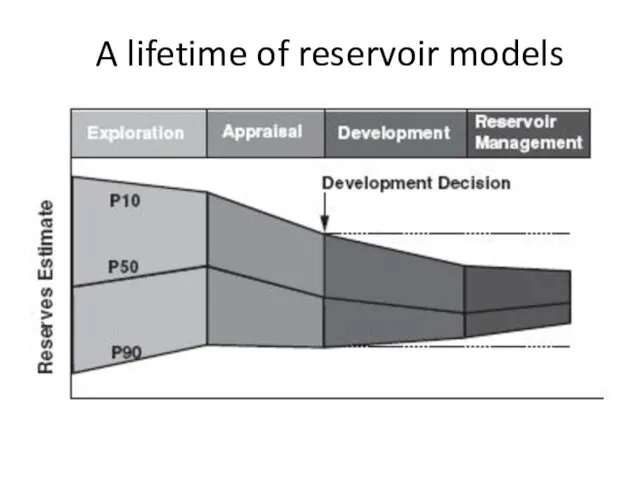

- 7. A lifetime of reservoir models

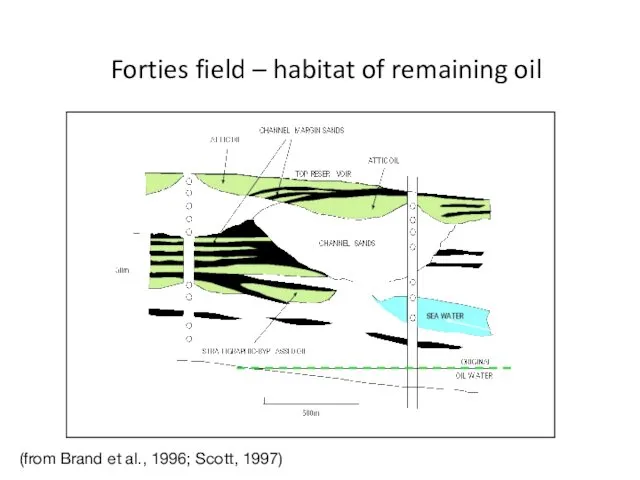

- 8. Forties field – habitat of remaining oil (from Brand et al., 1996; Scott, 1997)

- 9. Monetary value of an asset Recoverable resources (i.e. reserves) Rate of production Cost of production Oil

- 10. Aim MAXIMISE VALUE MINIMISE COST Maximise recovery Recovery Technology (speed up) People/Team Reservoir Knowledge/analysis CAPEX OPEX

- 11. RECOVERY Maximise value through…

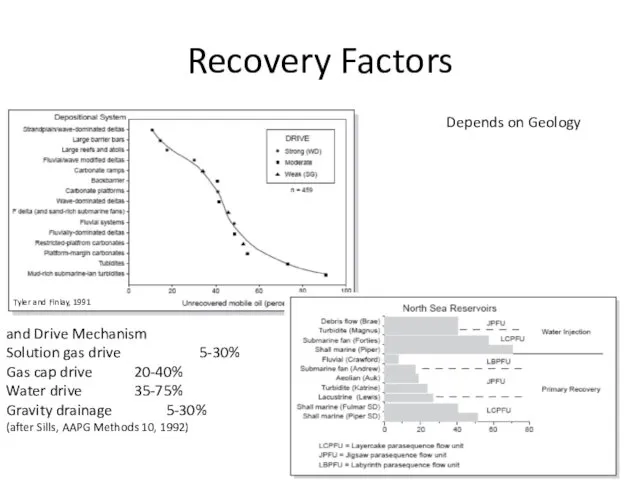

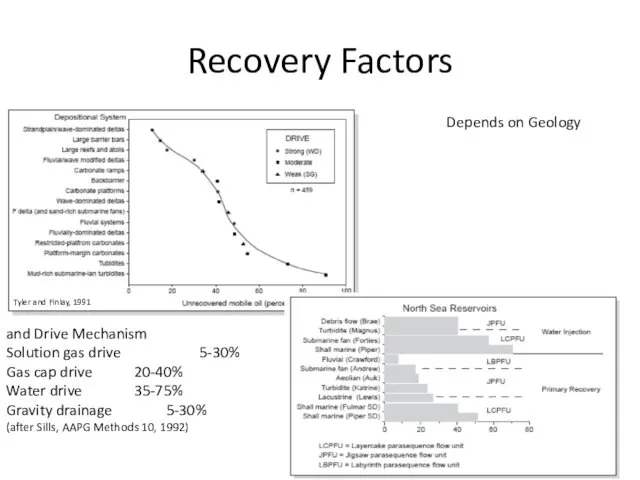

- 12. Recovery Factors Tyler and Finlay, 1991 Depends on Geology and Drive Mechanism Solution gas drive 5-30%

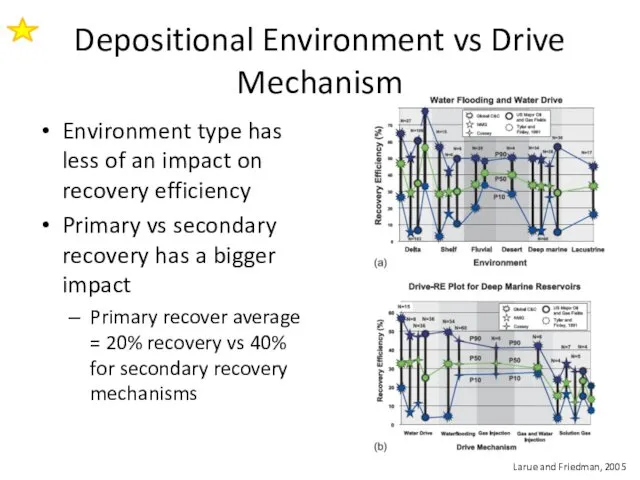

- 13. Depositional Environment vs Drive Mechanism Environment type has less of an impact on recovery efficiency Primary

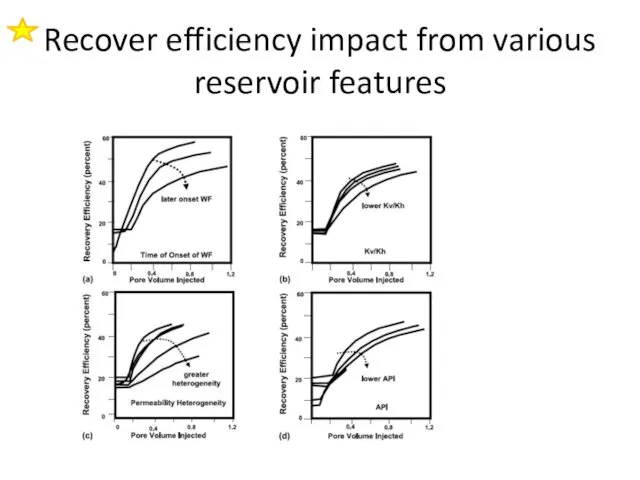

- 14. Recover efficiency impact from various reservoir features

- 15. Does connectivity influence recovery?

- 16. What is connectivity? Sandbody connectivity % of sand bodies that are connected to each other Reservoir

- 17. Examples of connectivity? Larue & Hovadik, 2006

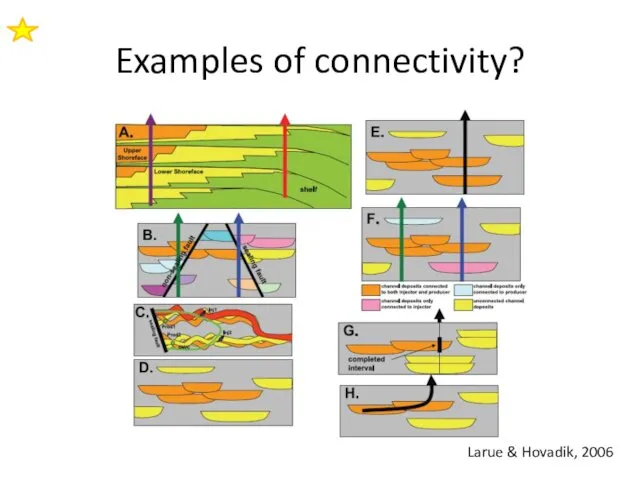

- 18. Relationship between connectivity and recovery Larue & Hovadik, 2006

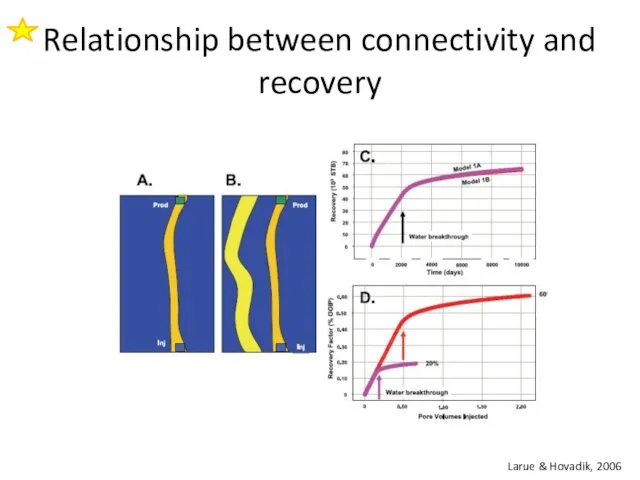

- 19. Static vs dynamic well connectivity Reservoir recoveries significantly below percolation prediction of connected sand bodies Static

