Содержание

- 2. Objectives After completing this training you should be: Able to install the MP C3003 series in

- 3. Requirements Metis-C1 with Cheetah operation panel. Windows PC. Field Service Manual. This presentation.

- 4. Pre-requisites and exam Before starting this training you must already have followed the My-Ricoh training for:

- 5. Module overview 1. Introduction 2. Installation 3. Maintenance 4. Detailed Section Descriptions 5. Troubleshooting 6. Android

- 6. 1. Introduction

- 7. Metis-C1 The Metis-C1 is the successor model of the Athena, Apollon and Diana series. The Metis-C1

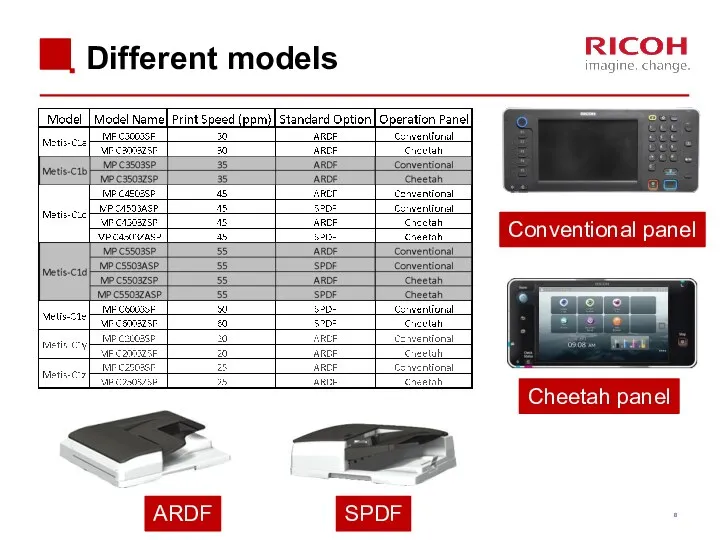

- 8. Different models ARDF SPDF Cheetah panel Conventional panel

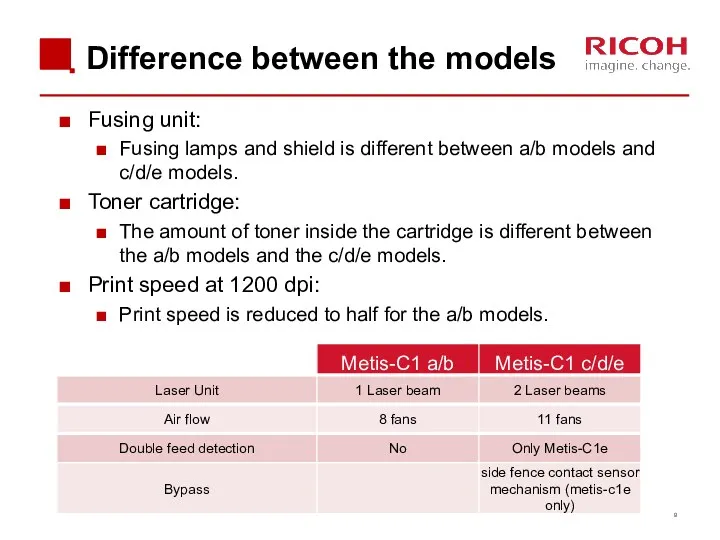

- 9. Difference between the models Fusing unit: Fusing lamps and shield is different between a/b models and

- 10. Yield and consumables Toner cartridges: Metis-C1a/b: K: 28k prints/bottle YMC: 18k prints/bottle Metis-C1c/d/e: K: 31k prints/bottle

- 11. Targets & reliability Average Print Volume (APV): Metis-C1a: 5k/month Metis-C1b: 7k/month Metis-C1c: 10k/month Metis-C1d: 12k/month Metis-C1e:

- 12. 2. Installation

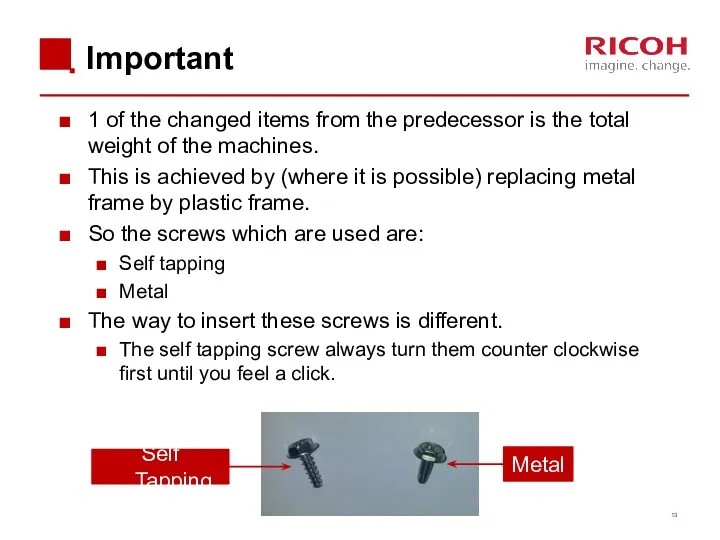

- 13. Important 1 of the changed items from the predecessor is the total weight of the machines.

- 14. Hardware Installation Basically, this is very simple. Remove packing materials. Remove the seals from the PCDUs

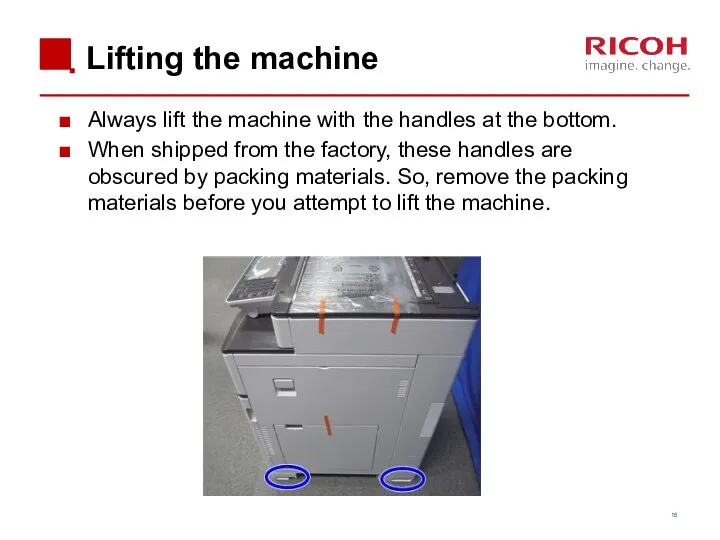

- 15. Lifting the machine Always lift the machine with the handles at the bottom. When shipped from

- 16. Removing the PCDU seals Each PCDU [A] has a seal [B] that must be removed during

- 17. Front covers PCDU’s & ITB unit Covers are not installed on the machine when it is

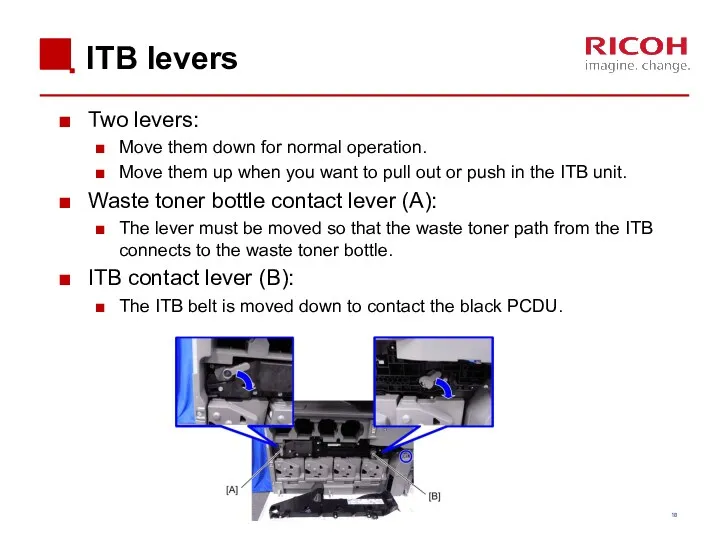

- 18. ITB levers Two levers: Move them down for normal operation. Move them up when you want

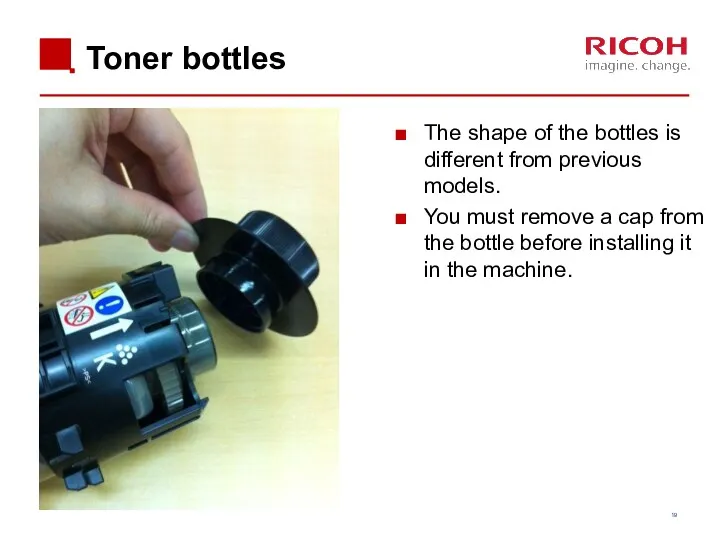

- 19. Toner bottles Toner bottles The shape of the bottles is different from previous models. You must

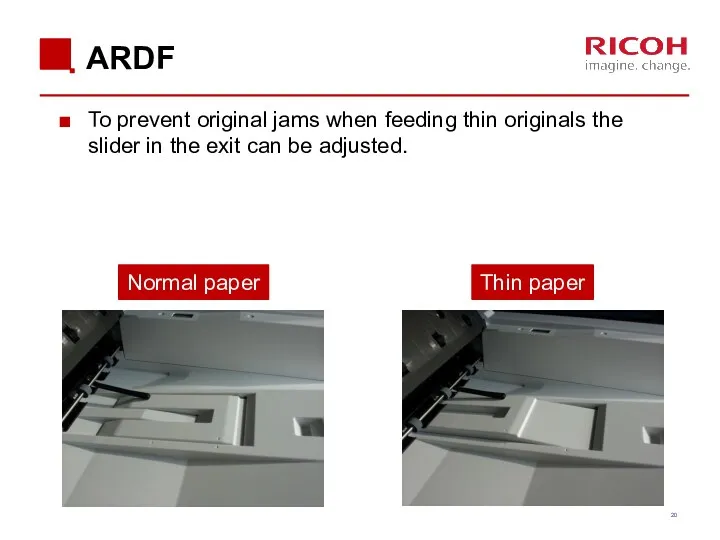

- 20. ARDF To prevent original jams when feeding thin originals the slider in the exit can be

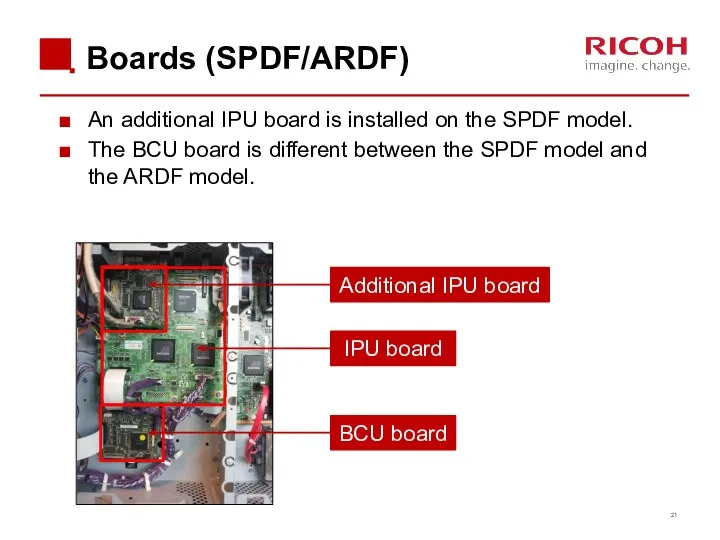

- 21. Boards (SPDF/ARDF) An additional IPU board is installed on the SPDF model. The BCU board is

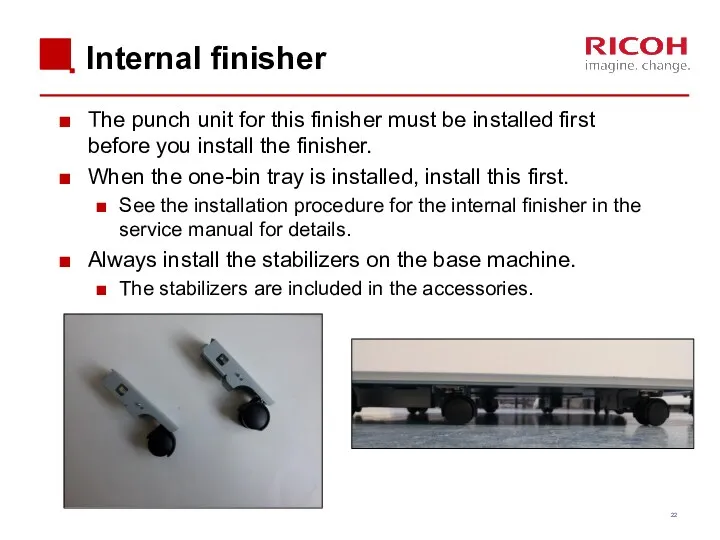

- 22. Internal finisher The punch unit for this finisher must be installed first before you install the

- 23. Finisher SR3140 (D687) Only for D687: Two stabilizers are included as accessories. They must be attached

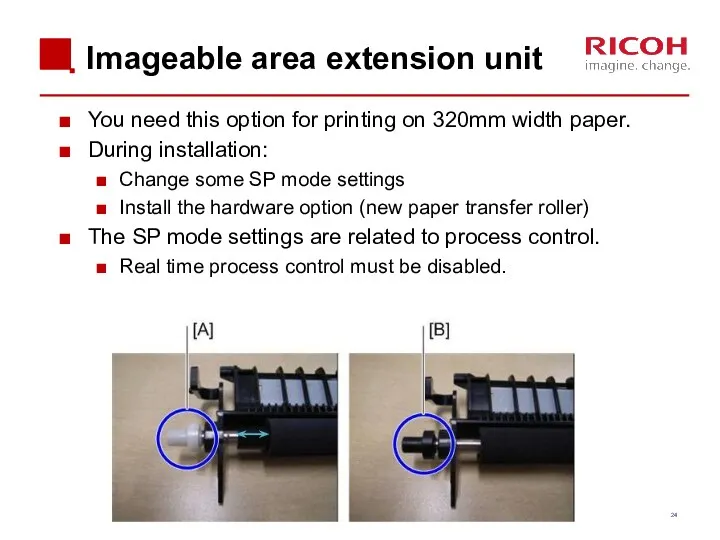

- 24. Imageable area extension unit You need this option for printing on 320mm width paper. During installation:

- 25. What can happen? SP setting is the normal setting (SRA3 paper not supported) and the optional

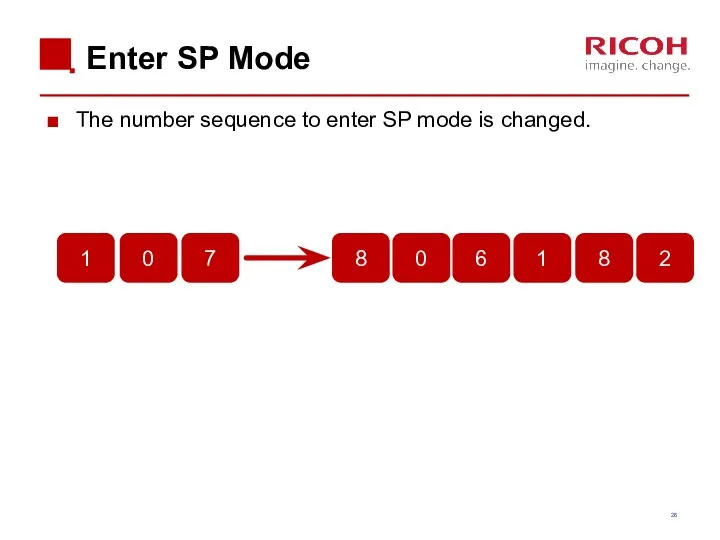

- 26. Enter SP Mode The number sequence to enter SP mode is changed.

- 27. SD Card Slots [A]: SD card slot 1 (option slot) [B]: SD card slot 2 (service

- 28. SD Card Merging In former models there are some SD card options that can’t be merged.

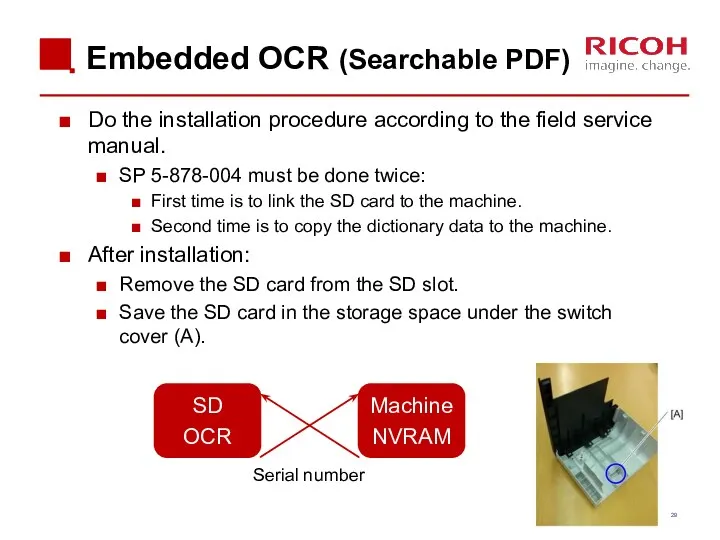

- 29. Embedded OCR (Searchable PDF) Do the installation procedure according to the field service manual. SP 5-878-004

- 30. After Installing the Machine and All Options After you have finished installing the machine, back up

- 31. 3. Maintenance

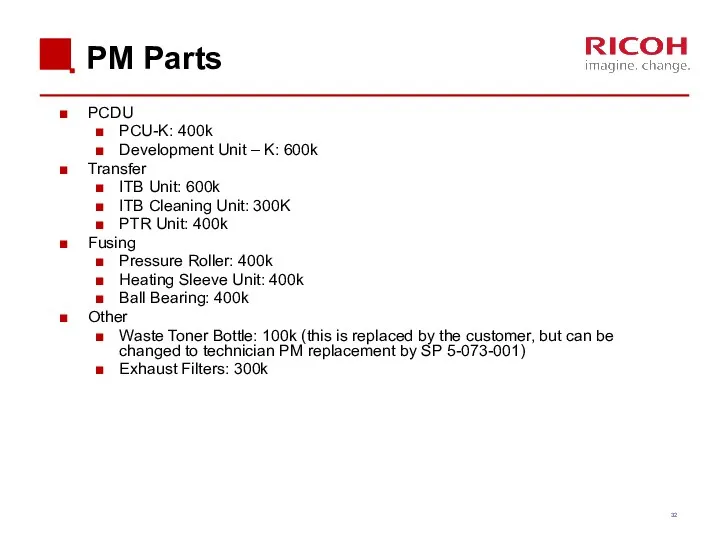

- 32. PM Parts PCDU PCU-K: 400k Development Unit – K: 600k Transfer ITB Unit: 600k ITB Cleaning

- 33. Yield Parts Development Unit – CMY: 600k PCU – CMY: 270k ARDF Feed Belt, Pick-up Roller,

- 34. Replacing a PM Part Execute the SP for forced detection of a new part. See the

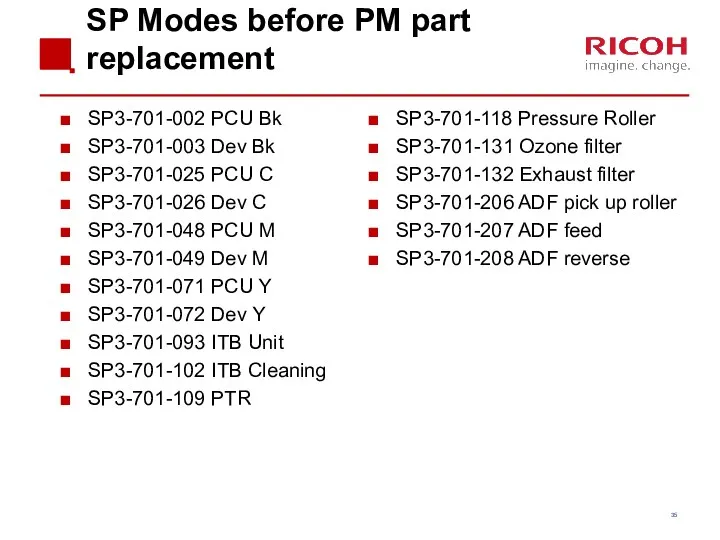

- 35. SP Modes before PM part replacement SP3-701-002 PCU Bk SP3-701-003 Dev Bk SP3-701-025 PCU C SP3-701-026

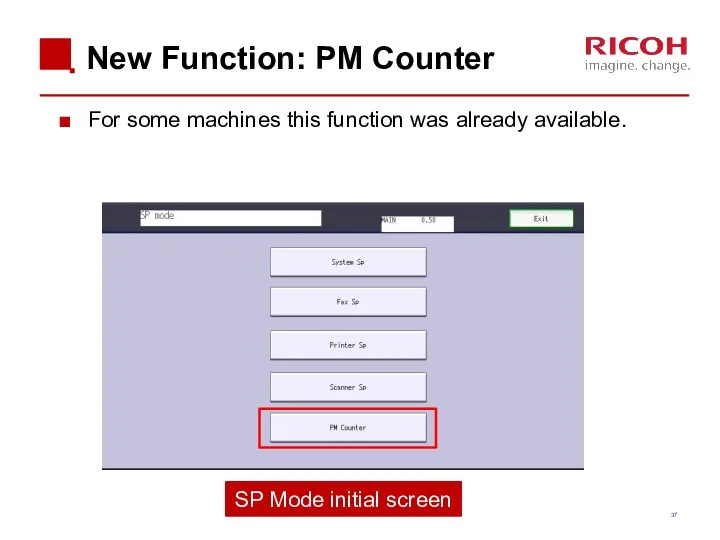

- 36. New Function: PM Counter New features on the PM counter display allow you to see the

