Содержание

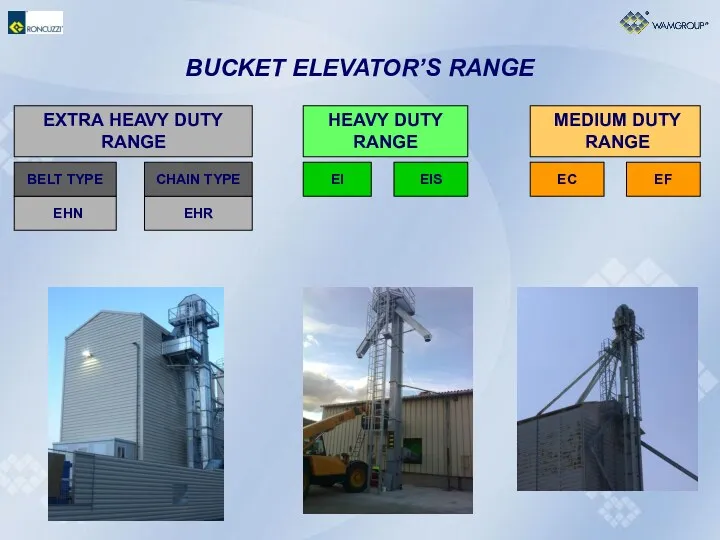

- 2. BUCKET ELEVATOR’S RANGE EXTRA HEAVY DUTY RANGE BELT TYPE CHAIN TYPE EHN EHR HEAVY DUTY RANGE

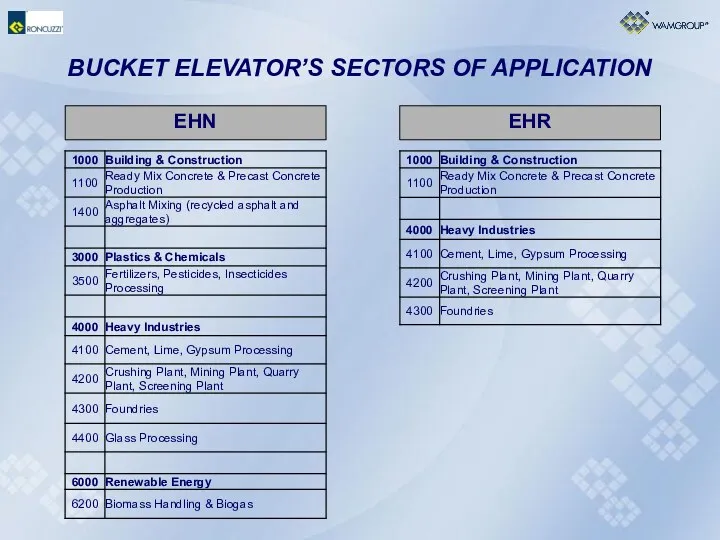

- 3. BUCKET ELEVATOR’S SECTORS OF APPLICATION EHN EHR

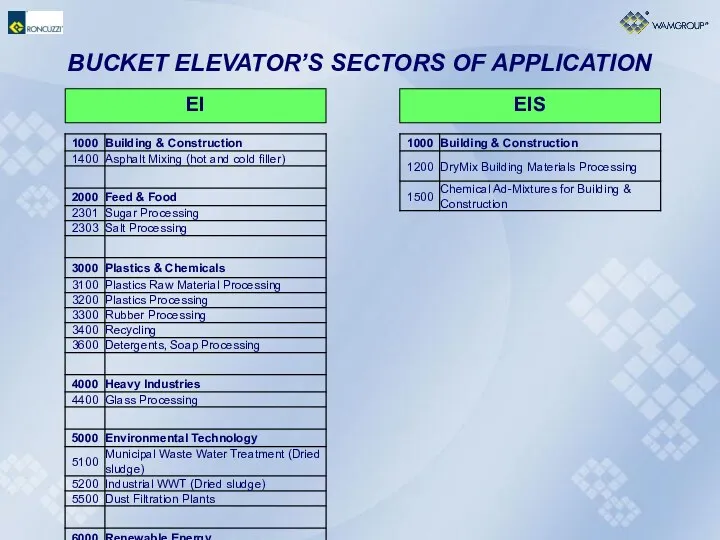

- 4. BUCKET ELEVATOR’S SECTORS OF APPLICATION EI EIS

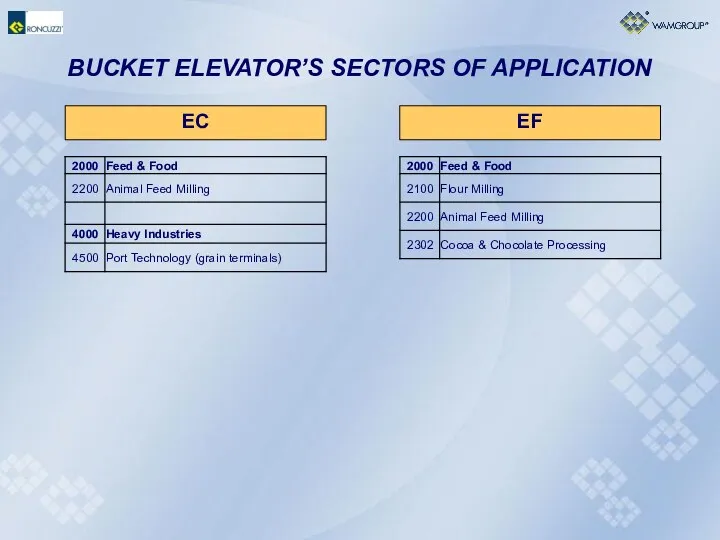

- 5. BUCKET ELEVATOR’S SECTORS OF APPLICATION EF EC

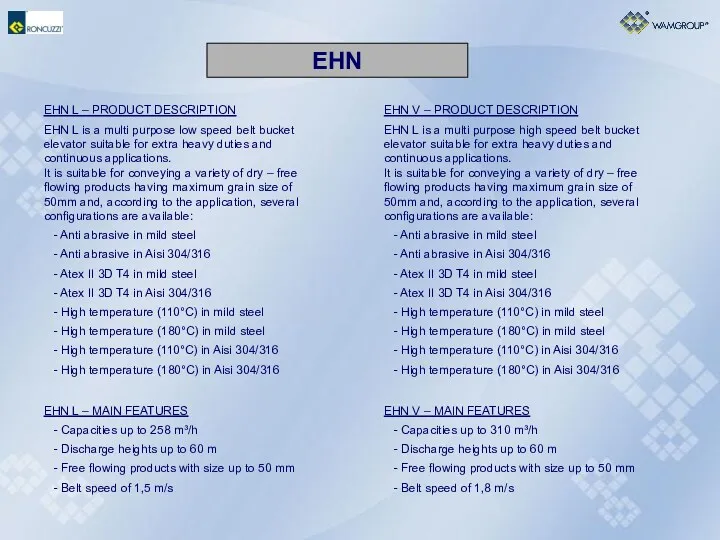