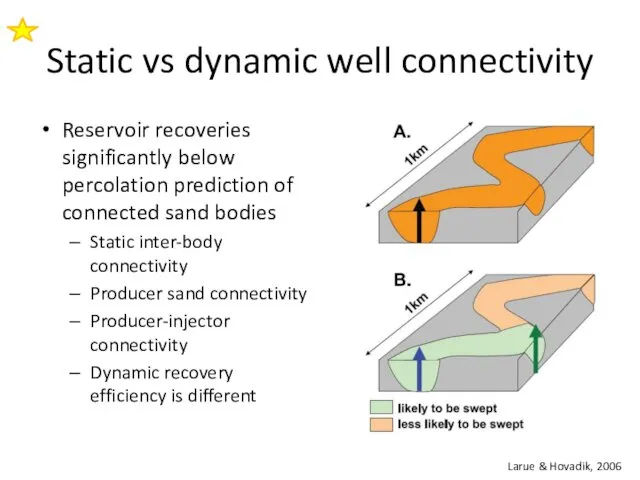

- 20. 2D Connectivity Hovadik & Larue, 2010

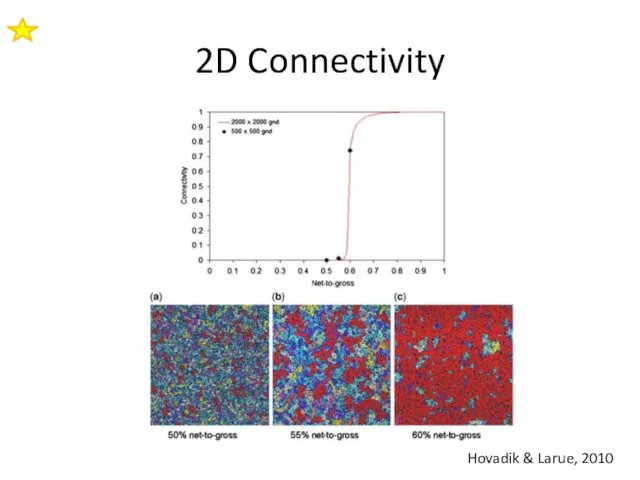

- 21. 3D percolation connectivity Hovadik & Larue, 2010

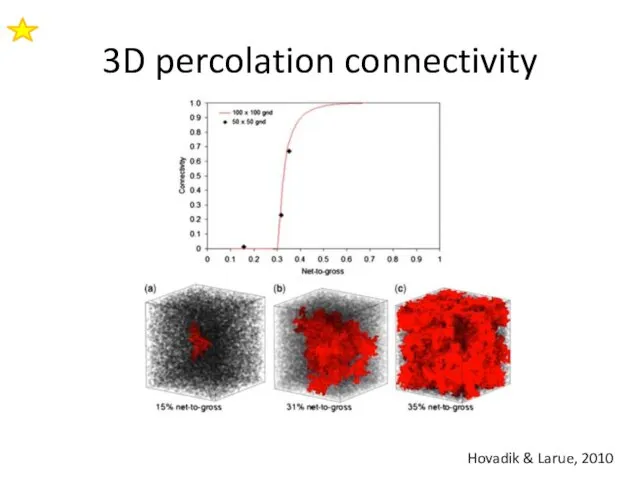

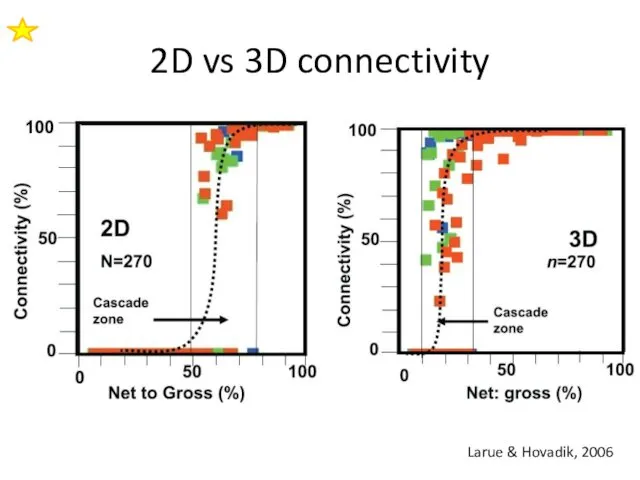

- 22. 2D vs 3D connectivity Larue & Hovadik, 2006

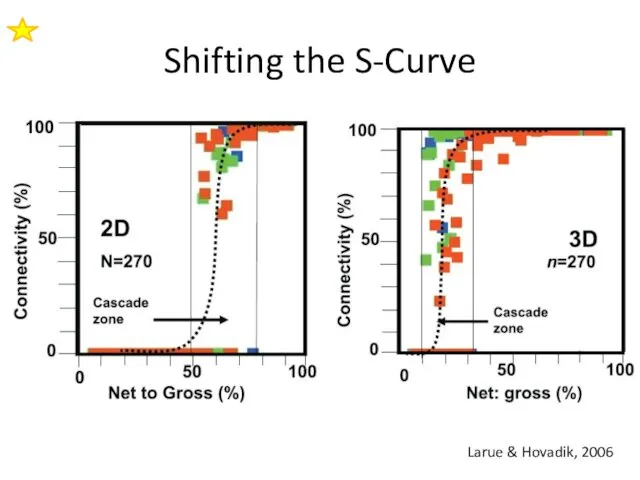

- 23. Shifting the S-Curve Larue & Hovadik, 2006

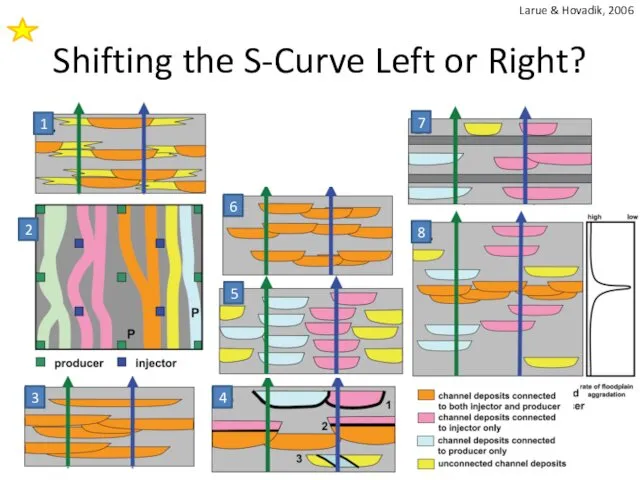

- 24. Shifting the S-Curve Left or Right? 1 2 3 6 7 8 5 4 Larue &

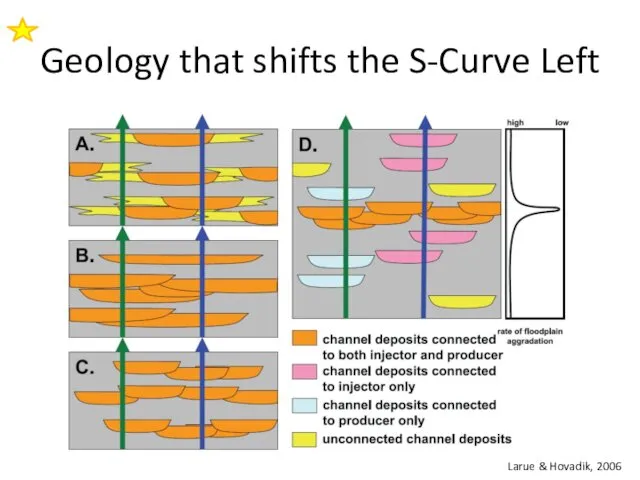

- 25. Geology that shifts the S-Curve Left Larue & Hovadik, 2006

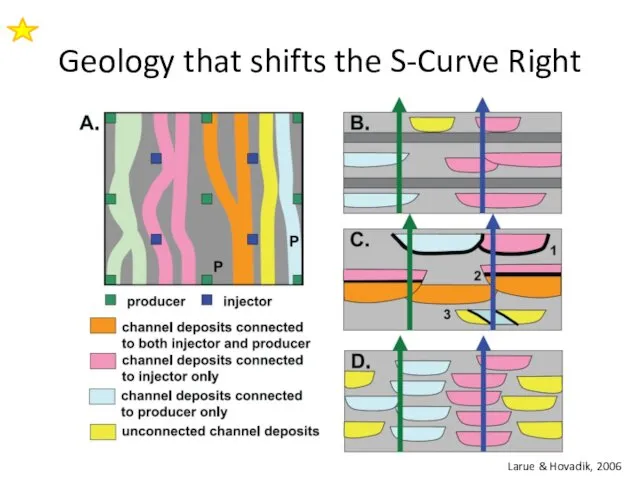

- 26. Geology that shifts the S-Curve Right Larue & Hovadik, 2006

- 27. Increasing 2D effect (shift to Right) Larue & Hovadik, 2006

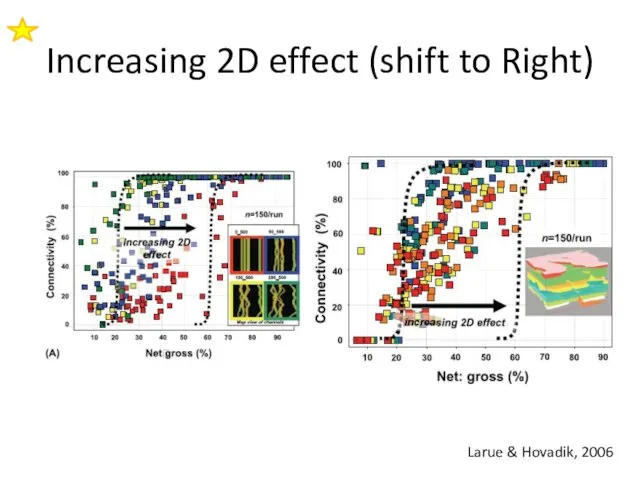

- 28. Volume support and the cascade zone Larue & Hovadik, 2006

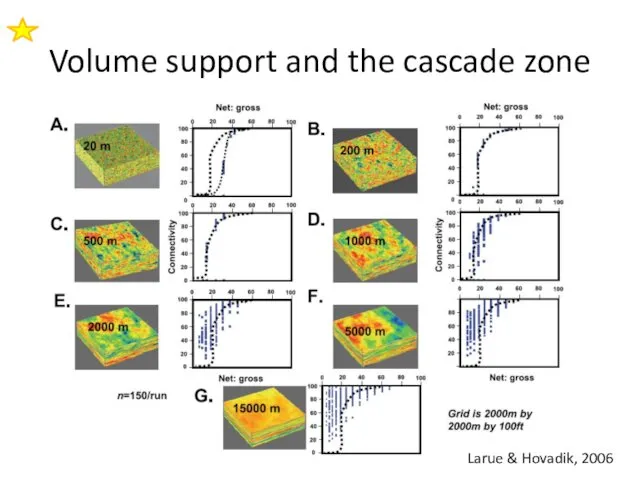

- 29. Geobody Anisotropy Hovadik & Larue, 2010

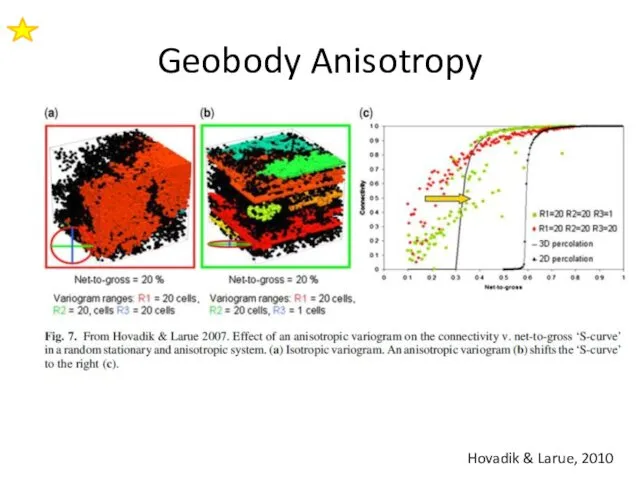

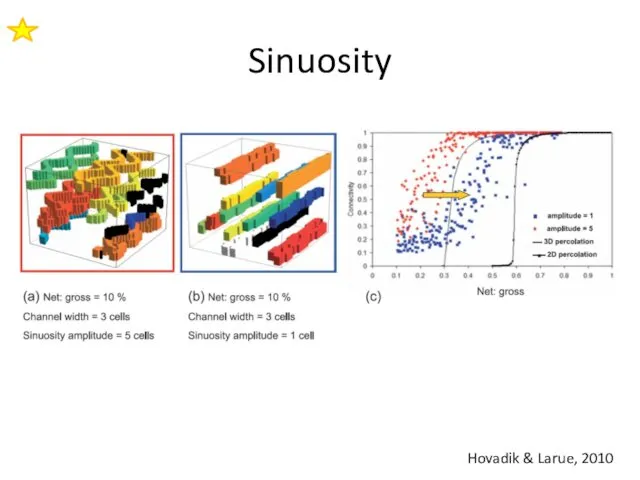

- 30. Sinuosity Hovadik & Larue, 2010

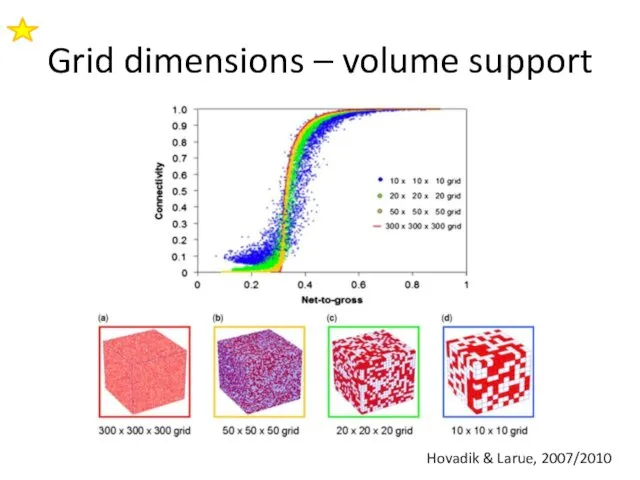

- 31. Grid dimensions – volume support Hovadik & Larue, 2007/2010

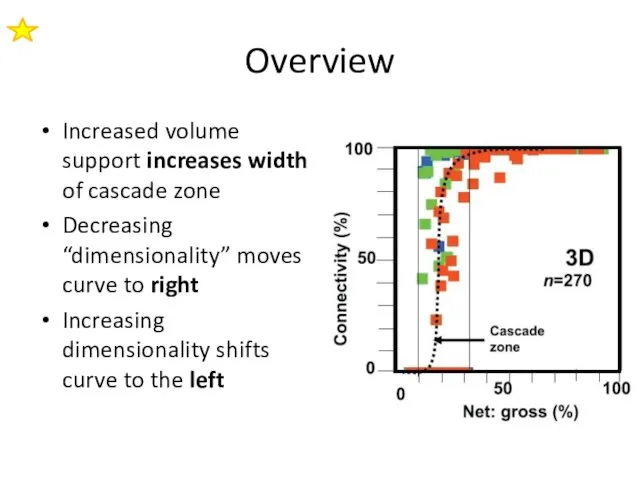

- 32. Overview Increased volume support increases width of cascade zone Decreasing “dimensionality” moves curve to right Increasing

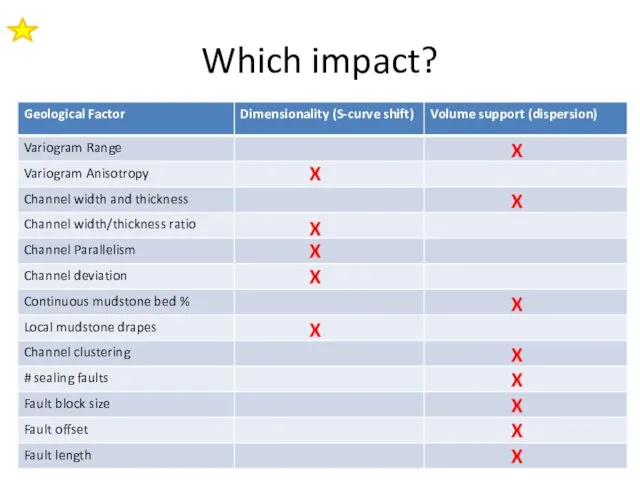

- 33. Which impact? X X X X X X X X X X X X X

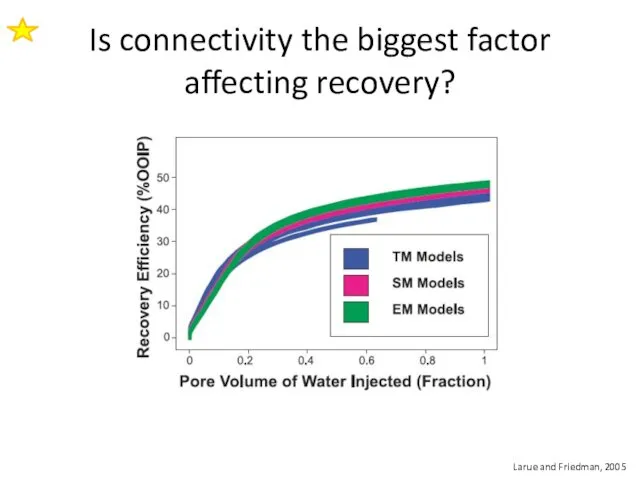

- 34. Is connectivity the biggest factor affecting recovery? Larue and Friedman, 2005

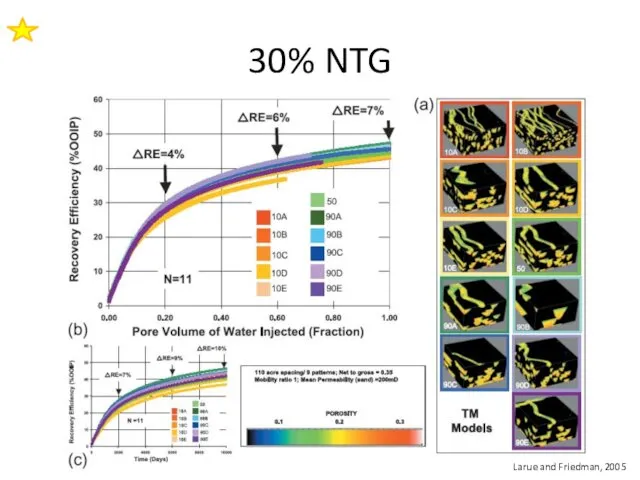

- 35. 30% NTG Larue and Friedman, 2005

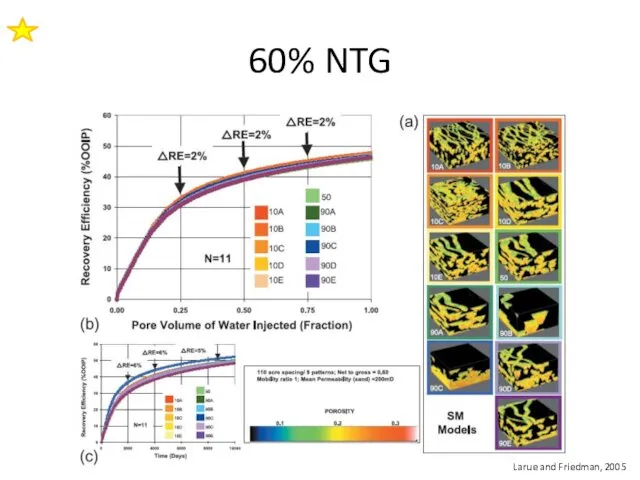

- 36. 60% NTG Larue and Friedman, 2005

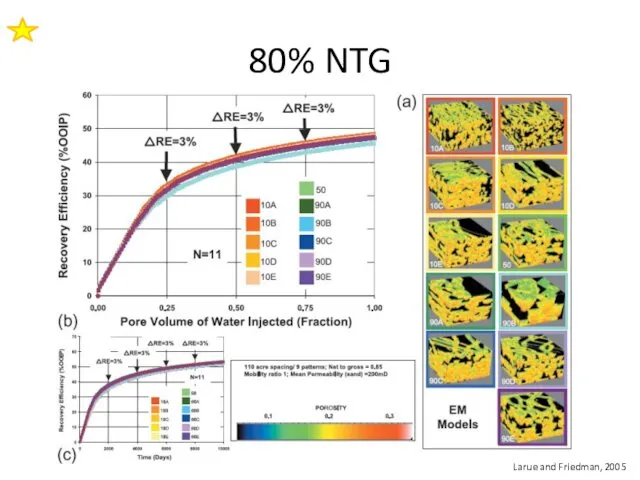

- 37. 80% NTG Larue and Friedman, 2005

- 38. Key factors affecting dynamic recovery Static connectivity SHAPE OF S-CURVE Dynamic “addons” Tortuosity Permeability Heterogeneity Inter-well

