- Главная

- Без категории

- Magnetic plates

Содержание

- 2. Features of using magnetic plates for milling machines If your work depends on working on a

- 3. Content: 1 What is a magnetic plate? 2 design Features 3 Technical characteristics 4 how the

- 4. What is a magnetic plate? Magnetic plates are a special type of equipment for milling machines

- 5. Help! Demagnetizer (demagnetizer) - it is necessary to remove the forces of attraction of the tool

- 6. Design features The main structural elements of a magnetic plate for a milling machine are: The

- 7. Technical parameters Technical conditions for the production of magnetic plates are regulated by GOST 16528-87. It

- 8. The principle of operation of the magnetic table The principle of operation of the plate is

- 10. Скачать презентацию

Слайд 2

Features of using magnetic plates for milling machines

If your work

Features of using magnetic plates for milling machines

If your work

depends on working on a milling machine , then increasing the number of products should be a priority for you. A good tool for increasing productivity will be a magnetic plate.

The magnetic plate for the milling machine will allow you to process more than one part at once, unlike standard Cams. And the processing will be carried out with the utmost precision and efficiency. Let's take a closer look at all the features of this device.

The magnetic plate for the milling machine will allow you to process more than one part at once, unlike standard Cams. And the processing will be carried out with the utmost precision and efficiency. Let's take a closer look at all the features of this device.

Слайд 3

Content:

1 What is a magnetic plate?

2 design Features

3 Technical characteristics

4 how

Content:

1 What is a magnetic plate?

2 design Features

3 Technical characteristics

4 how

the magnetic table works

5 operating instructions

6 expert Advice and price

5 operating instructions

6 expert Advice and price

Слайд 4

What is a magnetic plate?

Magnetic plates are a special type of

What is a magnetic plate?

Magnetic plates are a special type of

equipment for milling machines that is necessary for processing metal elements, which is necessary for fixing metal elements on the working surface of the machine under the influence of electromagnetic attraction.

Prior to their appearance, Cams were actively used to hold workpieces, which provided maximum retention during operation. But still magnetic plates have a number of more outstanding advantages in comparison with Cams:

there is an alternative to processing multiple workpieces at once;

the maximum accuracy of the impact is provided, which is associated with the phenomenon of heating the metal part. It expands, but does not deform like a part in clamps;

provide high reliability of fastening;

maintain the main performance characteristics at the original level for the entire period of use;

do not require annual (or more often) inspection and repair activities.

But the disadvantages are also present in these devices:

not used in jobs that require a large cutting force;

the residual magnetism of workpieces made of steel, but this feature will help to cope with the demagnetizer.

Prior to their appearance, Cams were actively used to hold workpieces, which provided maximum retention during operation. But still magnetic plates have a number of more outstanding advantages in comparison with Cams:

there is an alternative to processing multiple workpieces at once;

the maximum accuracy of the impact is provided, which is associated with the phenomenon of heating the metal part. It expands, but does not deform like a part in clamps;

provide high reliability of fastening;

maintain the main performance characteristics at the original level for the entire period of use;

do not require annual (or more often) inspection and repair activities.

But the disadvantages are also present in these devices:

not used in jobs that require a large cutting force;

the residual magnetism of workpieces made of steel, but this feature will help to cope with the demagnetizer.

Слайд 5

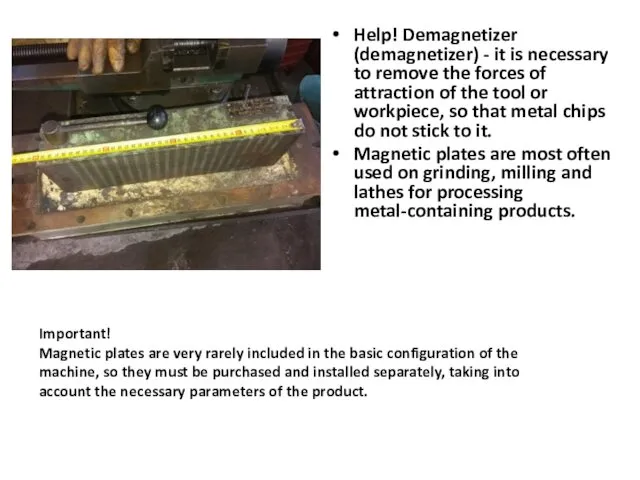

Help! Demagnetizer (demagnetizer) - it is necessary to remove the forces

Help! Demagnetizer (demagnetizer) - it is necessary to remove the forces

of attraction of the tool or workpiece, so that metal chips do not stick to it.