- 6. EHN L – PRODUCT DESCRIPTION EHN L is a multi purpose low speed belt bucket elevator

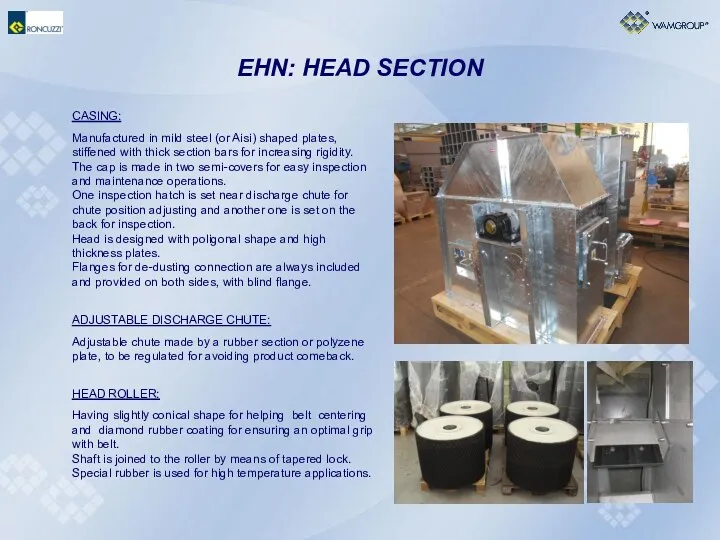

- 7. EHN: HEAD SECTION CASING: Manufactured in mild steel (or Aisi) shaped plates, stiffened with thick section

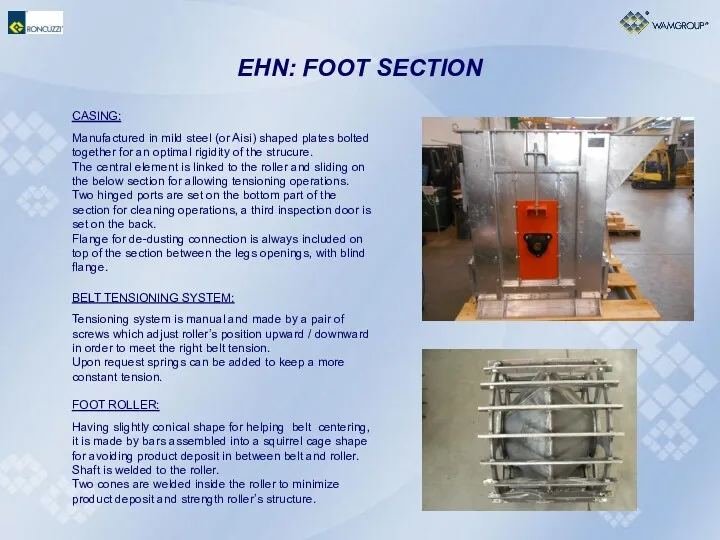

- 8. EHN: FOOT SECTION CASING: Manufactured in mild steel (or Aisi) shaped plates bolted together for an

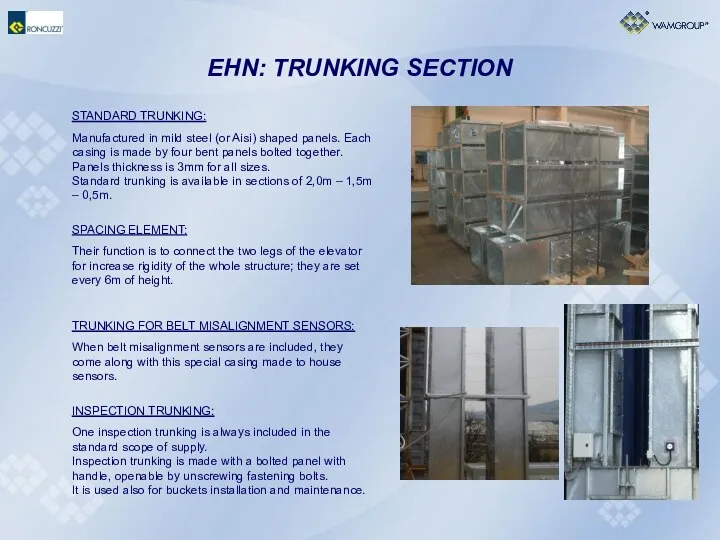

- 9. EHN: TRUNKING SECTION STANDARD TRUNKING: Manufactured in mild steel (or Aisi) shaped panels. Each casing is