- 39. Impact of tortuosity Larue & Hovadik, 2006

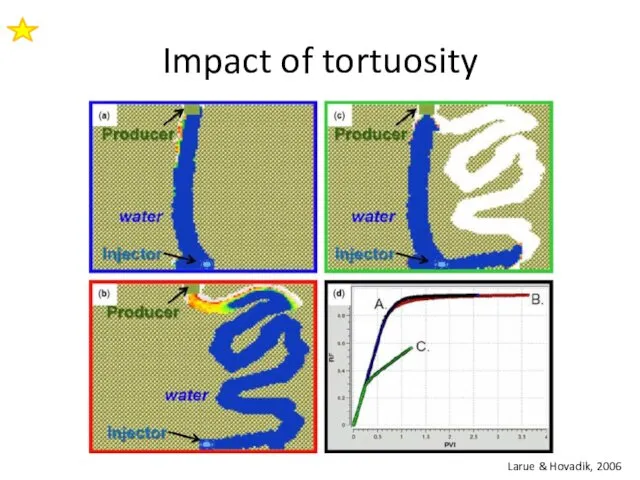

- 40. Impact of permeability heterogeneity Larue and Friedman, 2005

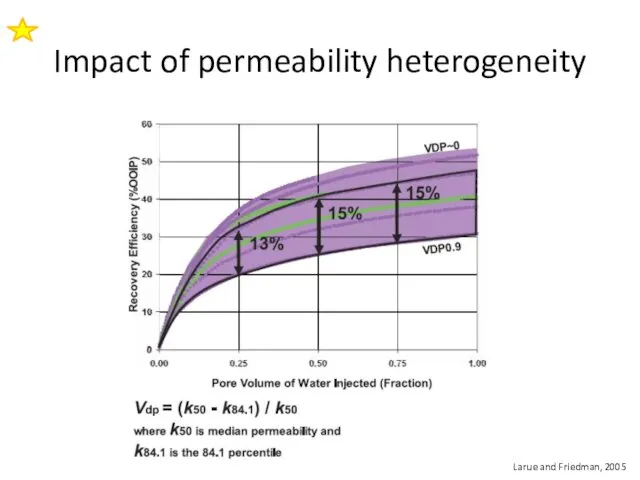

- 41. Thief zone impact on recovery Larue and Friedman, 2005

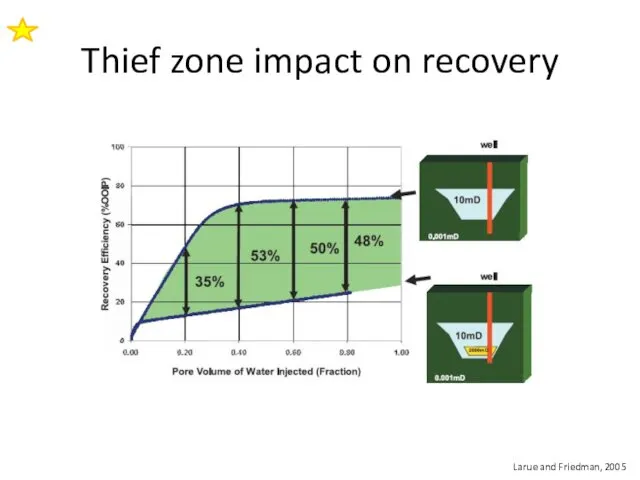

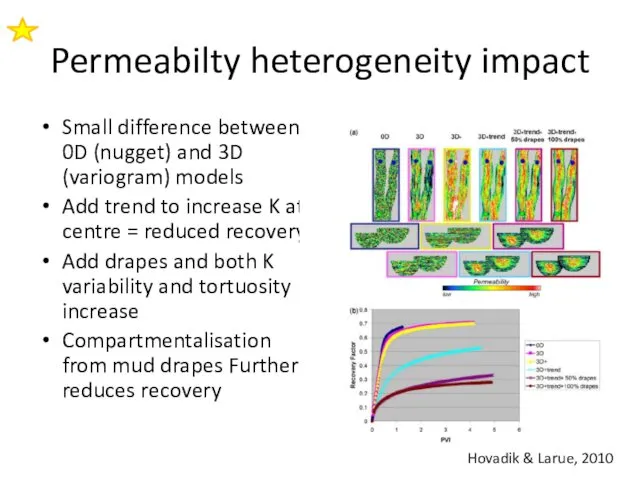

- 42. Permeabilty heterogeneity impact Small difference between 0D (nugget) and 3D (variogram) models Add trend to increase

- 43. Variogram range and Vdp combined Hovadik & Larue, 2010

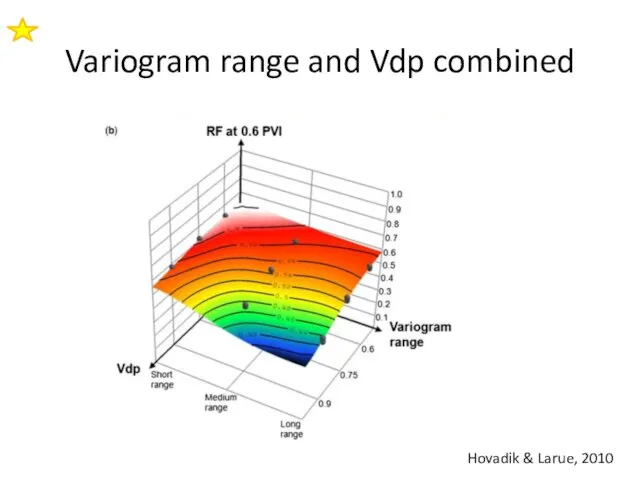

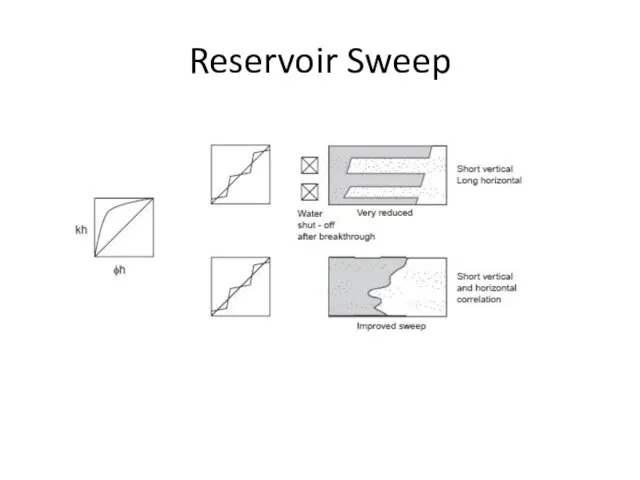

- 44. Reservoir Sweep

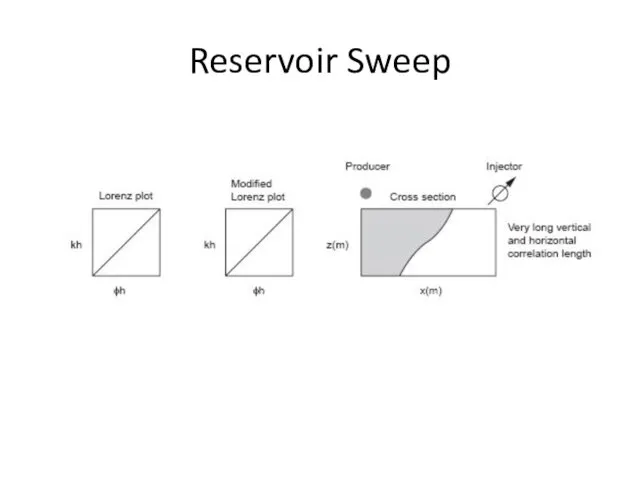

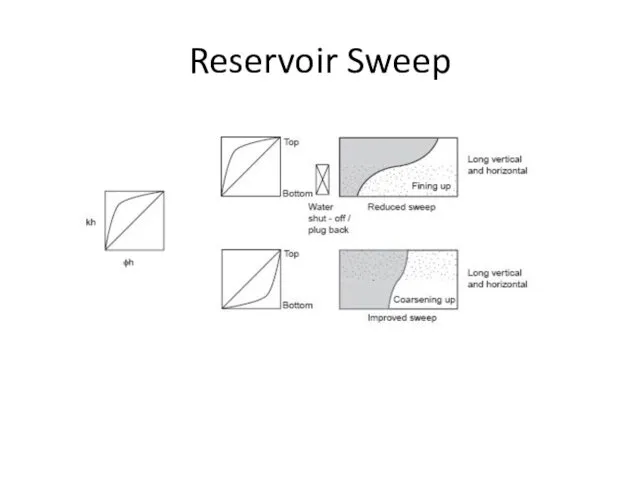

- 45. Reservoir Sweep

- 46. Reservoir Sweep

- 47. Impact of mobility ratio Larue and Friedman, 2005

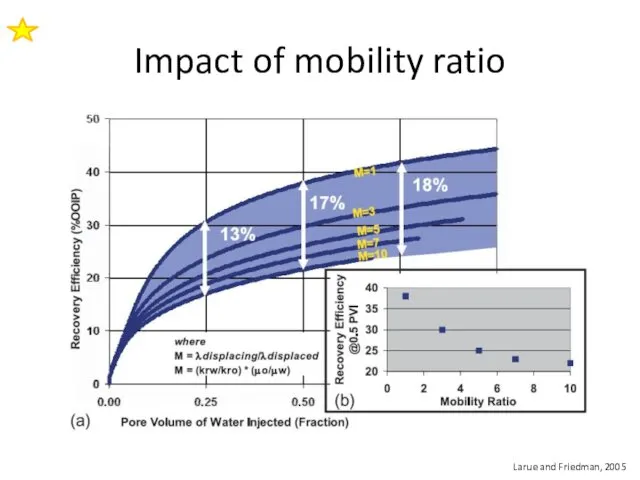

- 48. Impact of well pattern Larue and Friedman, 2005

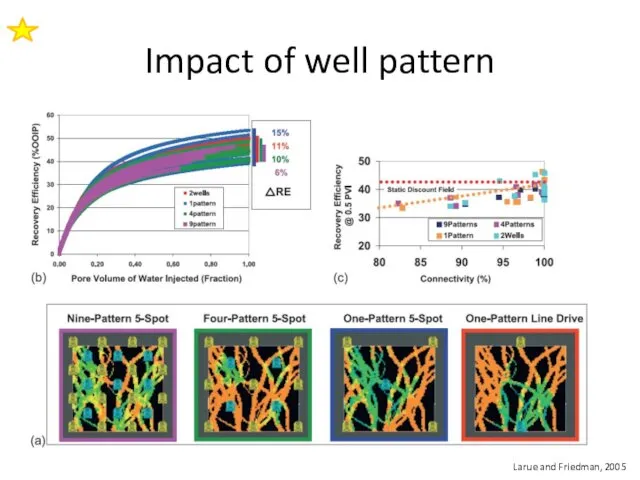

- 49. Well distance impact on recovery (dynamic connectivity) Hovadik & Larue, 2010

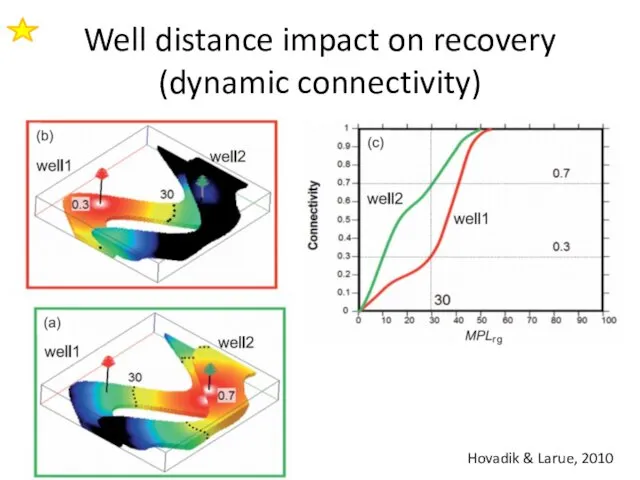

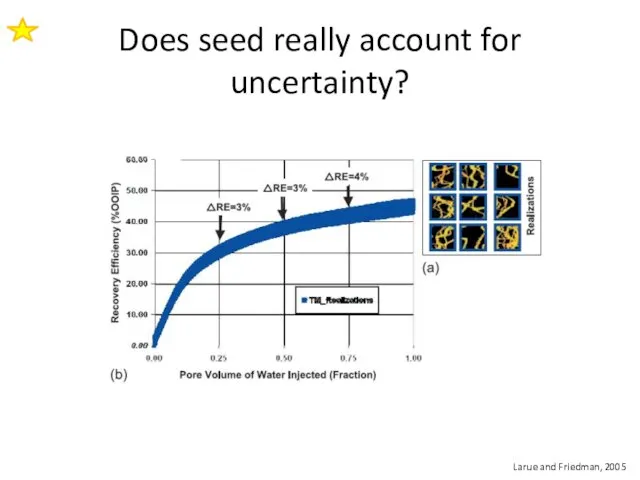

- 50. Does seed really account for uncertainty? Larue and Friedman, 2005

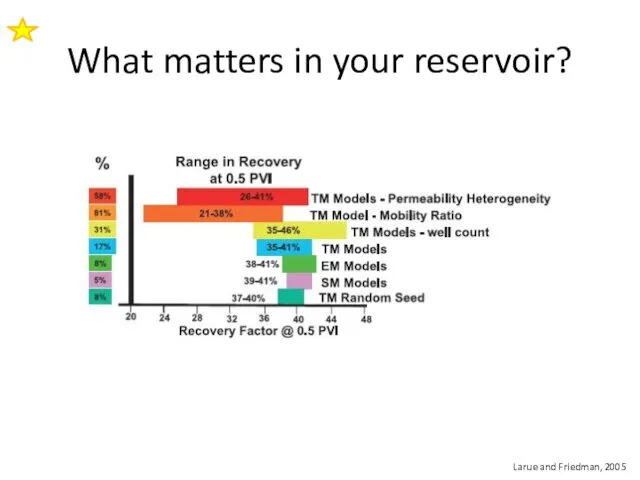

- 51. What matters in your reservoir? Larue and Friedman, 2005

- 52. Extreme edge cases: High NTG + Low Connectivity Manzocchi et al, 2007

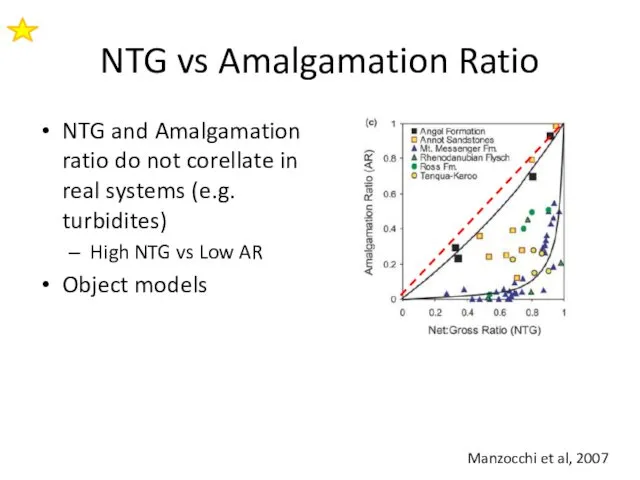

- 53. NTG vs Amalgamation Ratio NTG and Amalgamation ratio do not corellate in real systems (e.g. turbidites)

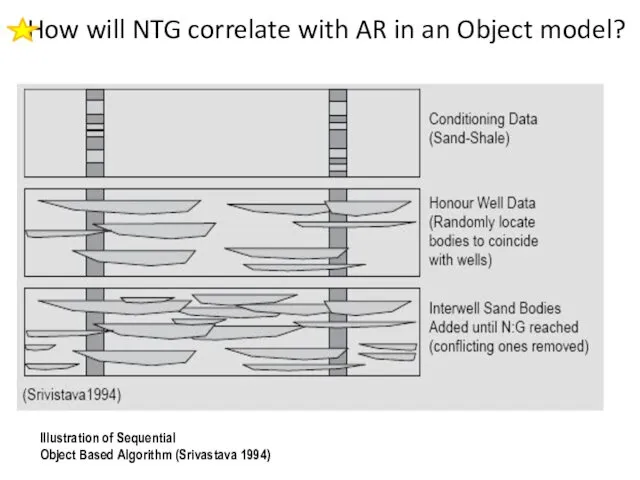

- 54. Object Based Modelling Convergence Problem Illustration of Sequential Object Based Algorithm (Srivastava 1994) As Number of

- 55. Geostatistical modelling conditioned to NTG High NTG system has short continuity of sandbodies vertically and laterally

