Содержание

- 2. Tabel of content Why Innova & PDS-NT Overview Innova Overview PDS-NT Equipment Monitoring Integration & customer

- 3. Innova and PDS-NT: Why? Maximize added value and reduce cost Process each bird into its most

- 6. Effective and efficient product allocation Deliver your customers Right products Right time Right volume In an

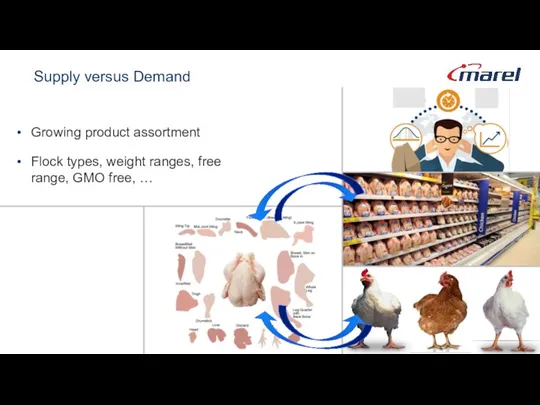

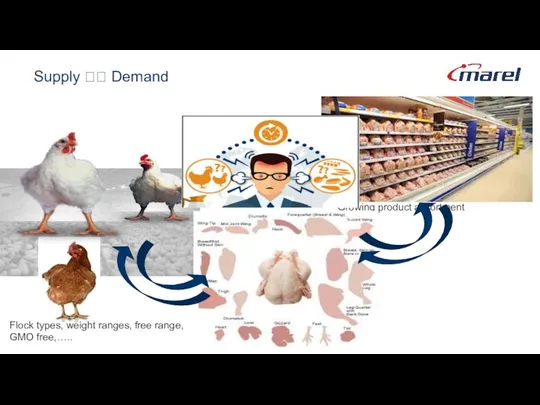

- 7. Supply versus Demand Growing product assortment Flock types, weight ranges, free range, GMO free, …

- 8. Supply ?? Demand

- 9. Tabel of content Why Innova & PDS-NT Overview Innova Overview PDS-NT Equipment Monitoring Integration & customer

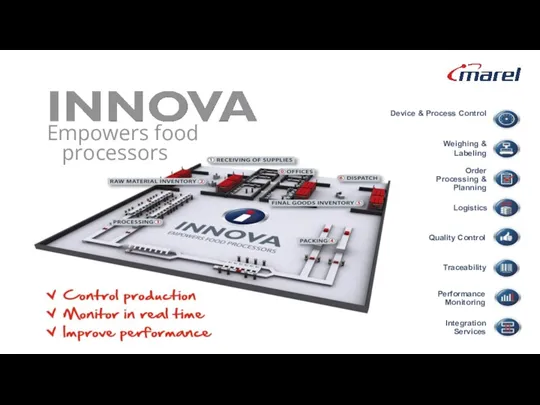

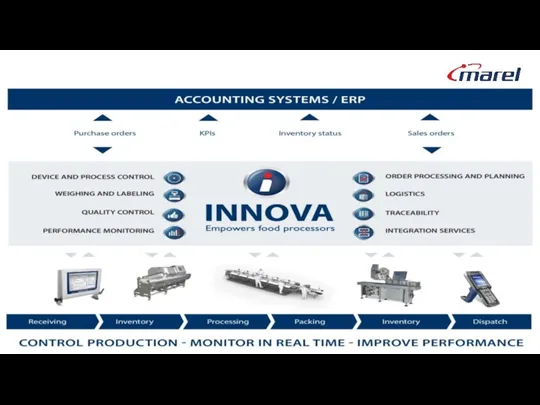

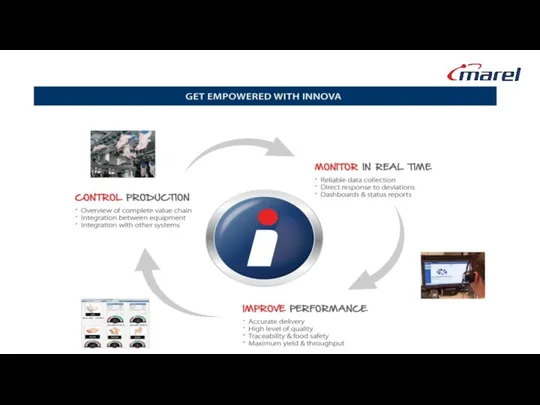

- 10. Empowers food processors Device & Process Control Weighing & Labeling Quality Control Performance Monitoring Order Processing

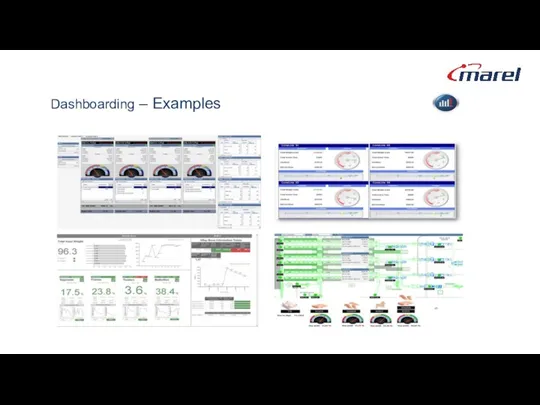

- 14. Dashboarding – Examples

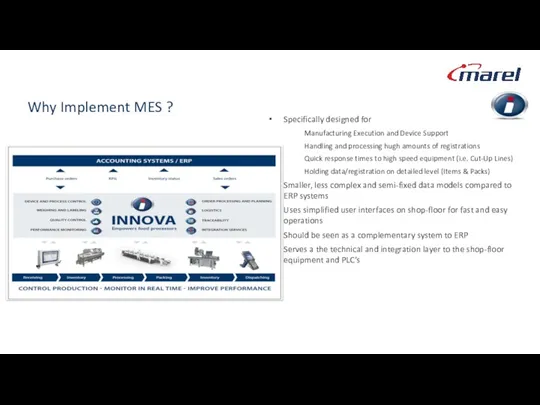

- 15. Why Implement MES ? Specifically designed for Manufacturing Execution and Device Support Handling and processing hugh

- 16. Integrated solutions – horizontal integration Linking processing steps together Prevent sub optimization

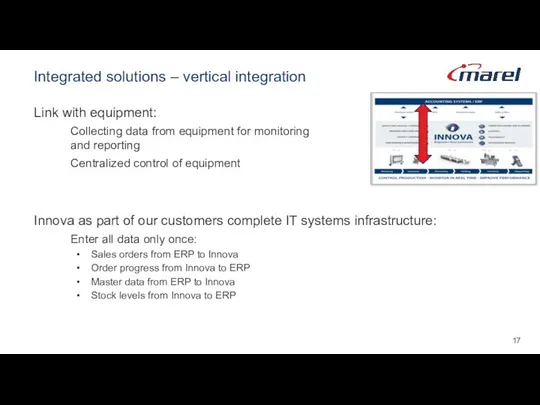

- 17. Integrated solutions – vertical integration Link with equipment: Collecting data from equipment for monitoring and reporting

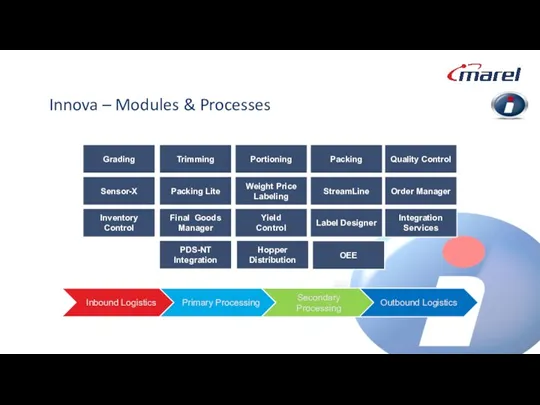

- 18. Innova – Modules & Processes Grading Sensor-X Inventory Control Trimming Packing Lite Final Goods Manager Portioning

- 20. Innova base

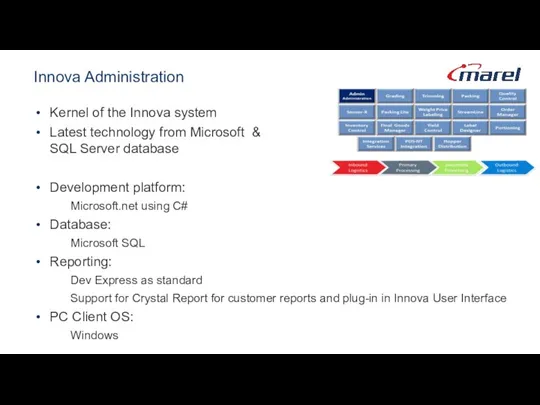

- 21. Innova Administration Kernel of the Innova system Latest technology from Microsoft & SQL Server database Development

- 22. Innova Packing

- 23. Innova Packing Innova offers simple as well as advanced packing and labeling solutions with full inventory,

- 24. Packing stations

- 25. Personal id-tags Logging in and out per station or department/line Employee Login/Logout

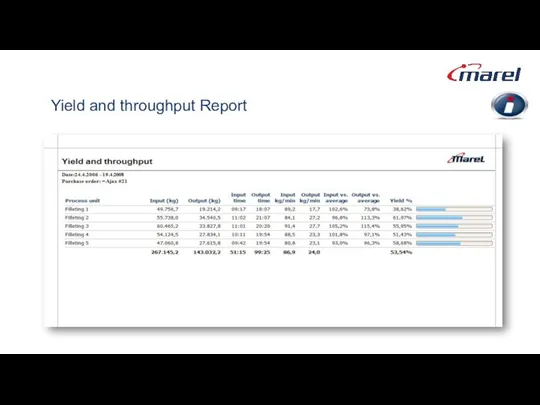

- 26. Yield and throughput Report

- 27. Innova Label management

- 28. Move away from preprinted labels X

- 29. Main features Labeling Easy to design labels with visual designer Full integration with the Innova production

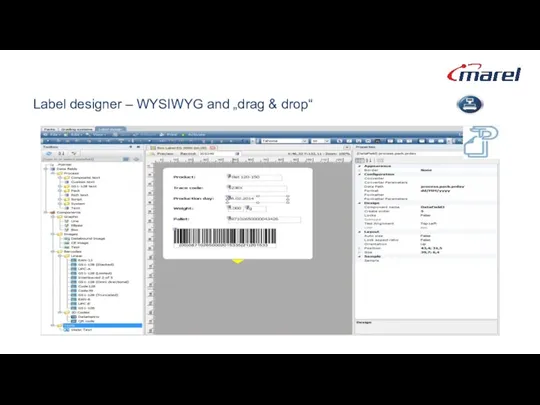

- 30. Label designer – WYSIWYG and „drag & drop“

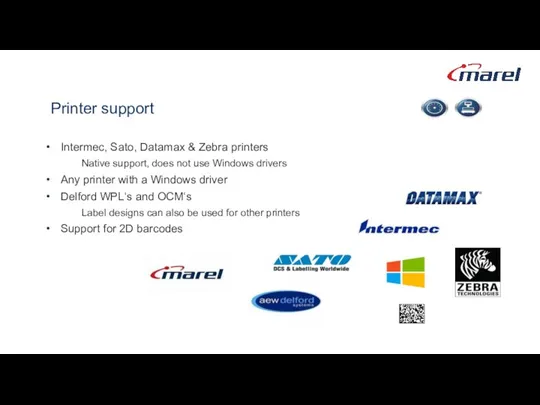

- 31. Printer support Intermec, Sato, Datamax & Zebra printers Native support, does not use Windows drivers Any

- 32. Innova Grading & Batching

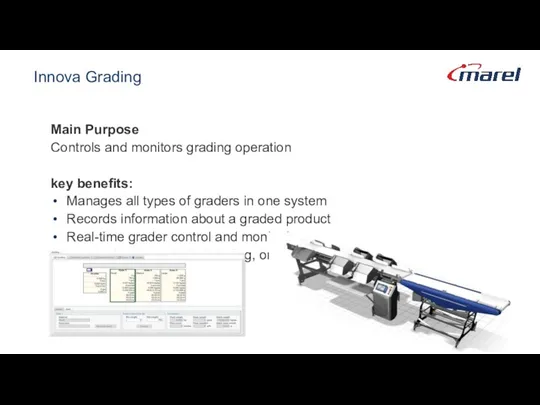

- 33. Innova Grading Main Purpose Controls and monitors grading operation key benefits: Manages all types of graders