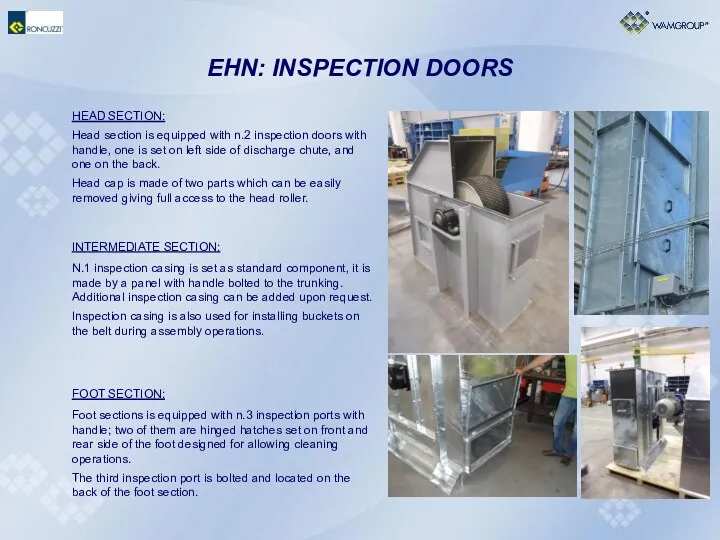

- 10. EHN: INSPECTION DOORS HEAD SECTION: Head section is equipped with n.2 inspection doors with handle, one

- 11. EHN: SURFACE FINISHING HOT GALVANIZING: Used as standard finishing for mild steel surfaces, all parts are

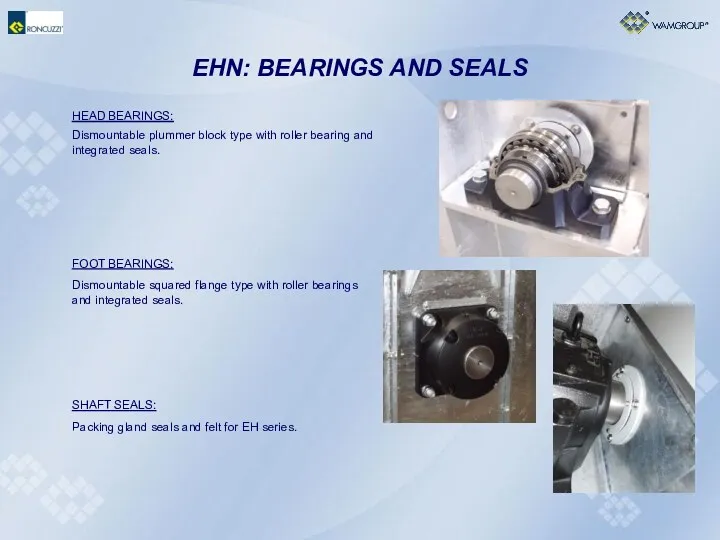

- 12. EHN: BEARINGS AND SEALS HEAD BEARINGS: Dismountable plummer block type with roller bearing and integrated seals.

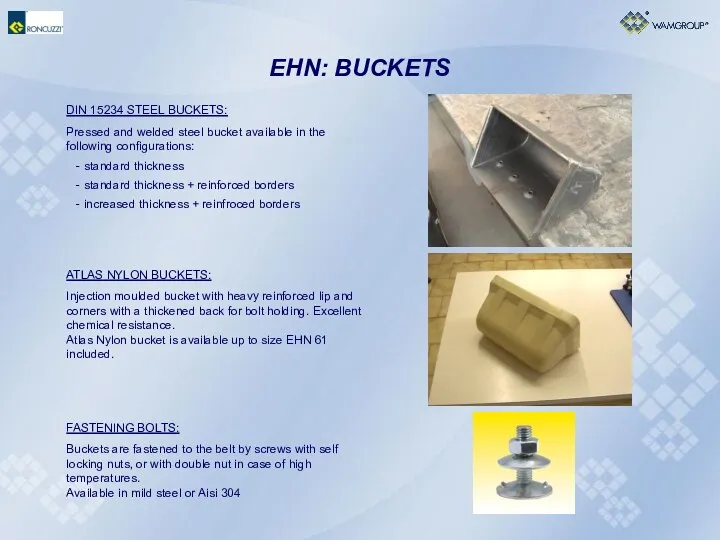

- 13. EHN: BUCKETS DIN 15234 STEEL BUCKETS: Pressed and welded steel bucket available in the following configurations:

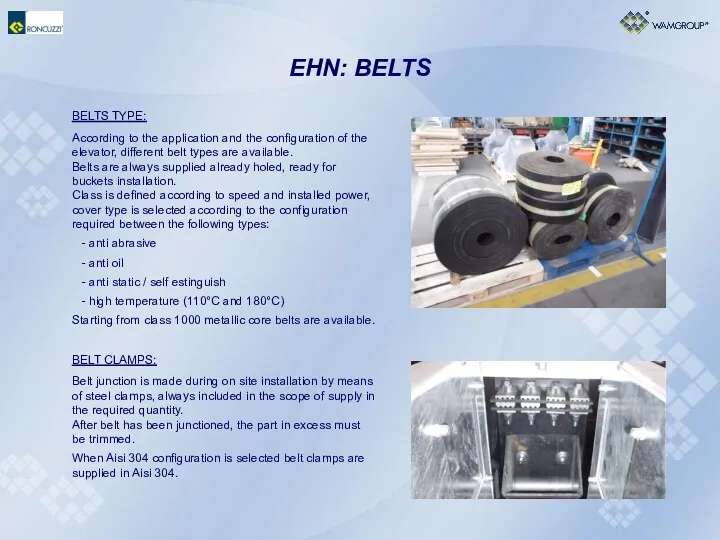

- 14. EHN: BELTS BELTS TYPE: According to the application and the configuration of the elevator, different belt

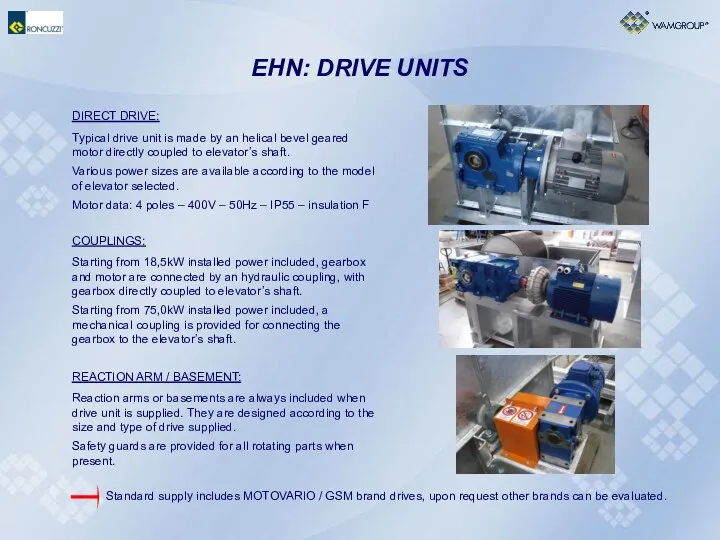

- 15. DIRECT DRIVE: Typical drive unit is made by an helical bevel geared motor directly coupled to

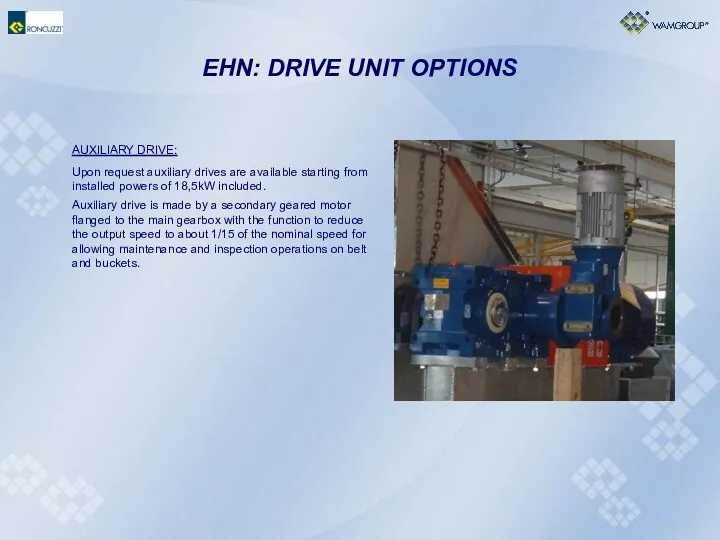

- 16. EHN: DRIVE UNIT OPTIONS AUXILIARY DRIVE: Upon request auxiliary drives are available starting from installed powers

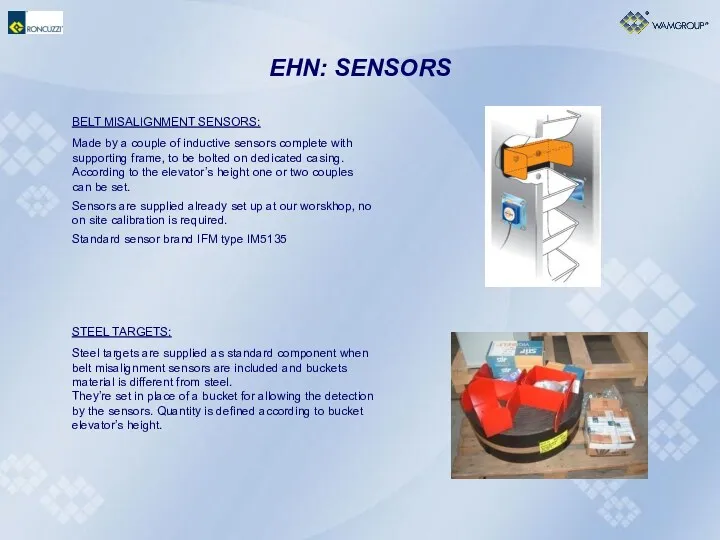

- 17. EHN: SENSORS BELT MISALIGNMENT SENSORS: Made by a couple of inductive sensors complete with supporting frame,