- 37. New Function: PM Counter For some machines this function was already available. SP Mode initial screen

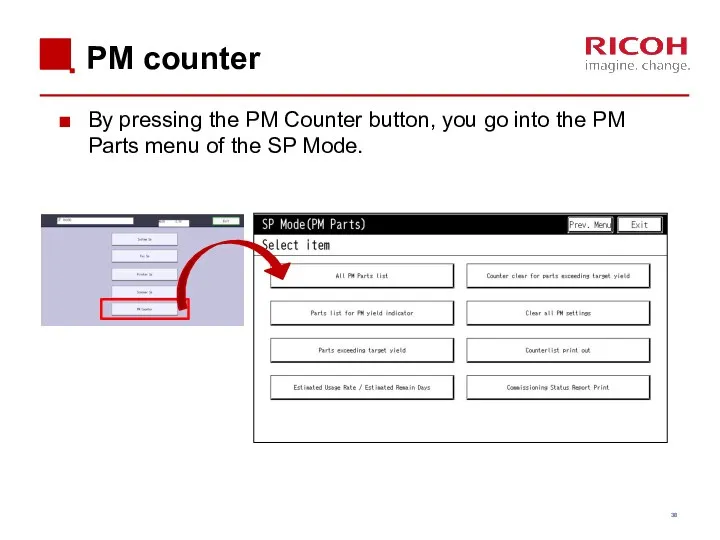

- 38. PM counter By pressing the PM Counter button, you go into the PM Parts menu of

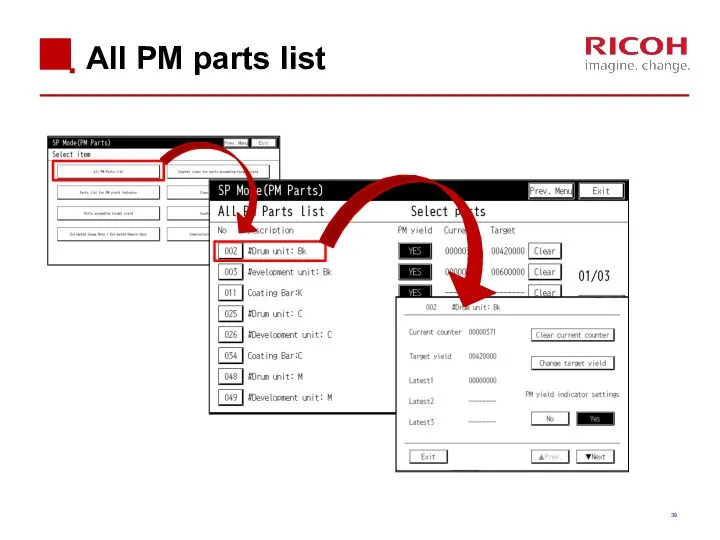

- 39. All PM parts list

- 40. Counter clear for parts exceeding target yield

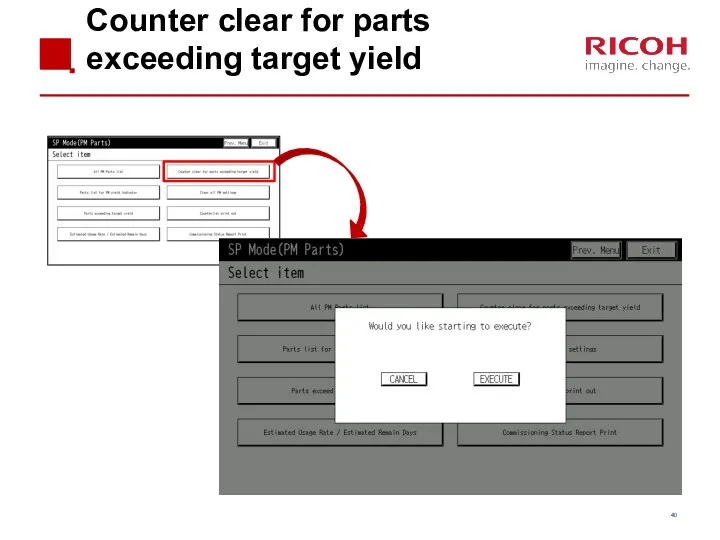

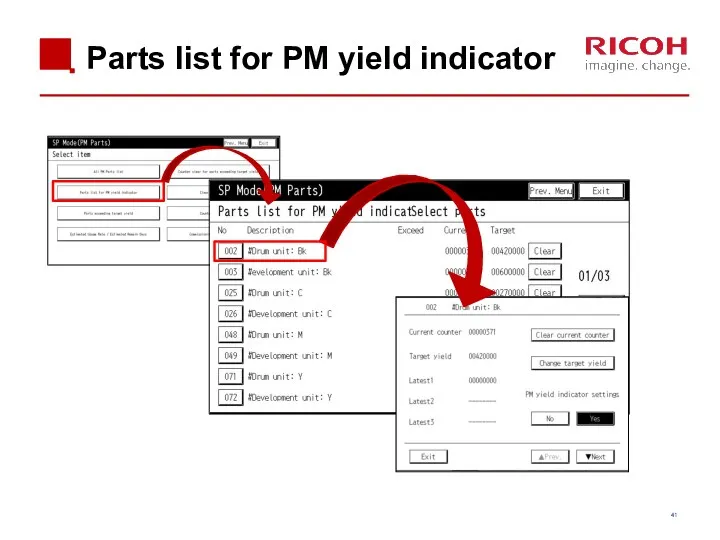

- 41. Parts list for PM yield indicator

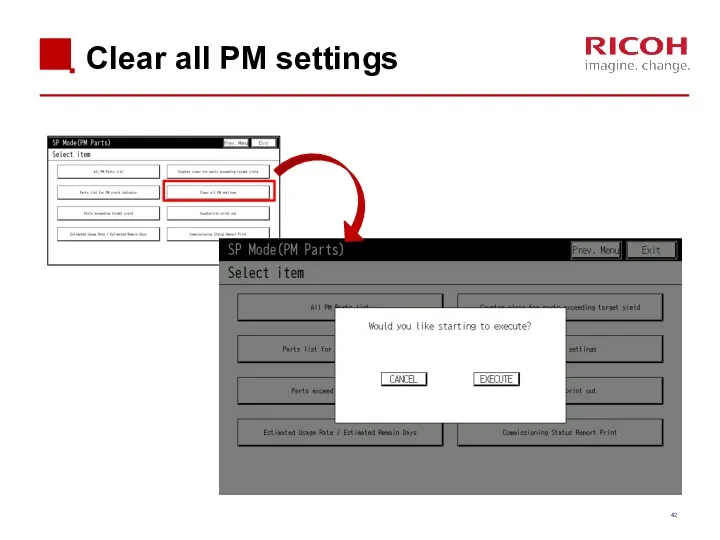

- 42. Clear all PM settings

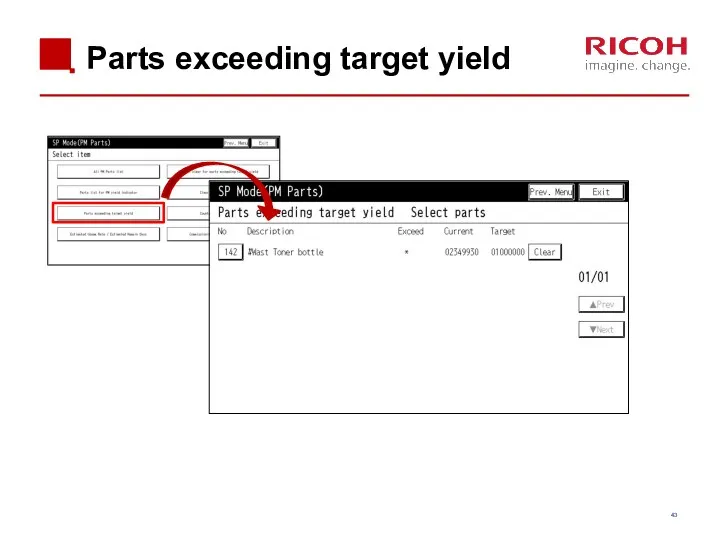

- 43. Parts exceeding target yield

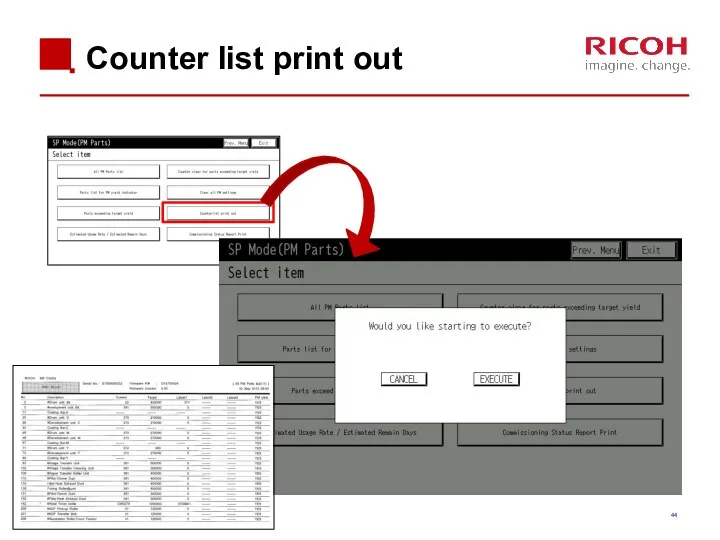

- 44. Counter list print out

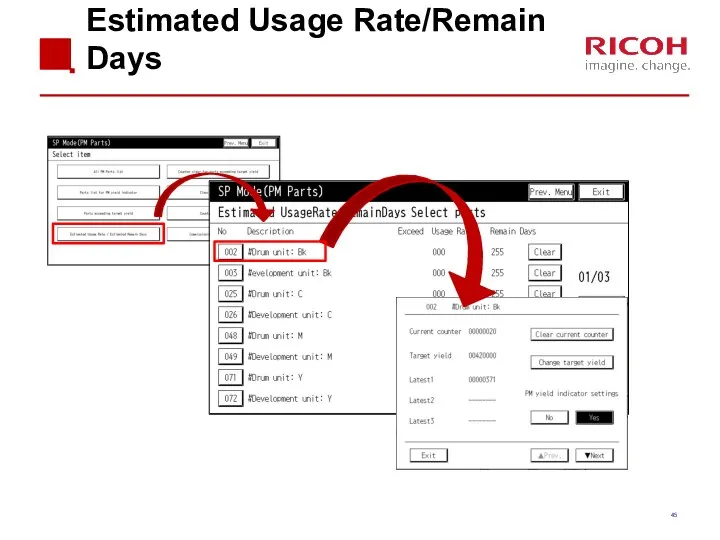

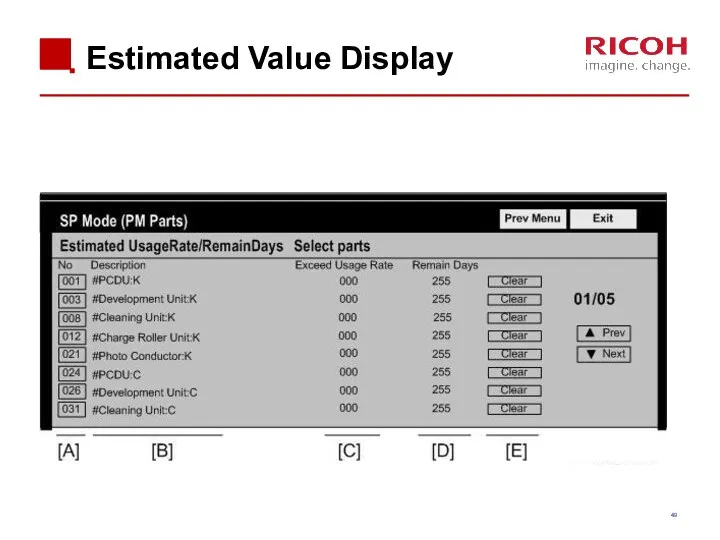

- 45. Estimated Usage Rate/Remain Days

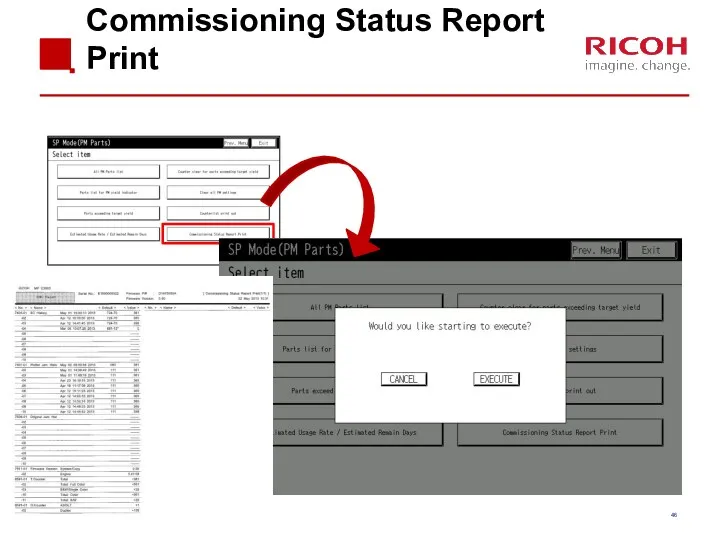

- 46. Commissioning Status Report Print

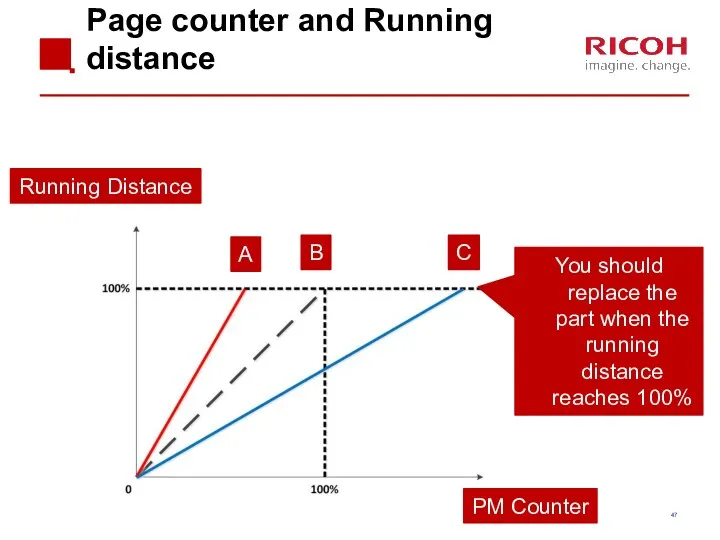

- 47. Page counter and Running distance PM Counter Running Distance A B C You should replace the

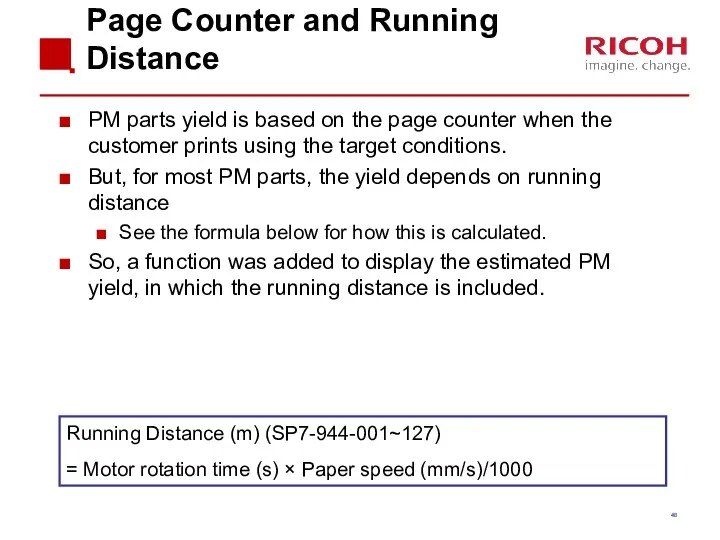

- 48. Page Counter and Running Distance PM parts yield is based on the page counter when the

- 49. Estimated Value Display

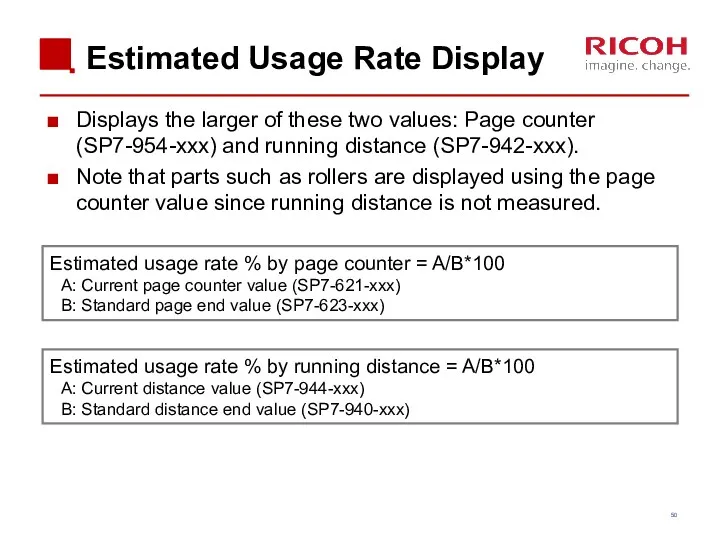

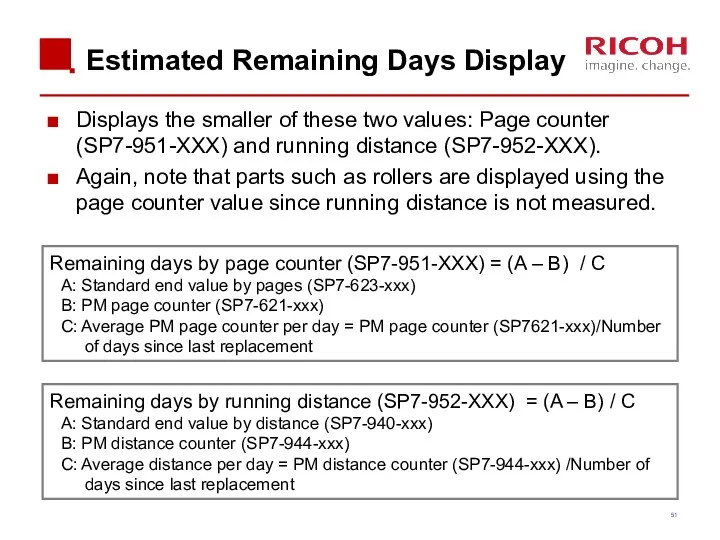

- 50. Estimated Usage Rate Display Displays the larger of these two values: Page counter (SP7-954-xxx) and running

- 51. Estimated Remaining Days Display Displays the smaller of these two values: Page counter (SP7-951-XXX) and running

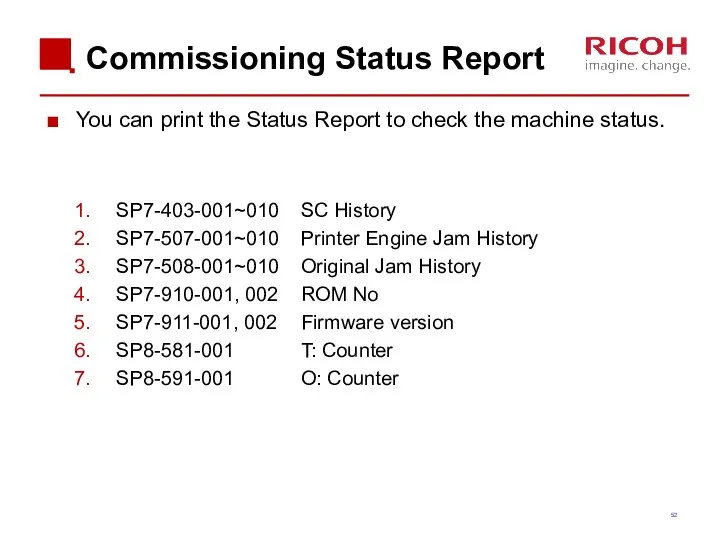

- 52. Commissioning Status Report You can print the Status Report to check the machine status. SP7-403-001~010 SC

- 53. 4. Detailed Section Descriptions

- 54. Chapter Overview 4.1 Machine Overview 4.2 Scanner 4.3 Laser Unit 4.4 PCDU 4.5 Toner Supply 4.6