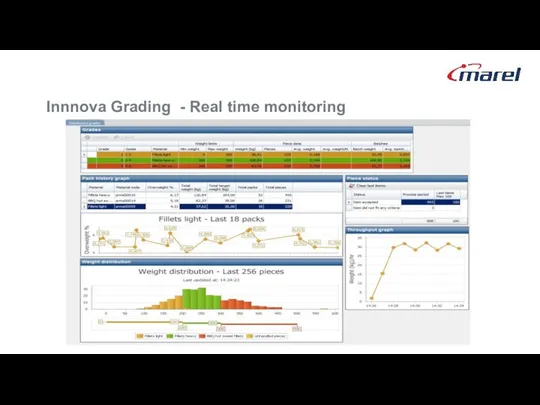

- 34. Innnova Grading - Real time monitoring

- 35. Innova Checkweighing

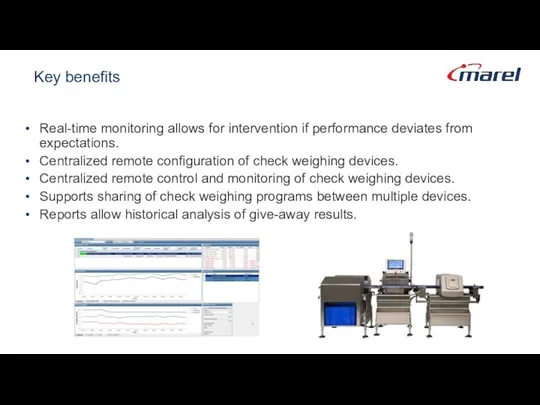

- 36. Key benefits Real-time monitoring allows for intervention if performance deviates from expectations. Centralized remote configuration of

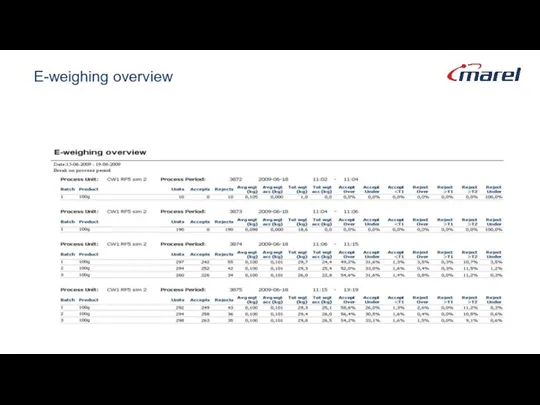

- 37. E-weighing overview

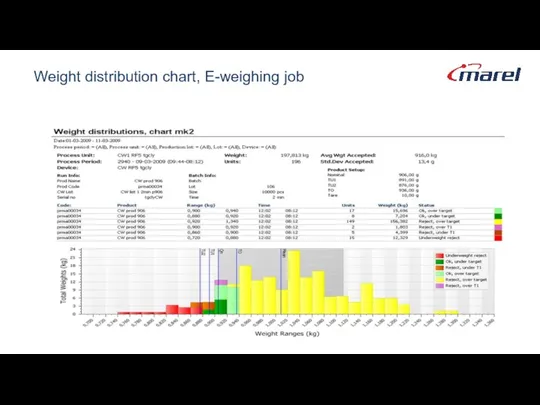

- 38. Weight distribution chart, E-weighing job

- 39. Innova Weight Price Labeler

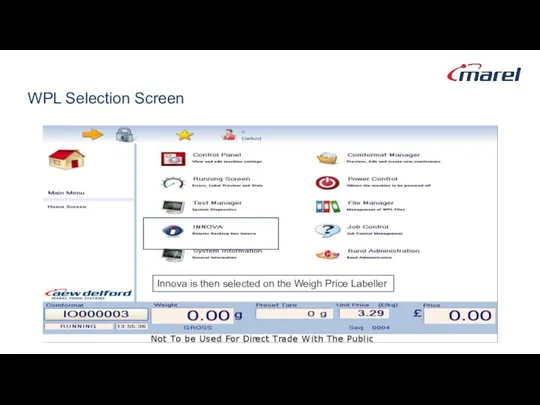

- 40. WPL Selection Screen Innova is then selected on the Weigh Price Labeller

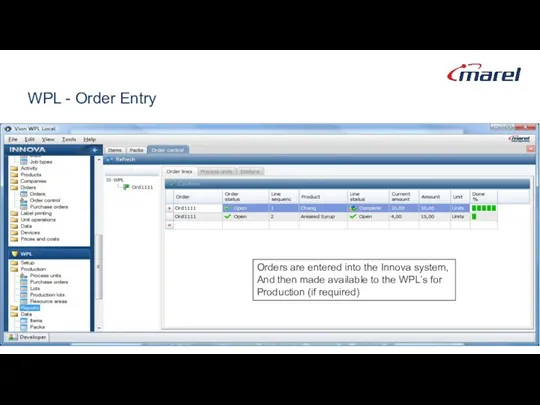

- 41. WPL - Order Entry Orders are entered into the Innova system, And then made available to

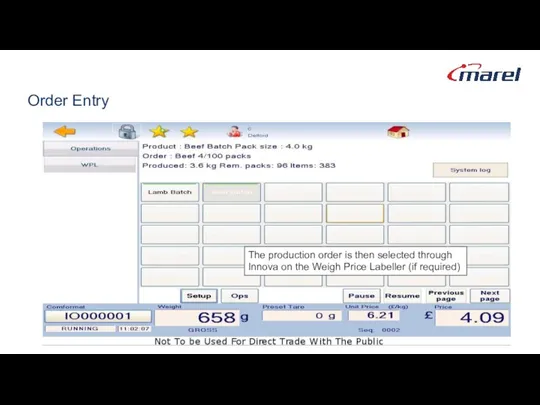

- 42. Order Entry The production order is then selected through Innova on the Weigh Price Labeller (if

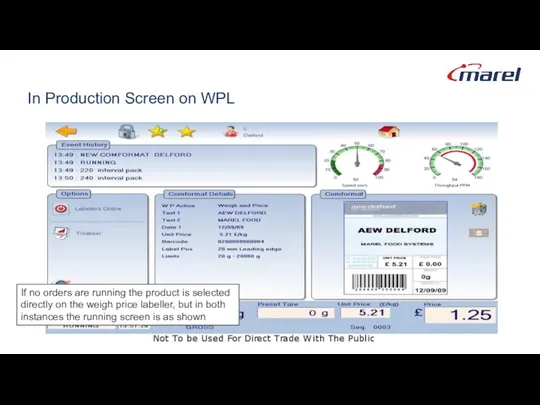

- 43. In Production Screen on WPL If no orders are running the product is selected directly on

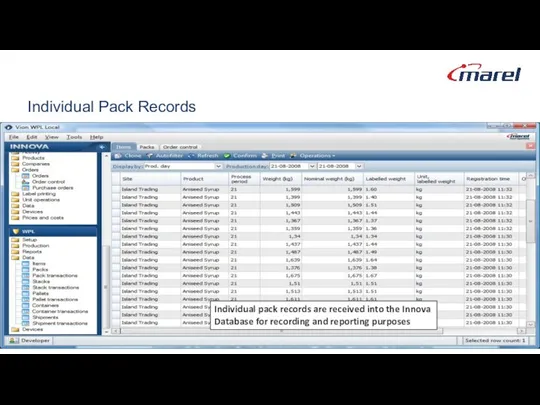

- 44. Individual Pack Records Individual pack records are received into the Innova Database for recording and reporting

- 45. Innova Portioning

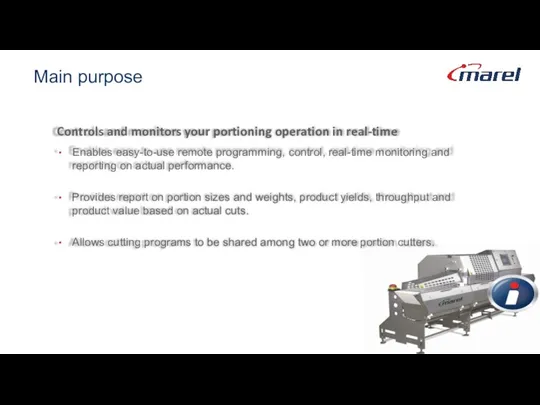

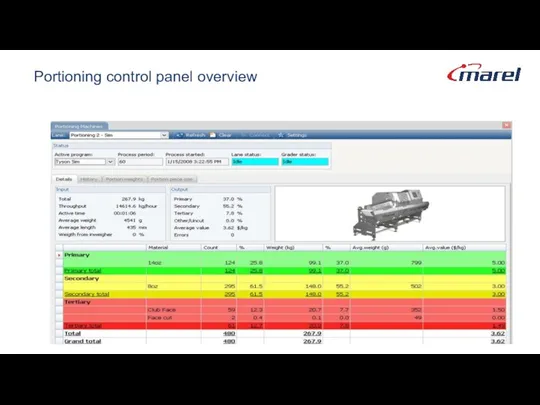

- 46. Main purpose Controls and monitors your portioning operation in real-time Enables easy-to-use remote programming, control, real-time

- 47. Portioning control panel overview

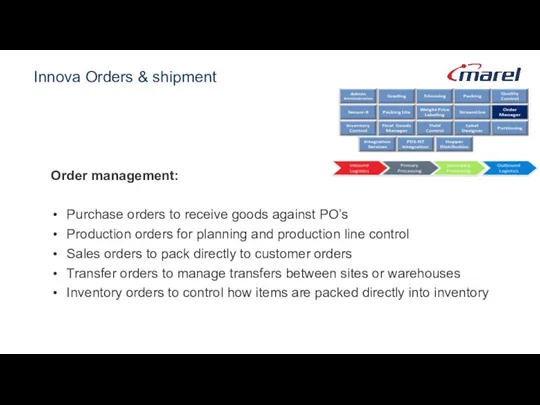

- 48. Innova Order Management

- 49. Innova Orders & shipment Order management: Purchase orders to receive goods against PO’s Production orders for

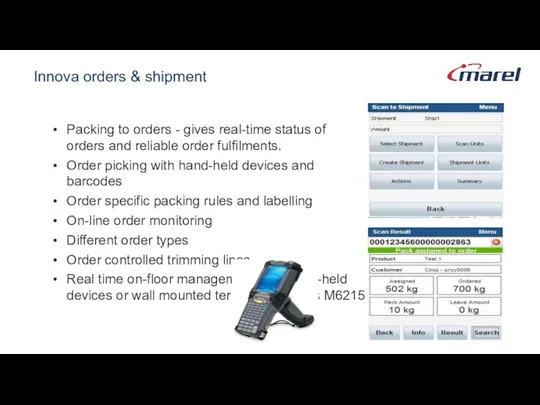

- 50. Innova orders & shipment Packing to orders - gives real-time status of orders and reliable order

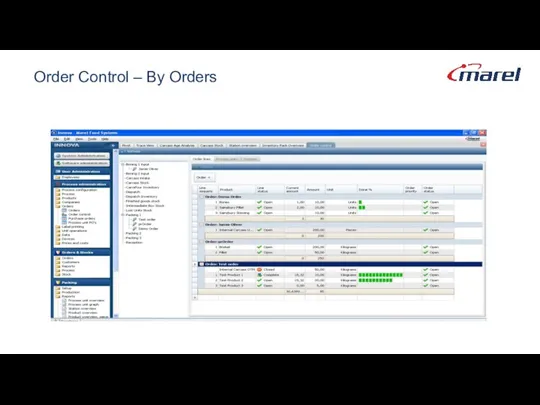

- 51. Order Control – By Orders

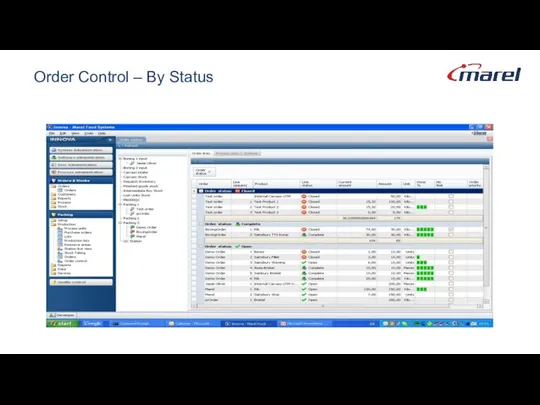

- 52. Order Control – By Status

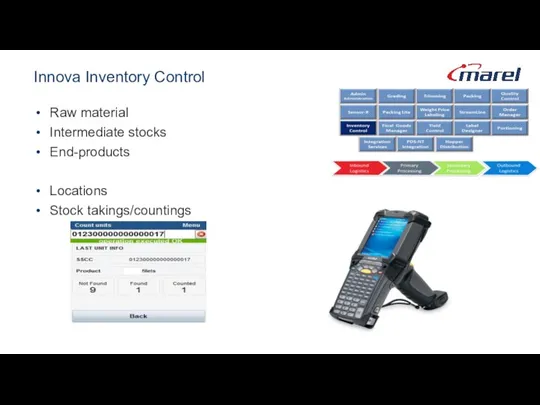

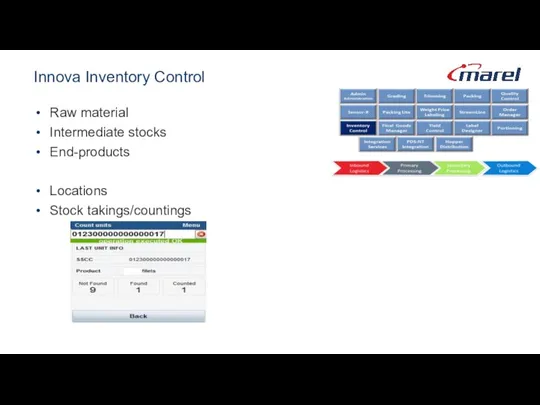

- 53. Innova Inventory Control Raw material Intermediate stocks End-products Locations Stock takings/countings