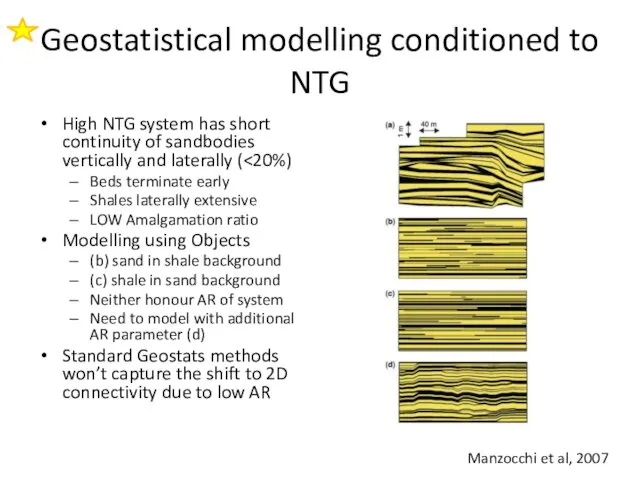

- 56. Overview of connectivity 30% 60% A+B NTG NTG Geobody size Total Recovery Impact of Geology More

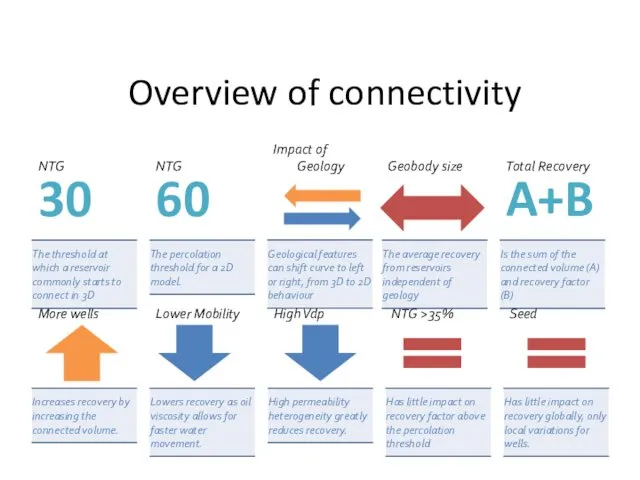

- 57. IMPROVED RECOVERY Maximise value through…

- 58. Recovery Factors Tyler and Finlay, 1991 Depends on Geology and Drive Mechanism Solution gas drive 5-30%

- 59. Improved Recover Factors Tyler and Finlay, 1991

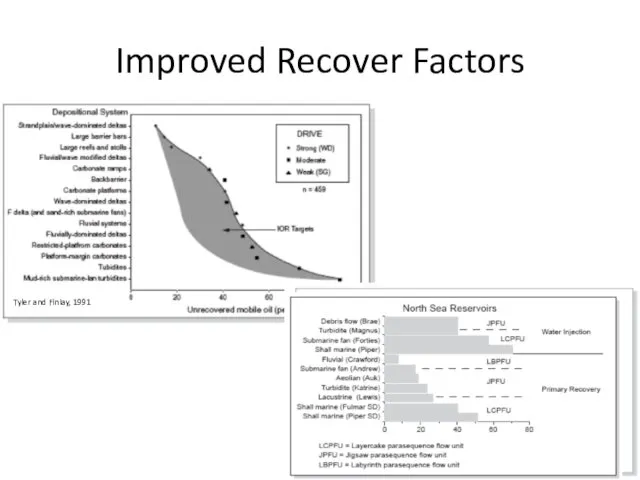

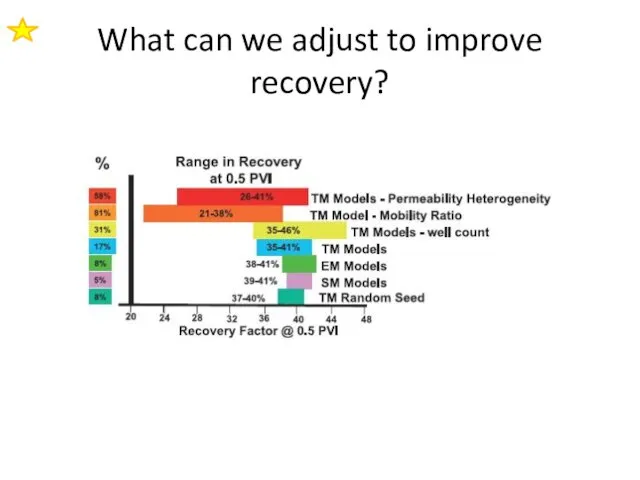

- 60. What can we adjust to improve recovery?

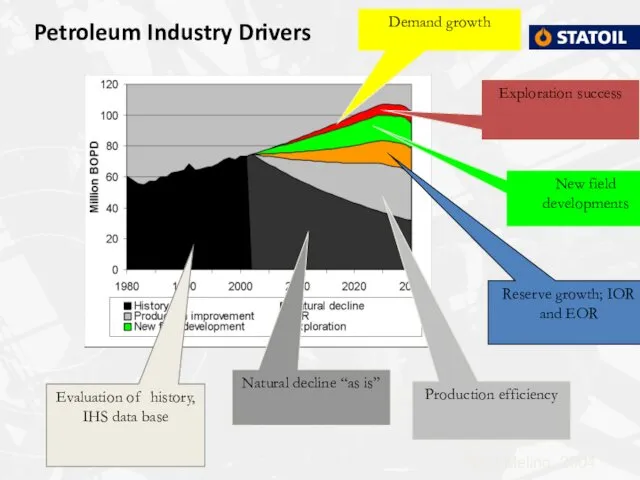

- 61. Evaluation of history, IHS data base Natural decline “as is” Production efficiency Reserve growth; IOR and

- 62. Production Capacity Increase in Mature Fields Time Production Overall Field Development Plan Detailed Seismic & Geology

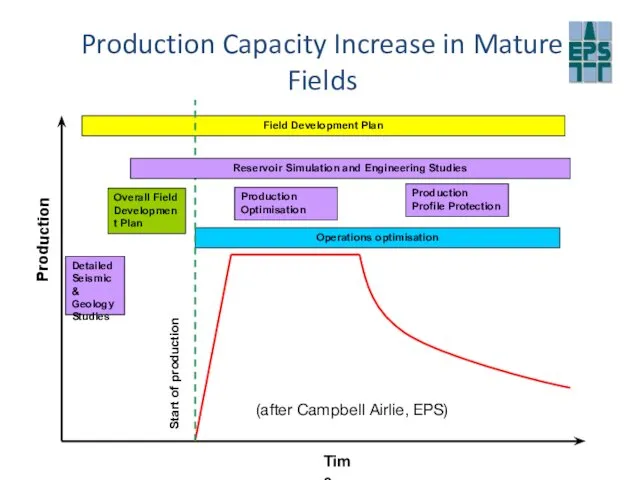

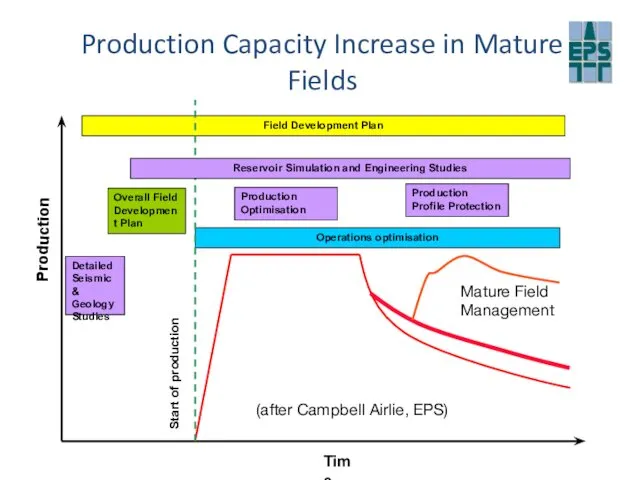

- 63. Production Capacity Increase in Mature Fields Time Production Overall Field Development Plan Detailed Seismic & Geology

- 64. INFILL DRILLING Example of….

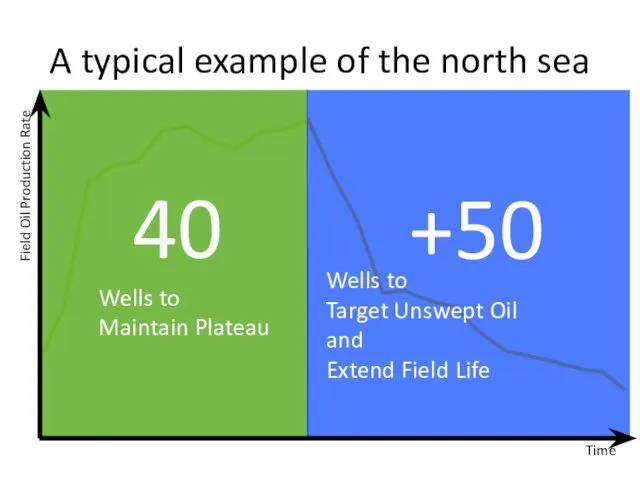

- 65. Time Field Oil Production Rate A typical example of the north sea

- 66. RM Example 1 Strategy for Statfjord Aadland et al., 1994 High well activity Horizontal wells Reservoir

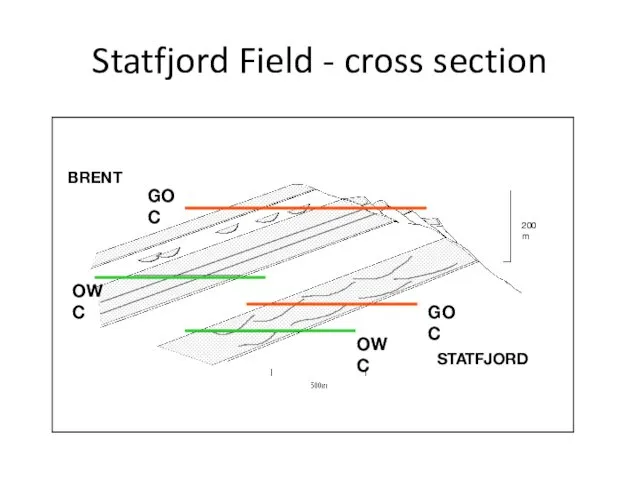

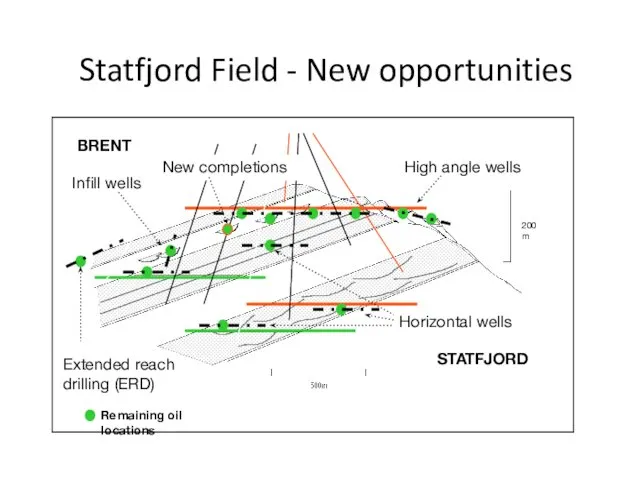

- 67. Statfjord Field - cross section GOC OWC GOC OWC BRENT STATFJORD 200m

- 68. Statfjord Field - initial production plan BRENT STATFJORD 200m Water injection Gas injection Oil production

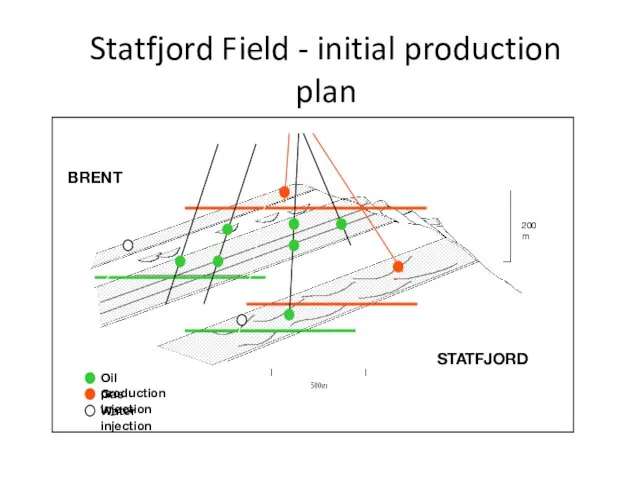

- 69. Statfjord Field - Remaining oil BRENT STATFJORD 200m Remaining oil locations Rim oil Attic oil Structural

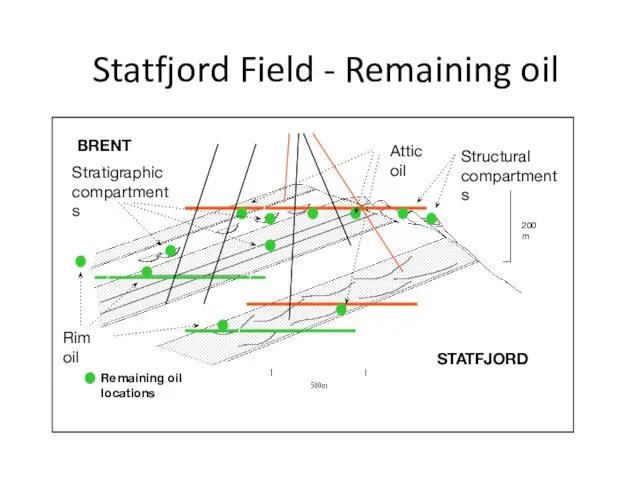

- 70. Statfjord Field - New opportunities BRENT STATFJORD 200m Remaining oil locations New completions Horizontal wells High

- 71. Example: Yibal Field, Oman Strategy for Yibal Field, Oman Horizontal wells Bypassed oil in a Carbonate

- 72. Modelling Characteristics and Sensitivities Original OWC Upper Shuaiba Matrix: Single pore system Uncertain Kv/Kh ratio Uncertain

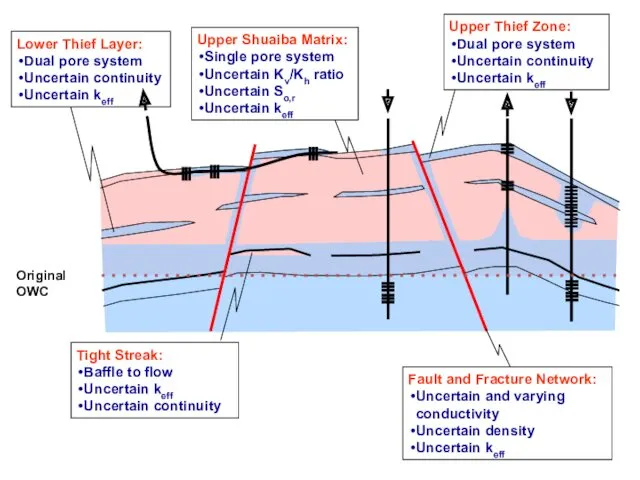

- 73. Yibal Field Development History Depletion and “phase” injection Aquifer injection Onset of horizontal drilling High density

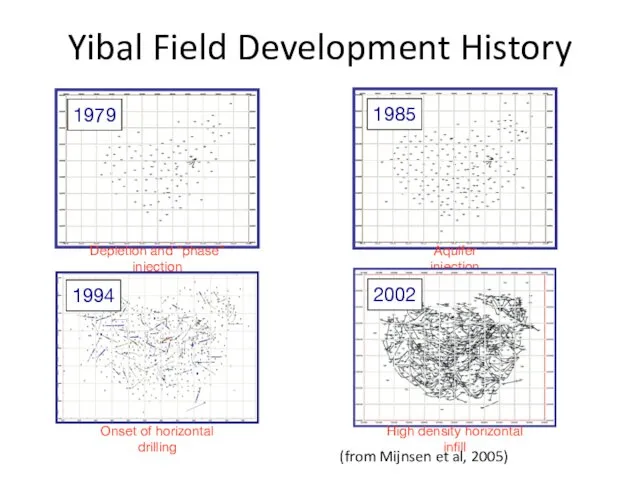

- 74. YIBAL FIELD: Water - Oil Rate vs RF Phase Aquifer Injection Horizontals 01/81 01/88 01/94 09/98