- 55. 4.1 Machine Overview

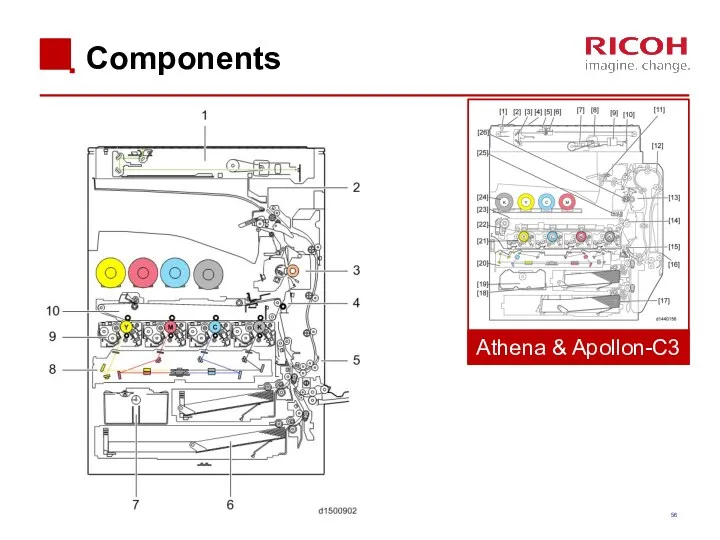

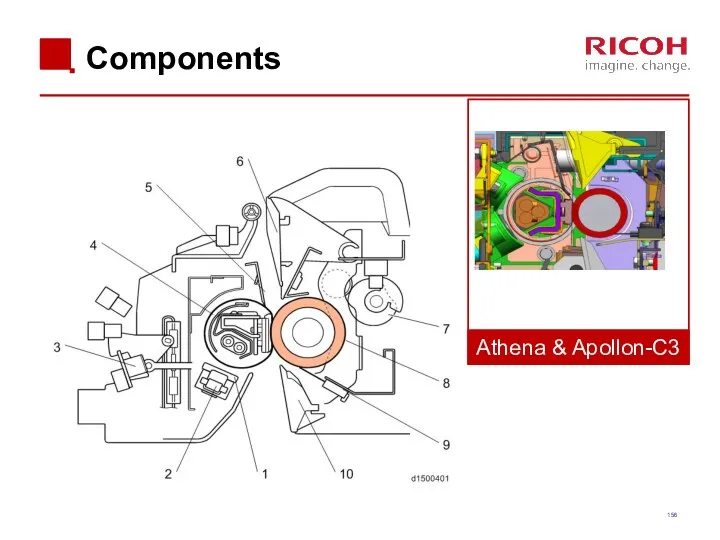

- 56. Components Athena & Apollon-C3

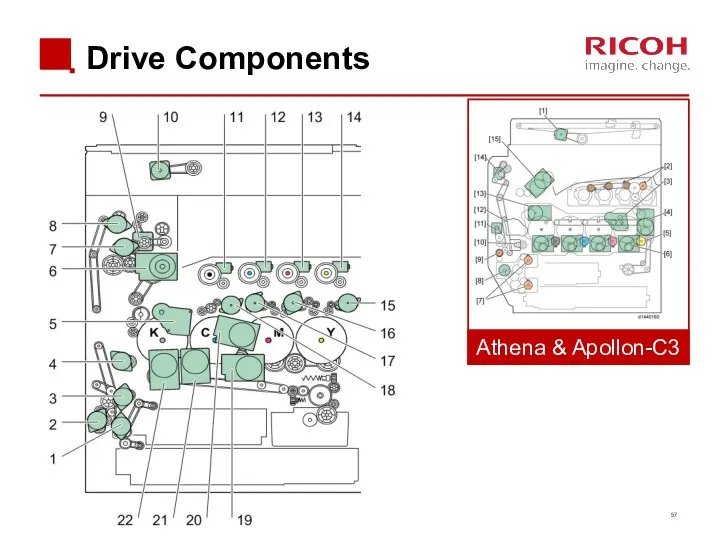

- 57. Drive Components Athena & Apollon-C3

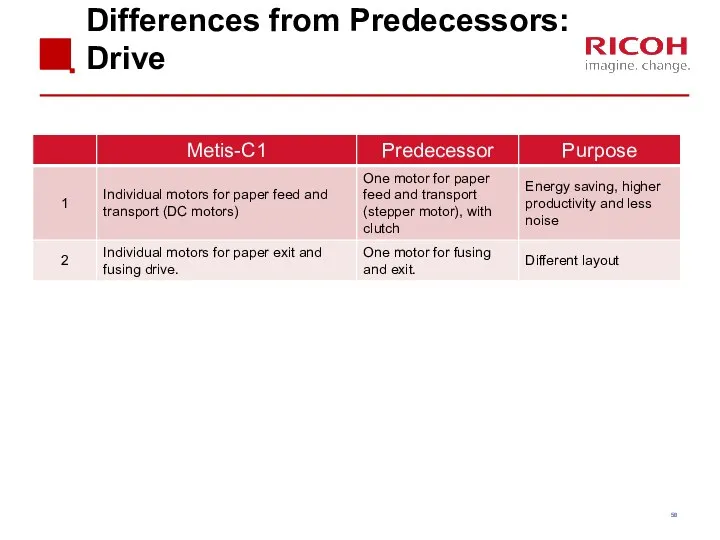

- 58. Differences from Predecessors: Drive

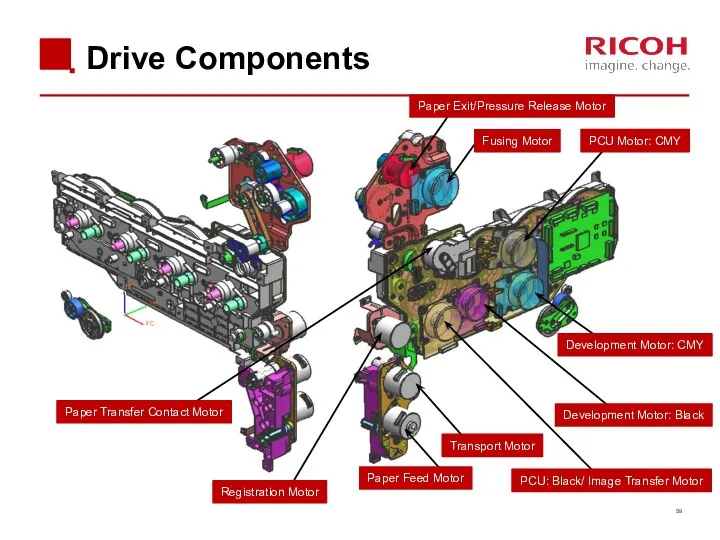

- 59. Drive Components Paper Feed Motor Transport Motor Registration Motor Paper Transfer Contact Motor Fusing Motor Development

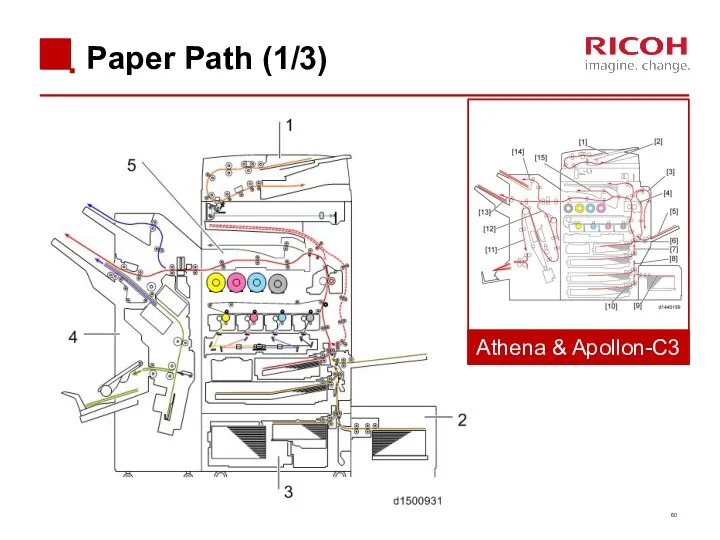

- 60. Paper Path (1/3) Athena & Apollon-C3

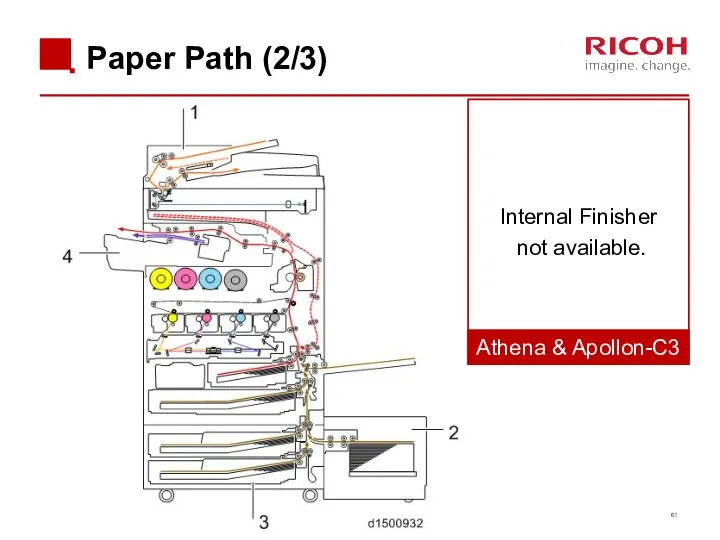

- 61. Paper Path (2/3) Athena & Apollon-C3 Internal Finisher not available.

- 62. Paper Path (3/3)

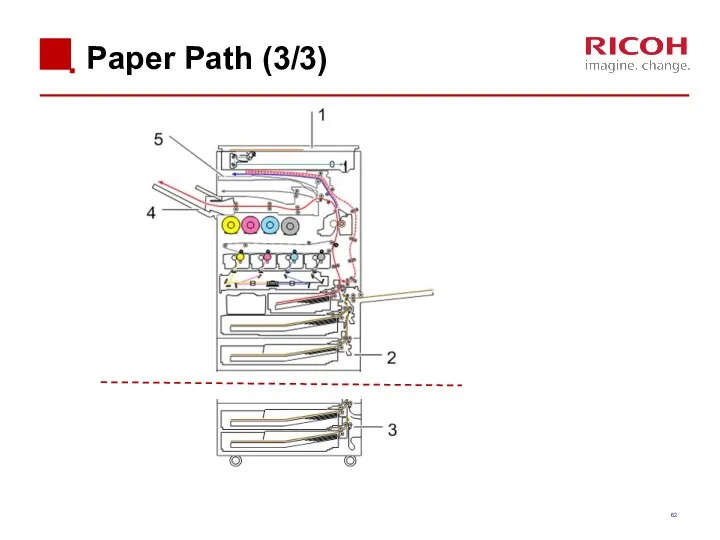

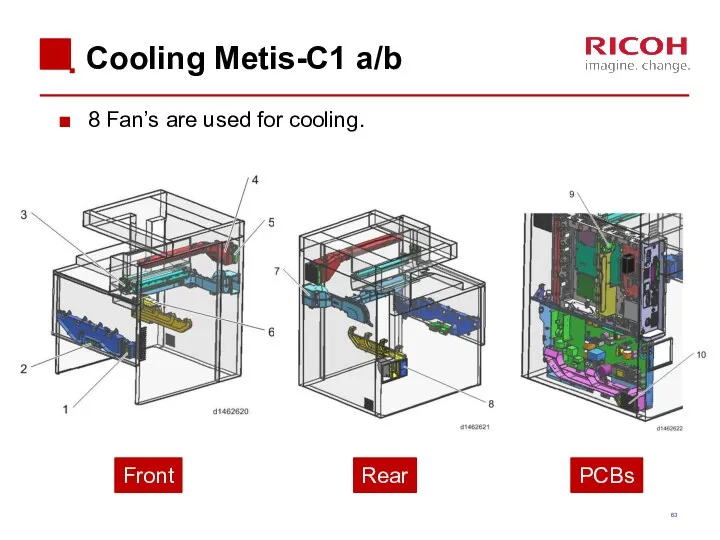

- 63. Cooling Metis-C1 a/b 8 Fan’s are used for cooling. Front Rear PCBs

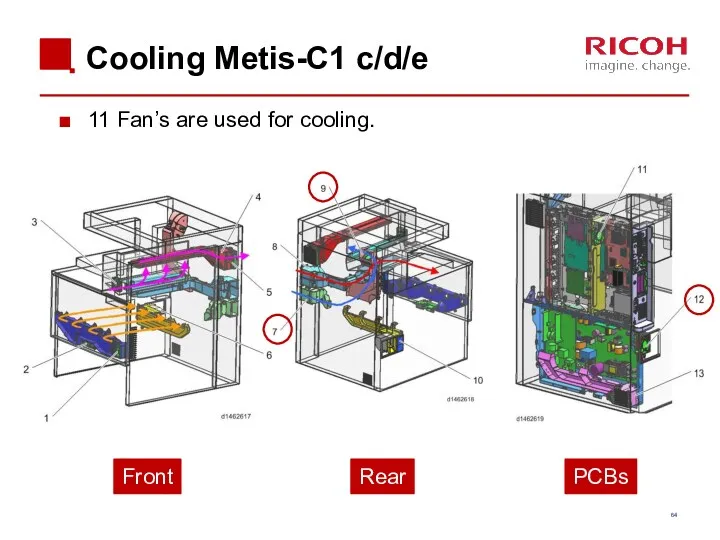

- 64. Cooling Metis-C1 c/d/e 11 Fan’s are used for cooling. Front Rear PCBs

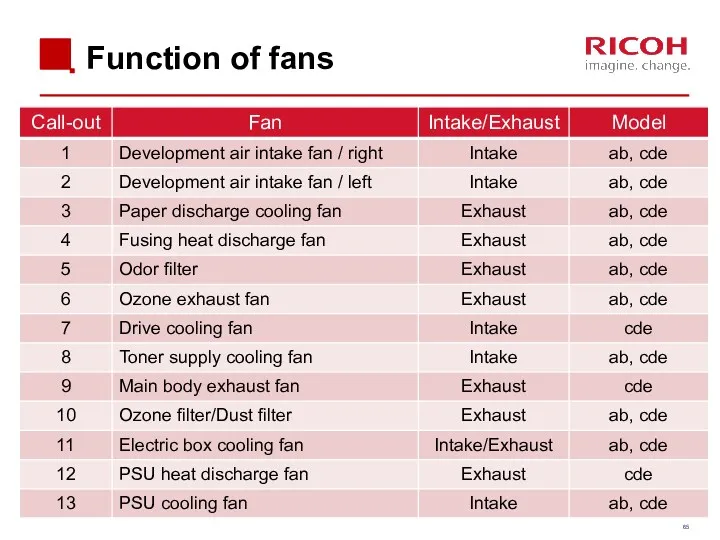

- 65. Function of fans

- 66. Cooling Notes Toner supply cooling duct: The shape of the duct for Met-C1c/d/e is different from

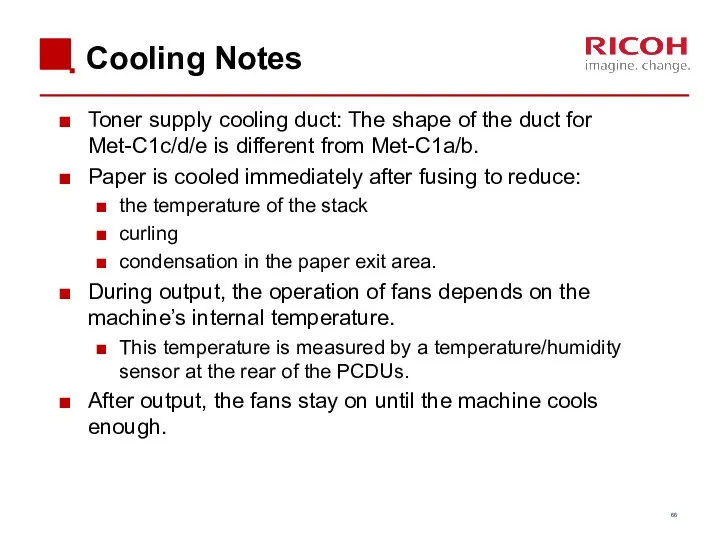

- 67. Differences from Predecessors: Electrical Components

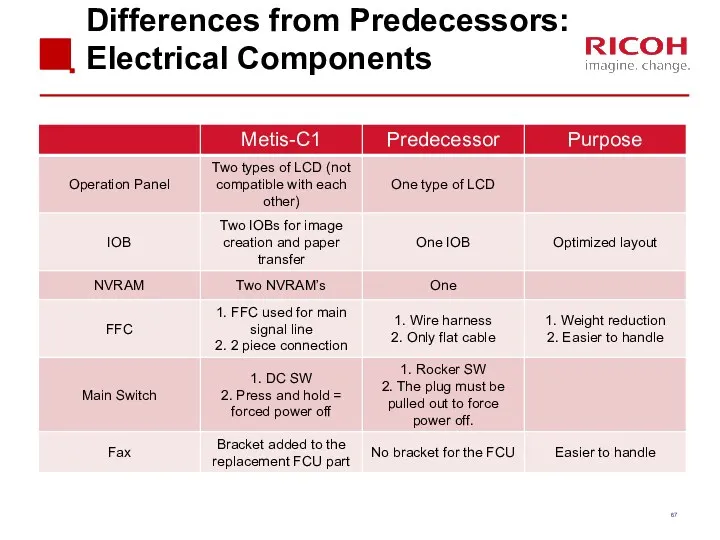

- 68. Locations of PCBs Inside the Controller Box IPU Sub (only if an SPDF is present) IPU

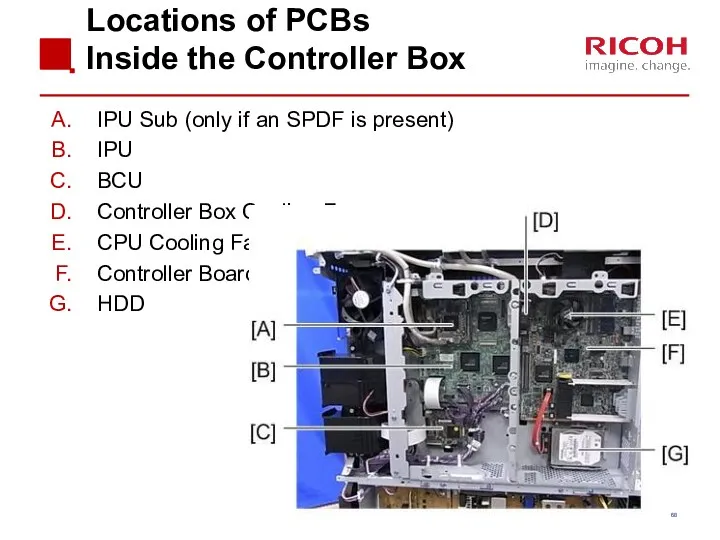

- 69. Locations of PCBs Behind the Controller Box HVP_TTS Imaging IOB

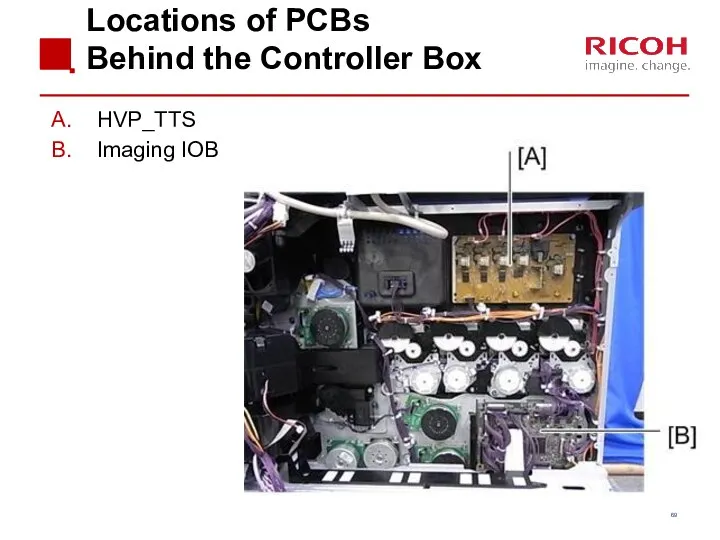

- 70. Locations of PCBs Inside the Power Box PSU (AC controller board) PSU (DC Power) PSU Cooling

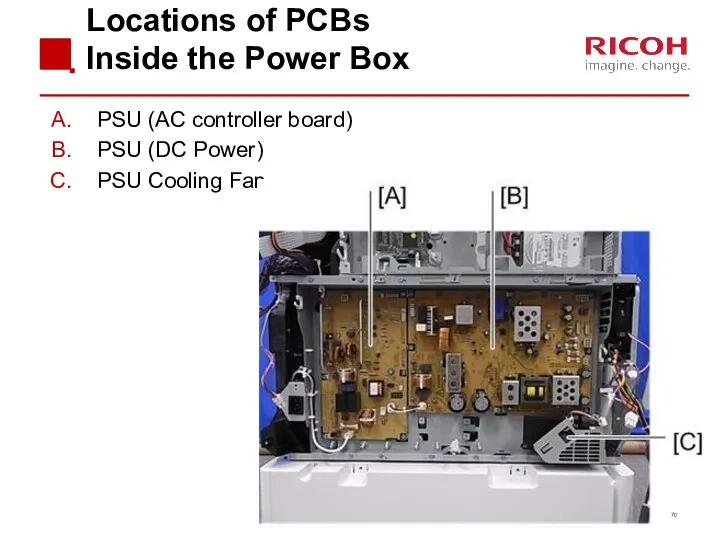

- 71. Locations of PCBs Behind the Power Box HVP_CB Paper Transport IOB

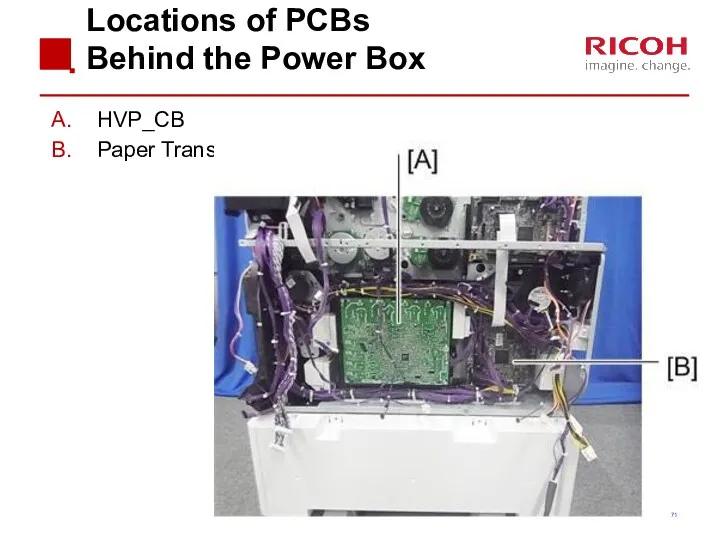

- 72. Differences from Predecessors: Servicing

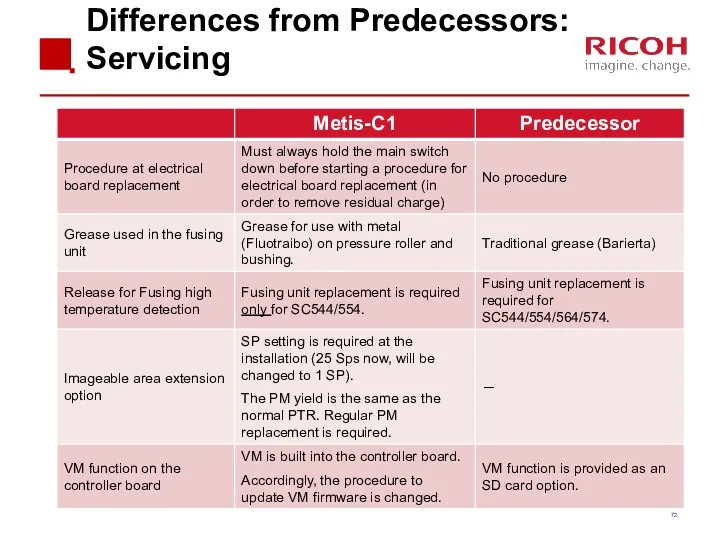

- 73. Switch off procedure Push the power switch [A] on the machine. Wait until the shut-off screen

- 74. Starting the machine again To start the machine, press the main power switch. If you press

- 75. Forced Shutdown In case normal shutdown does not complete, the machine has a forced shutdown function.