- 54. Innova Final Goods Management

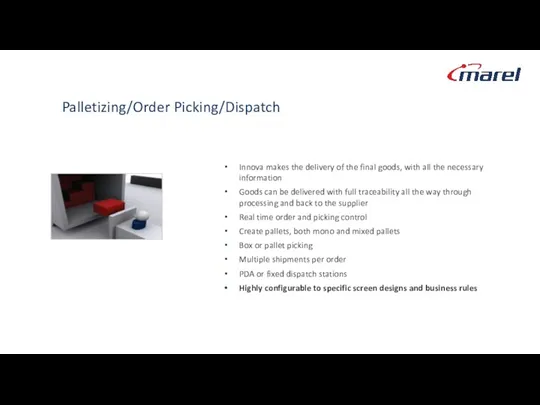

- 55. Palletizing/Order Picking/Dispatch Innova makes the delivery of the final goods, with all the necessary information Goods

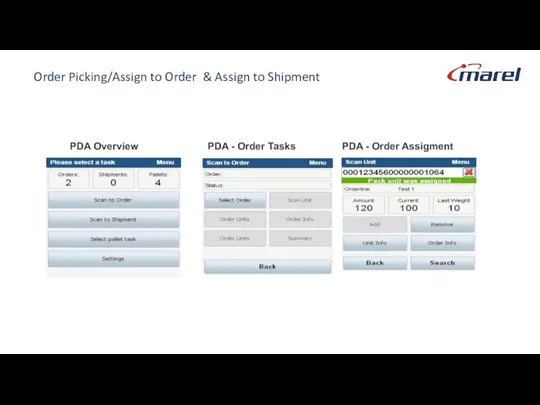

- 56. Order Picking/Assign to Order & Assign to Shipment PDA Overview PDA - Order Tasks PDA -

- 57. Innova Inventory Control

- 58. Innova Inventory Control Raw material Intermediate stocks End-products Locations Stock takings/countings

- 59. Raw material inventory Raw material stock levels are known at all times Items can be assigned

- 60. Finished Goods Inventory Finished goods are moved into inventory or produced directly to stock during the

- 61. Innova Quality Control

- 62. INNOVA Weight Price Labeler Allocation Checkweigher Gain paperless control and automation of your quality control from

- 64. INNOVA Gain quality control at all levels. Receiving live birds Slaughtering Processing Packaging Dispatch Also …..

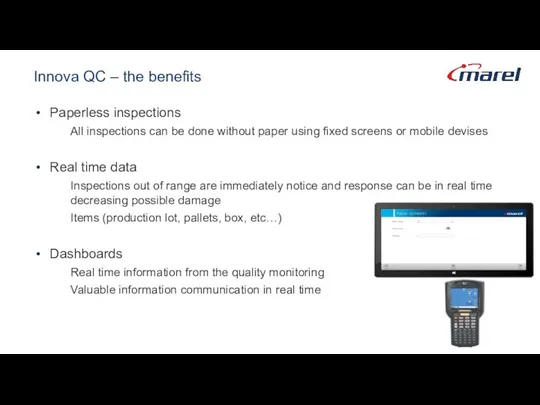

- 65. Innova QC – the benefits Paperless inspections All inspections can be done without paper using fixed

- 66. Innova QC – the benefits Easy access and analyses of data All records are available in

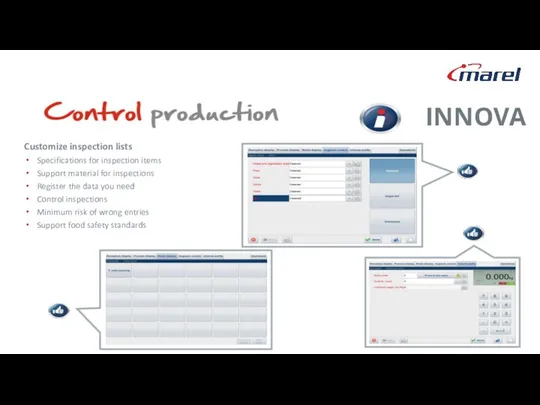

- 67. INNOVA Customize inspection lists Specifications for inspection items Support material for inspections Register the data you

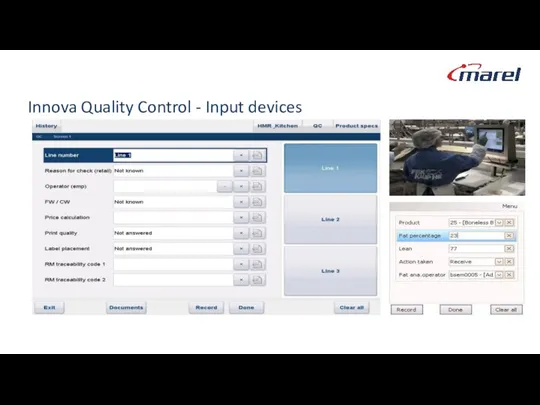

- 68. Innova Quality Control - Input devices

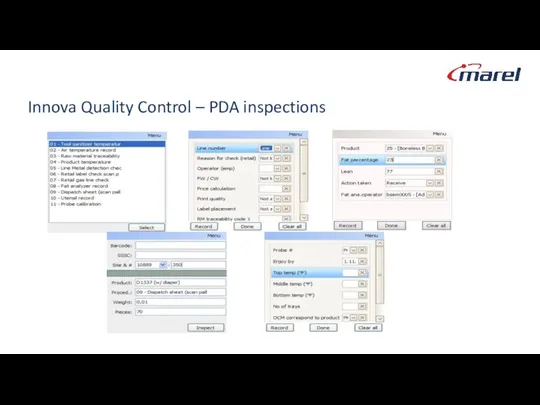

- 69. Innova Quality Control – PDA inspections

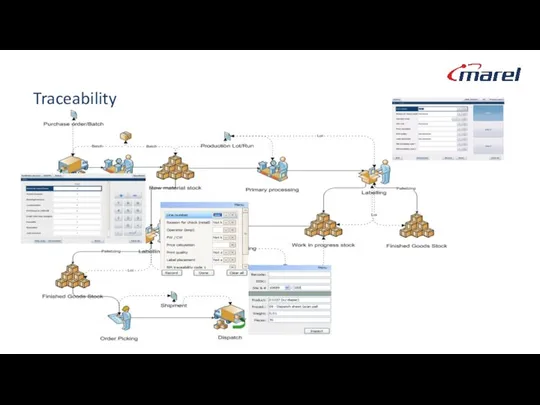

- 70. Traceability

- 71. Documentation system Documentation repository Document viewers, desktop and M6000. Attaching and accessing documents on the floor

- 72. Innova Dashboarding & Reporting

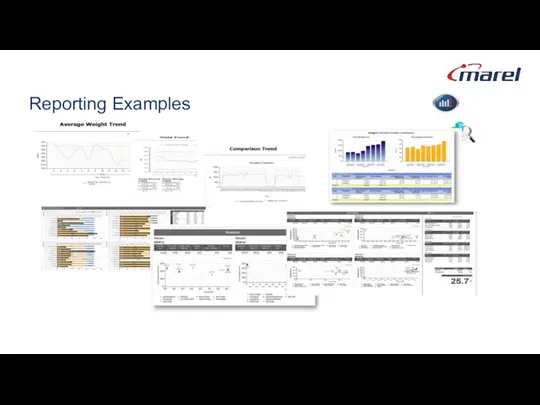

- 73. Reporting Examples

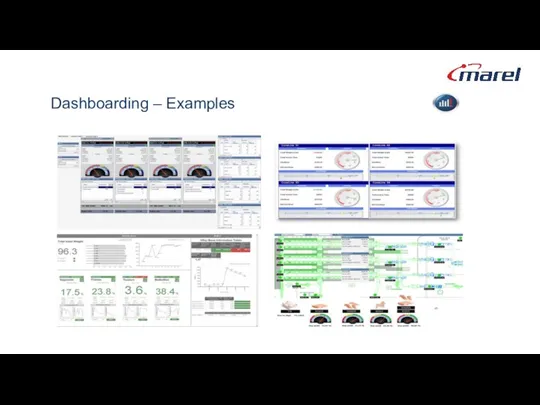

- 74. Dashboarding – Examples

- 75. IRIS Dashboarding/Real Time Monitoring

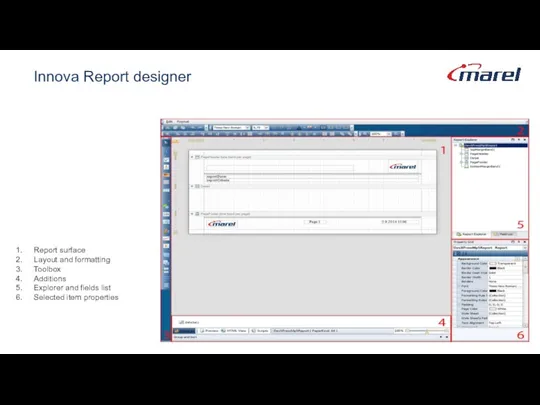

- 76. Innova Report designer Report surface Layout and formatting Toolbox Additions Explorer and fields list Selected item

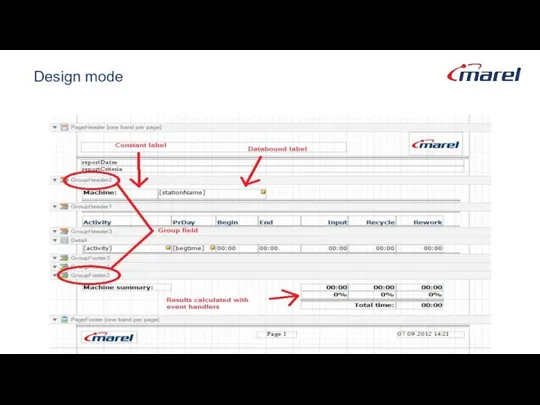

- 77. Design mode

- 78. Innova Integration Services

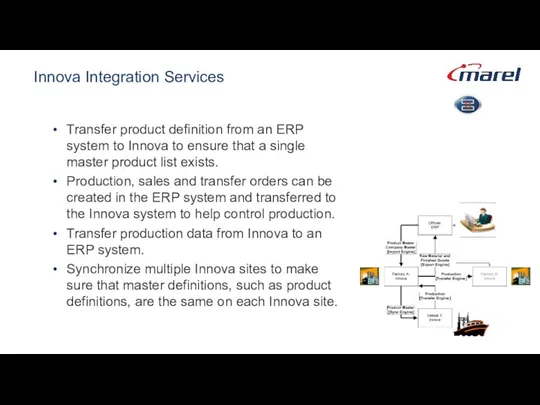

- 79. Innova Integration Services Transfer product definition from an ERP system to Innova to ensure that a

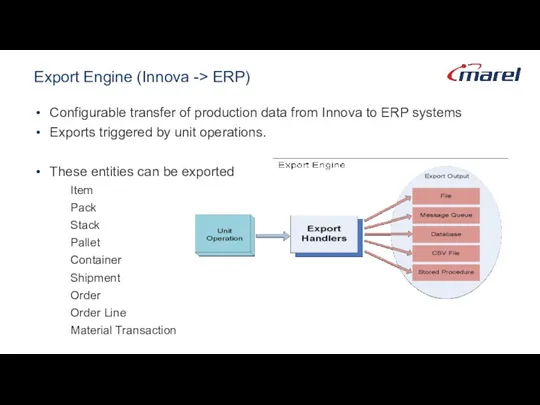

- 80. Export Engine (Innova -> ERP) Configurable transfer of production data from Innova to ERP systems Exports

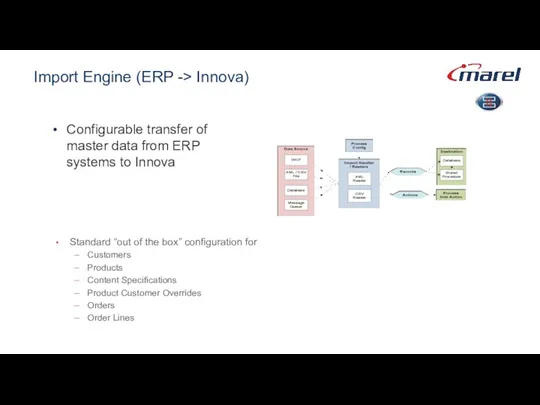

- 81. Import Engine (ERP -> Innova) Configurable transfer of master data from ERP systems to Innova Standard

- 82. Innova OEE

- 83. INNOVA How effectively are your production lines running? How many production stops do you have? Are