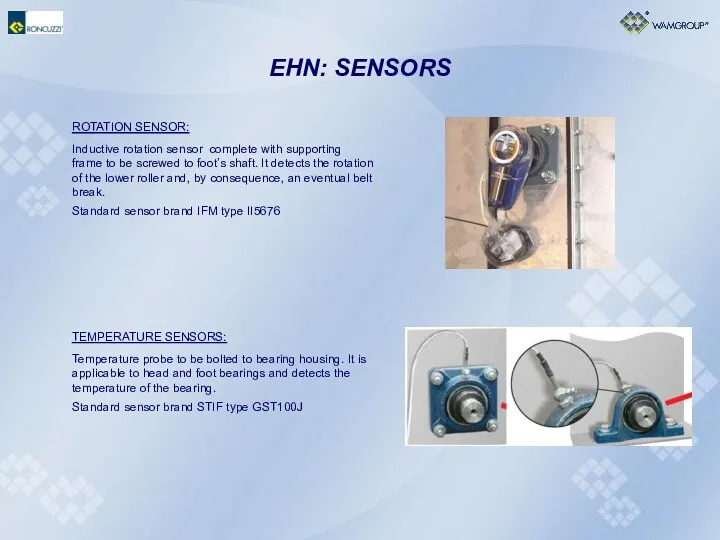

- 18. ROTATION SENSOR: Inductive rotation sensor complete with supporting frame to be screwed to foot’s shaft. It

- 19. EHN: ACCESSORIES INSPECTION PLATFORM: In galvanized mild steel including railings, for maintenance operations. Ladder not included.

- 20. EHN: ACCESSORIES PROTECTION CARTERS ON MOVING PARTS: Bolted protection carters set on head and foot shaft,

- 21. EHN: QUALITY AND CHECKS Bucket elevators components are always checked and tested according to the following

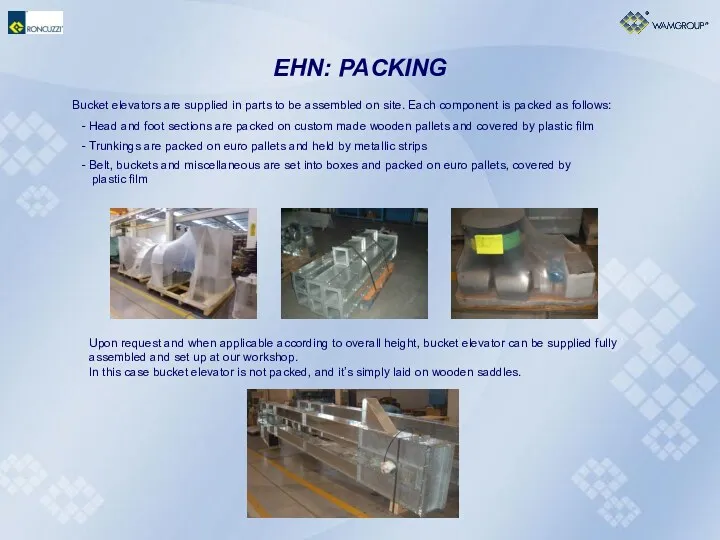

- 22. EHN: PACKING Bucket elevators are supplied in parts to be assembled on site. Each component is

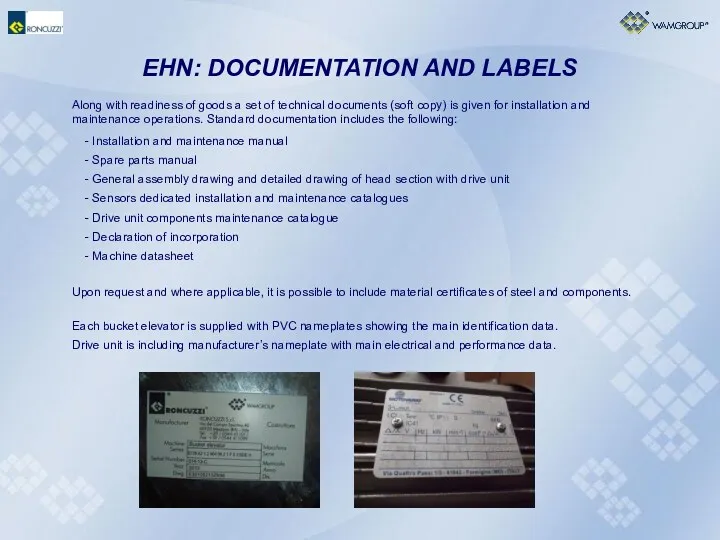

- 23. EHN: DOCUMENTATION AND LABELS Along with readiness of goods a set of technical documents (soft copy)

- 24. EHR – PRODUCT DESCRIPTION EHR is a multi purpose double chain bucket elevator suitable for extra

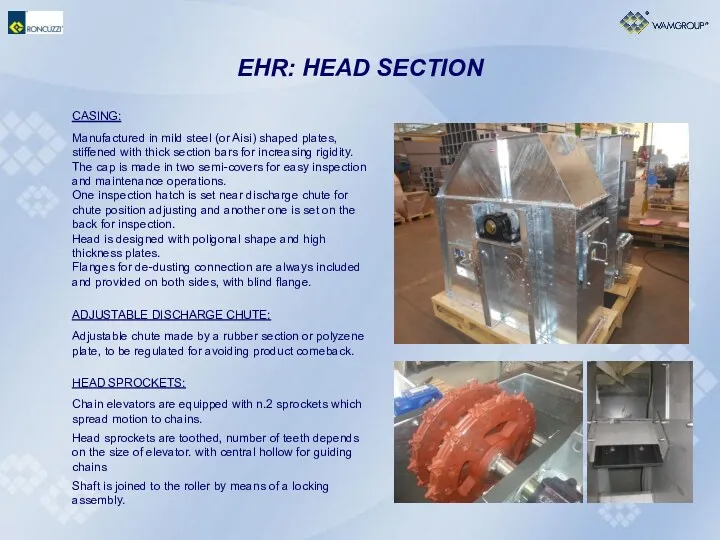

- 25. EHR: HEAD SECTION ADJUSTABLE DISCHARGE CHUTE: Adjustable chute made by a rubber section or polyzene plate,