- 76. Replacement of parts Some of the covers have tabs on them which break easily. The procedures

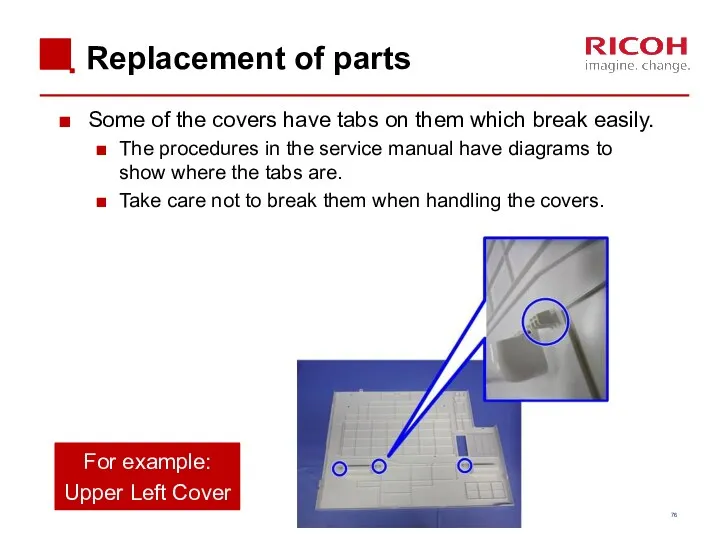

- 77. LCD Panel (1/2) LCD panels from two different vendors are used. Depending on which type is

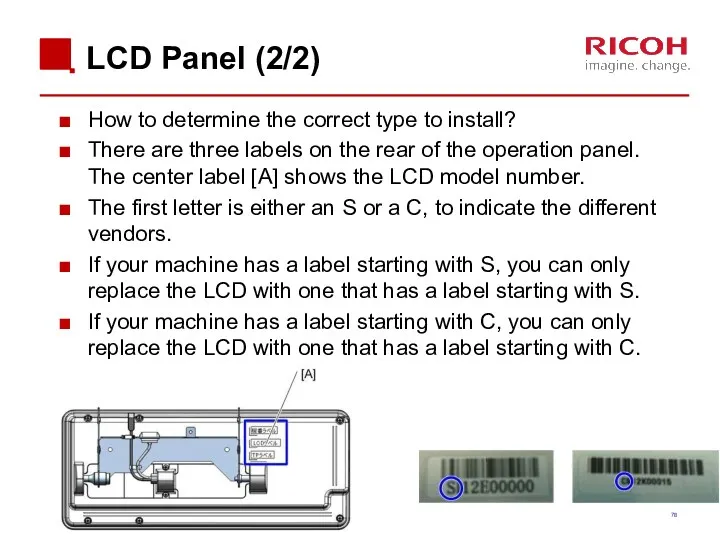

- 78. LCD Panel (2/2) How to determine the correct type to install? There are three labels on

- 79. Replacing NVRAMs on the Controller Board Make sure that the NVRAMs are installed in the correct

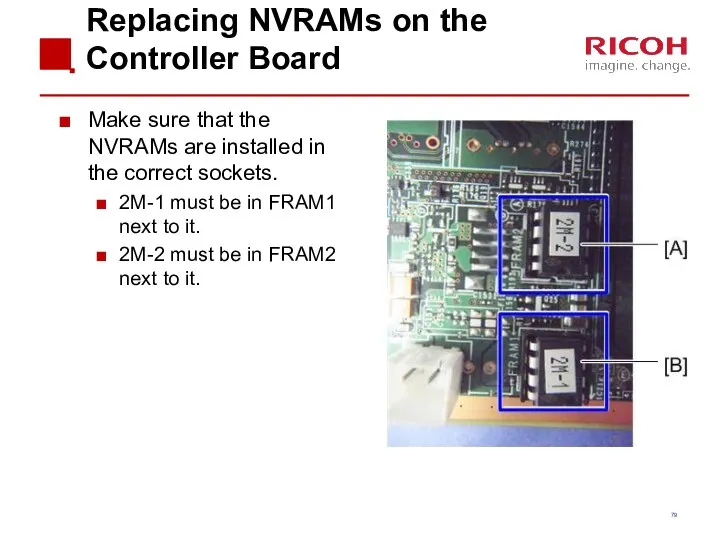

- 80. 4.2 Scanner

- 81. Differences from Predecessors: Scanner unit

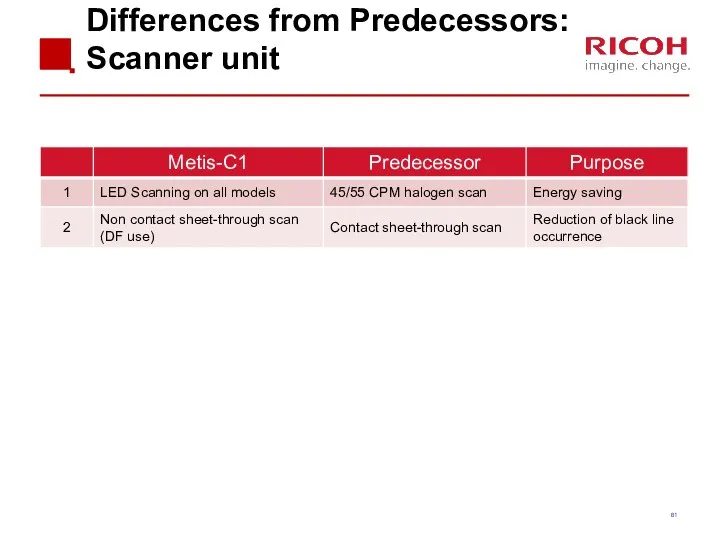

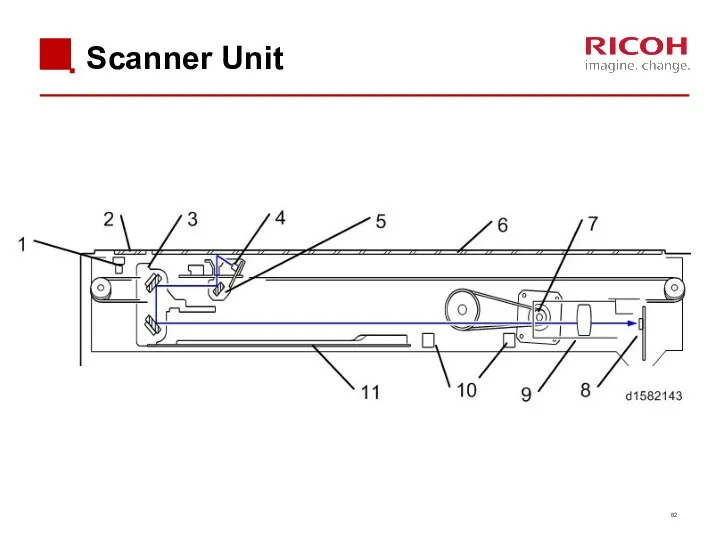

- 82. Scanner Unit

- 83. DF exposure glass Originals may cause streaks on the exposure glass. To prevent these streaks non-contact

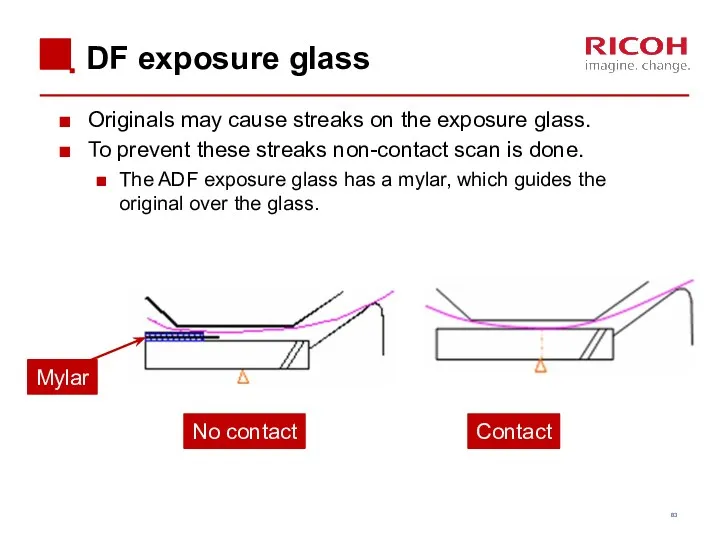

- 84. Dust Detection – Overview This function checks the ADF exposure glass for dust that can cause

- 85. Dust Detection (SP 4-020) SP 4-020-001: Enable/disable (default – disabled) SP 4-020-002: Sensitivity adjustment SP 4-020-003:

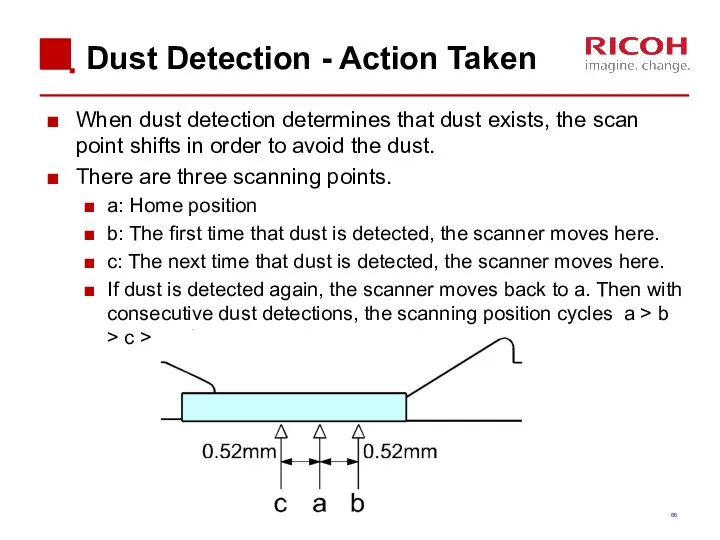

- 86. Dust Detection - Action Taken When dust detection determines that dust exists, the scan point shifts

- 87. Laser Unit

- 88. Differences from Predecessors: Laser unit

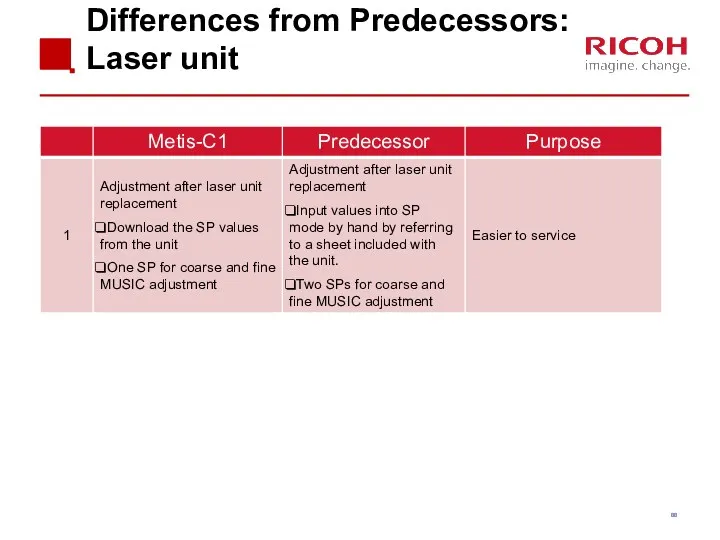

- 89. Overview

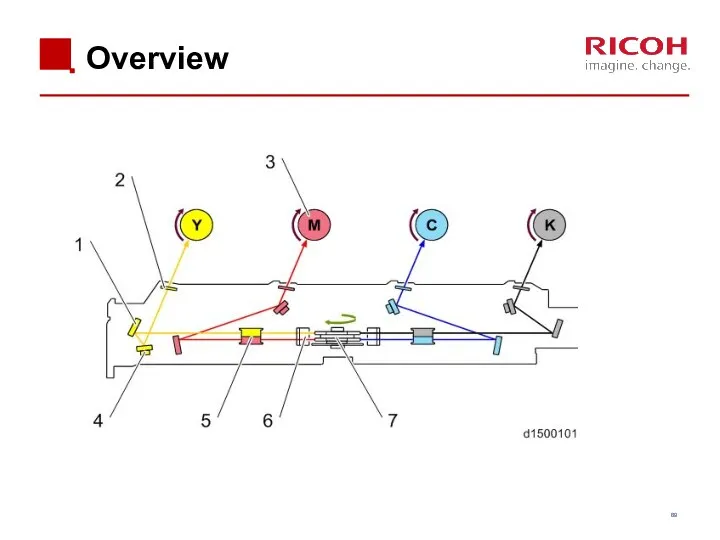

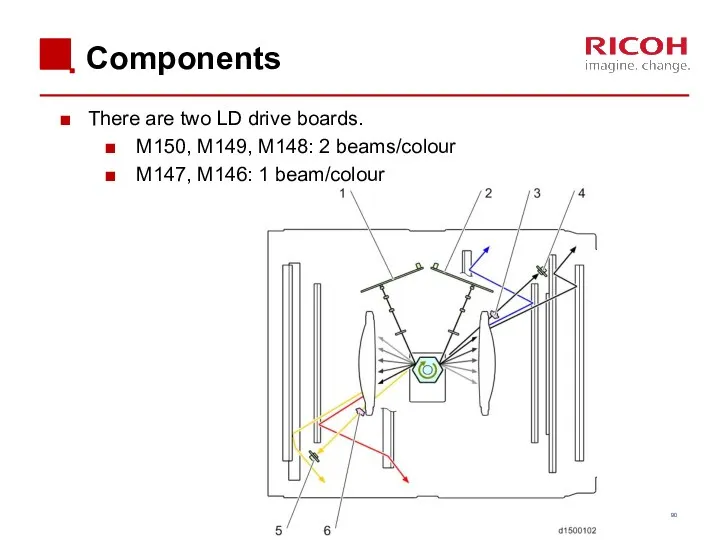

- 90. Components There are two LD drive boards. M150, M149, M148: 2 beams/colour M147, M146: 1 beam/colour

- 91. Skew Adjustment The 2nd mirrors for C, M, and Y have a motor to adjust the

- 92. Replacing the Laser Unit After installing the new unit: Disconnect the skew correction motor harness. Execute

- 93. PCDU

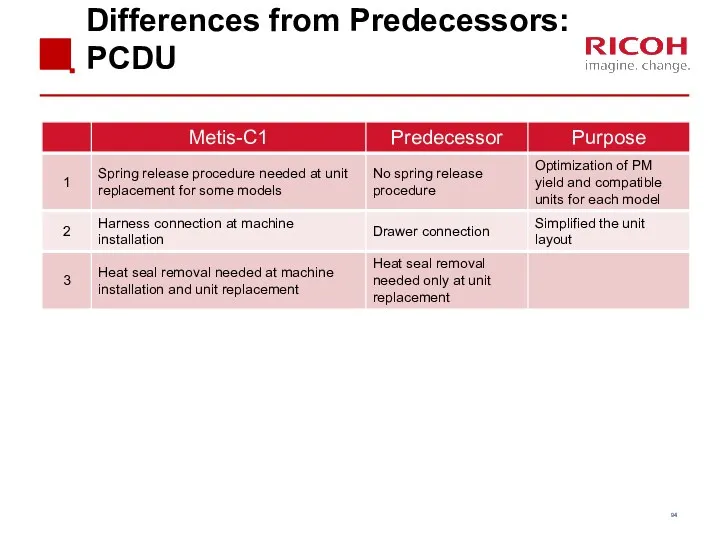

- 94. Differences from Predecessors: PCDU

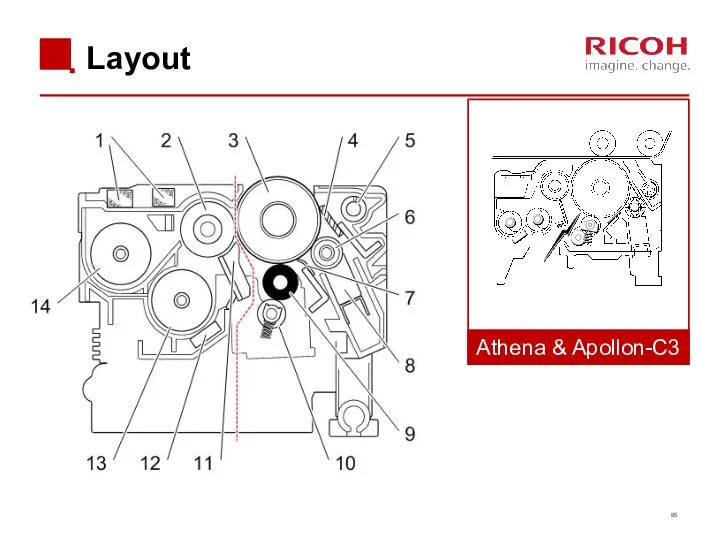

- 95. Layout Athena & Apollon-C3

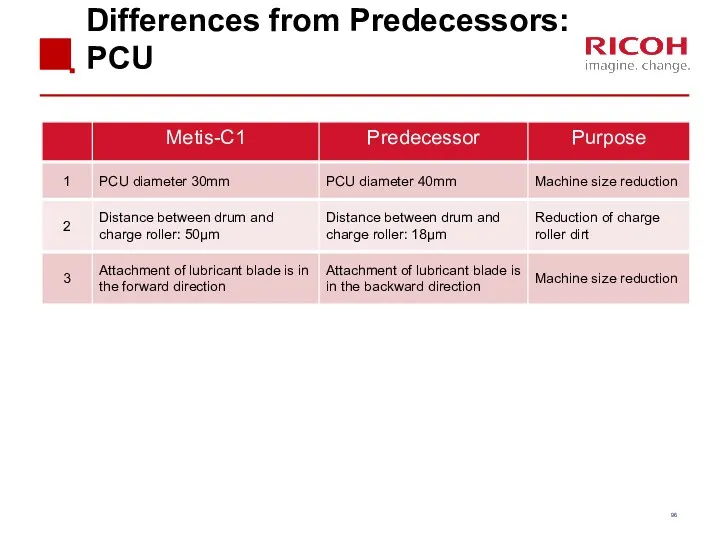

- 96. Differences from Predecessors: PCU

- 97. Differences from Predecessors: Development

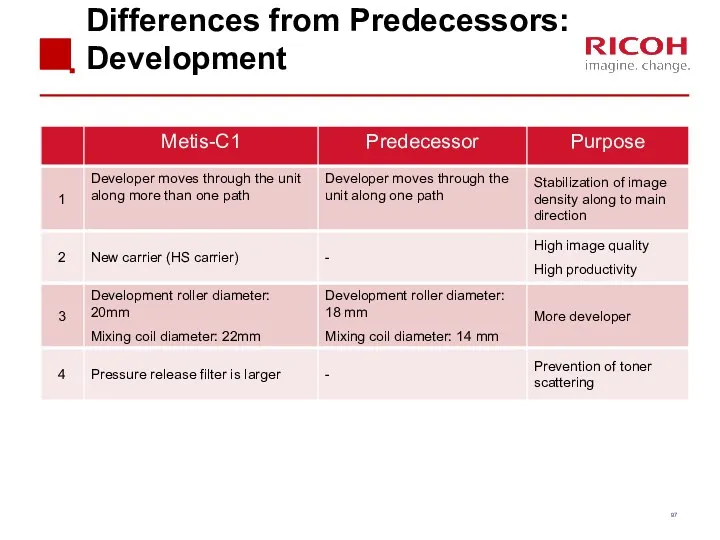

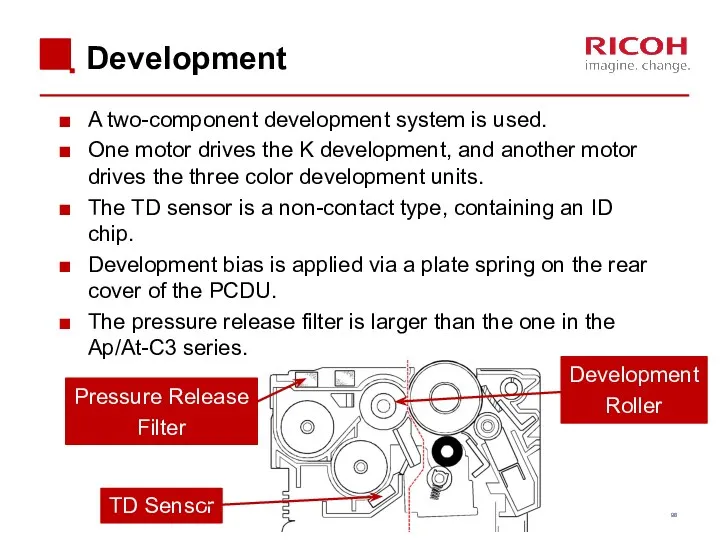

- 98. Development A two-component development system is used. One motor drives the K development, and another motor

- 99. Development Unit Components

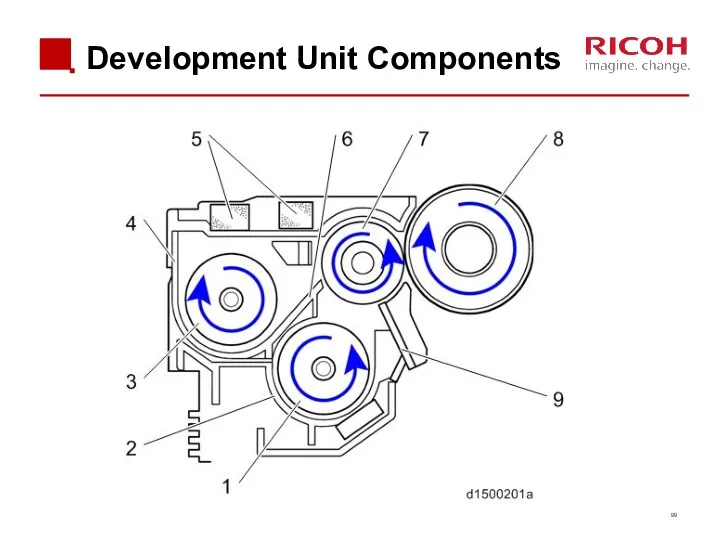

- 100. Replacing Note for PCDU or PCU Before replacing a PCU or PCDU, set SP3-701 to "1"