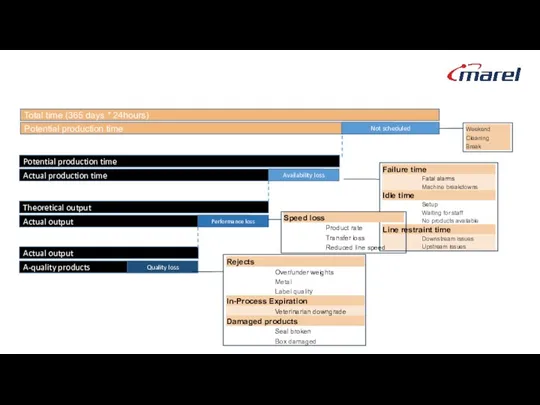

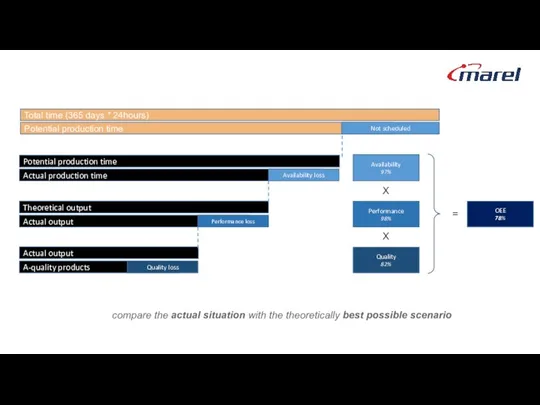

- 84. Potential production time Actual production time Availability loss Actual output Performance loss A-quality products Quality loss

- 85. Potential production time Actual production time Availability loss Actual output Performance loss A-quality products Quality loss

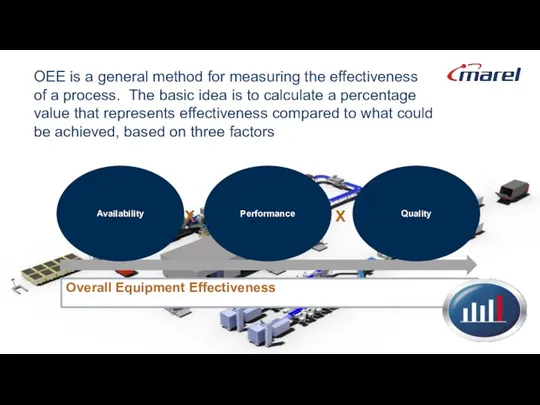

- 86. Overall Equipment Effectiveness X X Availability Performance Quality OEE is a general method for measuring the

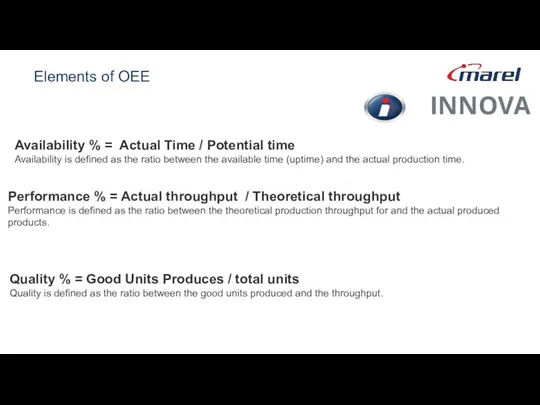

- 87. Elements of OEE INNOVA Availability % = Actual Time / Potential time Availability is defined as

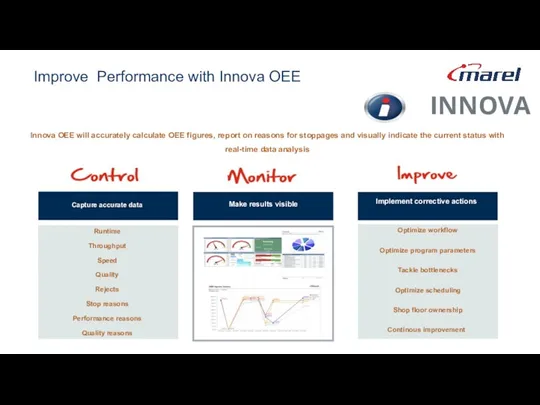

- 88. Improve Performance with Innova OEE Innova OEE will accurately calculate OEE figures, report on reasons for

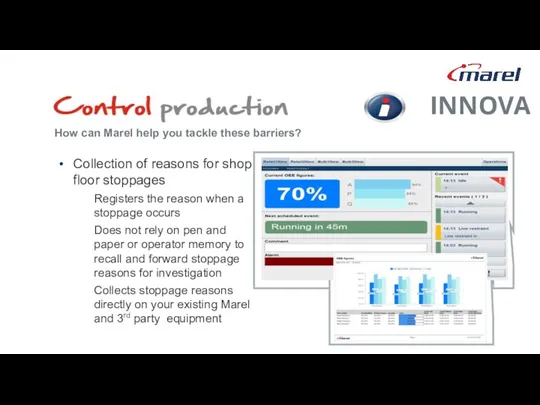

- 89. Collection of reasons for shop floor stoppages Registers the reason when a stoppage occurs Does not

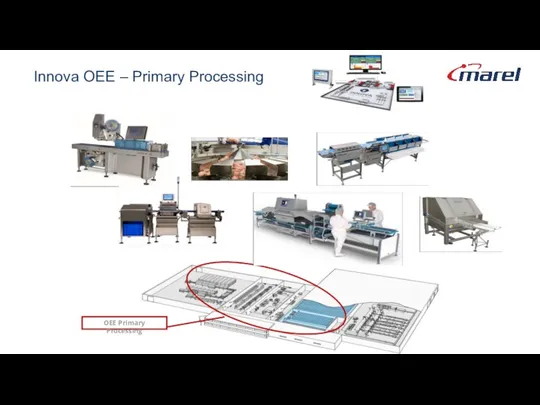

- 90. Innova OEE – Primary Processing OEE Primary Processing

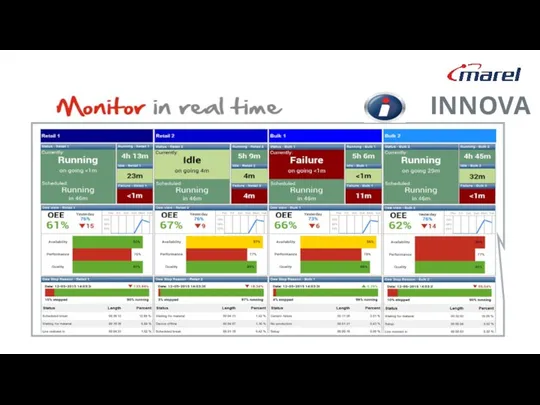

- 91. INNOVA

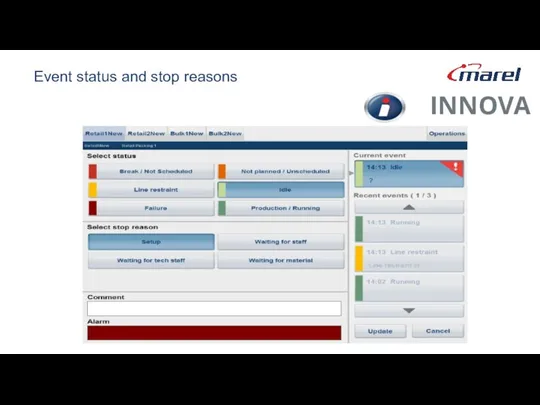

- 92. Event status and stop reasons INNOVA

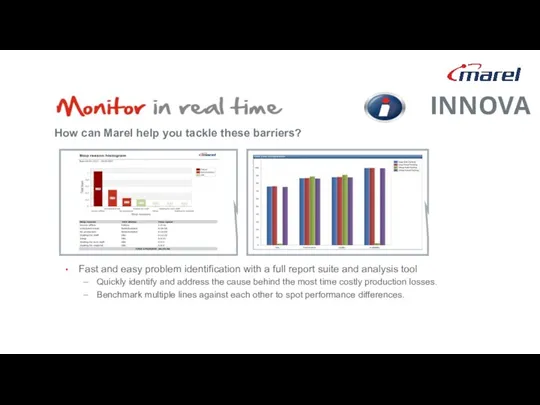

- 93. Fast and easy problem identification with a full report suite and analysis tool Quickly identify and

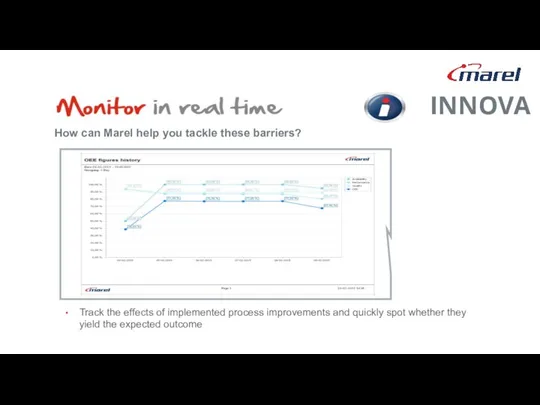

- 94. Track the effects of implemented process improvements and quickly spot whether they yield the expected outcome

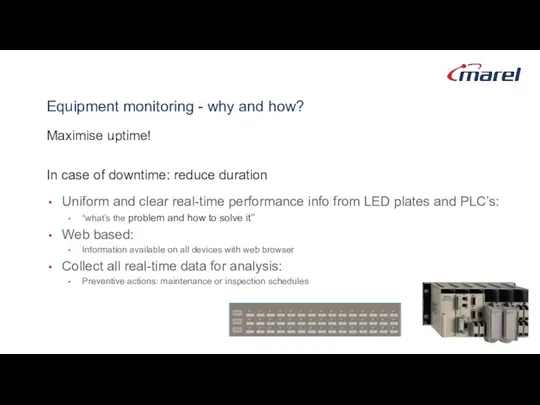

- 95. Equipment monitoring - why and how? Maximise uptime! In case of downtime: reduce duration Uniform and

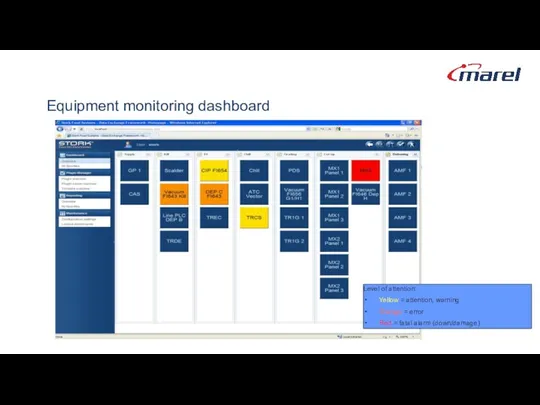

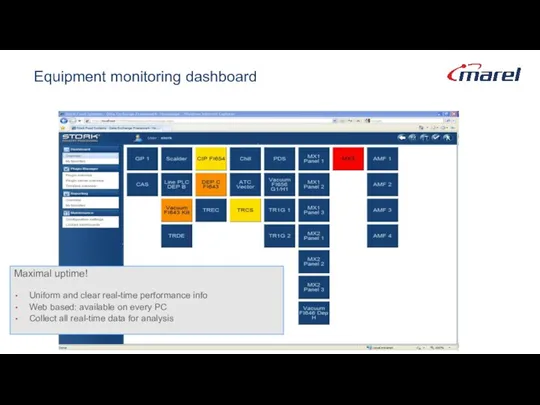

- 96. Equipment monitoring dashboard Level of attention: Yellow = attention, warning Orange = error Red = fatal