- 26. EHR: FOOT SECTION CHAIN TENSIONING SYSTEM: Tensioning system is manual and made by a pair of

- 27. EHR: TRUNKING SECTION STANDARD TRUNKING: Manufactured in mild steel (or Aisi) shaped panels. Each casing is

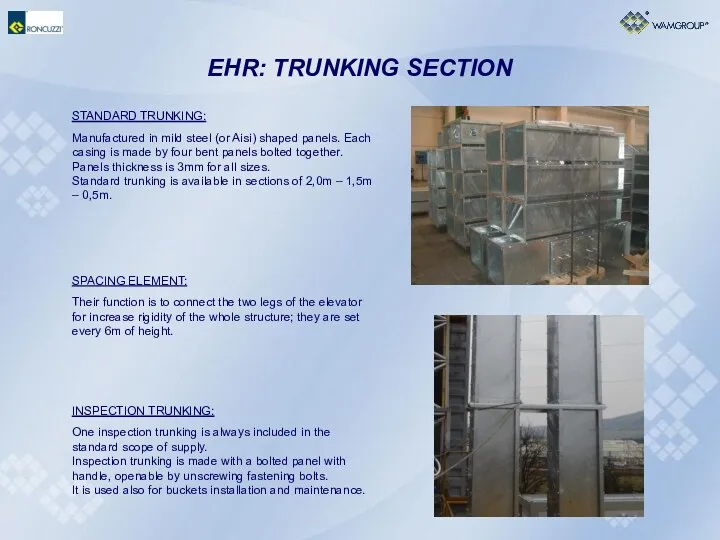

- 28. EHR: INSPECTION DOORS HEAD SECTION: Head section is equipped with n.2 inspection doors with handle, one

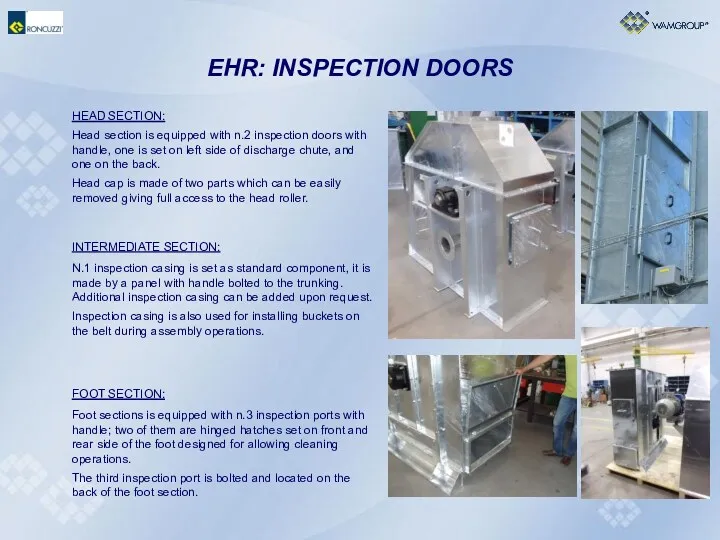

- 29. EHR: SURFACE FINISHING HOT GALVANIZING: Used as standard finishing for mild steel surfaces, all parts are

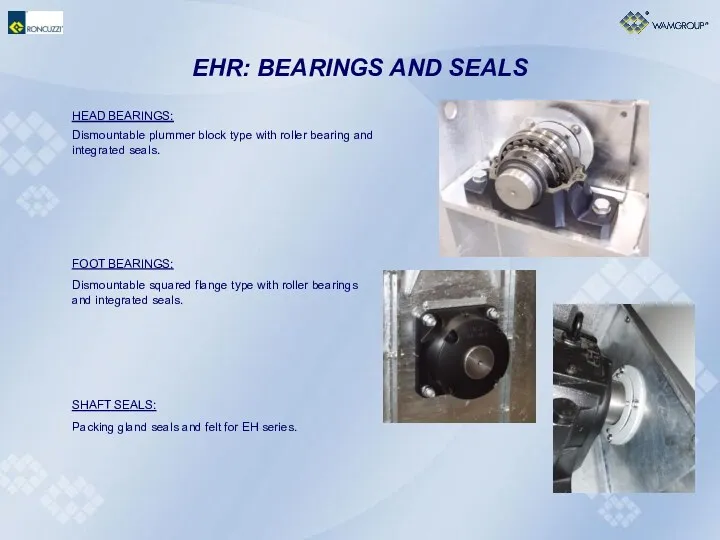

- 30. EHR: BEARINGS AND SEALS HEAD BEARINGS: Dismountable plummer block type with roller bearing and integrated seals.