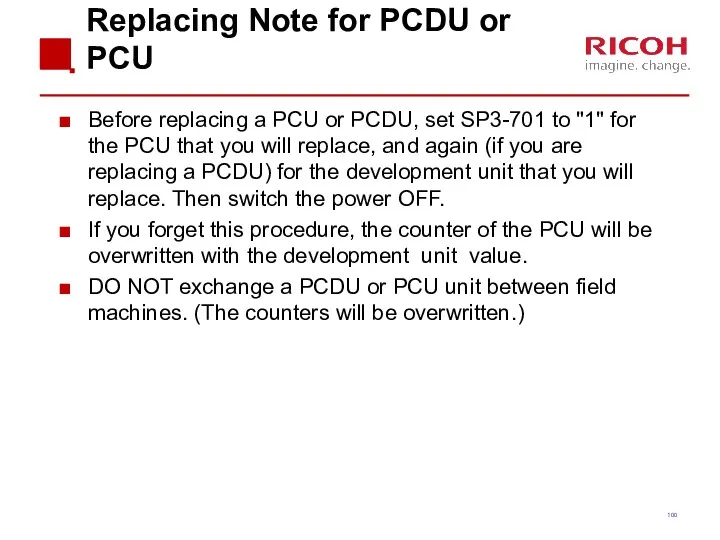

- 101. Replacement (1/3) Take care not to damage the part of the rear end block shown by

- 102. Replacement (2/3) If you join the drum unit and development unit while pressing the charge roller,

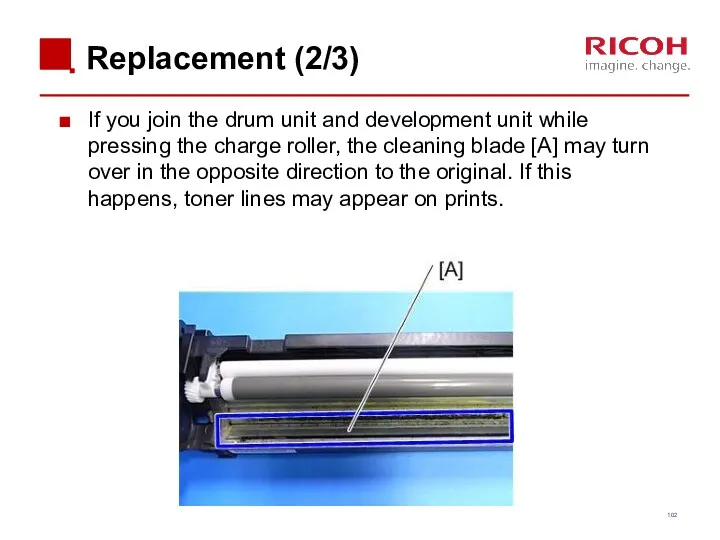

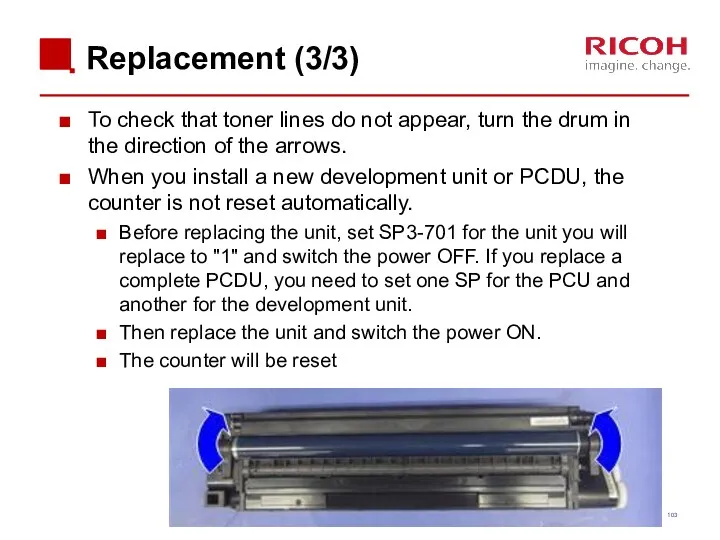

- 103. Replacement (3/3) To check that toner lines do not appear, turn the drum in the direction

- 104. Replacing the PCDU / PCU on a D149 or D150 An additional procedure is required when

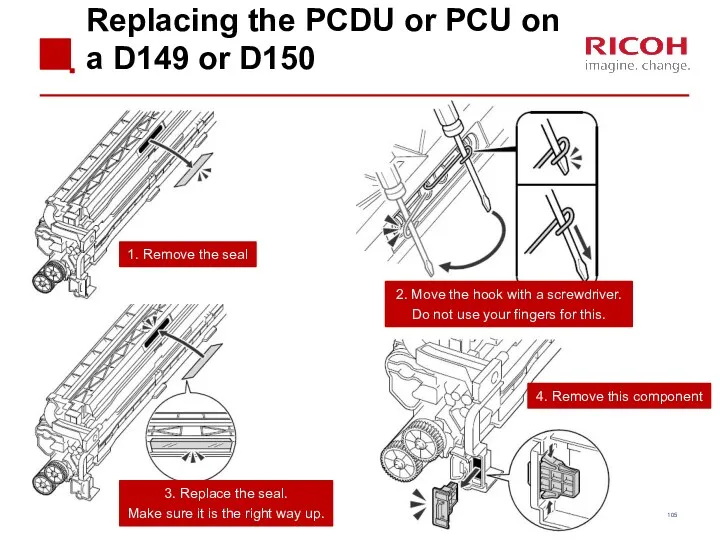

- 105. Replacing the PCDU or PCU on a D149 or D150 1. Remove the seal 2. Move

- 106. Toner Supply

- 107. Differences from Predecessors: Toner Supply

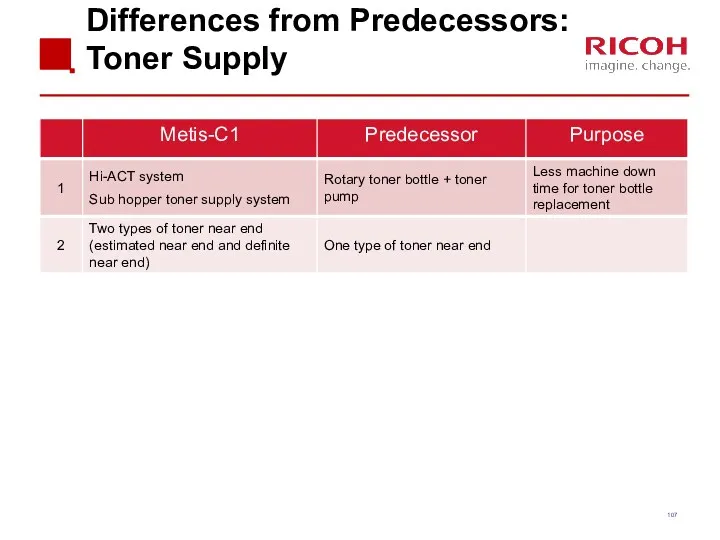

- 108. Layout Athena & Apollon-C3

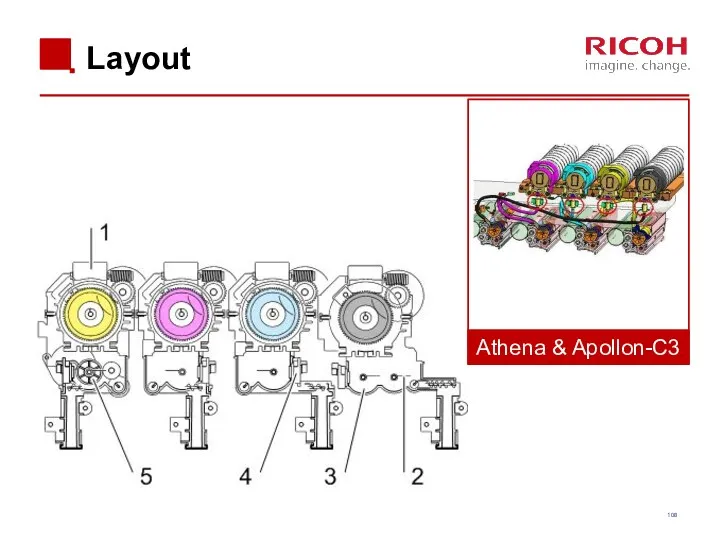

- 109. From bottle to sub hopper (1/2) When toner end is detected, the toner in the bottle

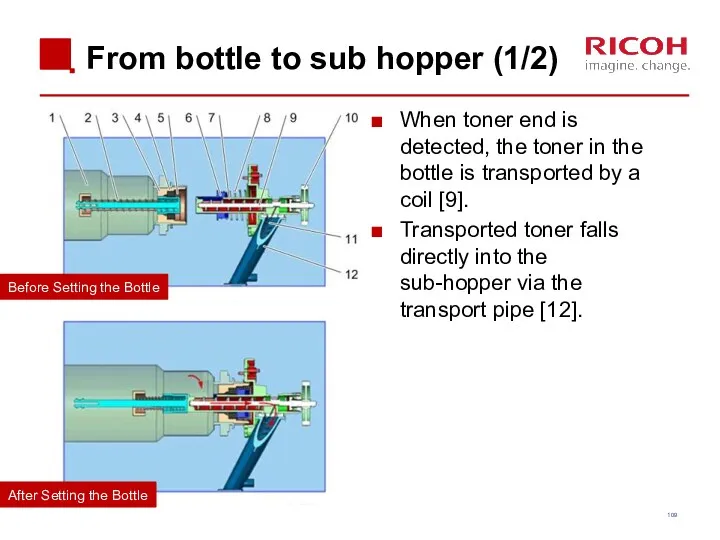

- 110. From bottle to sub hopper (2/2) To prevent toner from remaining, a spring [A] in the

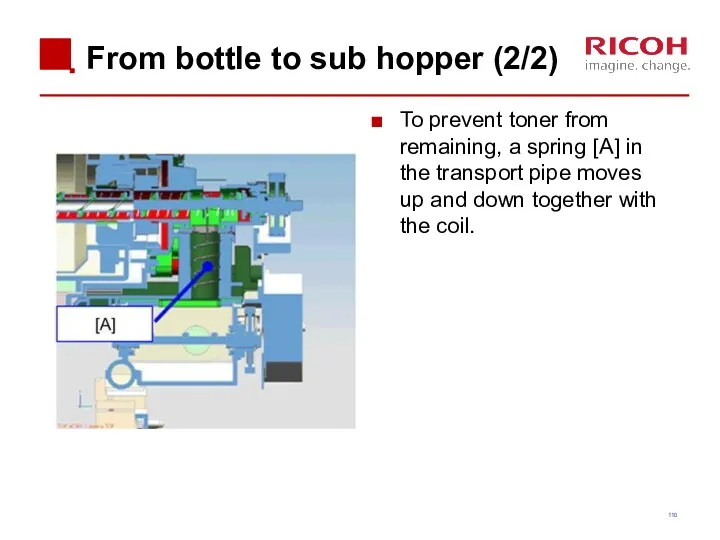

- 111. Toner Near-end Detection The machine estimates the amount of toner remaining in the cartridge using two

- 112. ‘Estimated Toner Near-end’ If the amount of remaining toner falls below a certain limit (SP3-110-001 to

- 113. ‘Definite Toner Near-end’ If the amount of remaining toner falls below a certain limit (SP3-120-001 to

- 114. Definite Toner Near-end detection The machine checks the toner end sensor every 200 ms while the

- 115. Toner End Detection After toner near-end is detected, the machine signals toner end if one of

- 116. Paper Feed

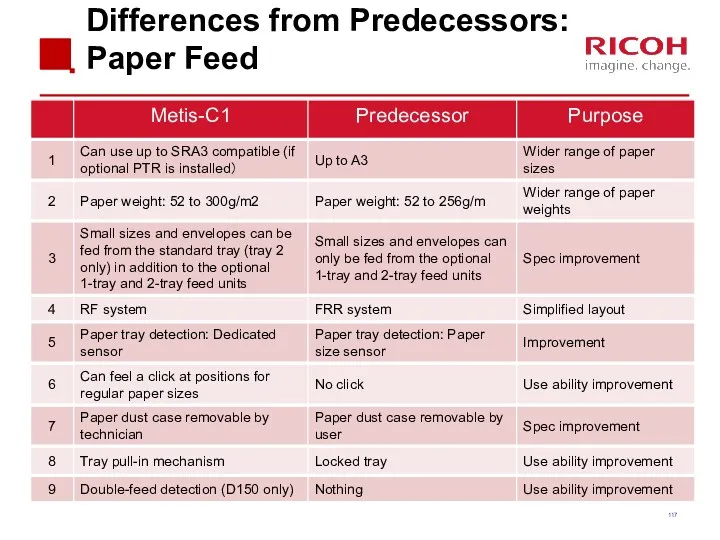

- 117. Differences from Predecessors: Paper Feed

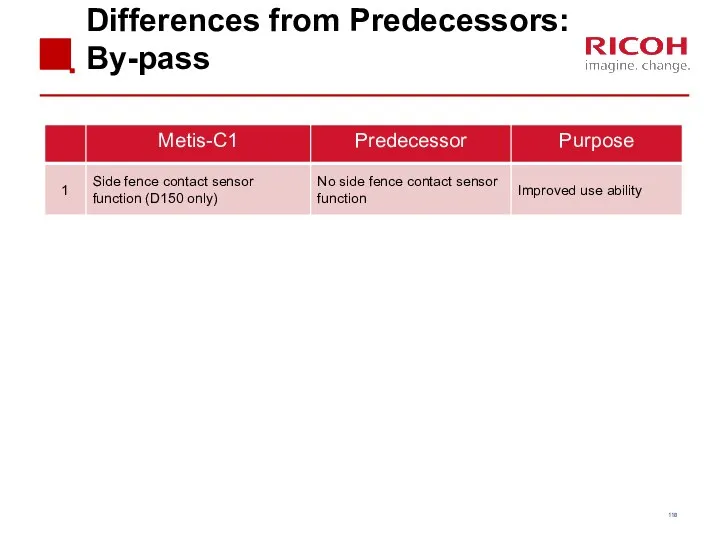

- 118. Differences from Predecessors: By-pass

- 119. Differences from Predecessors: Optional PFU

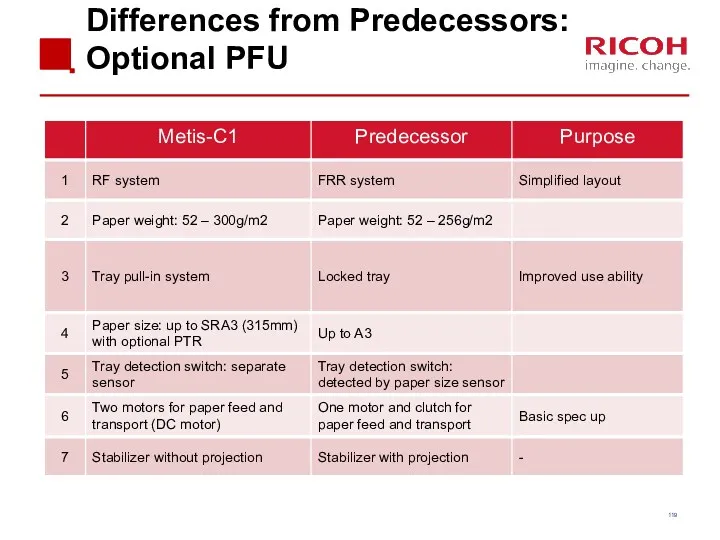

- 120. Differences from Predecessors: Tandem LCT

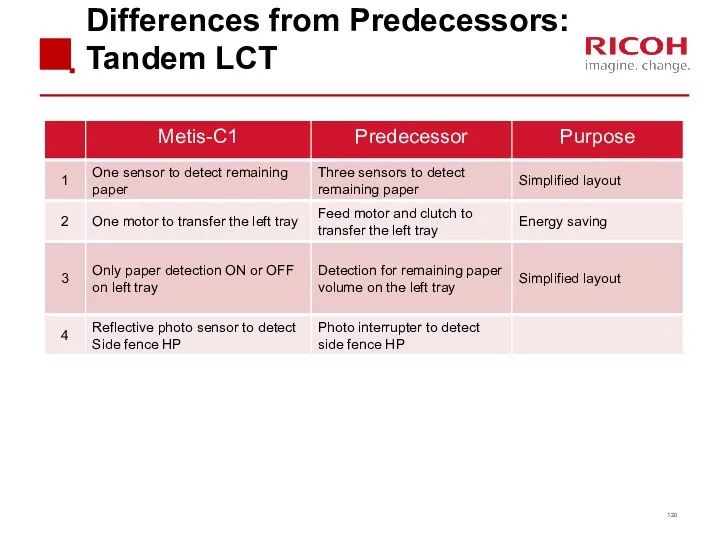

- 121. Differences from Predecessors: Side LCT

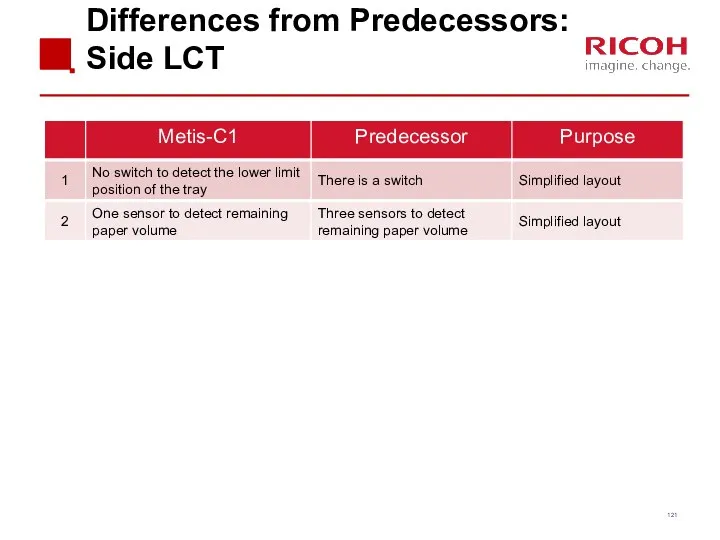

- 122. Overview

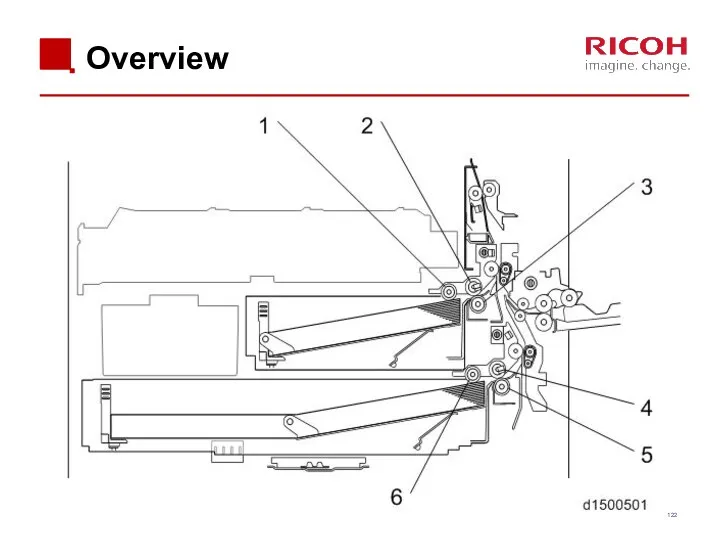

- 123. Drive (1) The paper feed motor(1) drives the pick-up and feed rollers in both trays. The

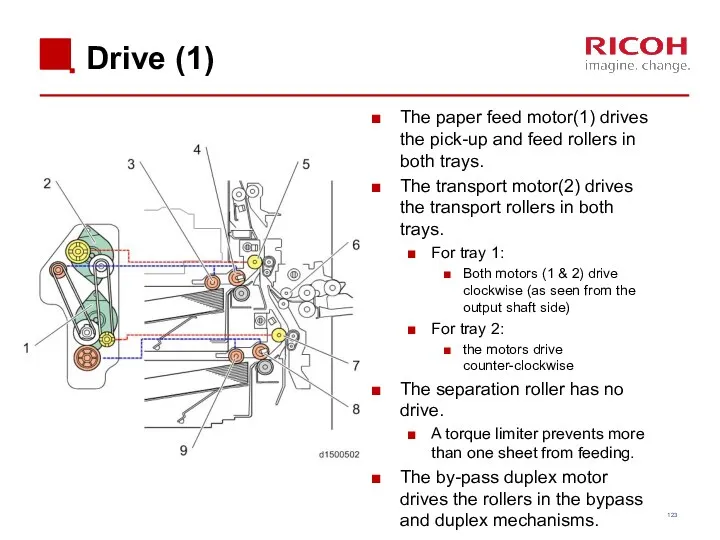

- 124. Bottom Plate Lift When the tray is removed, the coupling is released, and the base plate

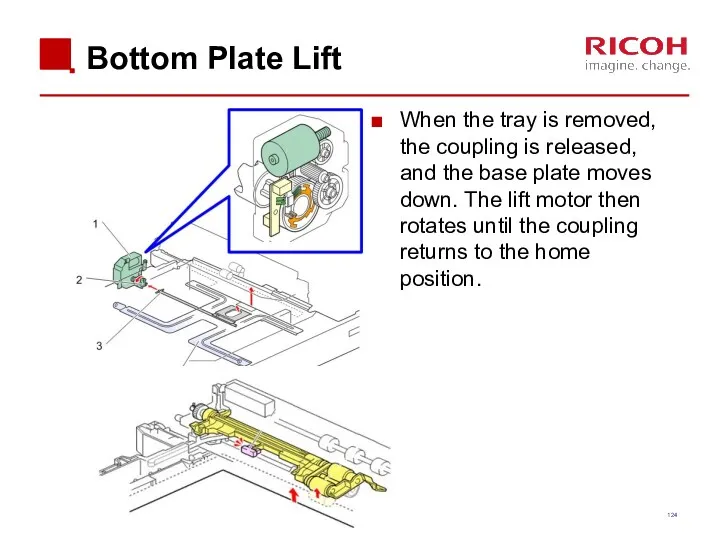

- 125. Remaining Paper Detection – Trays 1 and 2 The lift motor assembly contains two height sensors,