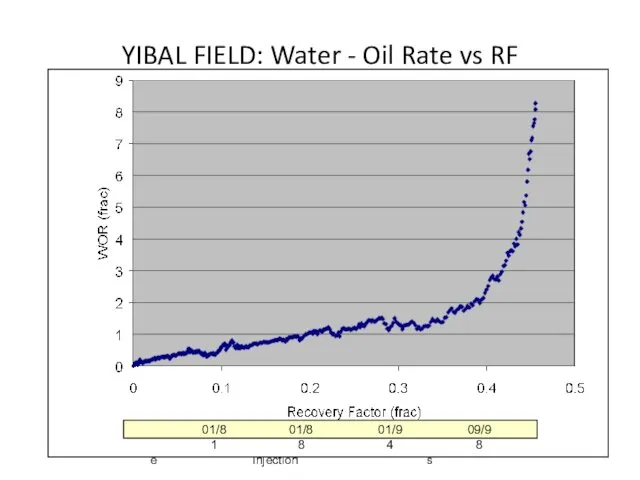

- 75. Seifert et al., 1996 Impact of well placement fluvial study SW NE compartmentalisation of pay facies

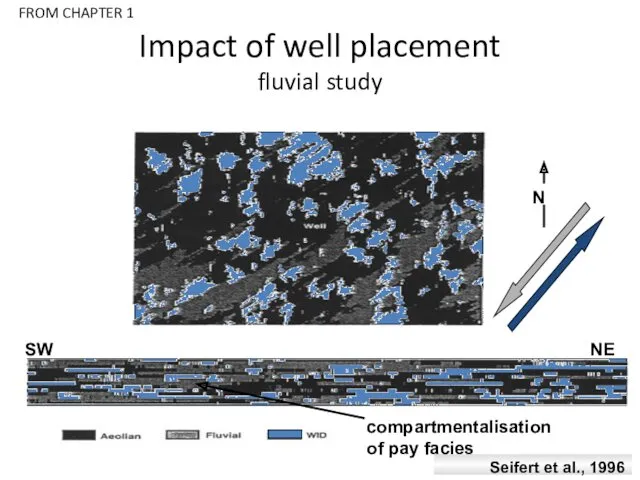

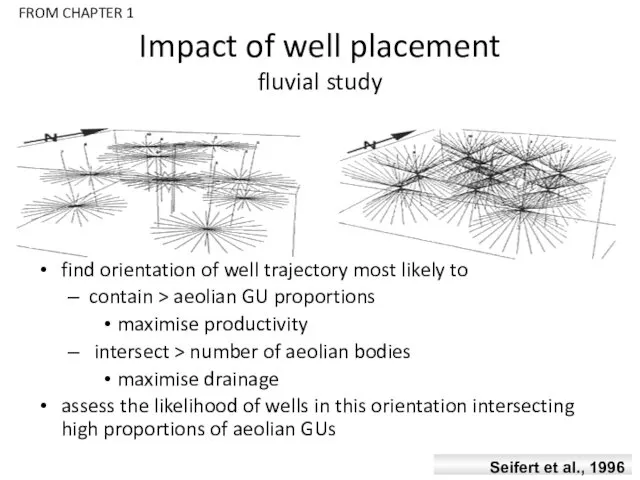

- 76. Seifert et al., 1996 Impact of well placement fluvial study find orientation of well trajectory most

- 77. Seifert et al., 1996 Impact of well placement results aeolian bodies intersected aeolian GU proportions horizontal

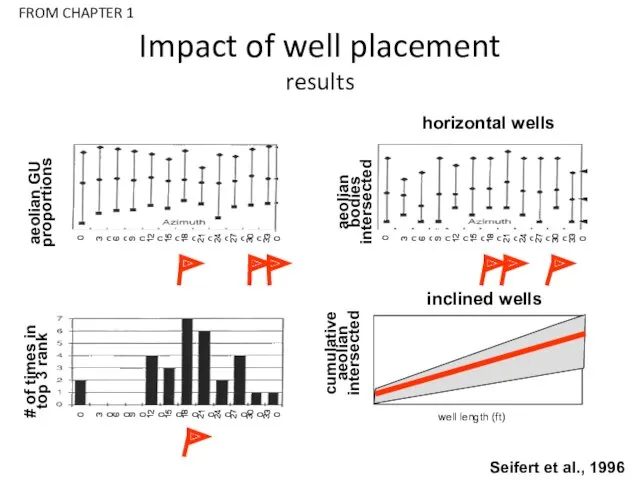

- 78. RM Example 3: Heather Field Compartmentalisation and Variable Recovery Crest Flank

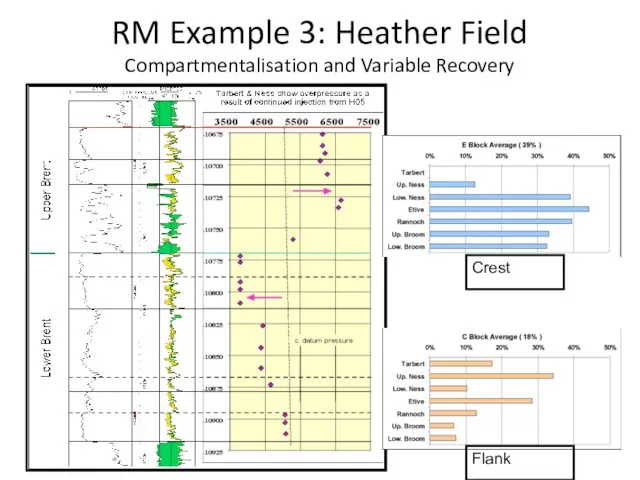

- 79. Infill Drilling – Heather Field Fault compartmentalisation

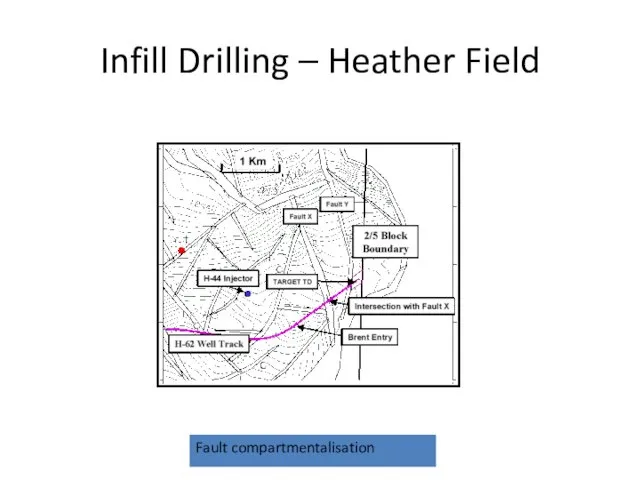

- 80. FRACCING Example of….

- 81. Example: Leman Field Strategy for Leman Field Mijnsson and Maskall 1994 Proactive hunt for gas Horizontal

- 82. Typical Rotliegend reservoir section

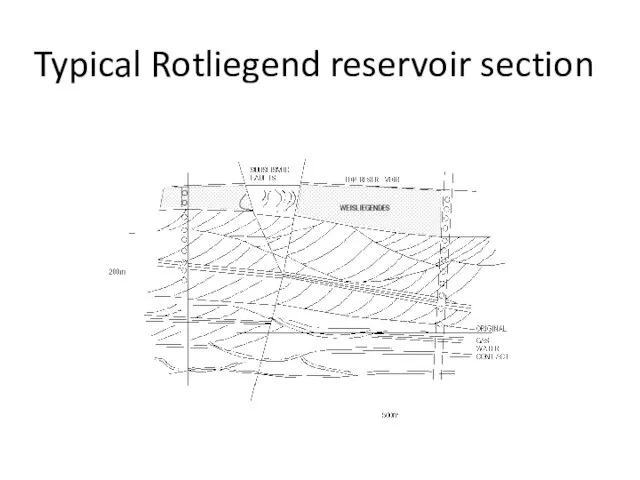

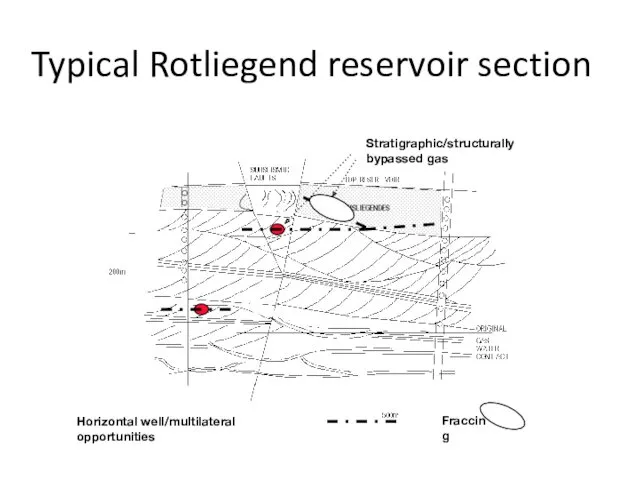

- 83. Typical Rotliegend reservoir section Bypassed gas Stratigraphic/structurally bypassed gas

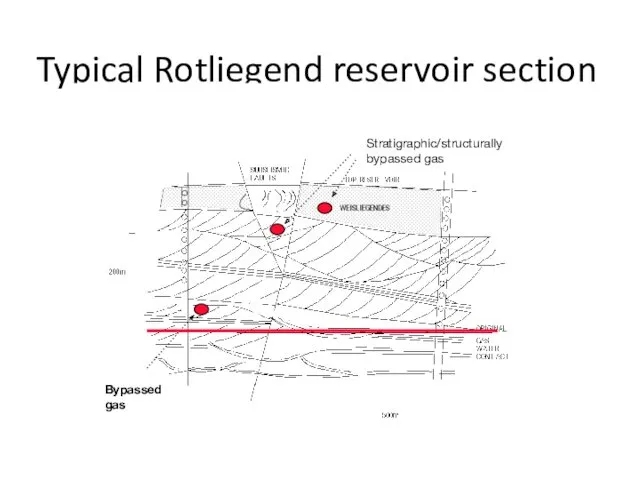

- 84. Typical Rotliegend reservoir section Horizontal well/multilateral opportunities Stratigraphic/structurally bypassed gas Fraccing

- 85. EOR (WAG) Example of….

- 86. IOR: New opportunities with CO2 Initial Waterflood Main CO2 flood ROZ CO2 flood mbd

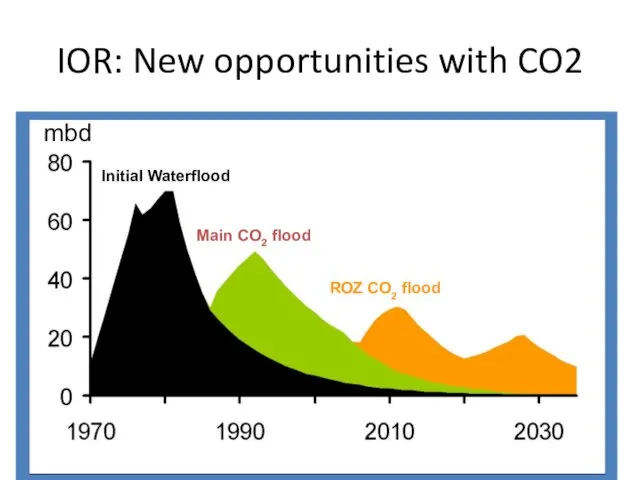

- 87. Example: Magnus Field Production & Injection History Commence water injection Moulds et al, 2010, SPE 134953

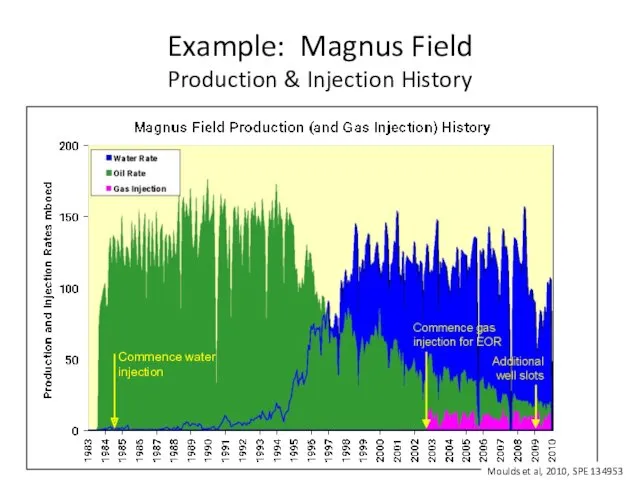

- 88. Improved oil recovery from EOR over waterflood Moulds et al, 2010, SPE 134953

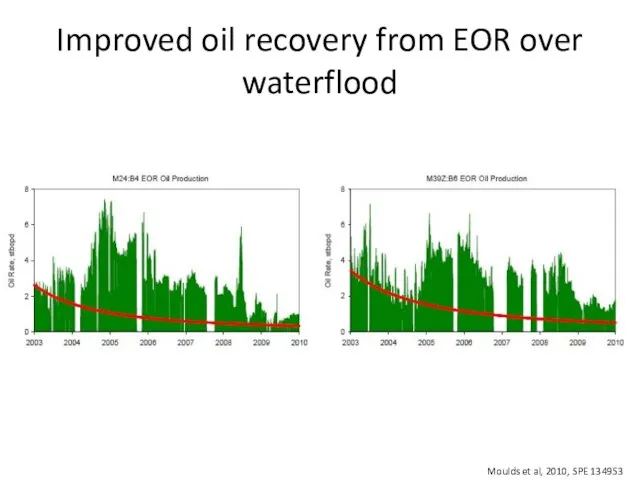

- 89. The Future – New Wells Magnus Extension Project 4 new slots, slot splitter technology enables 2

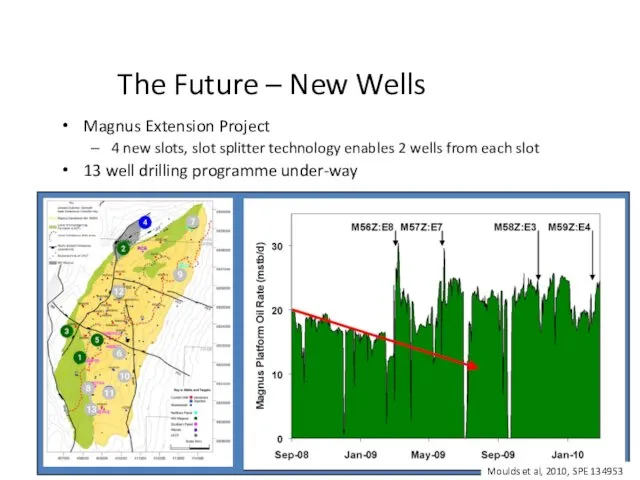

- 90. Target: Magnus Field Oil Remaining after waterflood EOR oil target: updip attic target and unswept oil

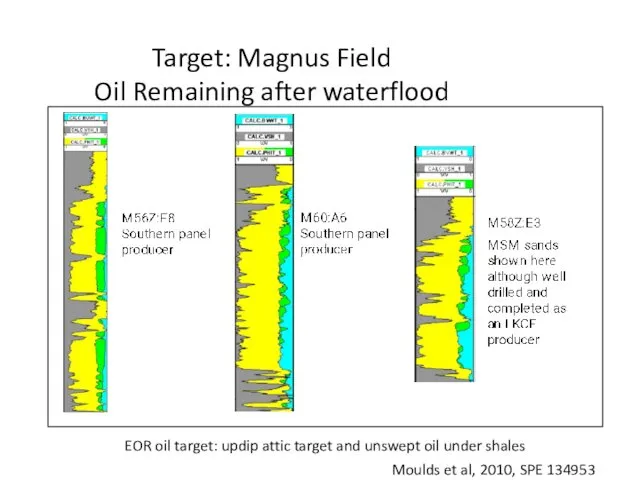

- 91. PEOPLE/TEAMS Maximise value through…

- 92. Synergy Output of a synergistic team is larger than the sum of the output of individuals….