Magnetic plates are most often used on grinding, milling and lathes for processing metal-containing products.

Magnetic plates are most often used on grinding, milling and lathes for processing metal-containing products.

Important!

Magnetic plates are very rarely included in the basic configuration of the machine, so they must be purchased and installed separately, taking into account the necessary parameters of the product.

Слайд 6

Design features

The main structural elements of a magnetic plate for a

Design features

The main structural elements of a magnetic plate for a

milling machine are:

The device body is made of soft steel. Its base has special oppositely charged protrusions.

A special cover that covers the work surface. The cover is one pole, and the rest of the surface is the opposite pole.

Coils-designed for direct current transmission.

A magnetic block is a mobile element that moves due to the operation of an eccentric top.

The device body is made of soft steel. Its base has special oppositely charged protrusions.

A special cover that covers the work surface. The cover is one pole, and the rest of the surface is the opposite pole.

Coils-designed for direct current transmission.

A magnetic block is a mobile element that moves due to the operation of an eccentric top.

Слайд 7

Technical parameters

Technical conditions for the production of magnetic plates are regulated

Technical parameters

Technical conditions for the production of magnetic plates are regulated

by GOST 16528-87. It describes all the characteristics of plates with different types of control.

The main parameters that affect the operation of magnetic plates are:

Overall dimensions-minimum starting from 10x25 cm and maximum up to 32x100 cm.the final dimensions of the workpiece depend on this value. Also, due to the large size of the plate, the load on the machine's work table increases.

Magnetic force-acts constantly and out of working position it is prevented by blocks of non-magnetic material. The limits of this value are 50-120 N / cm2.

The distance between the magnetic poles or coils. It determines the smallest size available for the manufactured part.

The main parameters that affect the operation of magnetic plates are:

Overall dimensions-minimum starting from 10x25 cm and maximum up to 32x100 cm.the final dimensions of the workpiece depend on this value. Also, due to the large size of the plate, the load on the machine's work table increases.

Magnetic force-acts constantly and out of working position it is prevented by blocks of non-magnetic material. The limits of this value are 50-120 N / cm2.

The distance between the magnetic poles or coils. It determines the smallest size available for the manufactured part.

Слайд 8

The principle of operation of the magnetic table

The principle of operation

The principle of operation of the magnetic table

The principle of operation

of the plate is quite simple and clear. A magnetic field is formed on its working surface, which fixes the metal workpieces. This function makes it possible to process not only the outer part of the materials, but also the side areas.

If necessary, multiple parts can be processed at the same time. Due to its magnetic properties, you can install an additional tool on the work plane that will be useful in your work.

Operating instructions

The magnetic plate should be unserved and the equipment passport should be examined.

Place it on the machine table.

Check the correct attachment and get started.

The workpiece made of ferromagnetic material must be placed on the work surface in the desired position and turn the lever 180 degrees. Check the reliability of the attachment.

To begin processing of the workpiece.

Metal shavings that form during operation can be removed with a brush after turning the handle 180 degrees. Then, after cleaning the surface, it is necessary to re-fix the workpiece with the handle.

At the end of the work, turn the handle and remove the workpiece.

Important!

The impact of the shock load on the workpiece fixed on the magnetic plate is unacceptable, since this leads to a decrease in the magnetization of individual elements and, accordingly, to a decrease in the forces of attraction

If necessary, multiple parts can be processed at the same time. Due to its magnetic properties, you can install an additional tool on the work plane that will be useful in your work.