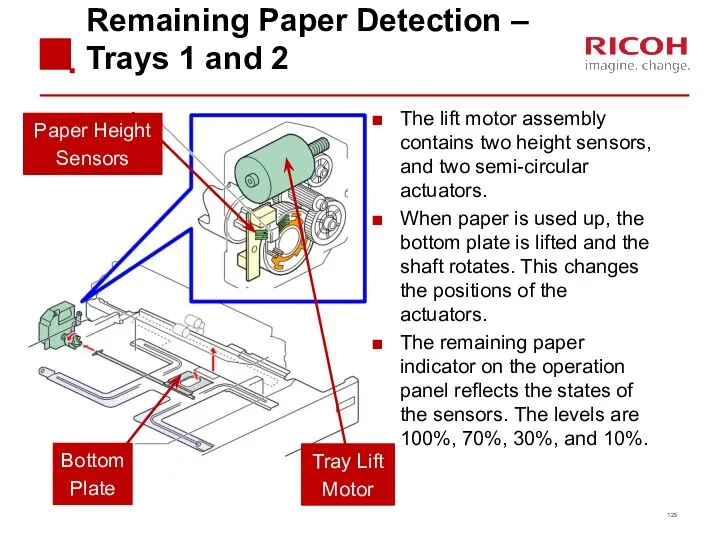

- 126. Paper Dust Removal A mylar sheet contacts the registration idle roller, and sends paper dust to

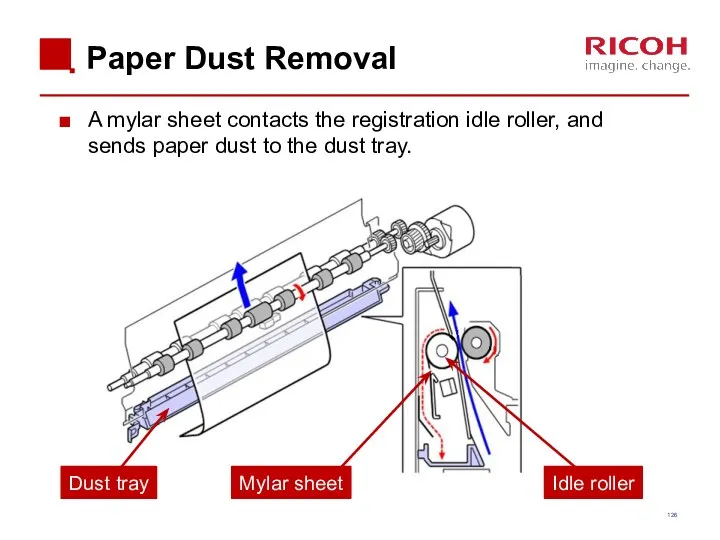

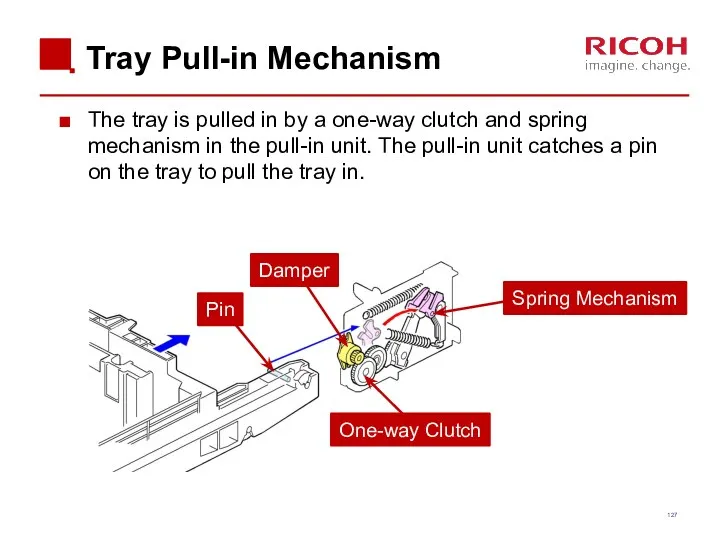

- 127. Tray Pull-in Mechanism The tray is pulled in by a one-way clutch and spring mechanism in

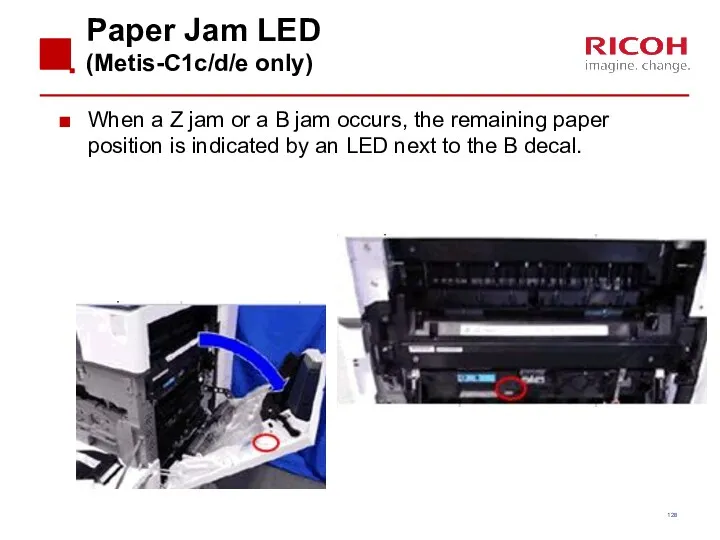

- 128. Paper Jam LED (Metis-C1c/d/e only) When a Z jam or a B jam occurs, the remaining

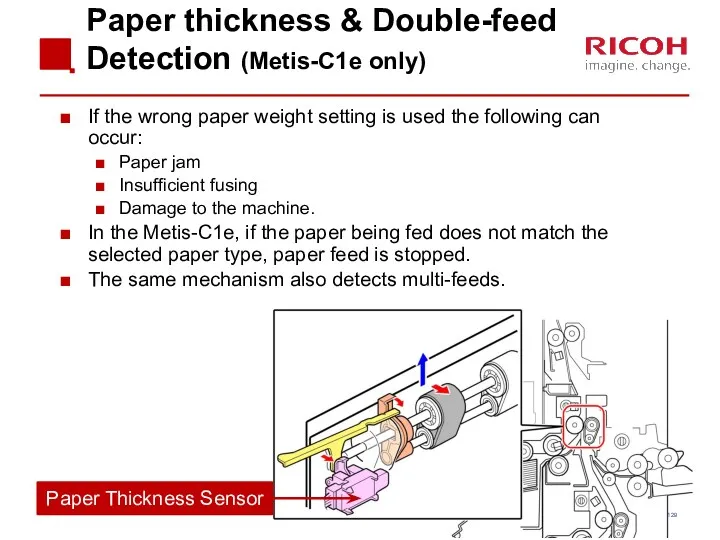

- 129. Paper thickness & Double-feed Detection (Metis-C1e only) If the wrong paper weight setting is used the

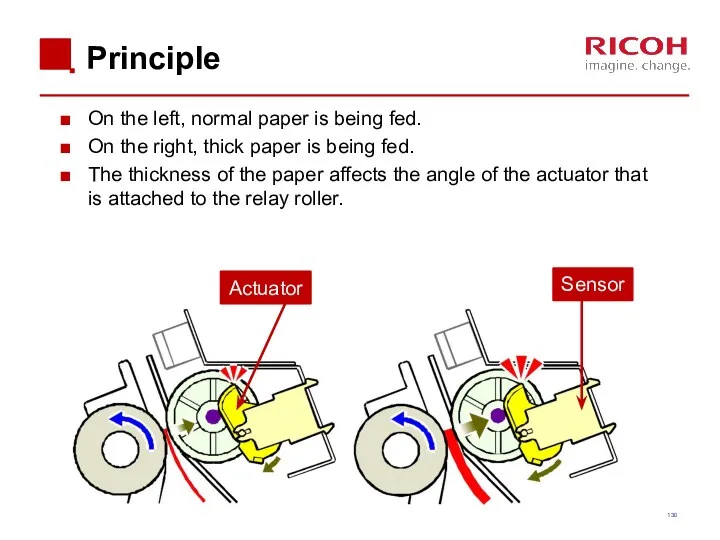

- 130. Principle On the left, normal paper is being fed. On the right, thick paper is being

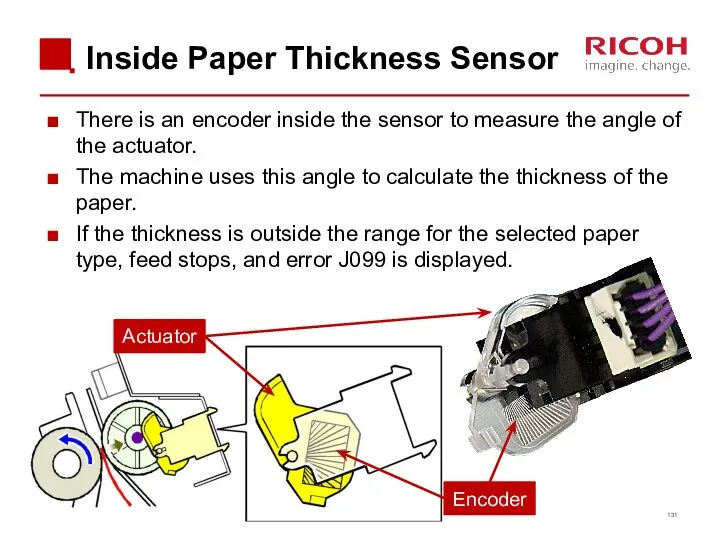

- 131. Inside Paper Thickness Sensor There is an encoder inside the sensor to measure the angle of

- 132. Double-feed Detection The machine compares the thickness of the current sheet with the previous sheet. If

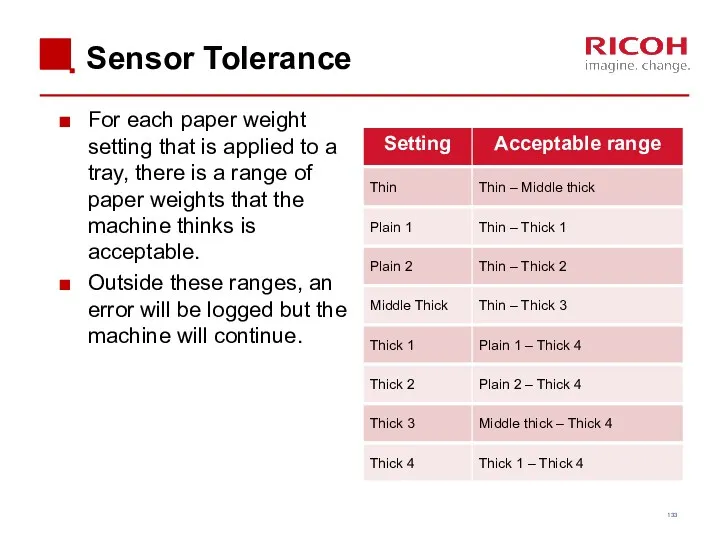

- 133. Sensor Tolerance For each paper weight setting that is applied to a tray, there is a

- 134. Paper Thickness Detection Other Points Sensor error detection The paper thickness sensor output value is measured

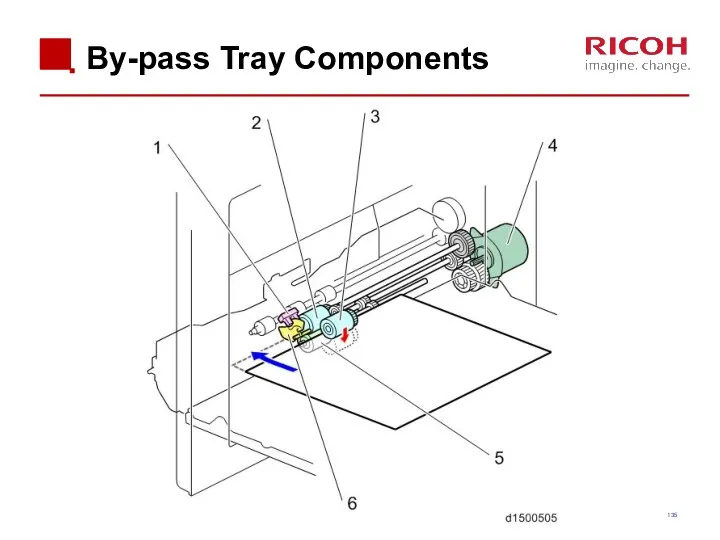

- 135. By-pass Tray Components

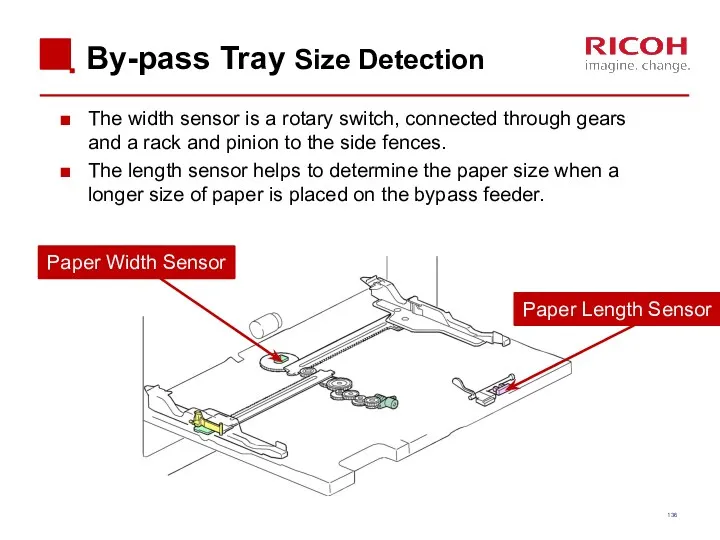

- 136. By-pass Tray Size Detection The width sensor is a rotary switch, connected through gears and a

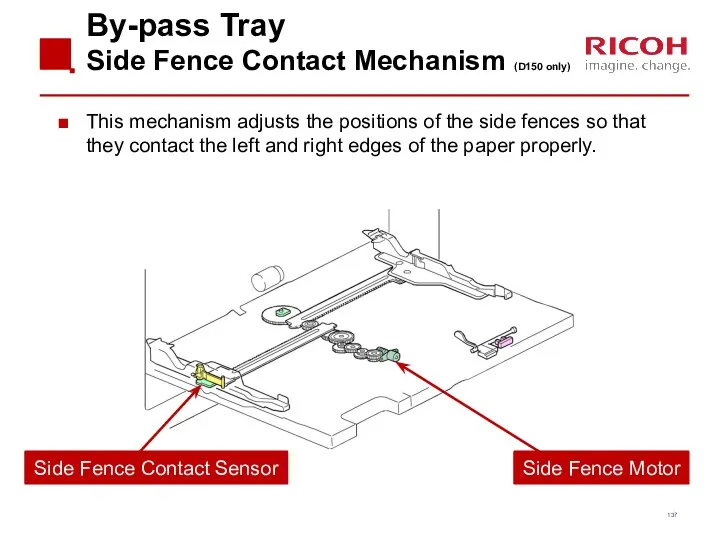

- 137. By-pass Tray Side Fence Contact Mechanism (D150 only) This mechanism adjusts the positions of the side

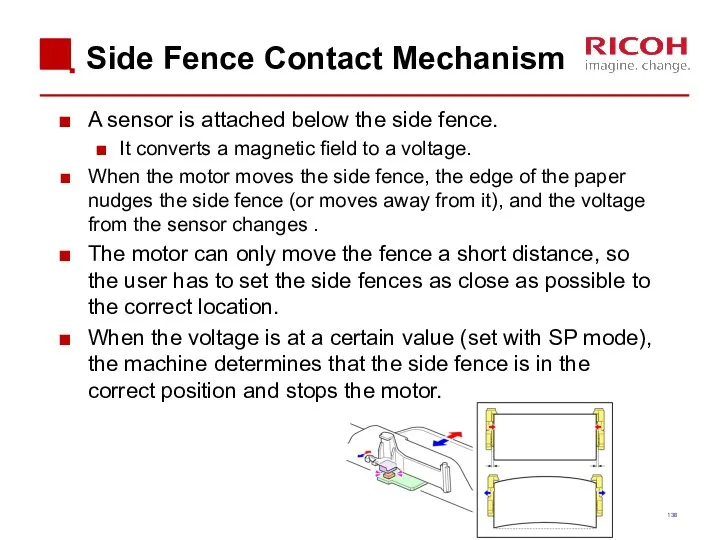

- 138. Side Fence Contact Mechanism A sensor is attached below the side fence. It converts a magnetic

- 139. Exercise Remove the 1st and 2nd paper feed unit and remove on the D150 the paper

- 140. Image Transfer

- 141. Differences from Predecessors: Image Transfer

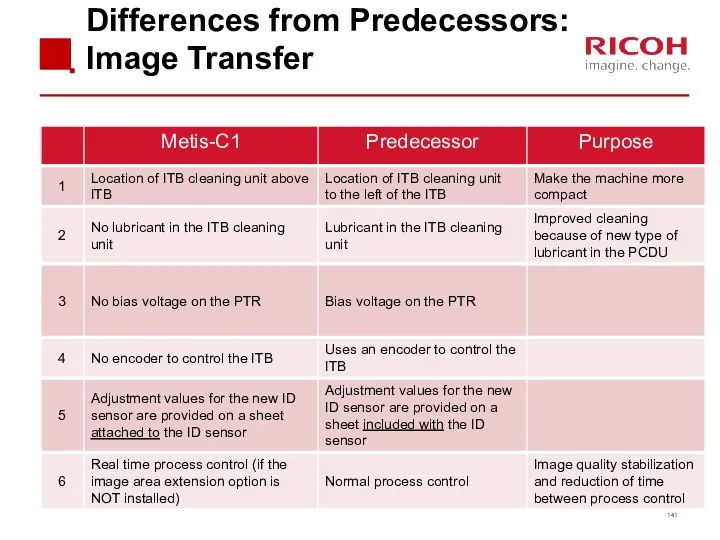

- 142. Overview Image Transfer Roller ITB Drive Roller Paper Transfer Roller ITB Cleaning Unit

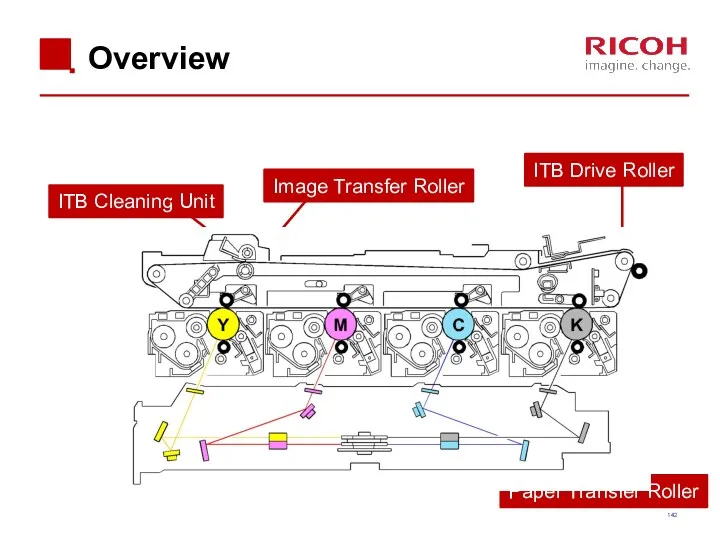

- 143. Drive The K drum motor drives the image transfer belt (ITB). The motor contains a monitoring

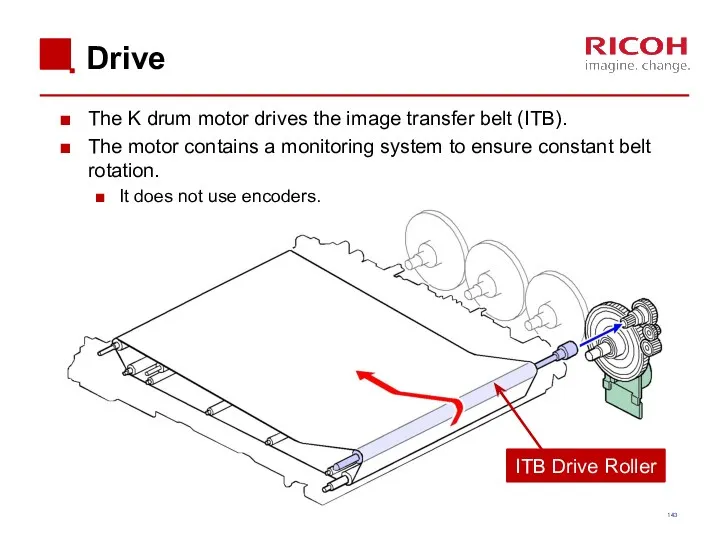

- 144. Power Supply Power is supplied to the image transfer rollers and the ITB drive roller from

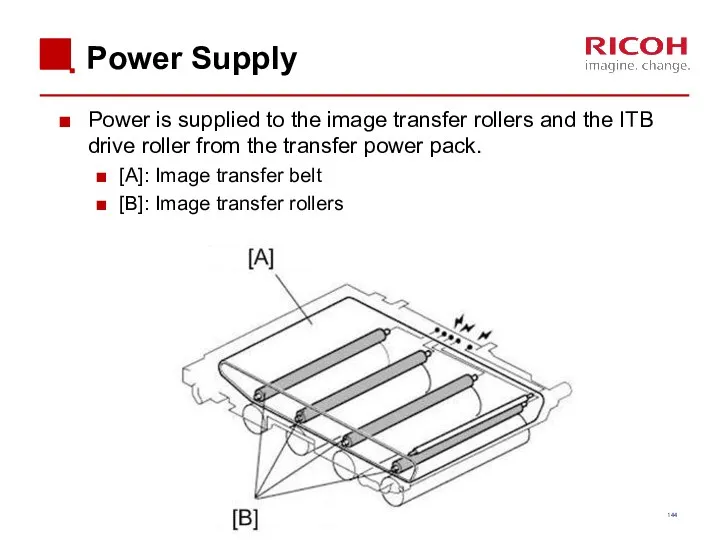

- 145. ITB Contact and Release The motor is also the toner supply motor for magenta. The direction

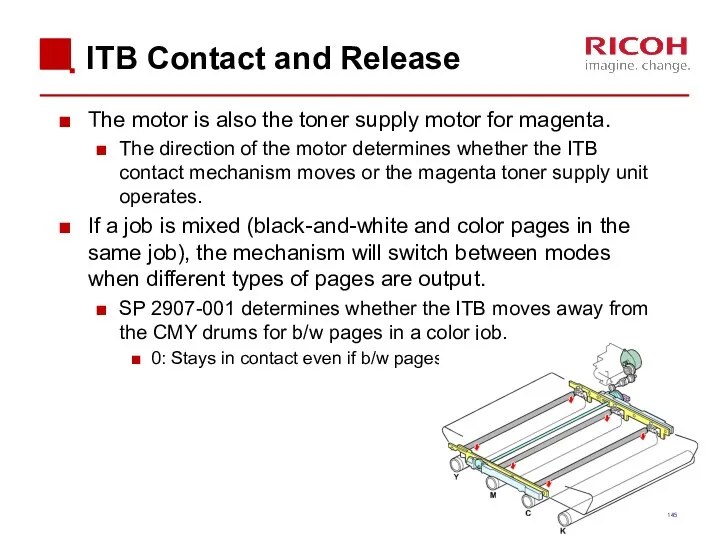

- 146. ITB Cleaning The cleaning unit is on top of the ITB unit. A counter blade is