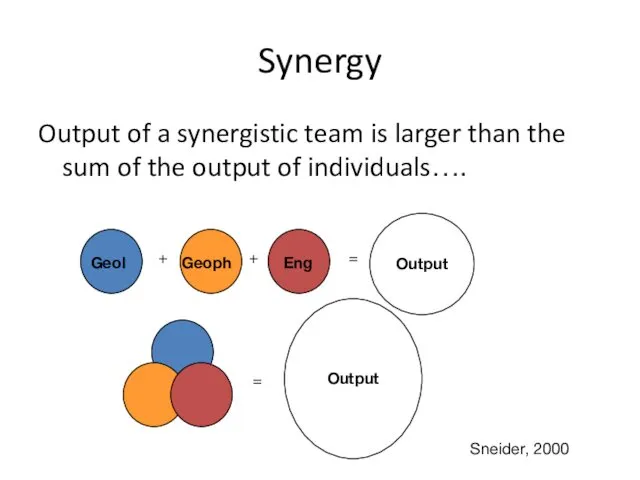

- 93. Synergy Is not: Geoengineering Any thing about multi-discipline work Anything to do with Energy Synergy Sum

- 94. REM is like Systems thinking System of interdependent processes Model Complexity of system rather than simplify

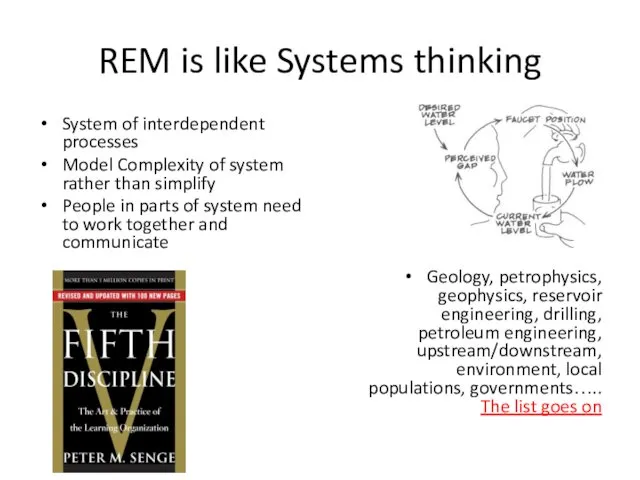

- 95. Field Management Plan (UK DTI) Reservoir Management Strategy - detailing the principles and objectives that the

- 96. RM Strategy Developing Implementing Monitoring Evaluating DIME - Satter and Thakur, 1994

- 97. WATER MANAGEMENT Increase costs through…

- 98. Reservoir Management Issues (1) a- Mechanical leaks: b - Behind Casing flow c - Oil-water contact:

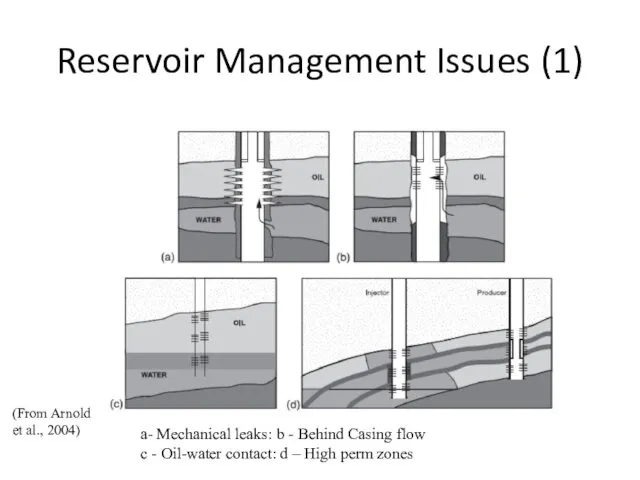

- 99. Reservoir Management Issues (2) e- Fractures: f – Fractures to water g - Coning: h –

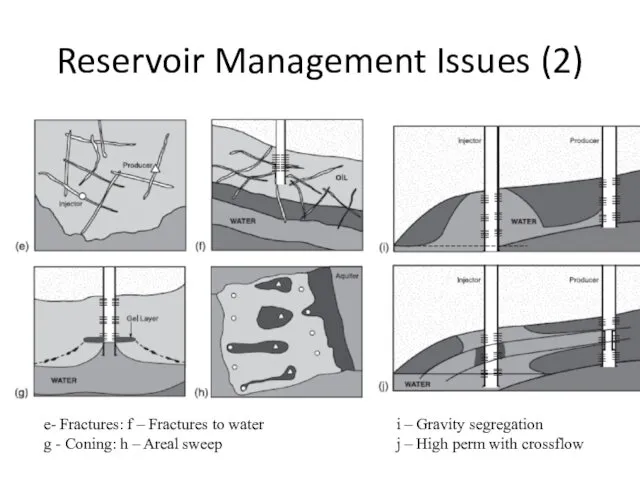

- 100. WATER SHUTOFF Example of….

- 101. Yibal Field Development History Depletion and “phase” injection Aquifer injection Onset of horizontal drilling High density

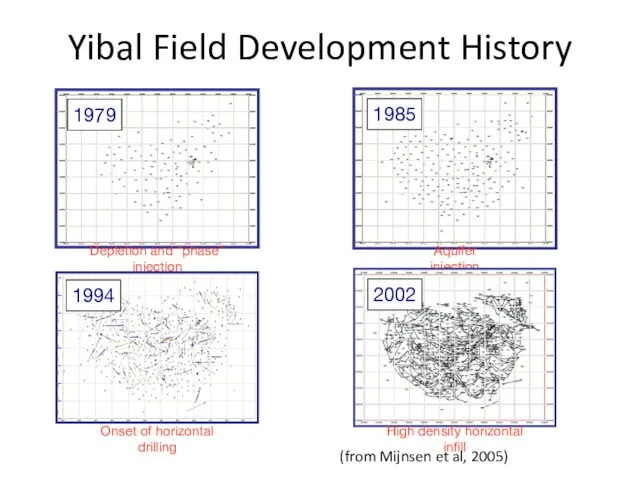

- 102. YIBAL FIELD: Water - Oil Rate vs RF Phase Aquifer Injection Horizontals 01/81 01/88 01/94 09/98

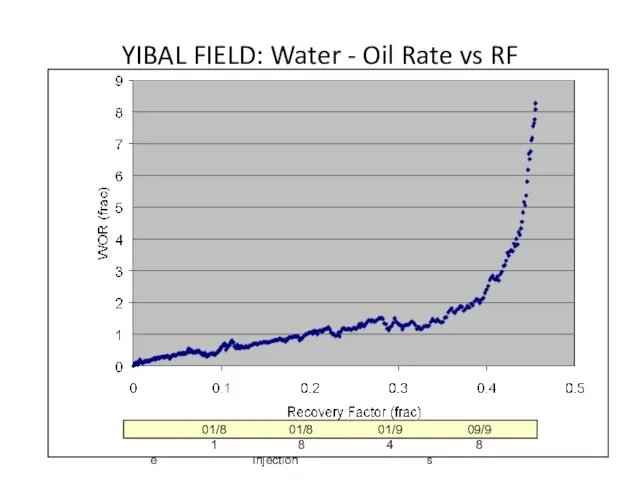

- 103. Brent Field Reservoir monitoring (Bryant and Livera, 1991)

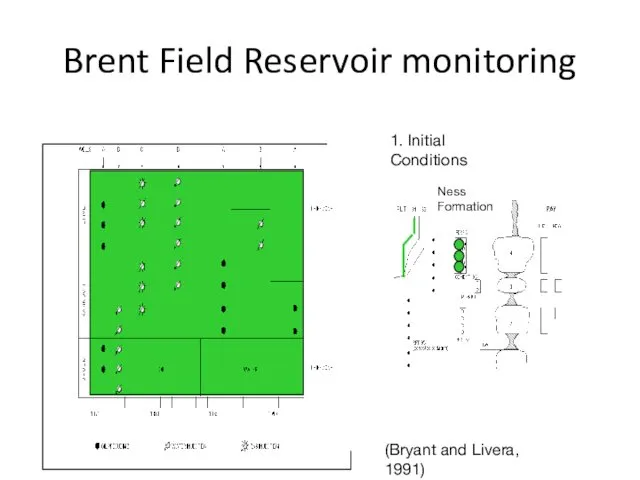

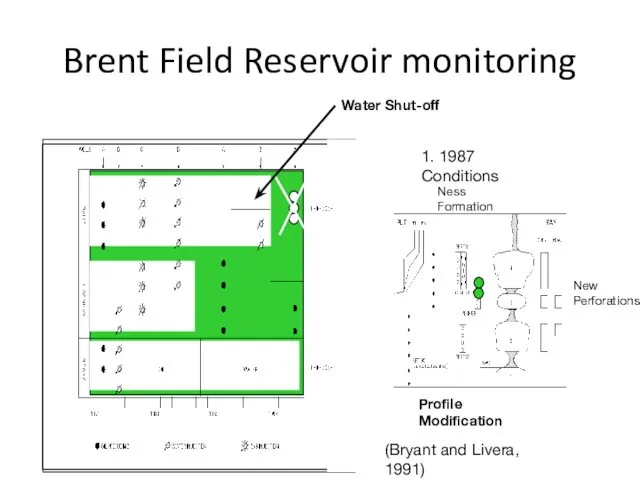

- 104. Brent Field Reservoir monitoring (Bryant and Livera, 1991) 1. Initial Conditions Ness Formation

- 105. Brent Field Reservoir monitoring (Bryant and Livera, 1991) 1. 1987 Conditions Ness Formation New Perforations Profile

- 106. SCALE MANAGEMENT Increase costs through…

- 107. Decline in Magnus production Moulds et al, 2010, SPE 134953

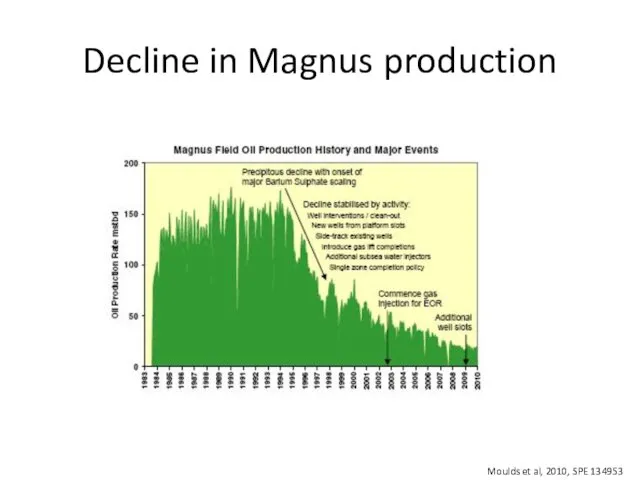

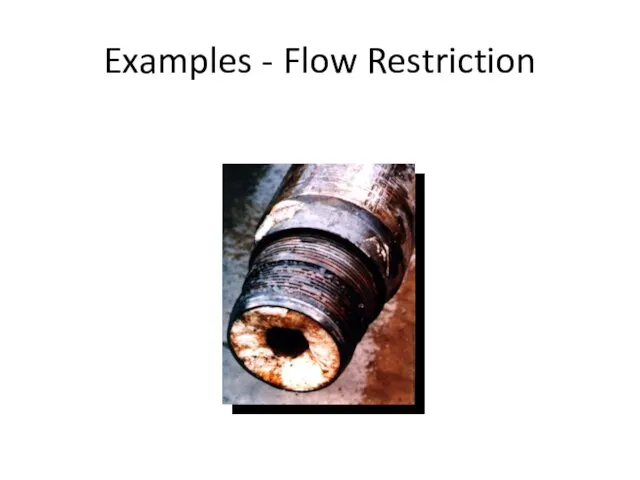

- 108. Examples - Flow Restriction

- 109. Examples - Facilities separator scaled up and after cleaning

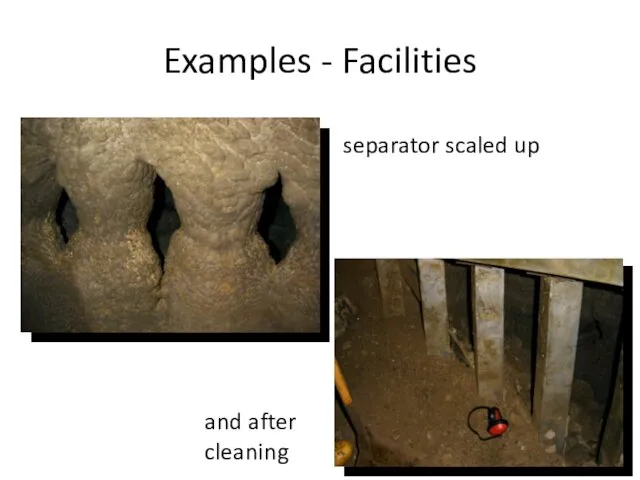

- 110. Water chemistry history match 154471 • Use of Water Chemistry Data in History Matching of a

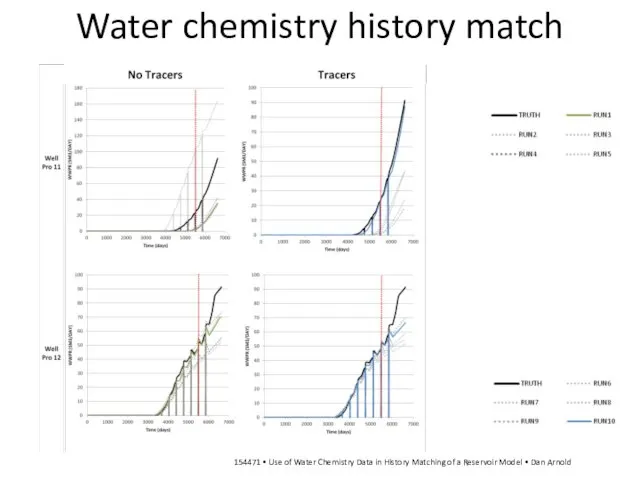

- 111. Probabilistic predictions of scaling in wells 154471 • Use of Water Chemistry Data in History Matching

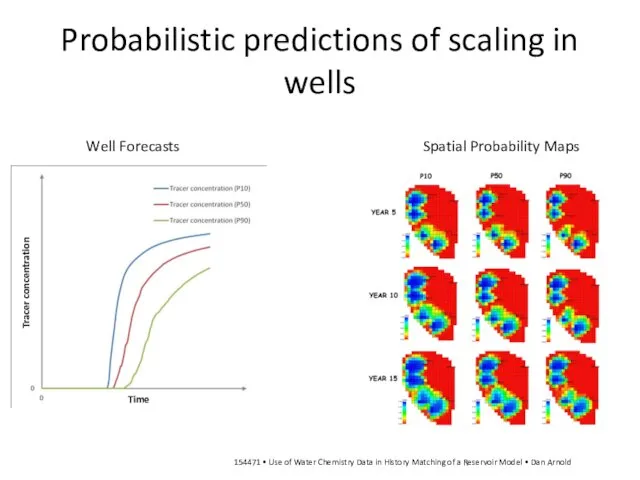

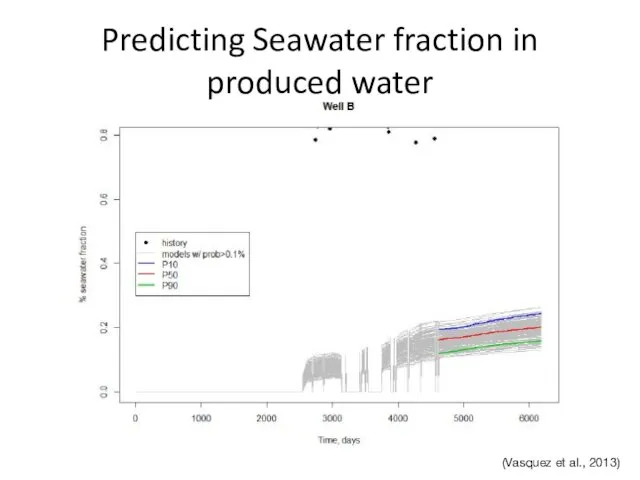

- 112. Predicting Seawater fraction in produced water (Vasquez et al., 2013)