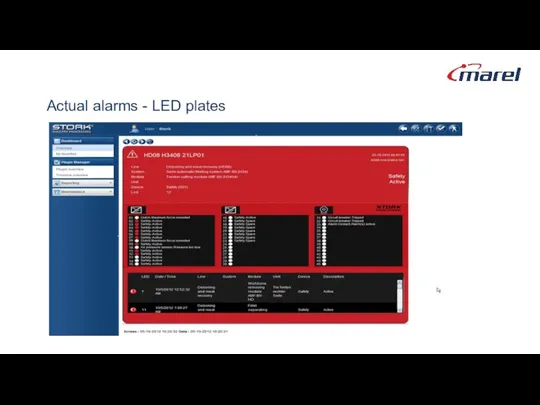

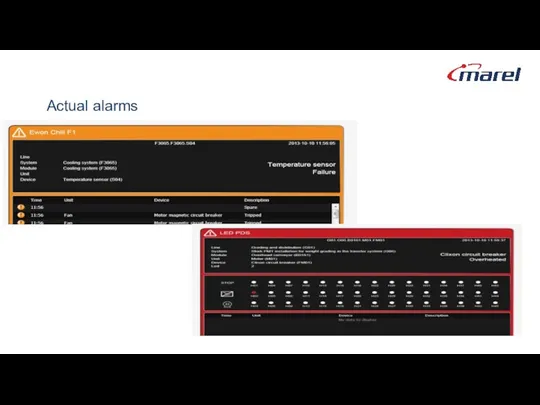

- 97. Actual alarms - LED plates

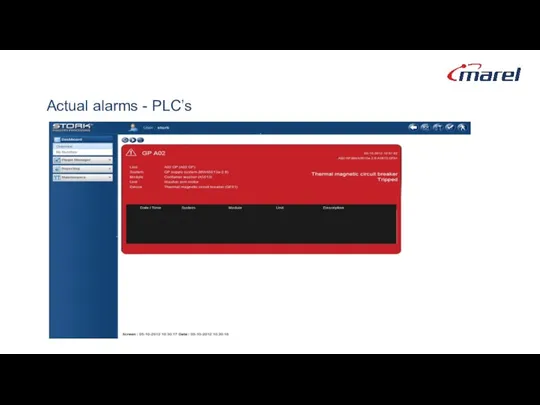

- 98. Actual alarms - PLC’s

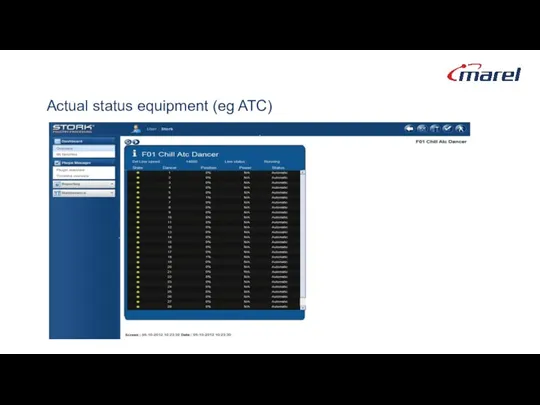

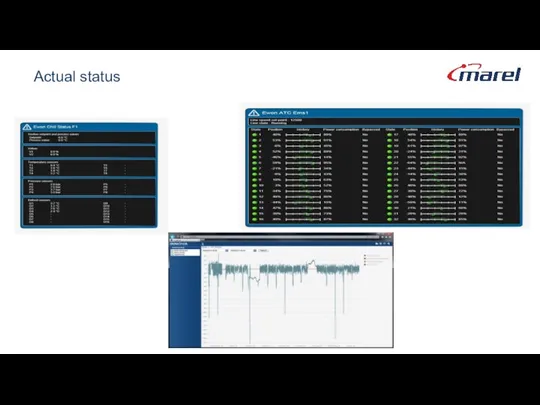

- 99. Actual status equipment (eg ATC)

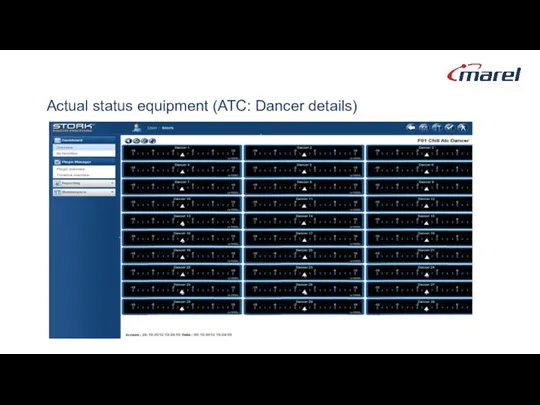

- 100. Actual status equipment (ATC: Dancer details)

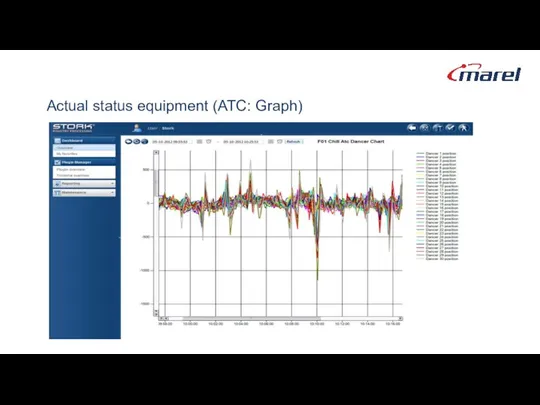

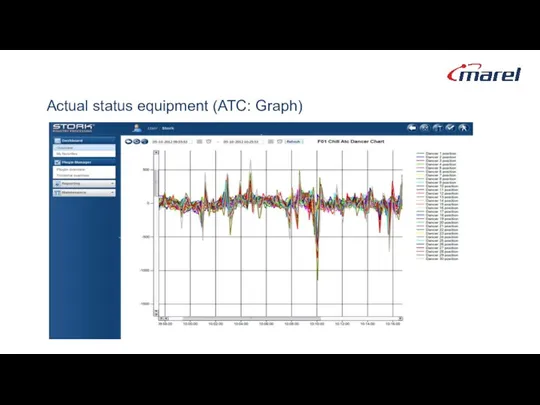

- 101. Actual status equipment (ATC: Graph)

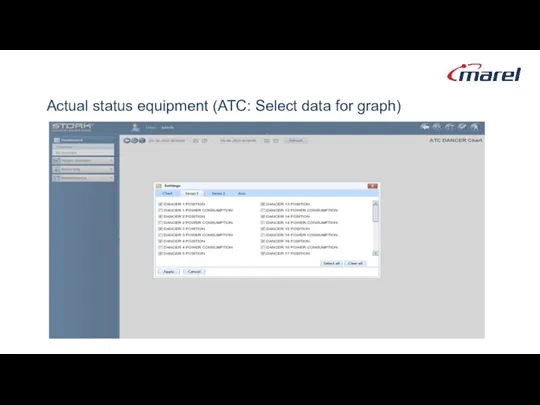

- 102. Actual status equipment (ATC: Select data for graph)

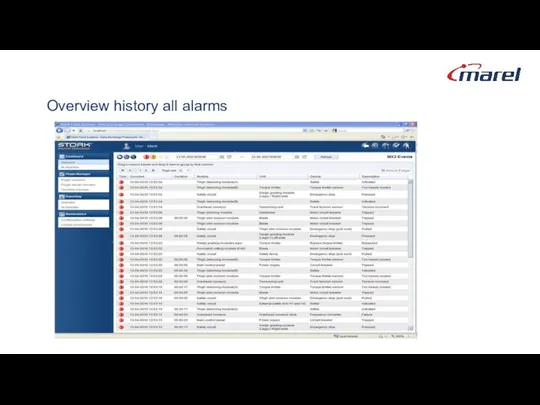

- 103. Overview history all alarms

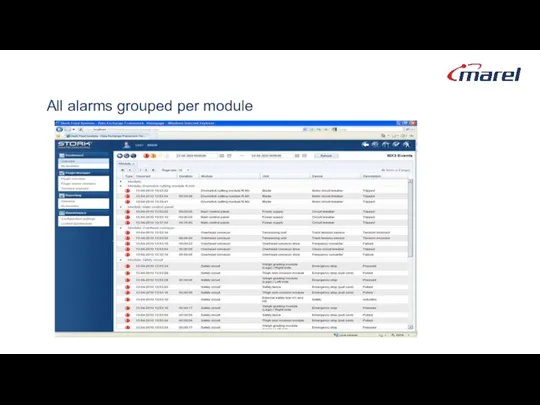

- 104. All alarms grouped per module

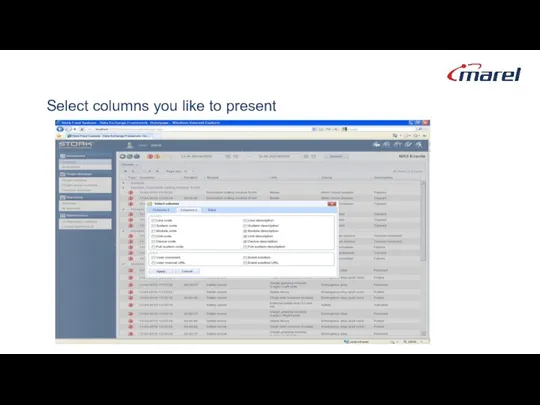

- 105. Select columns you like to present

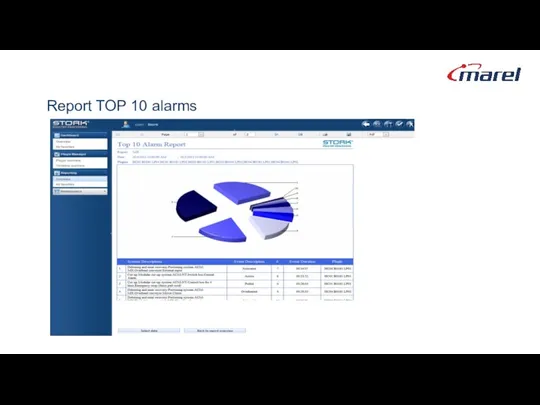

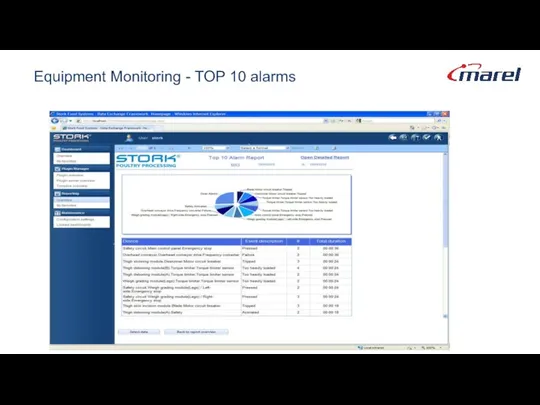

- 106. Report TOP 10 alarms

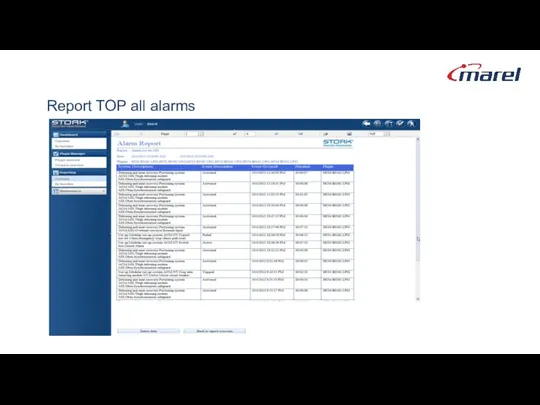

- 107. Report TOP all alarms

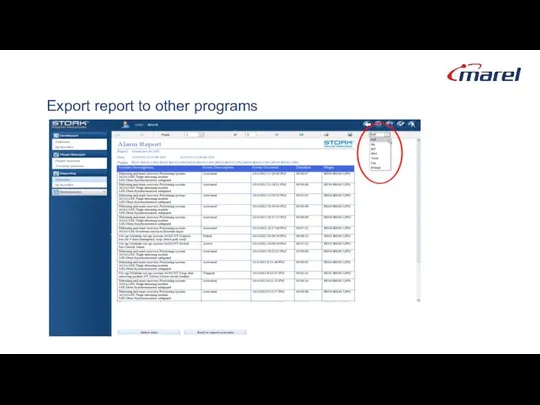

- 108. Export report to other programs

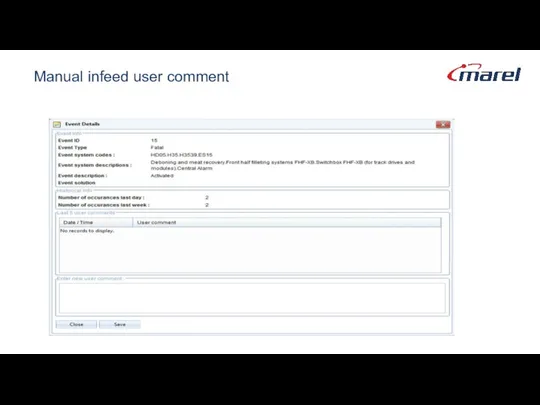

- 109. Manual infeed user comment

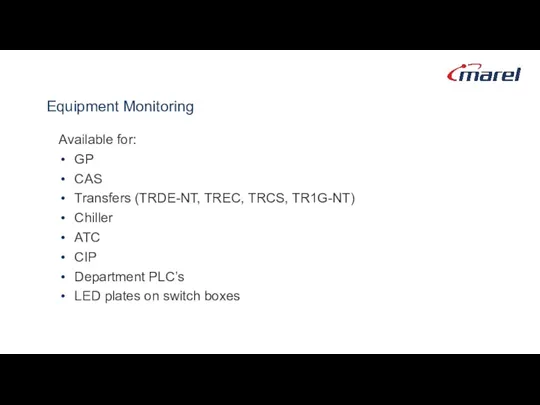

- 110. Equipment Monitoring Available for: GP CAS Transfers (TRDE-NT, TREC, TRCS, TR1G-NT) Chiller ATC CIP Department PLC’s