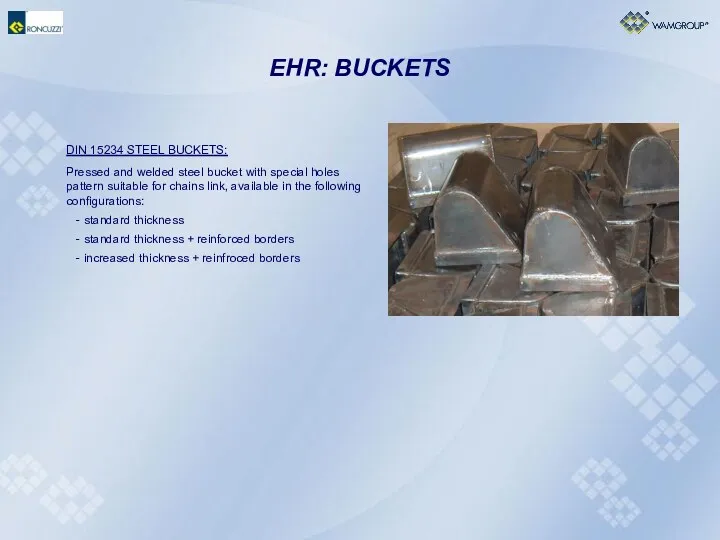

- 31. EHR: BUCKETS DIN 15234 STEEL BUCKETS: Pressed and welded steel bucket with special holes pattern suitable

- 32. EHR CHAINS: Double chain type DIN 22252 in hardened steel alloy, available in two configurations: -

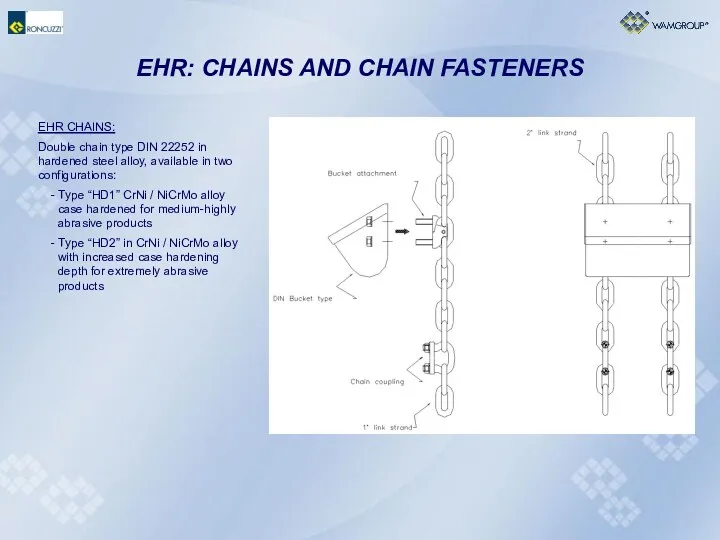

- 33. DIRECT DRIVE: Typical drive unit is made by an helical bevel geared motor directly coupled to

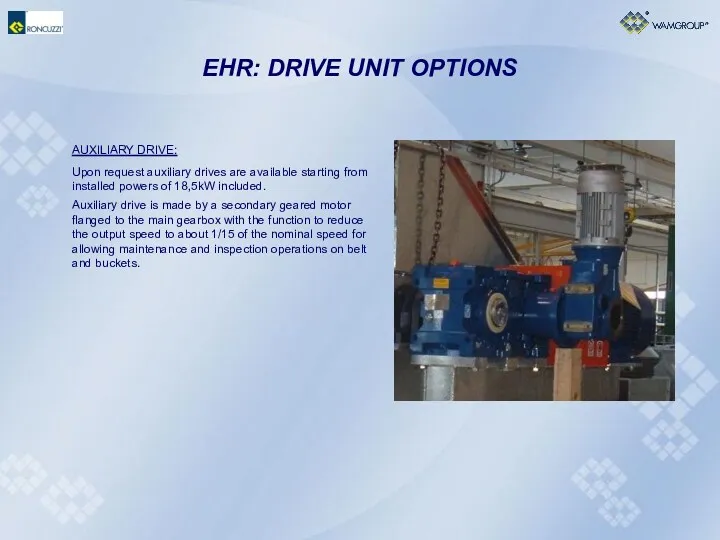

- 34. EHR: DRIVE UNIT OPTIONS AUXILIARY DRIVE: Upon request auxiliary drives are available starting from installed powers

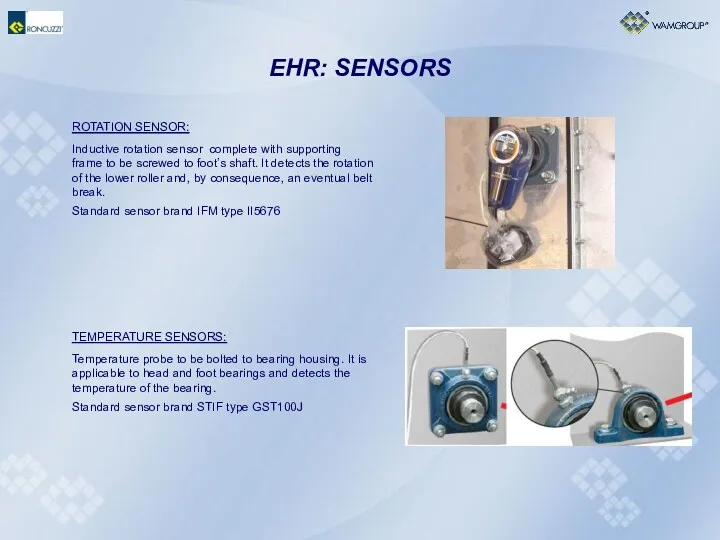

- 35. ROTATION SENSOR: Inductive rotation sensor complete with supporting frame to be screwed to foot’s shaft. It

- 36. EHR: ACCESSORIES INSPECTION PLATFORM: In galvanized mild steel including railings, for maintenance operations. Ladder not included.