- 113. Probability maps of seawater fraction P10 P50 P90

- 114. Results Optimization w/o accounting scale risk

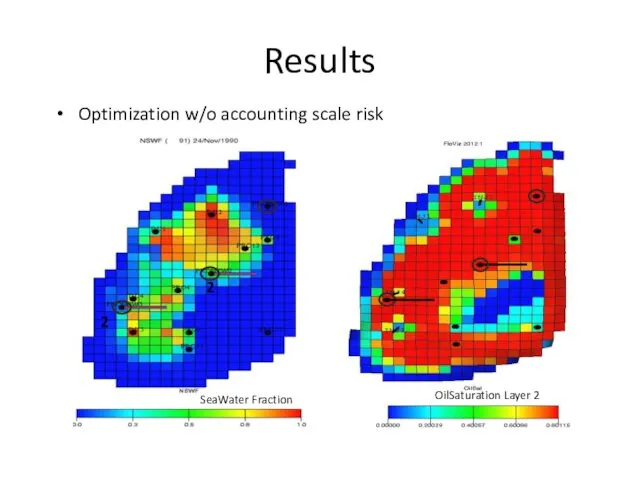

- 115. Results Optimization accounting scale risk SeaWater Fraction OilSaturation Layer 4 OilSaturation Layer 1

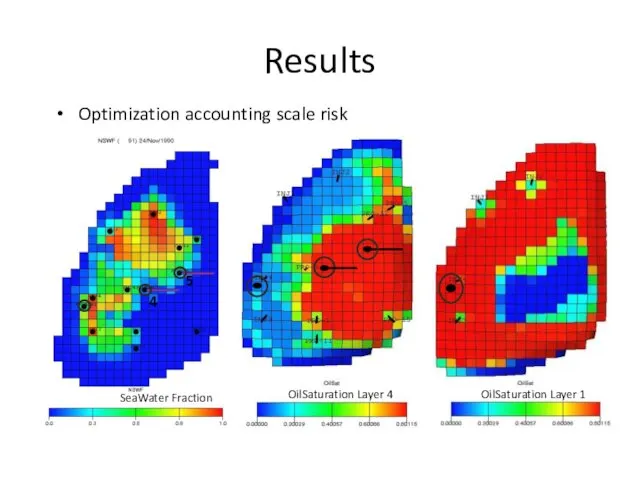

- 116. Results Layer open/shut w/o accounting scale risk accounting scale risk 0 1

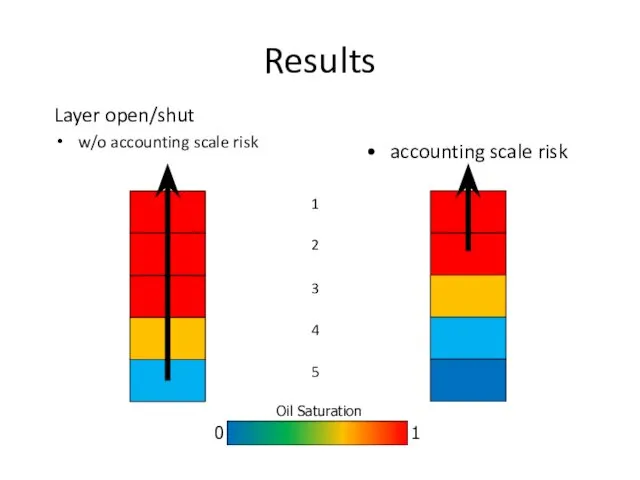

- 117. Impact in the value through… VALUE OF YOUR OIL

- 118. Two key things you don’t know How much oil you can extract Reservoir uncertainty Variations from

- 119. All oil is not created equally priced...

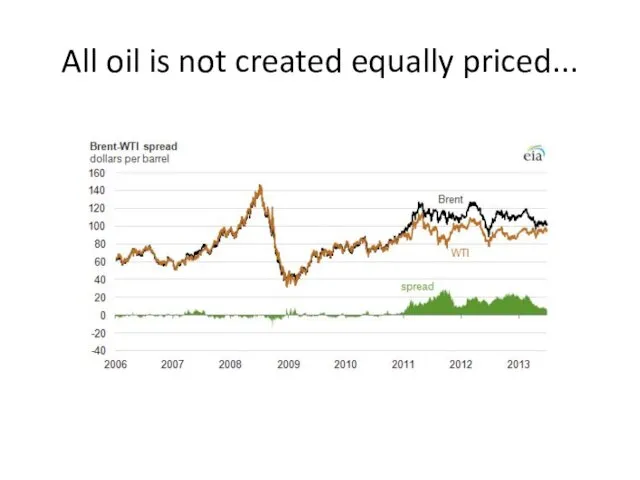

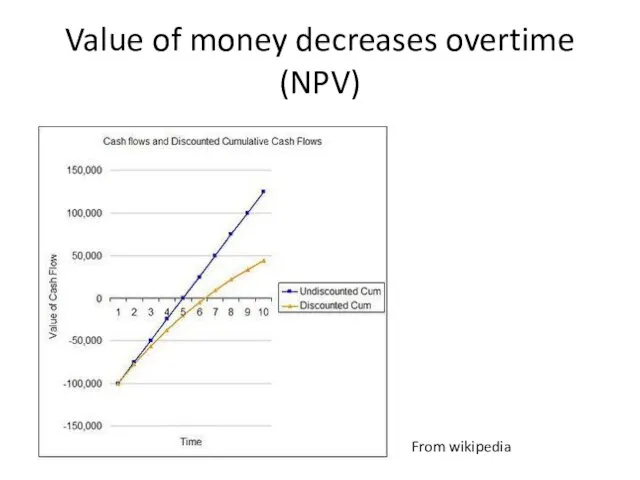

- 120. Time value of money where DPV is the discounted present value of the future cash flow

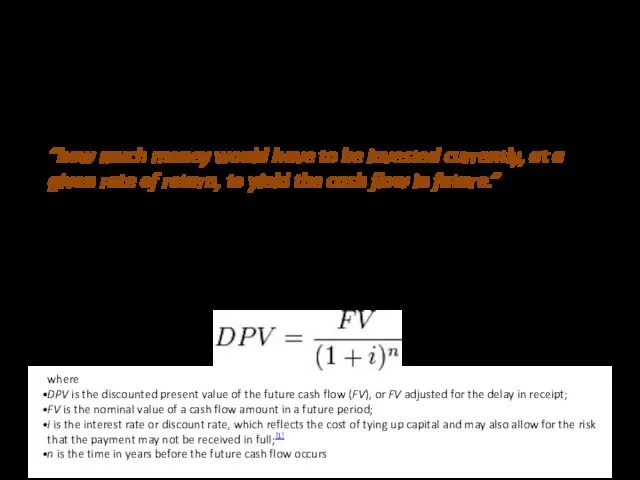

- 121. Value of money decreases overtime (NPV) From wikipedia

- 122. Compare value of companies Oil = 5,817 million barrels Gas = 24,948 billion cubic feet 1.75

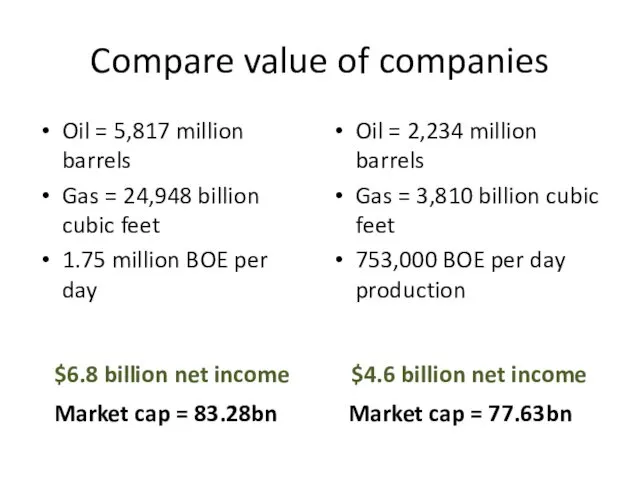

- 123. Compare strategy of companies Offshore, deep water, complex fields Ultra high production (60,000 bpd + per

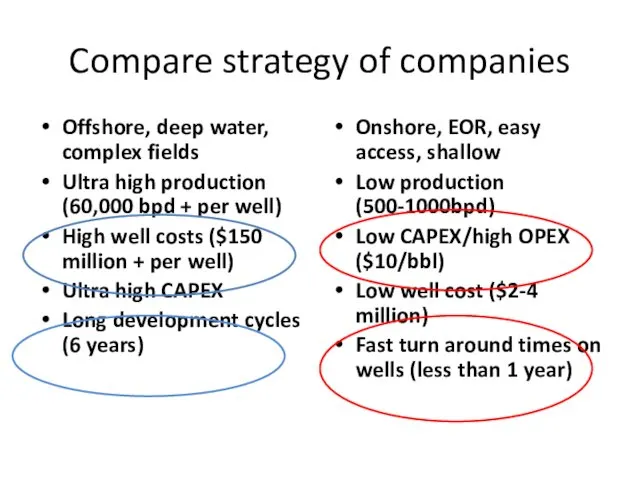

- 124. Lifting cost of oil (worldwide)

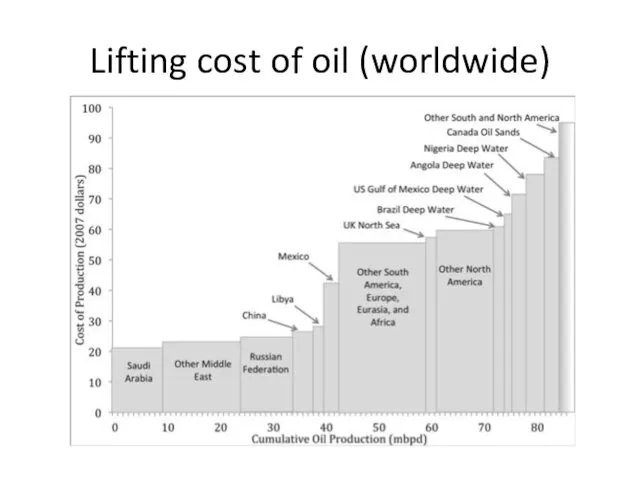

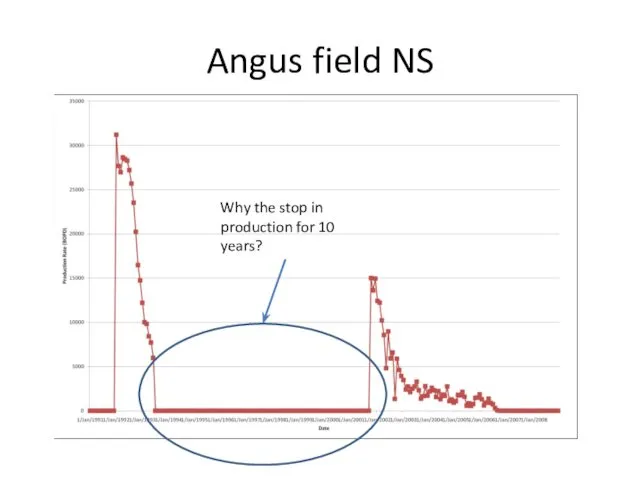

- 125. Angus field NS Why the stop in production for 10 years?

- 126. Aim MAXIMISE VALUE MINIMISE COST Maximise recovery Speed up recovery People/Team Reservoir Knowledge/analysis Recovery Technology CAPEX

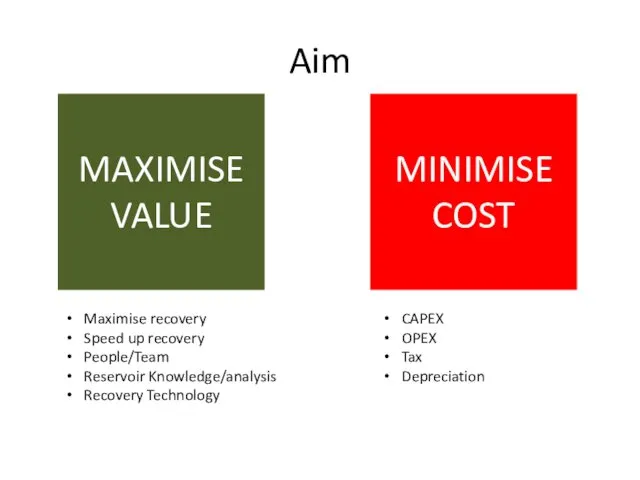

- 127. Aim MAXIMISE VALUE MINIMISE COST Maximise recovery Speed up recovery People/Team Reservoir Knowledge/analysis Recovery Technology CAPEX

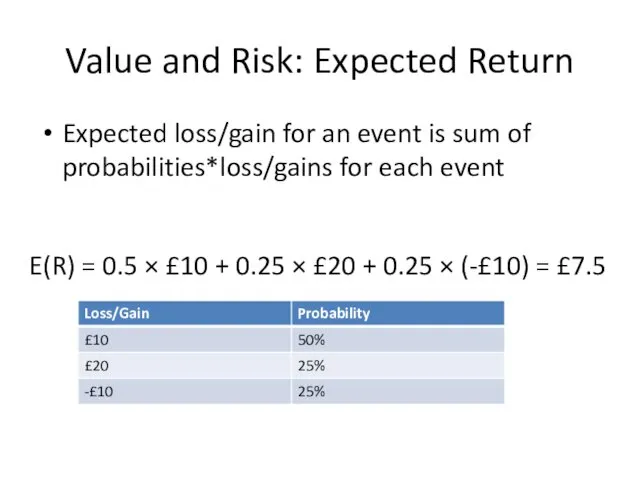

- 128. Value and Risk: Expected Return Expected loss/gain for an event is sum of probabilities*loss/gains for each

- 129. Decision tree analysis

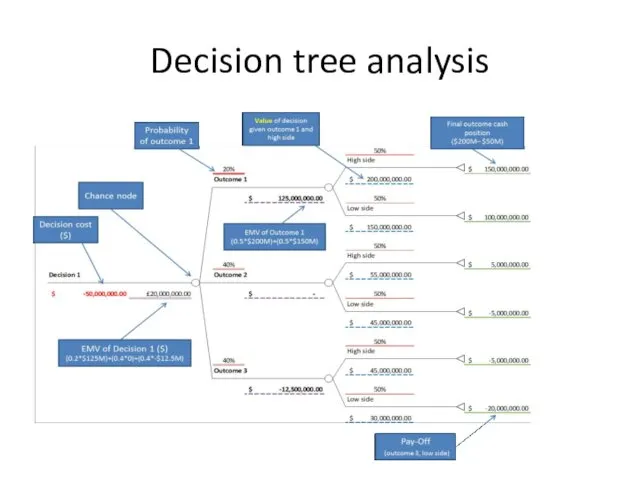

- 130. Discretisation of PDFs Convert continuous values into discrete to use in decision tree Several methods, such