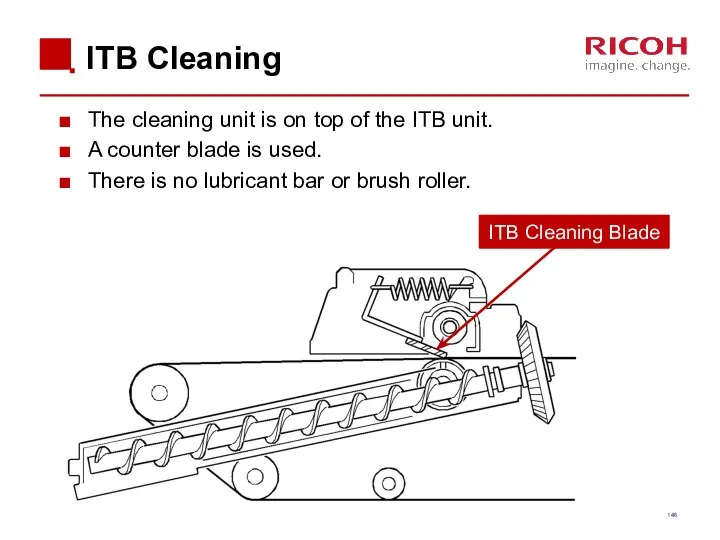

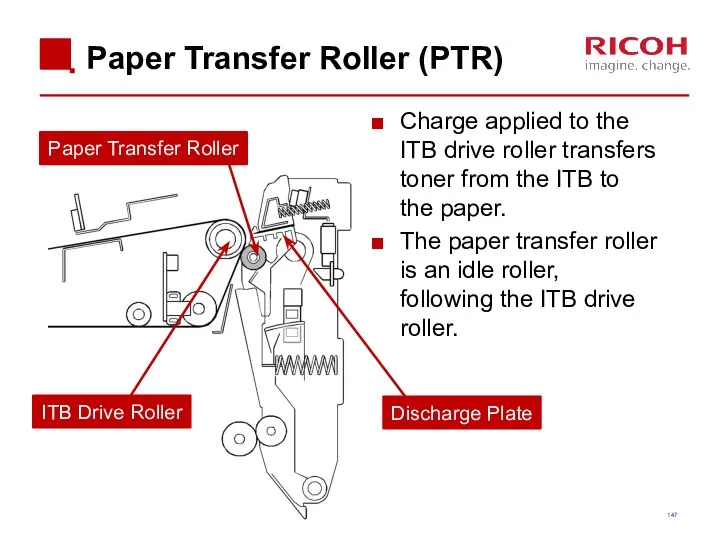

- 147. Paper Transfer Roller (PTR) Charge applied to the ITB drive roller transfers toner from the ITB

- 148. PTR Contact and Release During Process control or MUSIC the PTR is moved away from the

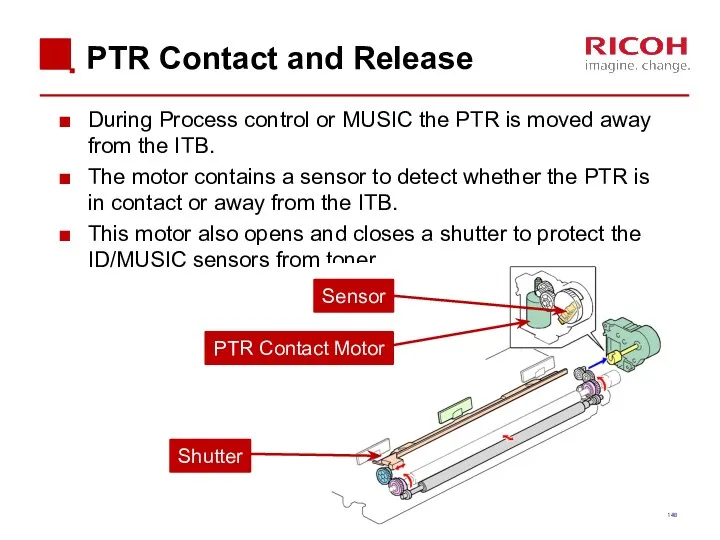

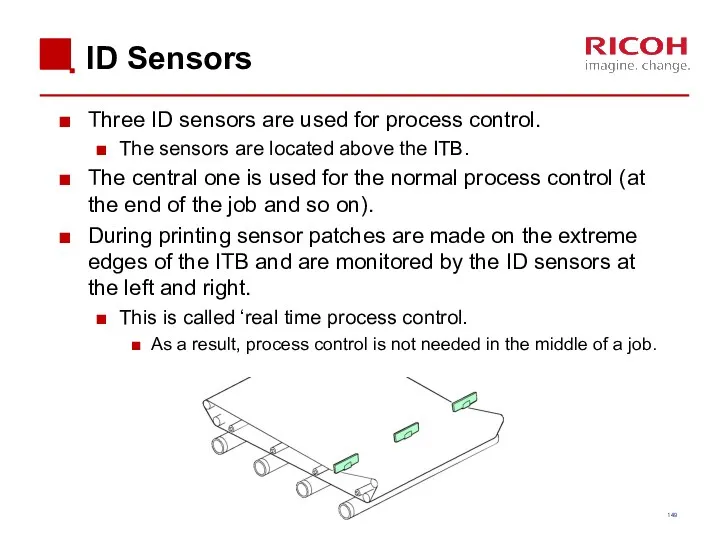

- 149. ID Sensors Three ID sensors are used for process control. The sensors are located above the

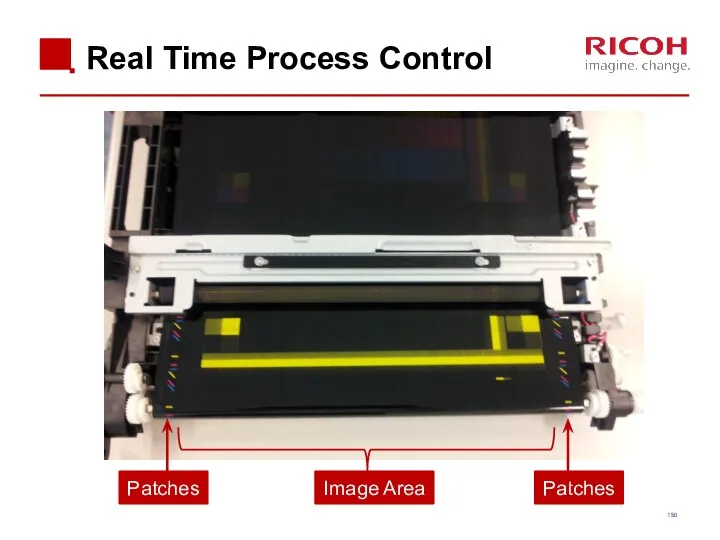

- 150. Real Time Process Control Image Area Patches Patches

- 151. Replacement ITB Lever Position Before you remove or insert the image transfer belt unit: Open the

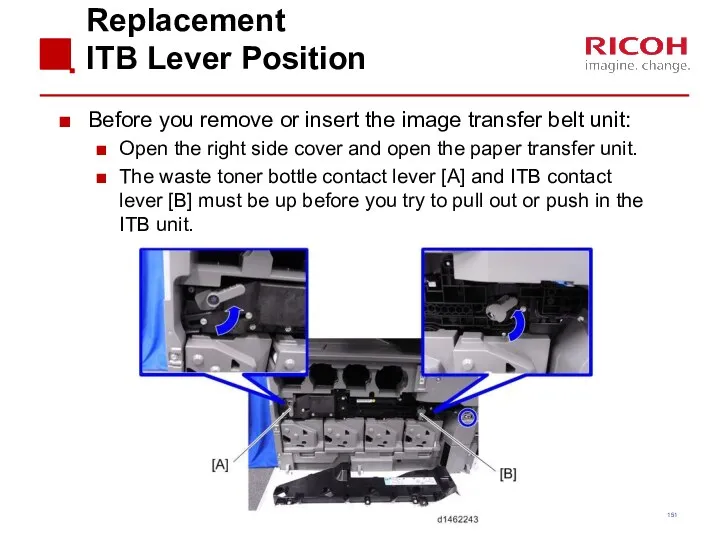

- 152. Replacement ITB Cleaning Unit When removing the ITB cleaning unit: Turn the ITB unit upside down

- 153. Replacement ID Sensors Before you replace the ID sensor, you must input the values 1-6 on

- 154. Fusing

- 155. Differences from Predecessors: Fusing

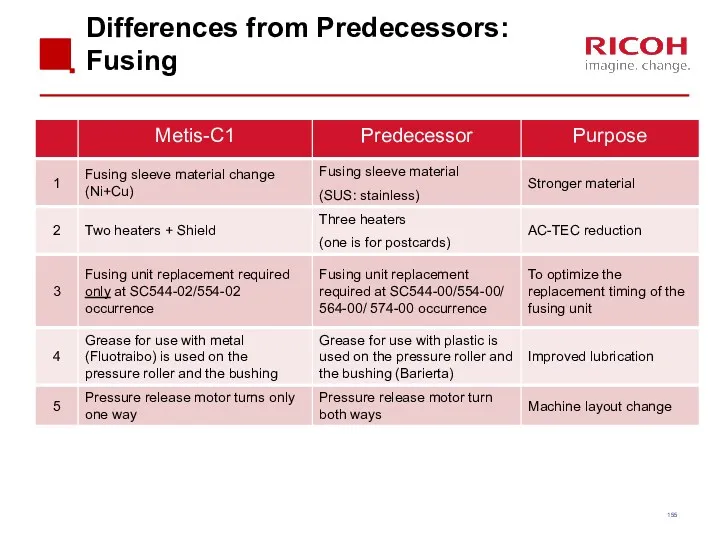

- 156. Components Athena & Apollon-C3

- 157. QSU-DH Fusing Method The fusing system is the same as the Athena-C3 and Apollon-C3 (free belt

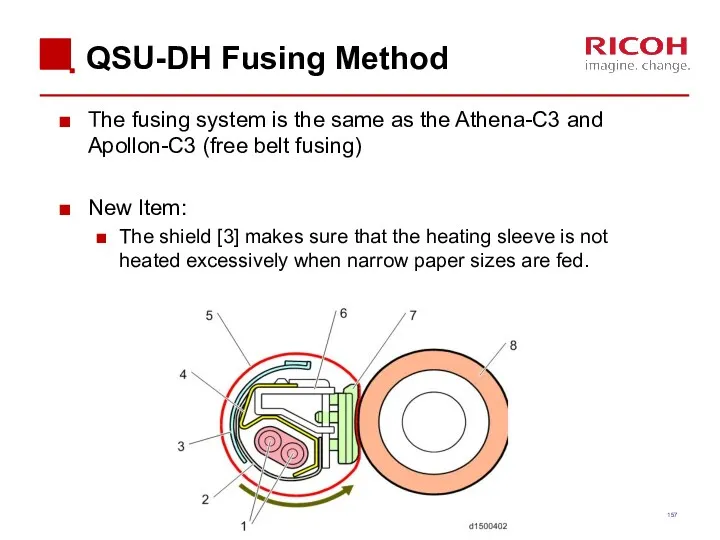

- 158. Shield To prevent the temperature at the edges of the heating sleeve from getting too high

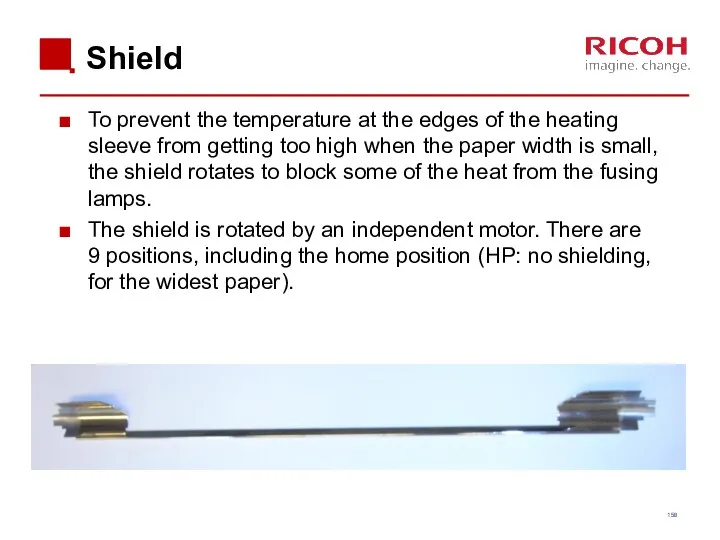

- 159. Shield Rotation A B C D E F J I H G

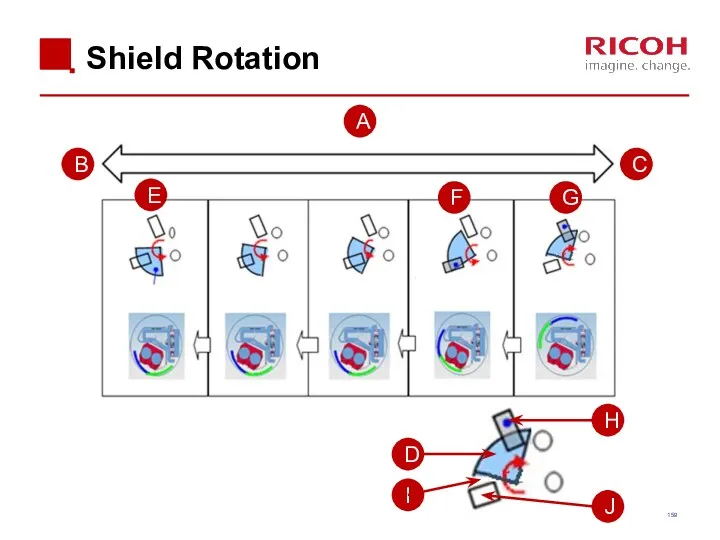

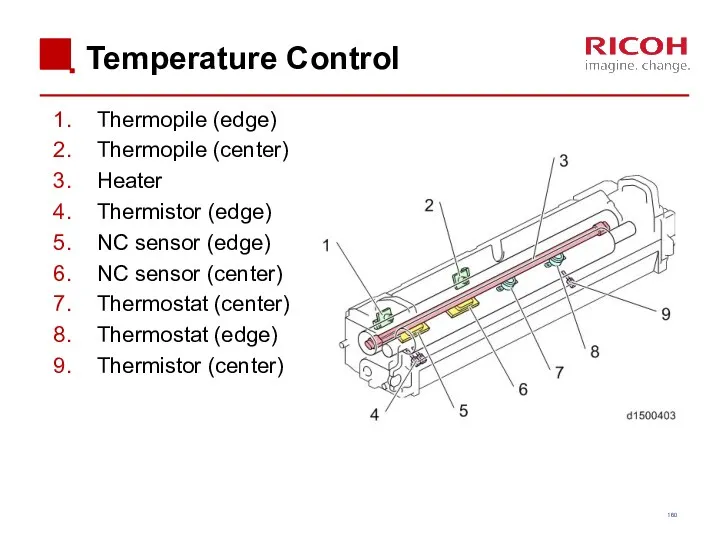

- 160. Temperature Control Thermopile (edge) Thermopile (center) Heater Thermistor (edge) NC sensor (edge) NC sensor (center) Thermostat

- 161. CPM Down Control Handling Low Temperatures The central thermopile is checked at regular intervals, and if

- 162. CPM Down Control Handling High Temperatures Because the fusing unit has a low heat capacity, the

- 163. Fusing Temperature Detection The temperature is checked at regular intervals. If the temperature is above a

- 164. Paper Passage Time Depending on the paper size, it may not be possible to use a

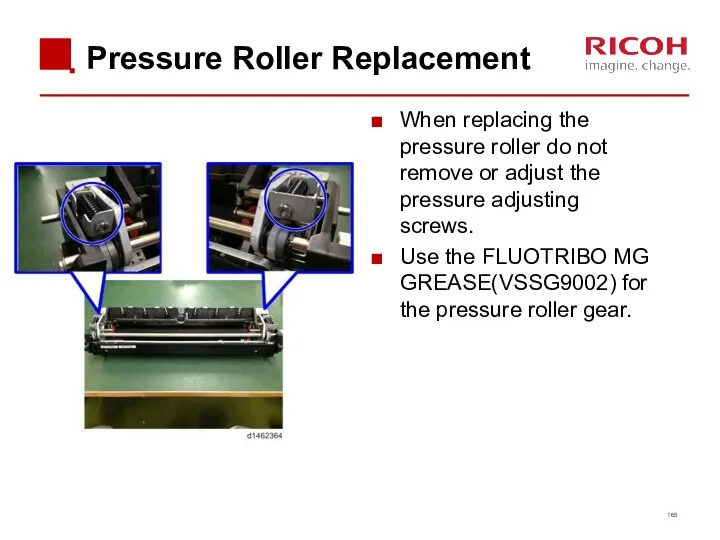

- 165. Pressure Roller Replacement When replacing the pressure roller do not remove or adjust the pressure adjusting

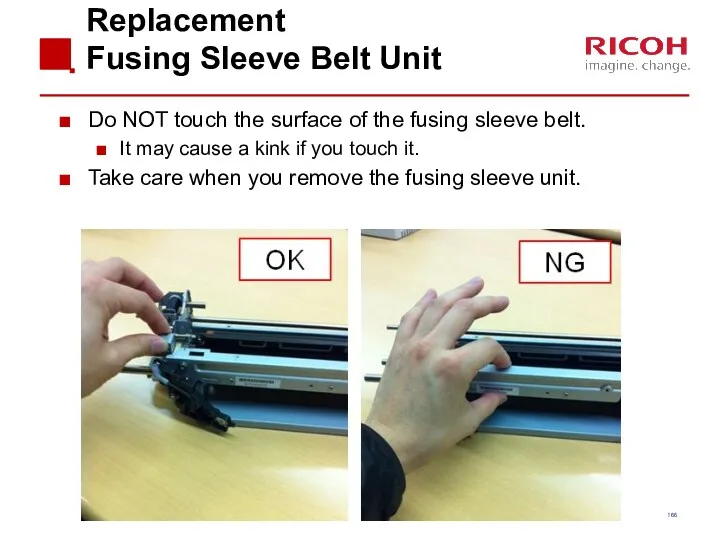

- 166. Replacement Fusing Sleeve Belt Unit Do NOT touch the surface of the fusing sleeve belt. It

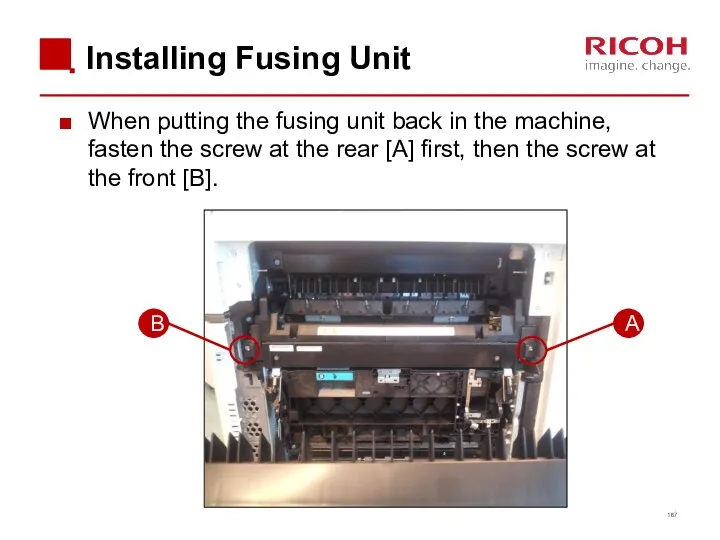

- 167. Installing Fusing Unit When putting the fusing unit back in the machine, fasten the screw at

- 168. Fusing Shield Motor Test Remove the fusing unit. The motor rotation is not visible when the

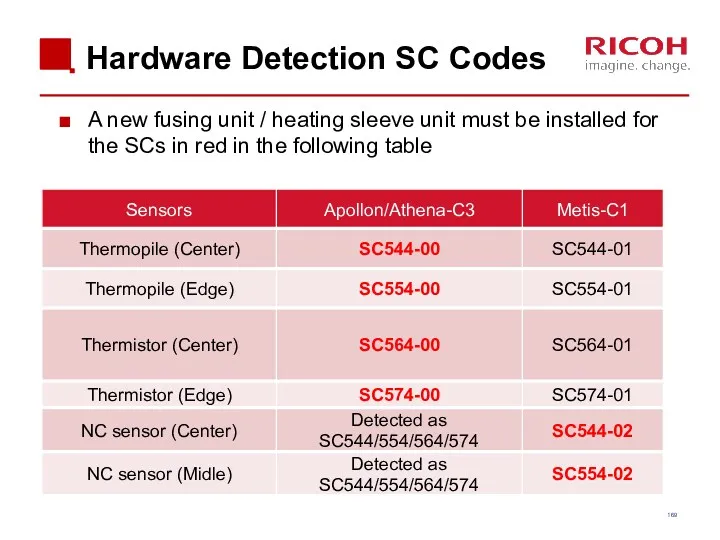

- 169. Hardware Detection SC Codes A new fusing unit / heating sleeve unit must be installed for

- 170. Paper Exit, Duplex

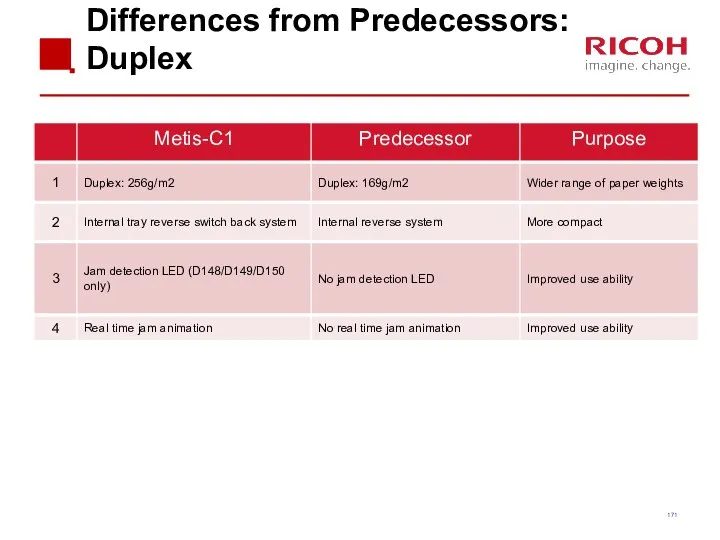

- 171. Differences from Predecessors: Duplex

- 172. Paper Exit To feed the paper to the standard exit, without duplexing, the junction gate stays