- 37. EHR: ACCESSORIES PROTECTION CARTERS ON MOVING PARTS: Bolted protection carters set on head and foot shaft,

- 38. EHR: QUALITY AND CHECKS Bucket elevators components are always checked and tested according to the following

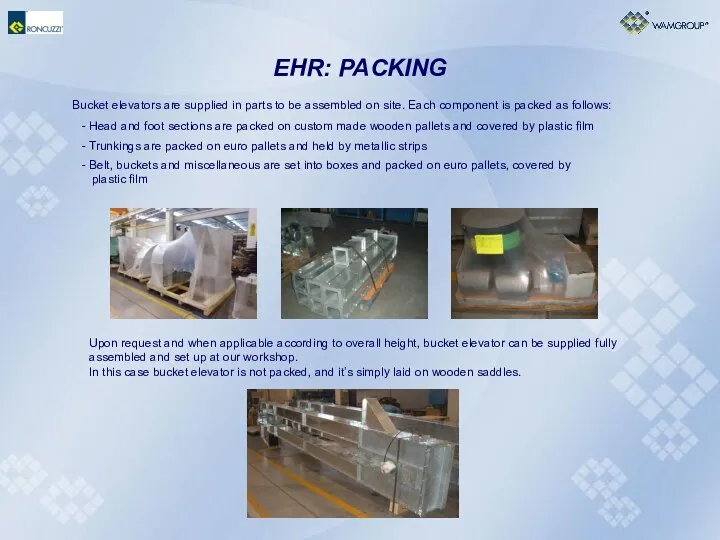

- 39. EHR: PACKING Bucket elevators are supplied in parts to be assembled on site. Each component is

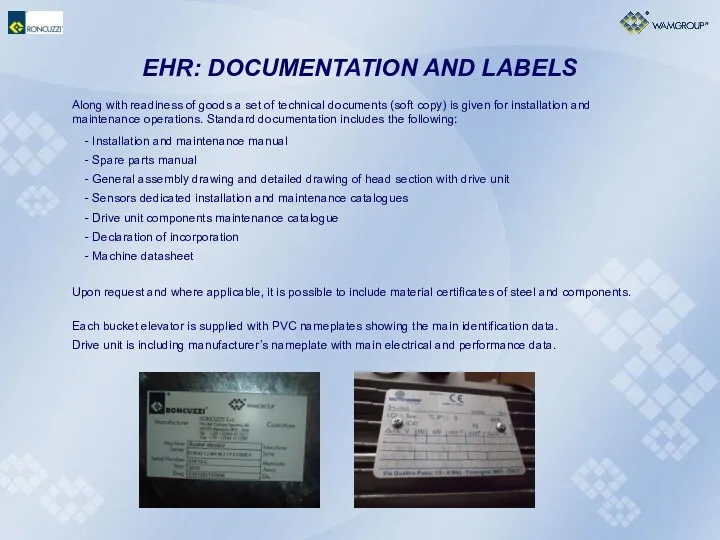

- 40. EHR: DOCUMENTATION AND LABELS Along with readiness of goods a set of technical documents (soft copy)

- 42. Скачать презентацию

Предложение по проведению мероприятий в FUN24

Предложение по проведению мероприятий в FUN24 Dega Optical — первый оптический торговый бренд

Dega Optical — первый оптический торговый бренд Здоровье с озера Байкал

Здоровье с озера Байкал Запасные части для окна, оклада, откоса. Каталог компании Velux

Запасные части для окна, оклада, откоса. Каталог компании Velux Территориальный маркетинг

Территориальный маркетинг Психологическая практика онлайн. Как получить 20 клиентов на онлайн-встречи без рекламы и вложений

Психологическая практика онлайн. Как получить 20 клиентов на онлайн-встречи без рекламы и вложений Рекламные возможности в молле Парк Хаус

Рекламные возможности в молле Парк Хаус Digital-стратегия. Подготовка сайта к продвижению

Digital-стратегия. Подготовка сайта к продвижению Jagerettes Toolkit 2020

Jagerettes Toolkit 2020 Презентация разработки СТЗ

Презентация разработки СТЗ Путешествия на яхтах по всему миру

Путешествия на яхтах по всему миру Медиапланирование в Интернете

Медиапланирование в Интернете Удаленный менеджер поставщика маркетплейсов

Удаленный менеджер поставщика маркетплейсов Соленья Капустные дольки. Обязательный ассортимент

Соленья Капустные дольки. Обязательный ассортимент Территориальный маркетинг

Территориальный маркетинг Летние каникулы в Ирландии

Летние каникулы в Ирландии Функциональные чаи Teavitall. Greenway Global

Функциональные чаи Teavitall. Greenway Global Разработка позиционирования торговой марки

Разработка позиционирования торговой марки Услуги по анализу конкурентов и брендингу. Портфолио

Услуги по анализу конкурентов и брендингу. Портфолио Коммуникационный проект

Коммуникационный проект Методика проведения SWOT анализа

Методика проведения SWOT анализа Дизайн упаковки

Дизайн упаковки Совершенствование процесса обеспечения запасными частями автомобилей марки BMW

Совершенствование процесса обеспечения запасными частями автомобилей марки BMW Коммуникативные модели рекламы

Коммуникативные модели рекламы Market research Coca-Cola

Market research Coca-Cola Реклама в Интернете

Реклама в Интернете Совершенствование маркетинговой деятельности в организациях общественного питания

Совершенствование маркетинговой деятельности в организациях общественного питания Особенности использования финансовых и нефинансовых способов поддержки инновационных проектов

Особенности использования финансовых и нефинансовых способов поддержки инновационных проектов