Operating instructions

The magnetic plate should be unserved and the equipment passport should be examined.

Place it on the machine table.

Check the correct attachment and get started.

The workpiece made of ferromagnetic material must be placed on the work surface in the desired position and turn the lever 180 degrees. Check the reliability of the attachment.

To begin processing of the workpiece.

Metal shavings that form during operation can be removed with a brush after turning the handle 180 degrees. Then, after cleaning the surface, it is necessary to re-fix the workpiece with the handle.

At the end of the work, turn the handle and remove the workpiece.

Important!

The impact of the shock load on the workpiece fixed on the magnetic plate is unacceptable, since this leads to a decrease in the magnetization of individual elements and, accordingly, to a decrease in the forces of attraction

- Предыдущая

Европейская философия 17-19 вековСледующая -

Величайший философ древности Сократ

Среднее арифметическое. Среднее значение величины

Среднее арифметическое. Среднее значение величины Теория управления

Теория управления Задание №9 ОГЭ. Обобщенный план варианта КИМ 2016 года для ГИА выпускников IХ классов по информатике и ИКТ

Задание №9 ОГЭ. Обобщенный план варианта КИМ 2016 года для ГИА выпускников IХ классов по информатике и ИКТ Пасха

Пасха Способы поверхностного упрочнения прокатных валков

Способы поверхностного упрочнения прокатных валков Номенклатура органических соединений

Номенклатура органических соединений Розробка інтегрованої автоматизованої системи управління виготовленням спирту з використанням хмарного середовища

Розробка інтегрованої автоматизованої системи управління виготовленням спирту з використанням хмарного середовища Проект Музей мяча. История, разновидности мяча, игры с мячом

Проект Музей мяча. История, разновидности мяча, игры с мячом Адаптивная физическая культура. Общие положения

Адаптивная физическая культура. Общие положения Чрезвычайные ситуации природного характера

Чрезвычайные ситуации природного характера Как запустить мейлинг с нулевым бюджетом

Как запустить мейлинг с нулевым бюджетом Открытое акционерное общество Холдинговая компания Якутуголь

Открытое акционерное общество Холдинговая компания Якутуголь Елді мекендердің су желісін төсеу

Елді мекендердің су желісін төсеу Презентация Музей истории села МОУ Лобанихинская СОШ

Презентация Музей истории села МОУ Лобанихинская СОШ Неопределенная форма глагола - инфинитив

Неопределенная форма глагола - инфинитив презентация педагогического проекта Учимся жить вместе

презентация педагогического проекта Учимся жить вместе Цифровой образовательный ресурс Социальное развитие детей дошкольного возраста (тест для педагогов дошкольных образовательных учреждений)

Цифровой образовательный ресурс Социальное развитие детей дошкольного возраста (тест для педагогов дошкольных образовательных учреждений) Сигнатурное комбо устройство MiVue™ i85

Сигнатурное комбо устройство MiVue™ i85 Судебная система в Российской Федерации

Судебная система в Российской Федерации Типы рыночных структур

Типы рыночных структур Ввод и редактирование текста

Ввод и редактирование текста Развитие познавательной активности у обучающихся средствами ИКТ в рамках ФГОС (на примере уроков географии)

Развитие познавательной активности у обучающихся средствами ИКТ в рамках ФГОС (на примере уроков географии) Цветы в нашей жизни. Диск

Цветы в нашей жизни. Диск Творческий проект Бисероплетение

Творческий проект Бисероплетение Добровольное медицинское страхование сотрудников ООО РДВ-СОФТ

Добровольное медицинское страхование сотрудников ООО РДВ-СОФТ Физминутка на движение Веселая зарядка

Физминутка на движение Веселая зарядка дифференциация гласных а я

дифференциация гласных а я Классный час .Тема 23 февраля - день защитника Отечества 1Б класс с творческими работами

Классный час .Тема 23 февраля - день защитника Отечества 1Б класс с творческими работами