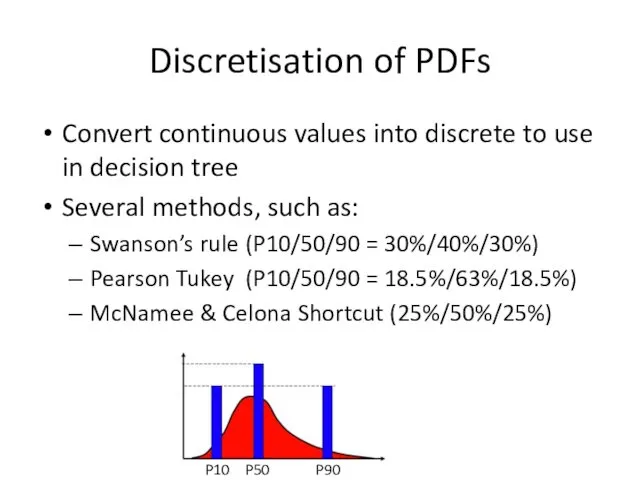

- 131. RESERVOIR DEVELOPMENT OPTIMISATION Maximise value through…

- 132. What do we mean by optimisation Process of improving something to find the best compromise among

- 133. Optimisation example Model 1 Model 2

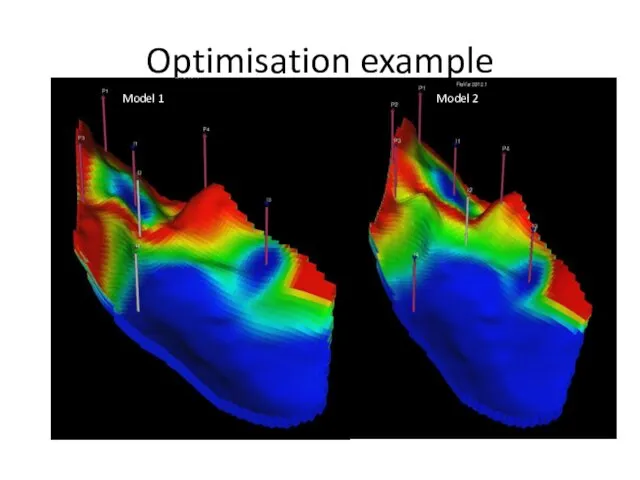

- 134. Optimisation often involves trade-offs MAXIMISE VALUE MINIMISE COST Maximise recovery Speed up recovery People/Team Reservoir Knowledge/analysis

- 135. Automated optimisation A set of algorithms available that can automate the optimisation process Define problem as

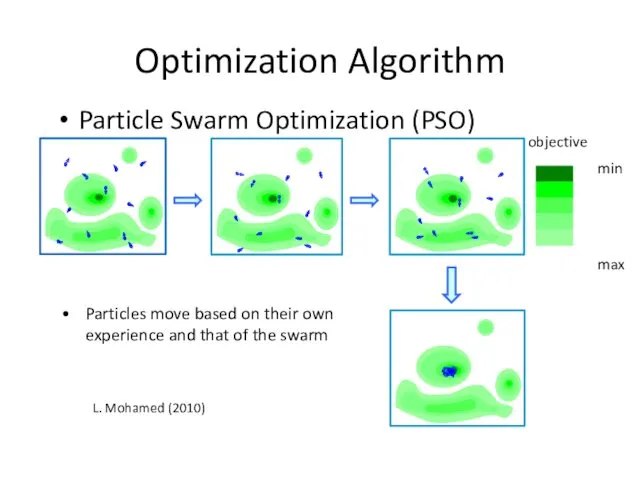

- 136. Optimization Algorithm Particle Swarm Optimization (PSO) Particles move based on their own experience and that of

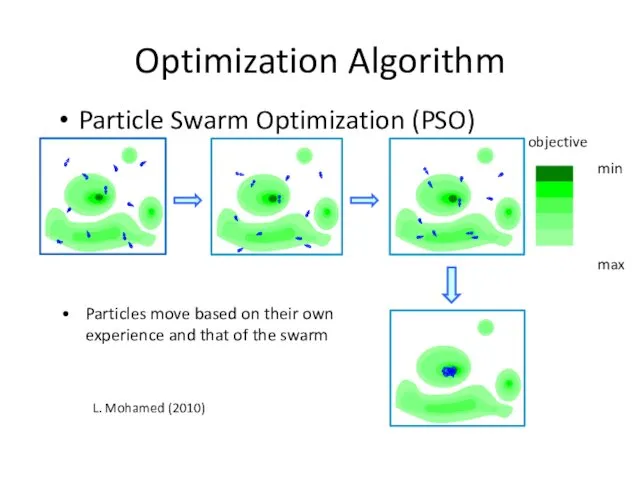

- 137. How many wells? Vary well status and well locations Model 1 Model 2

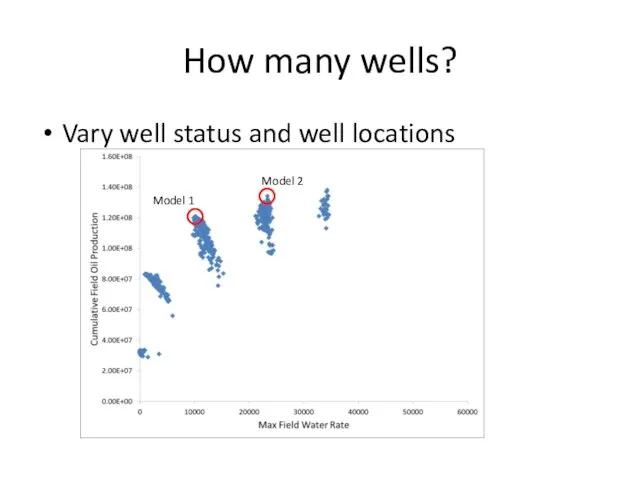

- 138. Real life trade-off in optimisation Vary injection well rates and locations of wells Well rates in

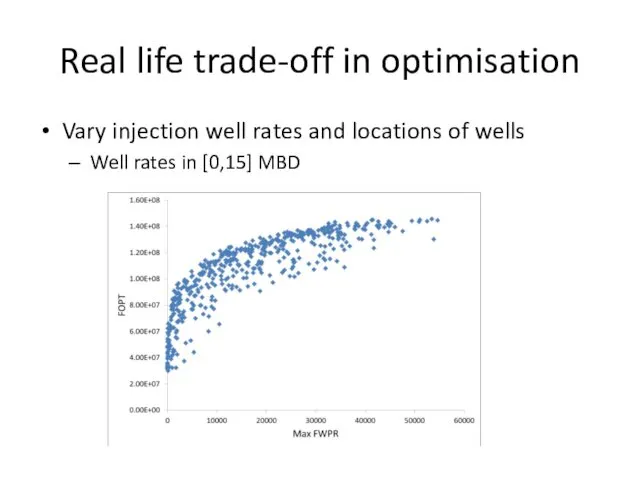

- 139. MSc students vs an algorithm? Original MSc development plan (4 injectors, 4 producers) 10% 55% 77

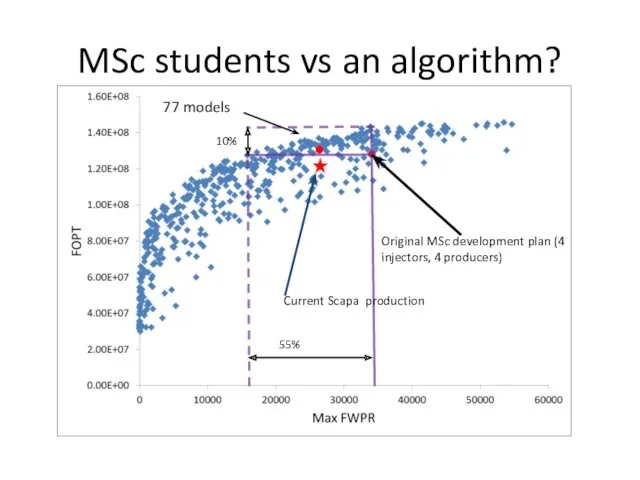

- 140. Optimization of Infill Well Locations Trade-off: ~1.2 bbls long term 1 bbl short term MOBOA –

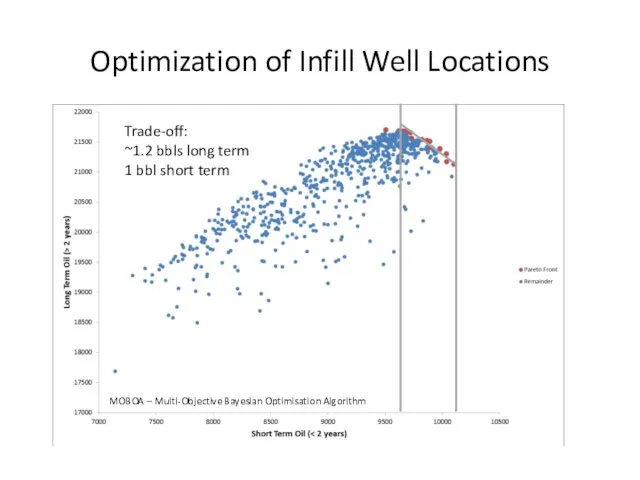

- 141. In review Creating value from of our asset Ongoing, Life-of-field process Risk in decisions from uncertainty

- 142. Summary of strategies Developing plans Maximise oil/gas prod. – field rehabilitation Implementing SOA facilities and wells

- 143. RM Strategy Evaluating Developing Implmenting Monitoring EDIM - as in Edim-bourg……….

- 144. Reservoir Management - key points Integration Synergy Persistence Proactive

- 145. Optimization Algorithm Particle Swarm Optimization (PSO) Particles move based on their own experience and that of

- 146. Application in North Sea

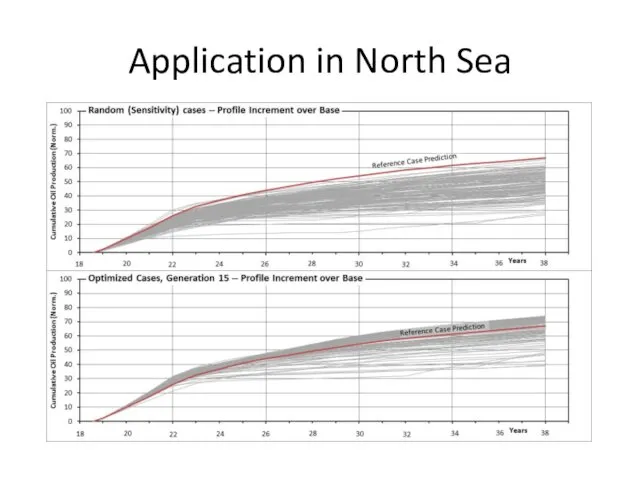

- 147. North Sea Application – Pareto Plot

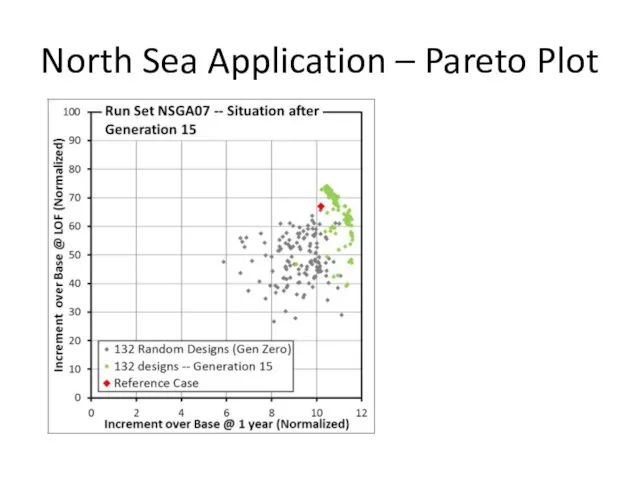

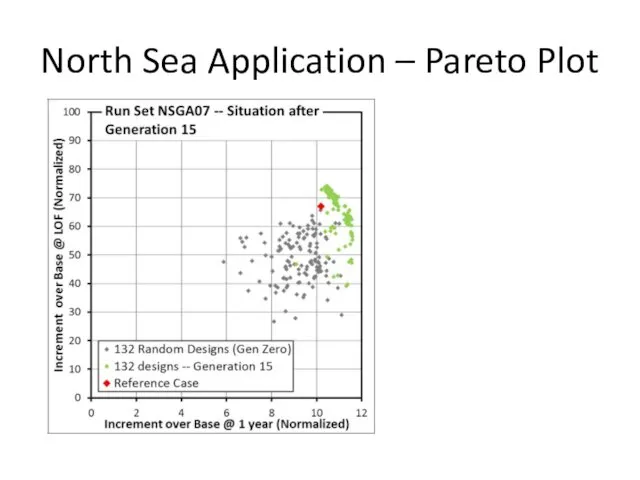

- 148. North Sea Application – Pareto Plot

- 149. Example: Brent Field Brent Field Depressurisation Christiansen and Wilson, 1998, James et al., 1999 Optimise oil

- 150. Brent Field (from James et al., 1999) OIIP 3800mmbbls GIIP 7.5TCF Reserves(99) 200mmbbls & 2.6TCF (biggest

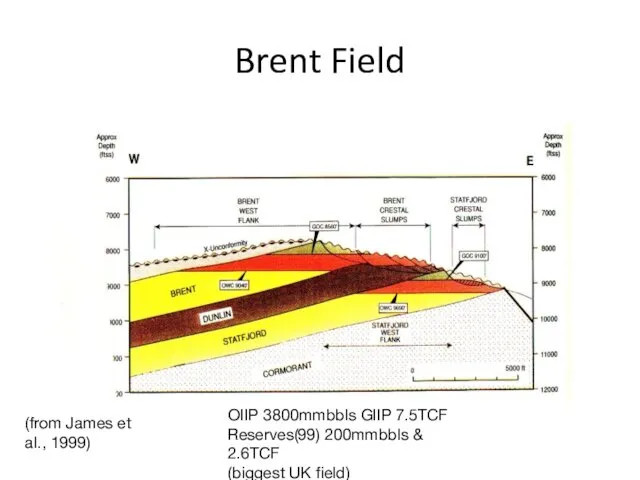

- 152. Скачать презентацию

Землетрясения. Шкала магнитуд

Землетрясения. Шкала магнитуд Соль-Илецк. Ключевая информация о городе

Соль-Илецк. Ключевая информация о городе Разнообразие природы родного края. Белгородская область

Разнообразие природы родного края. Белгородская область Основные понятия города

Основные понятия города Бразилия

Бразилия Черная металлургия

Черная металлургия Экономикогеографическая характеристика Китая

Экономикогеографическая характеристика Китая Озера та лимани України. Водосховища. Канали

Озера та лимани України. Водосховища. Канали Озёра и болота. Урок географии в 6 классе

Озёра и болота. Урок географии в 6 классе Народы Северного Кавказа

Народы Северного Кавказа Властивості води

Властивості води Живая и неживая природа

Живая и неживая природа Ориентирование на местности. Азимут. (6 класс)

Ориентирование на местности. Азимут. (6 класс) Климат Южной Америки. География материков и океанов. 7 класс

Климат Южной Америки. География материков и океанов. 7 класс Россия на карте мира

Россия на карте мира Классификация природных ресурсов

Классификация природных ресурсов Латын Америкасы

Латын Америкасы Түркия Республикасы

Түркия Республикасы Дальневосточный экономический район

Дальневосточный экономический район United Kingdom Quiz

United Kingdom Quiz Рельеф суши. Равнины. Актуализация знаний

Рельеф суши. Равнины. Актуализация знаний Государственное регулирование демографических процессов и миграции

Государственное регулирование демографических процессов и миграции 7 чудес России

7 чудес России Лесные зоны России

Лесные зоны России Водопады мира

Водопады мира Кипр

Кипр Северо-Кавказский Экономический район

Северо-Кавказский Экономический район Границы географической оболочки. Состав географической оболочки

Границы географической оболочки. Состав географической оболочки