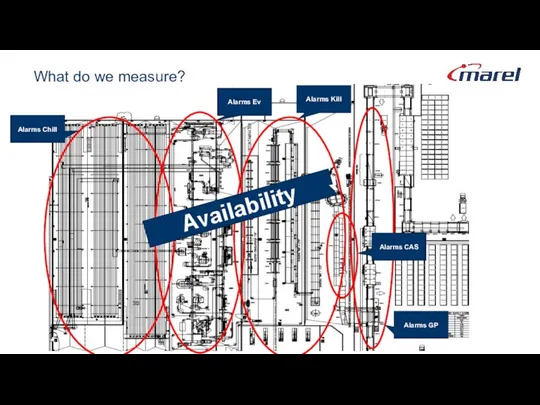

- 111. What do we measure? Availability

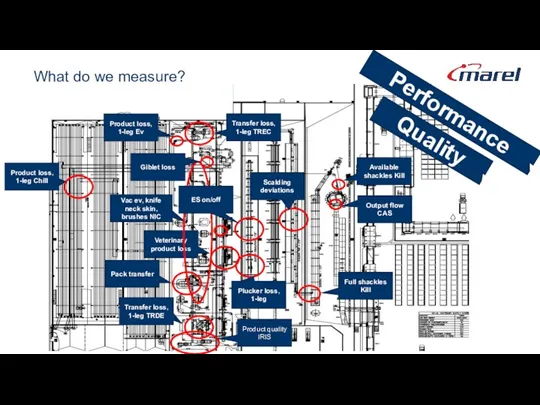

- 112. What do we measure? Quality Performance

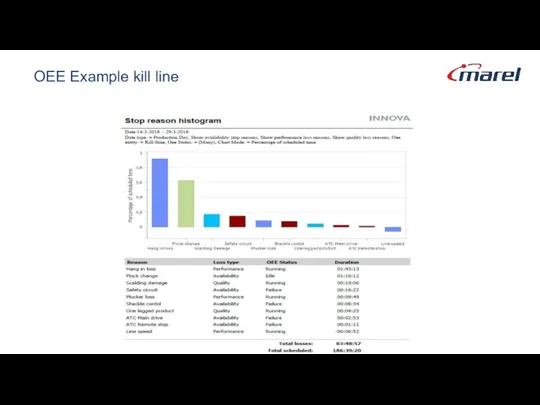

- 113. OEE Example kill line

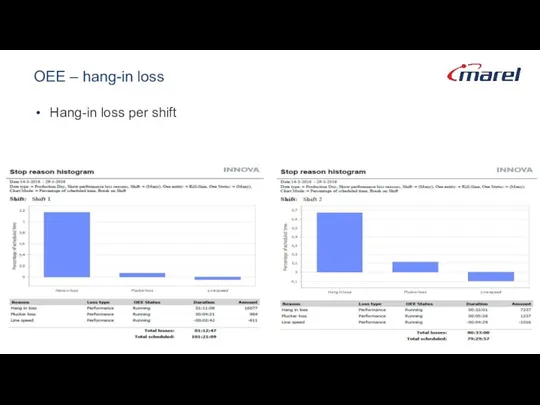

- 114. OEE – hang-in loss Hang-in loss per shift

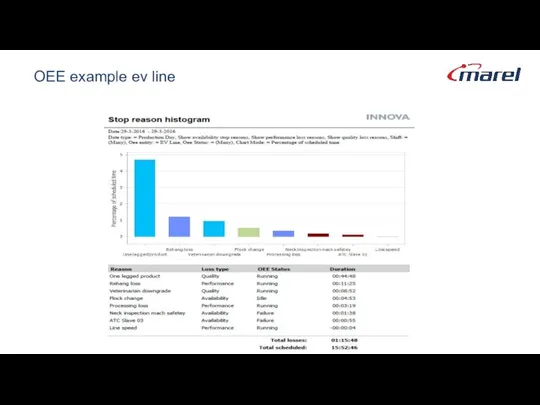

- 115. OEE example ev line

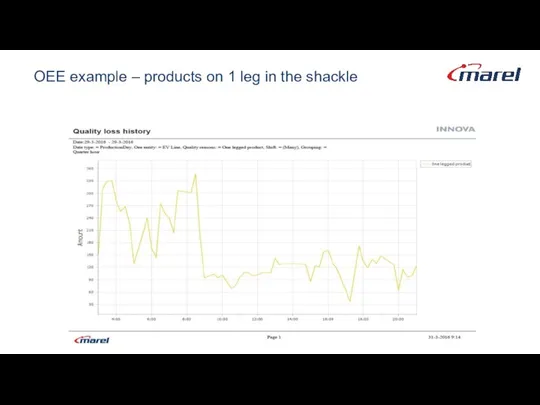

- 116. OEE example – products on 1 leg in the shackle

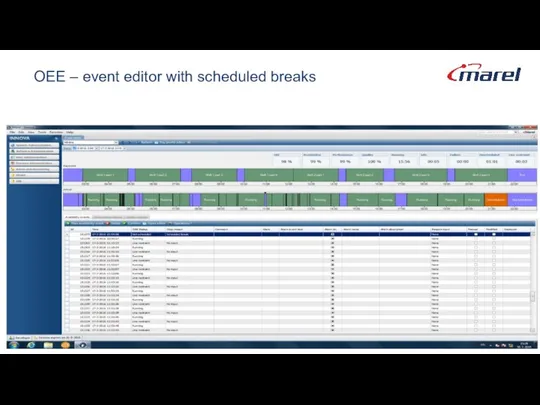

- 117. OEE – event editor with scheduled breaks

- 118. OEE – giblet processing

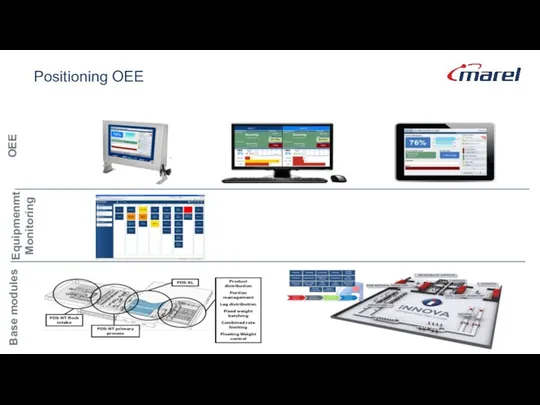

- 119. Positioning OEE

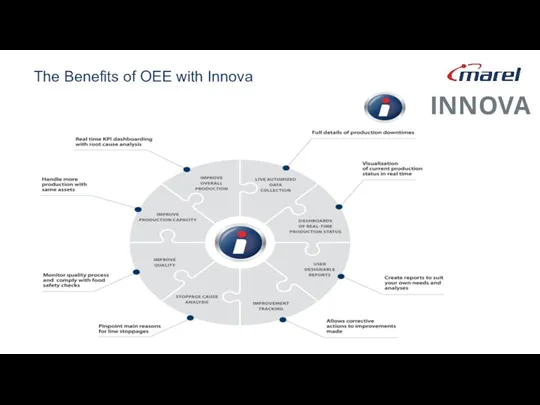

- 120. The Benefits of OEE with Innova INNOVA

- 121. Innova Service Portfolio

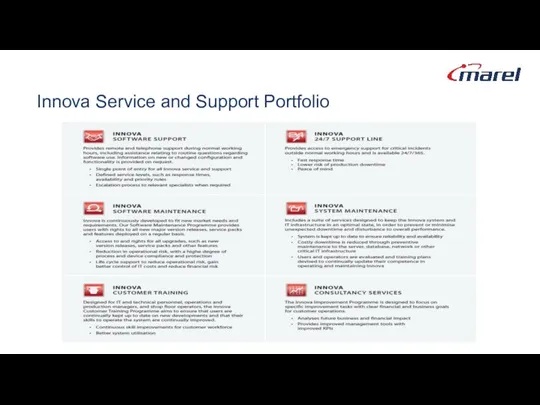

- 122. Innova Service and Support Portfolio

- 123. Tabel of content Why Innova & PDS-NT Overview Innova Overview PDS-NT Equipment Monitoring Integration & customer

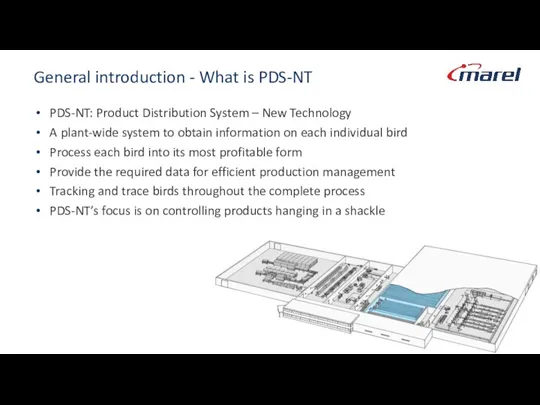

- 124. General introduction - What is PDS-NT PDS-NT: Product Distribution System – New Technology A plant-wide system

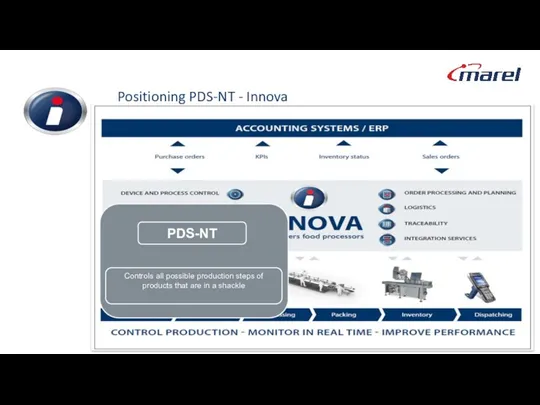

- 125. Positioning PDS-NT - Innova s

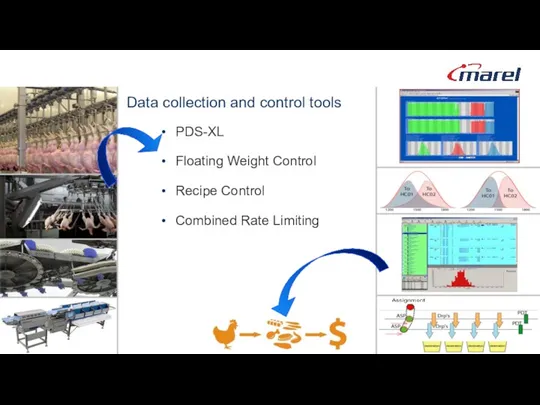

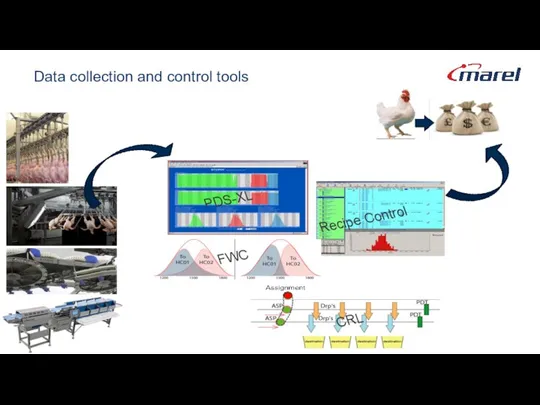

- 126. Data collection and control tools PDS-XL Floating Weight Control Recipe Control Combined Rate Limiting

- 127. Accurate and reliable data collectors Improved data for process optimization!

- 128. Data collection and control tools

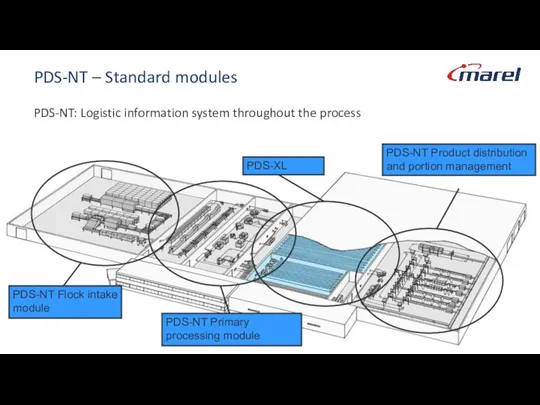

- 129. PDS-NT – Standard modules PDS-NT: Logistic information system throughout the process PDS-NT Flock intake module PDS-NT

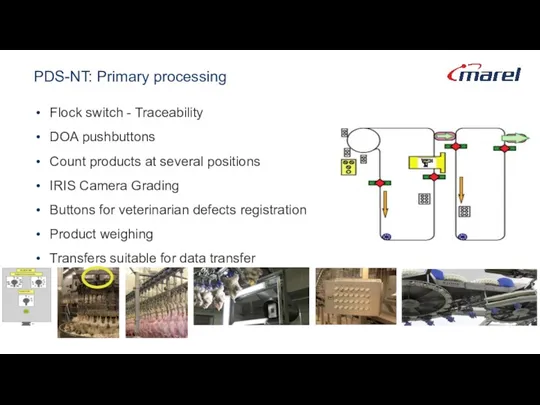

- 130. PDS-NT: Primary processing Flock switch - Traceability DOA pushbuttons Count products at several positions IRIS Camera

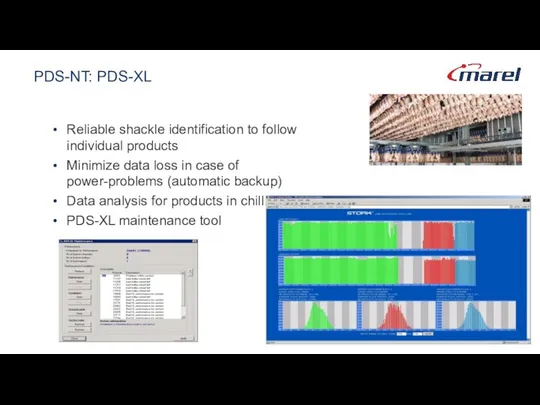

- 131. PDS-NT: PDS-XL Reliable shackle identification to follow individual products Minimize data loss in case of power-problems

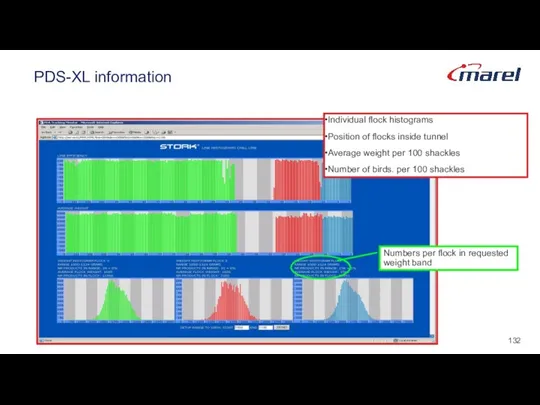

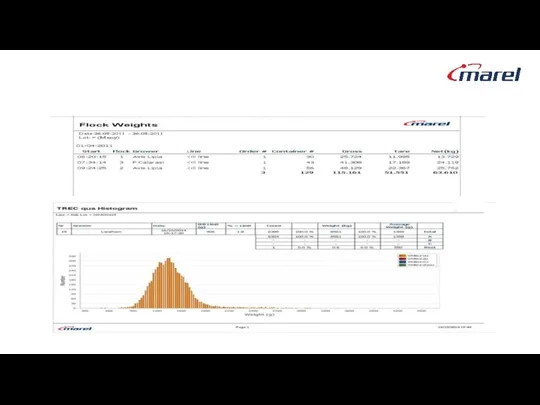

- 132. PDS-XL information Individual flock histograms Position of flocks inside tunnel Average weight per 100 shackles Number

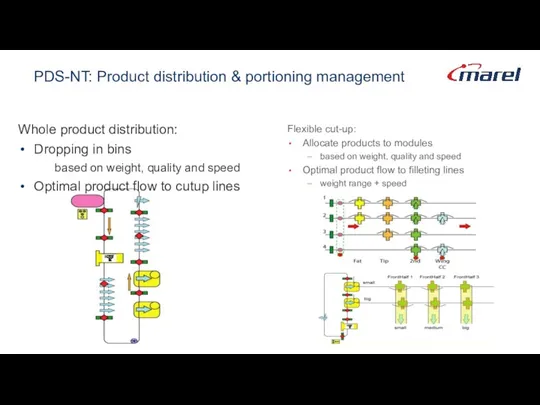

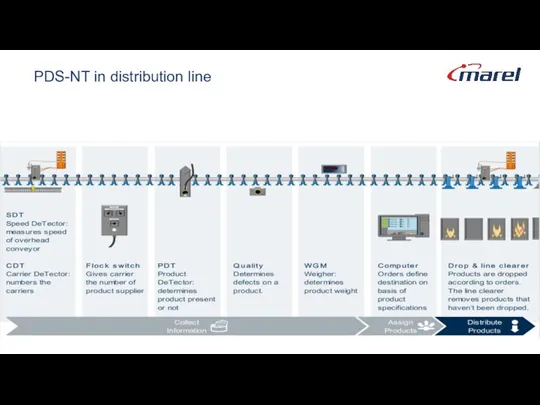

- 133. PDS-NT: Product distribution & portioning management Whole product distribution: Dropping in bins based on weight, quality

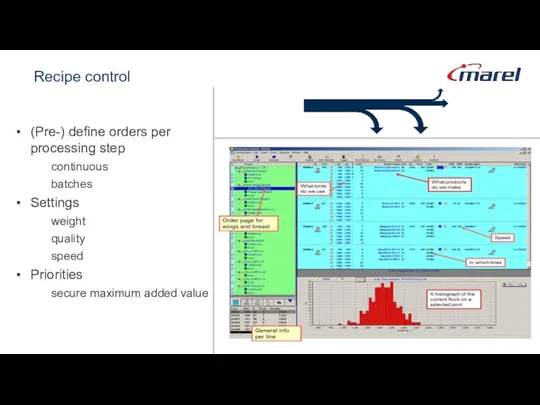

- 134. Recipe control (Pre-) define orders per processing step continuous batches Settings weight quality speed Priorities secure

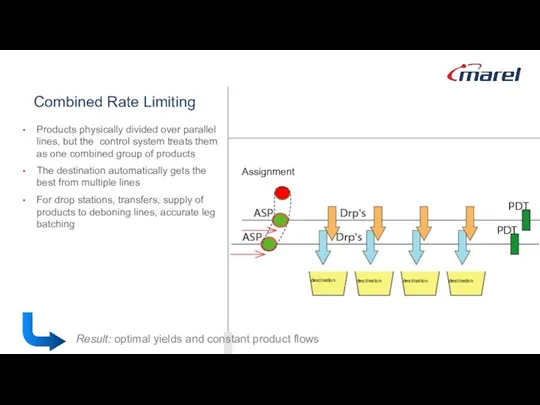

- 135. Products physically divided over parallel lines, but the control system treats them as one combined group

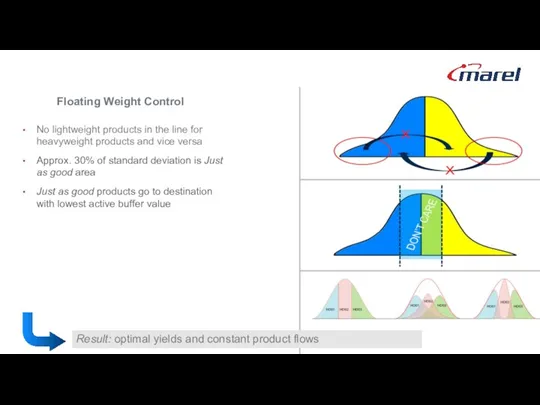

- 136. No lightweight products in the line for heavyweight products and vice versa Approx. 30% of standard

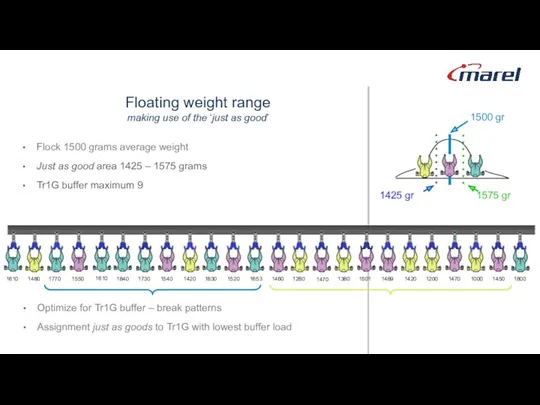

- 137. Floating weight range making use of the ‘just as good’ 1730 1540 1420 1830 1520 1653

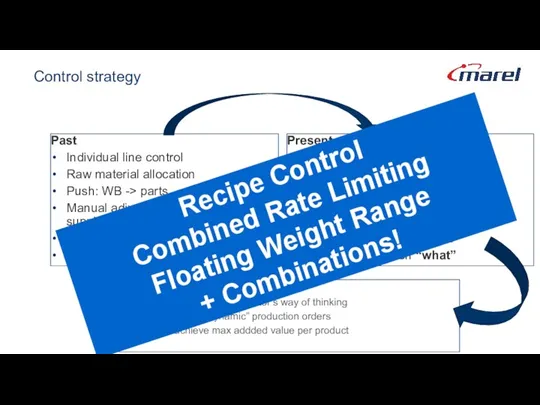

- 138. Control strategy Past Individual line control Raw material allocation Push: WB -> parts Manual adjustments to

- 144. PDS-NT in distribution line

- 145. Innova Traceability

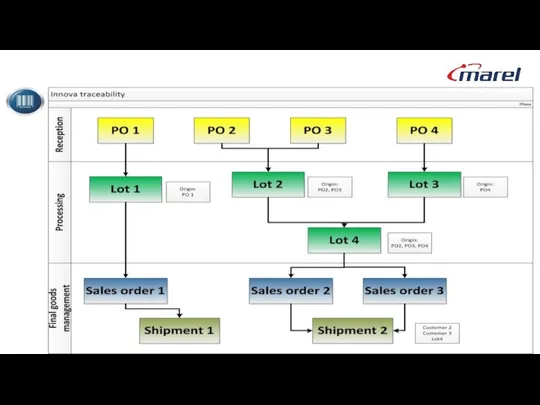

- 146. Traceability in the supply chain Intake: link to farms – live birds Processing: tracking & tracing

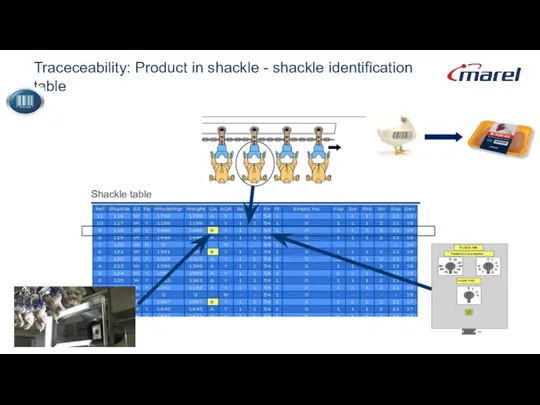

- 147. Traceceability: Product in shackle - shackle identification table Shackle table

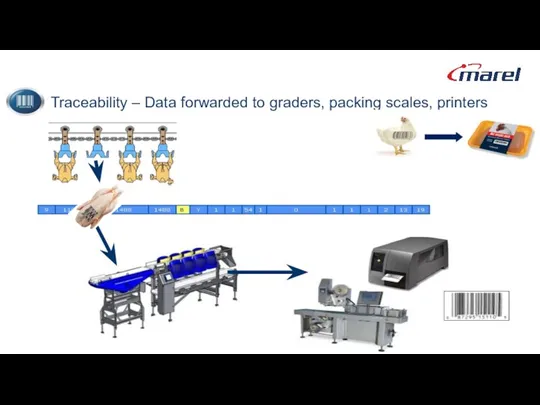

- 148. Traceability – Data forwarded to graders, packing scales, printers

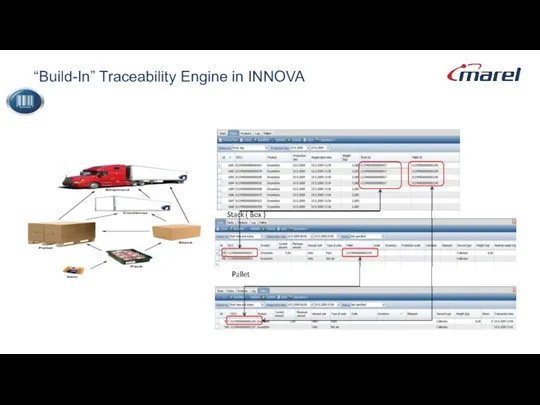

- 150. “Build-In” Traceability Engine in INNOVA

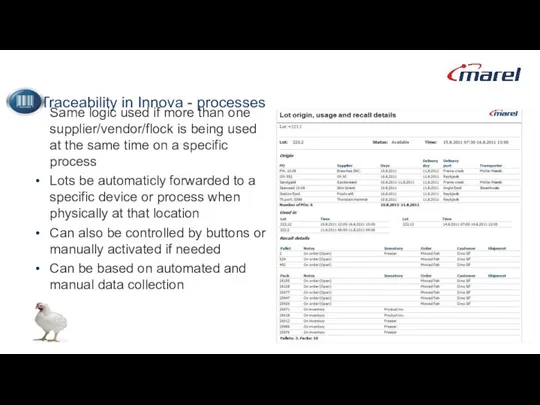

- 151. Traceability in Innova - processes Same logic used if more than one supplier/vendor/flock is being used

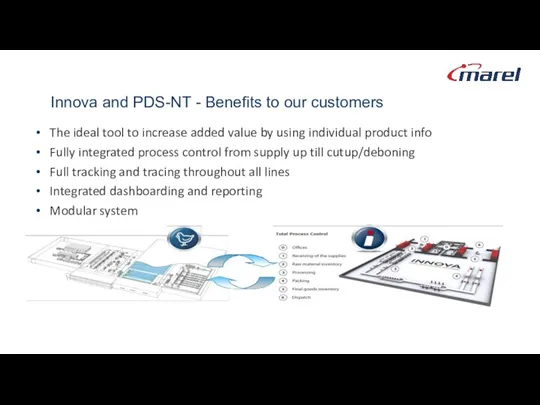

- 152. Innova and PDS-NT - Benefits to our customers The ideal tool to increase added value by

- 153. Tabel of content Why Innova & PDS-NT Overview Innova Overview PDS-NT Equipment Monitoring Integration & customer

- 154. Equipment monitoring dashboard Maximal uptime! Uniform and clear real-time performance info Web based: available on every

- 155. Actual alarms

- 156. Actual status

- 157. Actual status equipment (ATC: Graph)

- 158. Equipment Monitoring - TOP 10 alarms

- 159. Tabel of content Why Innova & PDS-NT Overview Innova Overview PDS-NT Equipment Monitoring Integration & customer

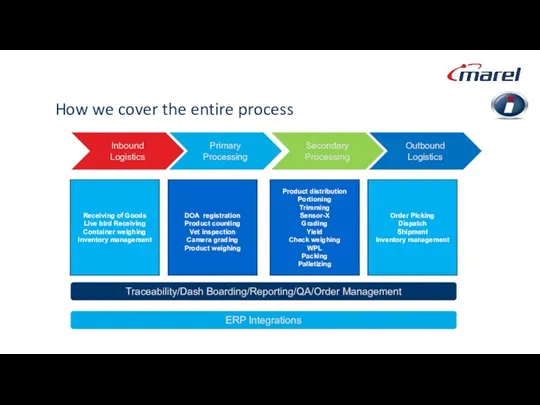

- 160. How we cover the entire process Inbound Logistics Primary Processing Secondary Processing Outbound Logistics Order Picking

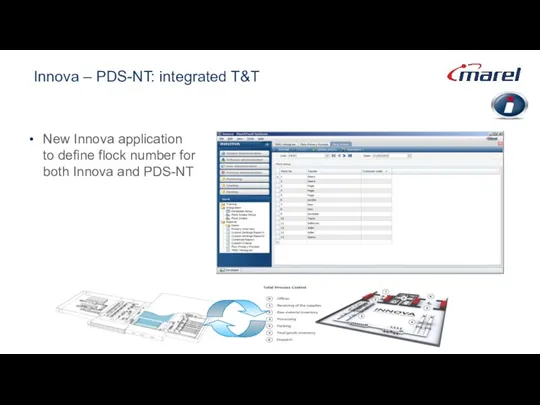

- 161. Innova – PDS-NT: integrated T&T New Innova application to define flock number for both Innova and

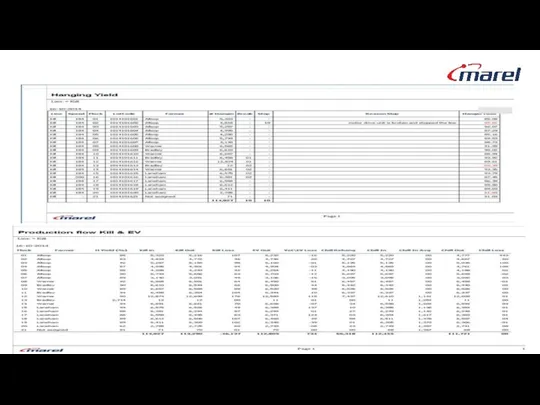

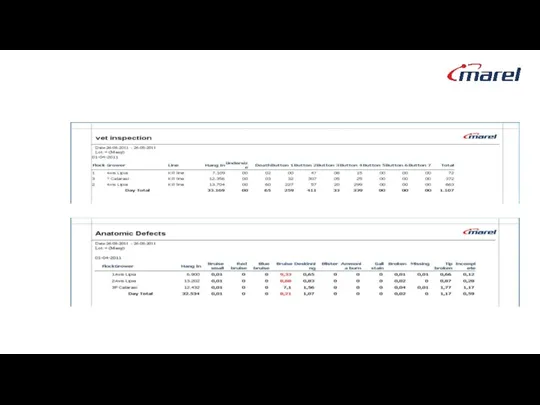

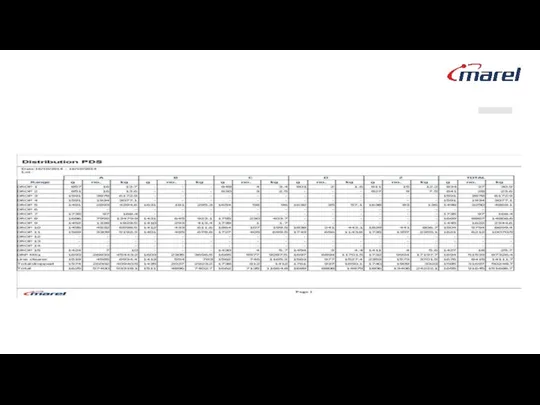

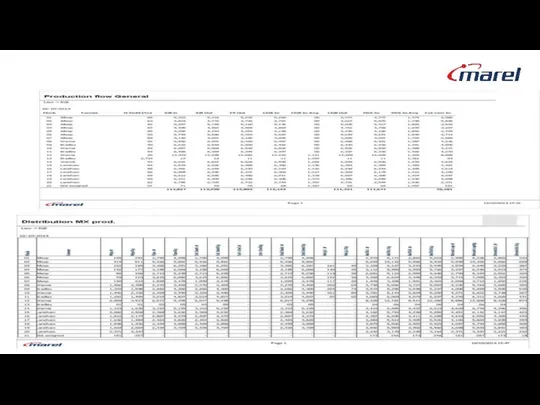

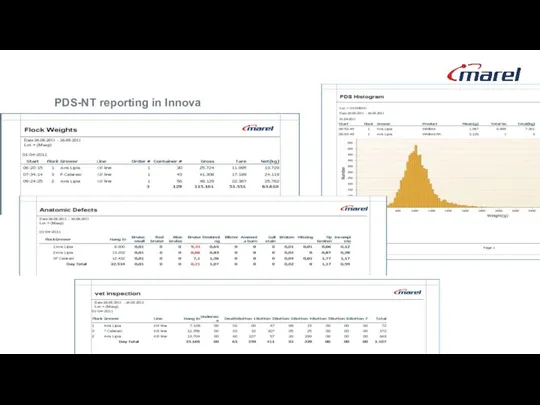

- 162. PDS-NT reporting in Innova

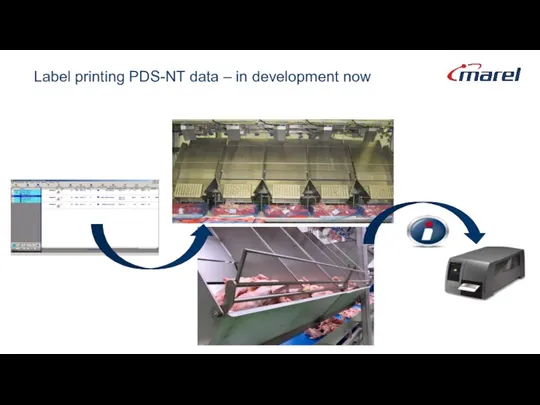

- 163. Label printing PDS-NT data – in development now

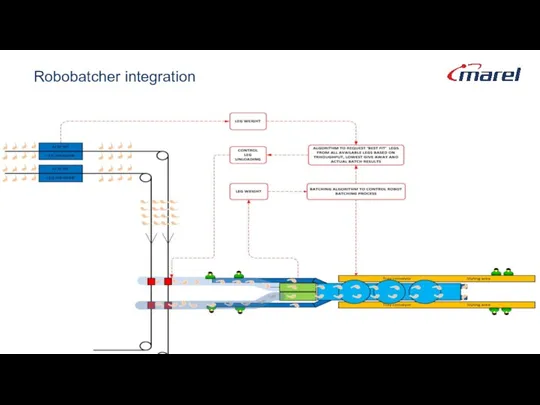

- 164. Robobatcher integration

- 165. With Innova & PDS-NT you get… A tool to measure the health of your processes and

- 167. Скачать презентацию

Использование мультимедийных технологий в работе учителя-логопеда

Использование мультимедийных технологий в работе учителя-логопеда Русское искусство в.п.18 века. Архитектура. Живопись. Скульптура

Русское искусство в.п.18 века. Архитектура. Живопись. Скульптура Технология. К урокам. Диск Диск Диск Диск Диск Диск

Технология. К урокам. Диск Диск Диск Диск Диск Диск Вычитание, умножение и деление рациональных чисел

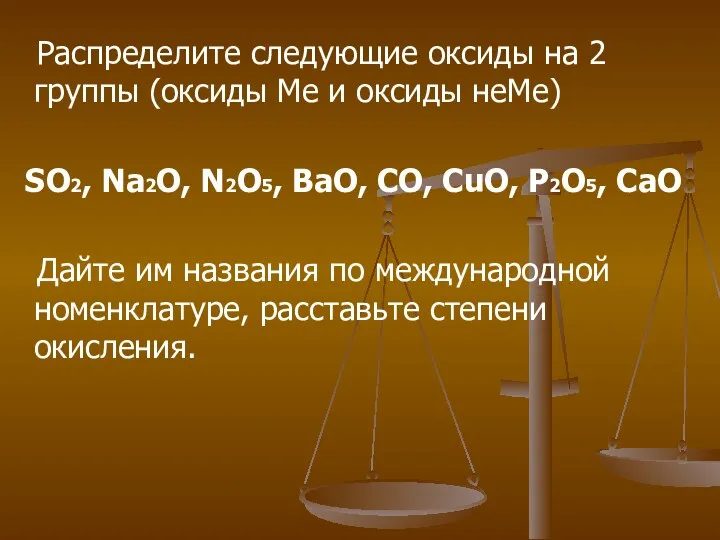

Вычитание, умножение и деление рациональных чисел Основные законы в химии

Основные законы в химии Презентация конспекта урока по теме Мягкий знак vol.2

Презентация конспекта урока по теме Мягкий знак vol.2 Практическая работа Определение ГП реки, обозначение рек на контурной карте (6 кл.)

Практическая работа Определение ГП реки, обозначение рек на контурной карте (6 кл.) 20230921_urok_3.poschety_i_vychisleniya_v_tablitsah

20230921_urok_3.poschety_i_vychisleniya_v_tablitsah Презентация Климат и климатические ресурсы

Презентация Климат и климатические ресурсы Прокуратура Российской Федерации. Организационно-правовые основы деятельности прокуратуры

Прокуратура Российской Федерации. Организационно-правовые основы деятельности прокуратуры Как читать карту

Как читать карту Музыкальный инструмент - заместитель РУБЕЛЬ

Музыкальный инструмент - заместитель РУБЕЛЬ Симметрия многогранников

Симметрия многогранников Діни ағымдардың қоғамға кері әсері

Діни ағымдардың қоғамға кері әсері 10 социально-экономическое развитие страны в 1960-х – середине 1980-х гг

10 социально-экономическое развитие страны в 1960-х – середине 1980-х гг Библейские сказания. История Древнего мира

Библейские сказания. История Древнего мира Исследования на Международной космической станции

Исследования на Международной космической станции Схемо- и системотехника электронных средств

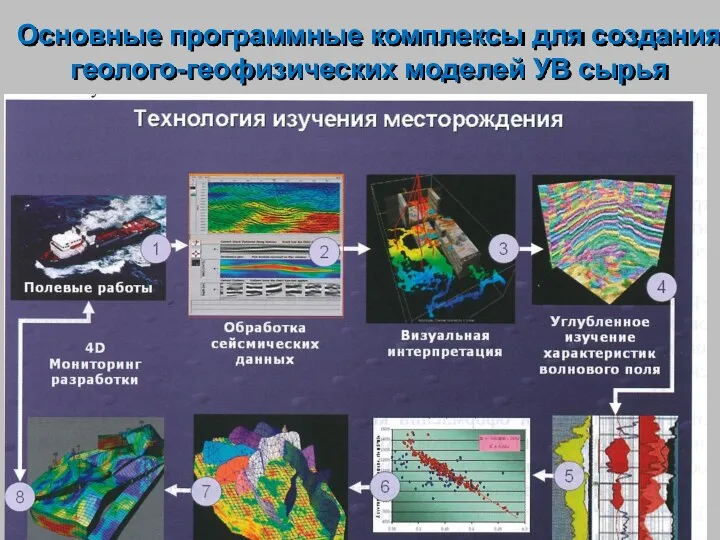

Схемо- и системотехника электронных средств Основные программные комплексы для создания геолого-геофизических моделей УВ сырья

Основные программные комплексы для создания геолого-геофизических моделей УВ сырья Обобщение знаний по теме Литосфера

Обобщение знаний по теме Литосфера Мистическое число 13

Мистическое число 13 Презентация к уроку химии в 8-м классе по теме Основания

Презентация к уроку химии в 8-м классе по теме Основания 20231011_oeni_-_konferentsiya_-_kopiya111

20231011_oeni_-_konferentsiya_-_kopiya111 Поняття про ораторську компетенцію

Поняття про ораторську компетенцію Напряженность электростатического поля

Напряженность электростатического поля Портрет в музыке и живописи

Портрет в музыке и живописи Молекулярная биология. Достижения, проблемы и перспективы. (Лекция 13-а)

Молекулярная биология. Достижения, проблемы и перспективы. (Лекция 13-а) Православная позиция

Православная позиция