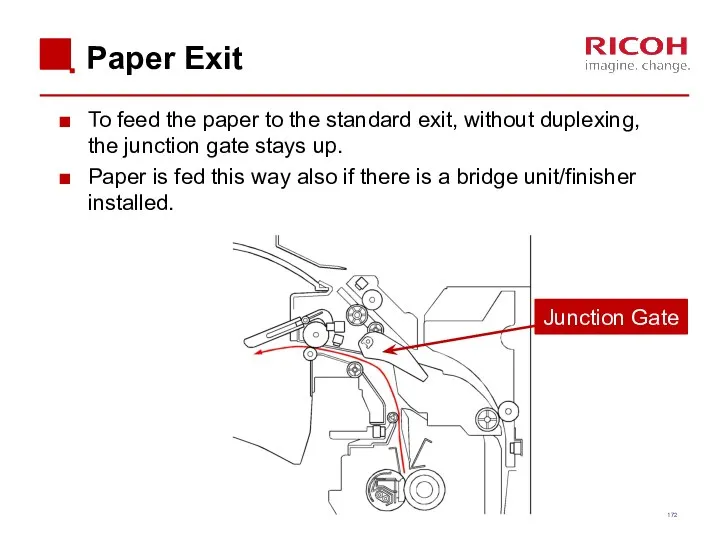

- 173. Duplex Feed Path

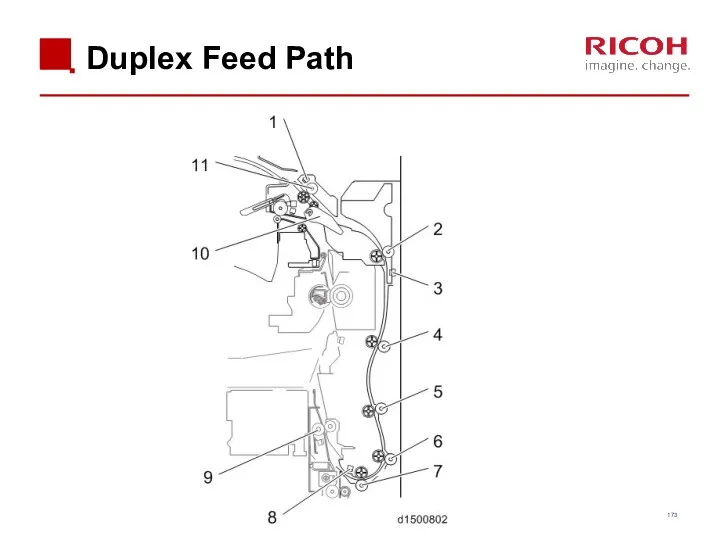

- 174. Duplex Feed Inverter Area

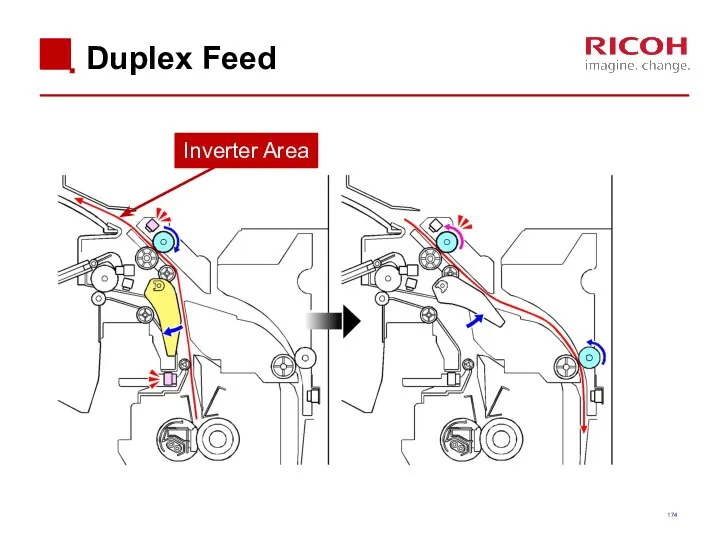

- 175. Interleaving The following items have influence on the number of sheets inside the machine: Paper length

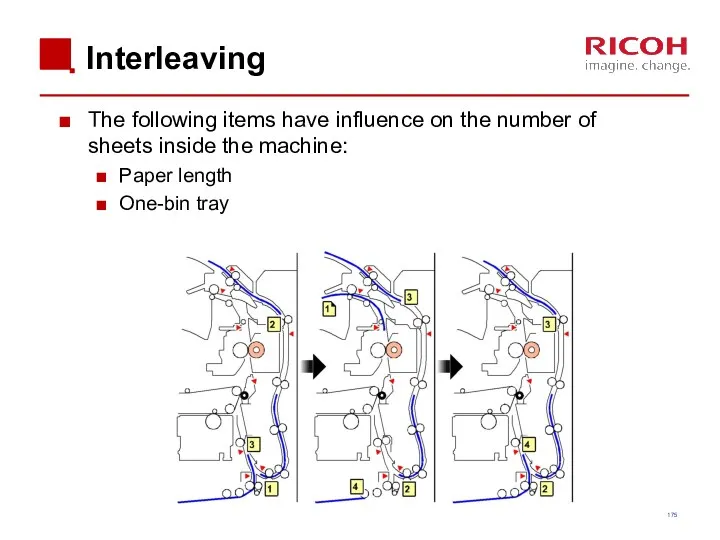

- 176. Waste Toner Collection

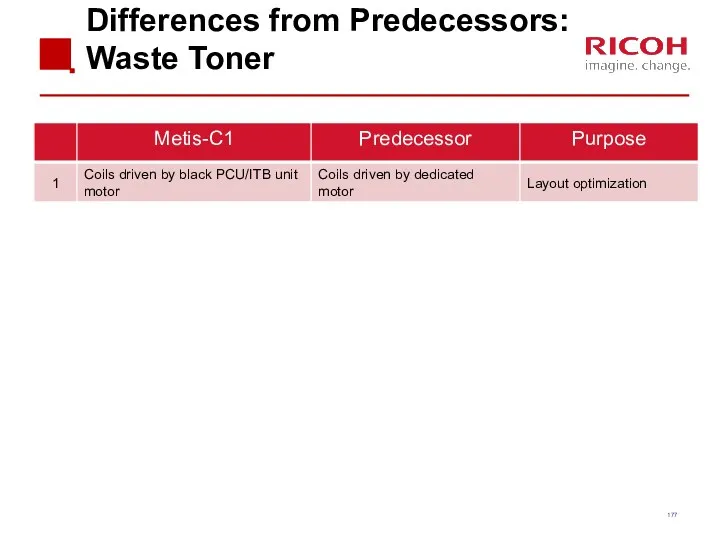

- 177. Differences from Predecessors: Waste Toner

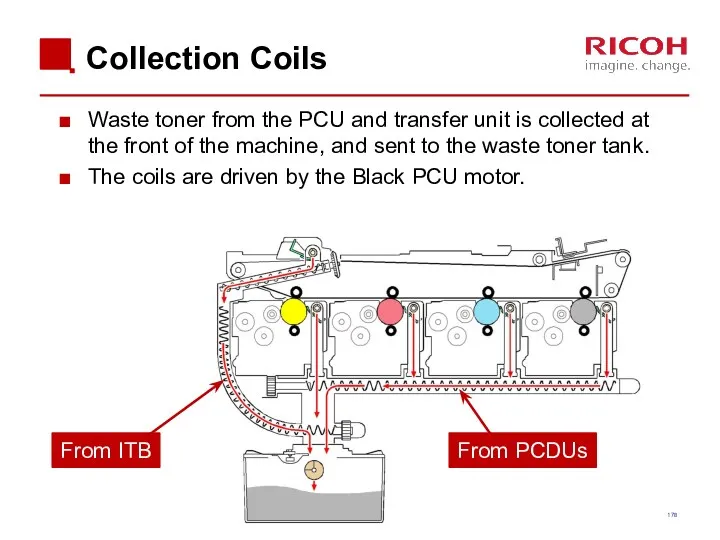

- 178. Collection Coils Waste toner from the PCU and transfer unit is collected at the front of

- 179. Sensors Bottle set switch: If this does not detect the bottle, the machine cannot print. Bottle

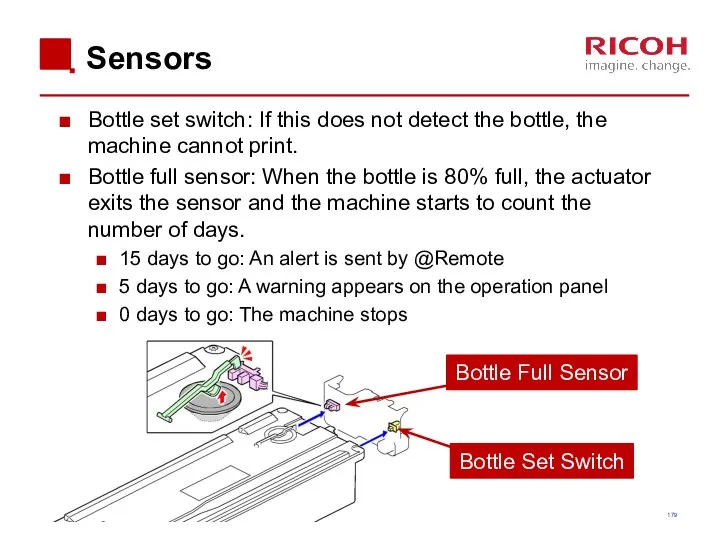

- 180. 5. Troubleshooting

- 181. Capturing the Debug Logs (1/3) Debug logs for the controller, engine, and operation panel can be

- 182. Capturing the Debug Logs (2/3) Insert the SD card into the slot on the side of

- 183. Capturing the Debug Logs (3/3) The debug logs are saved with the following file names and

- 184. 6. Android Operation Panel Smart Operation Panel Type M3 (D148)

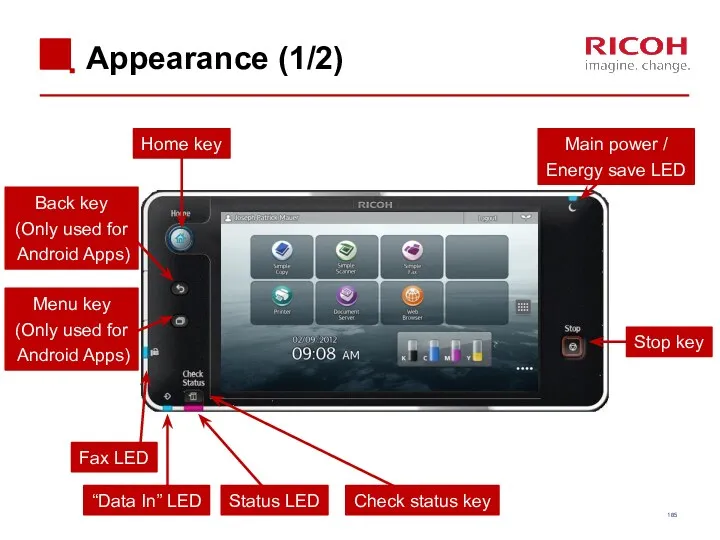

- 185. Appearance (1/2) Home key Back key (Only used for Android Apps) Check status key Stop key

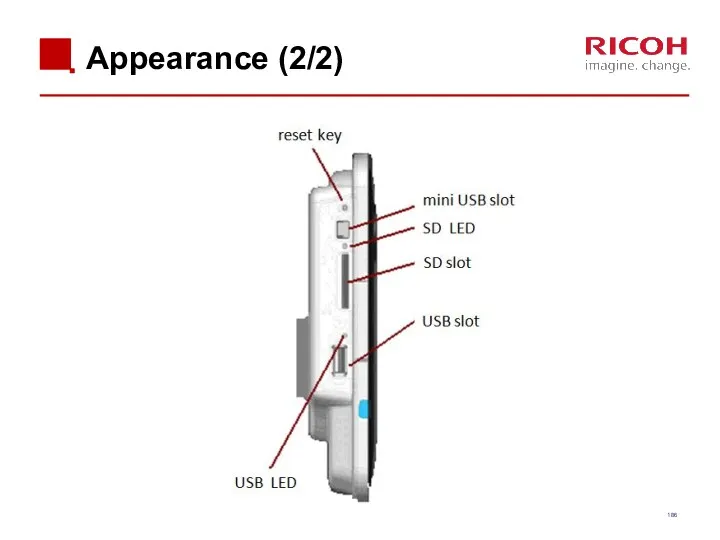

- 186. Appearance (2/2)

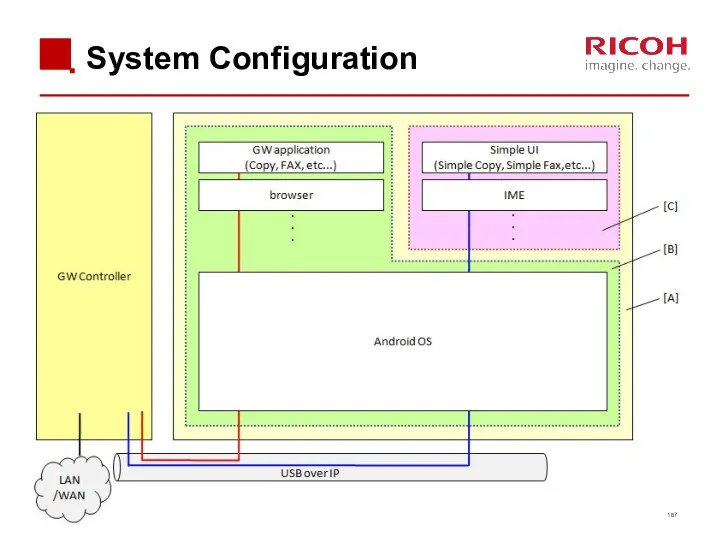

- 187. System Configuration

- 188. Basic information (1/3) There are two kinds of applications. 1) Android applications You can use “flick

- 189. Basic information (2/3) You can customize the Home display. You can add widgets (Toner remaining, clock,

- 190. Basic information (3/3) SC or machine status is displayed in legacy mode. There is no independent

- 191. Applications

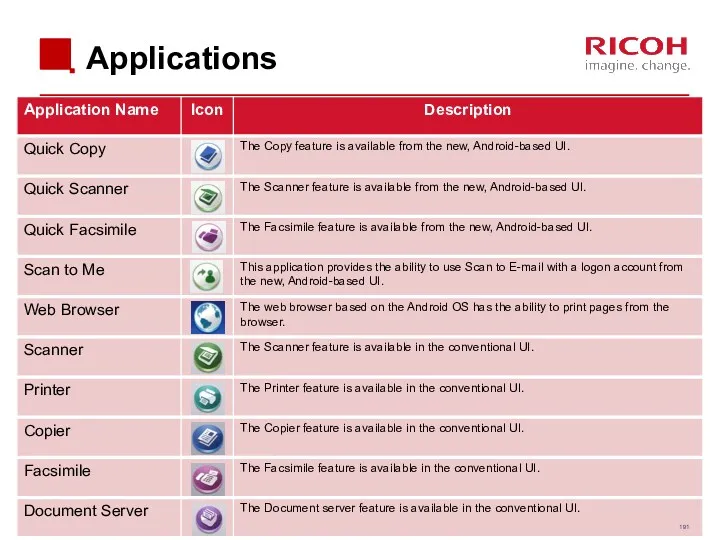

- 192. Legacy UI on Cheetah Legacy UI will be prepared for all MFP functions, such as Copy,

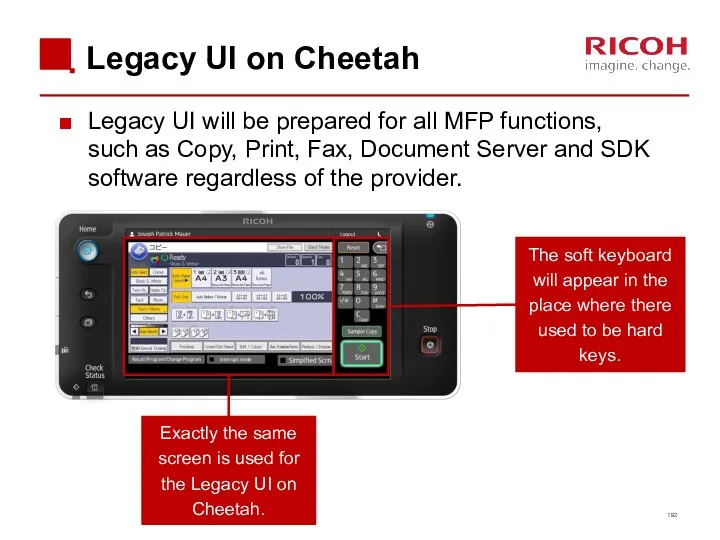

- 193. Start up There are two start up displays: GW controller and Android) Android GW controller

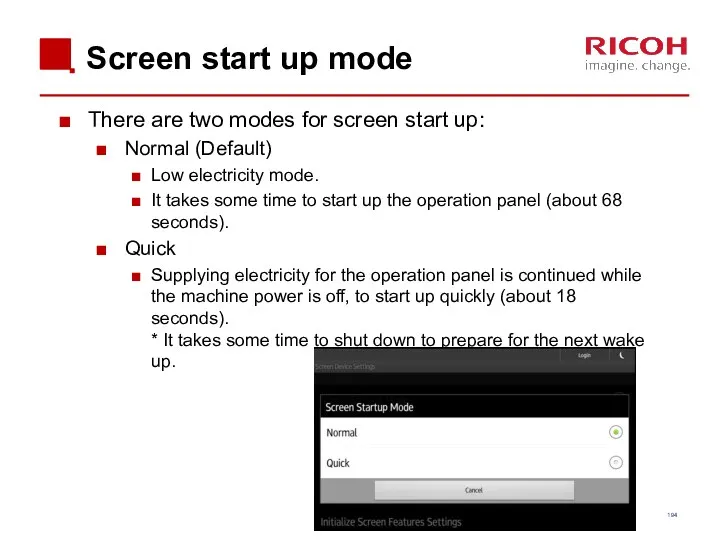

- 194. Screen start up mode There are two modes for screen start up: Normal (Default) Low electricity

- 195. Special shut down mode There are two special shut down modes: Shut down for maintenance. When

- 196. Service Modes There are three SP modes. Machine service mode Android operation panel service mode Recovery

- 198. Скачать презентацию

![Removing the PCDU seals Each PCDU [A] has a seal](/_ipx/f_webp&q_80&fit_contain&s_1440x1080/imagesDir/jpg/201019/slide-15.jpg)

![SD Card Slots [A]: SD card slot 1 (option slot)](/_ipx/f_webp&q_80&fit_contain&s_1440x1080/imagesDir/jpg/201019/slide-26.jpg)

![Switch off procedure Push the power switch [A] on the](/_ipx/f_webp&q_80&fit_contain&s_1440x1080/imagesDir/jpg/201019/slide-72.jpg)

Районирование территории России

Районирование территории России Презентация 3

Презентация 3 Where is the bed

Where is the bed Противокариозные зубные пасты с кальцием и фосфором

Противокариозные зубные пасты с кальцием и фосфором Проблемное обучение на уроках химии

Проблемное обучение на уроках химии Методики обследования памяти в дошкольный, школьный возраст, у взрослых людей

Методики обследования памяти в дошкольный, школьный возраст, у взрослых людей Археологические памятники презентация

Археологические памятники презентация Исследовательская работа Хуулгаазын Дошка

Исследовательская работа Хуулгаазын Дошка Стереотипы, их роль в процессе общения. Этика

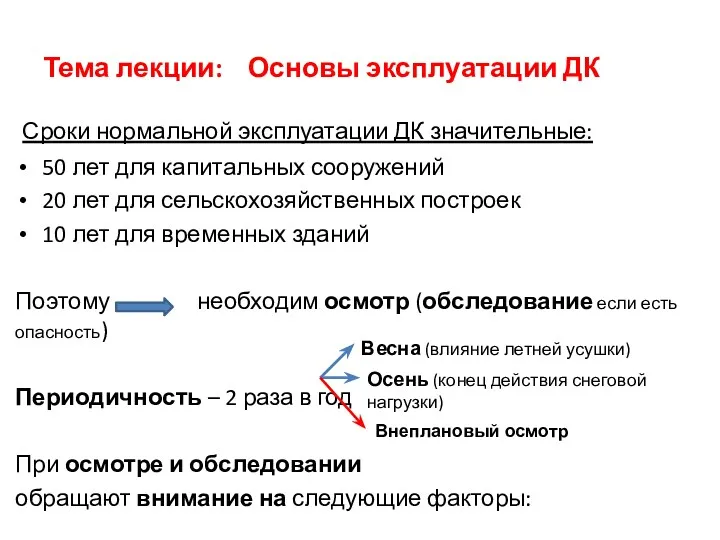

Стереотипы, их роль в процессе общения. Этика Основы эксплуатации ДК

Основы эксплуатации ДК Сочинение по картине В. Серова Девочка с персиками

Сочинение по картине В. Серова Девочка с персиками На грани вымирания. Амурский тигр

На грани вымирания. Амурский тигр фізика нано лек 3. Типи кристалічних ґраток

фізика нано лек 3. Типи кристалічних ґраток Миниатюрная ведущая, способная преувеличить масштаб любого события!

Миниатюрная ведущая, способная преувеличить масштаб любого события! Вдов солдатских нелегкие судьбы…Солдатские вдовы

Вдов солдатских нелегкие судьбы…Солдатские вдовы Случаи сложения вида +4

Случаи сложения вида +4 Системы счисления

Системы счисления Етті өңдейтің өнеркәсіптердің маңызы және сою цехы

Етті өңдейтің өнеркәсіптердің маңызы және сою цехы Совершенствование речевого развития детей через театрализованную деятельность.

Совершенствование речевого развития детей через театрализованную деятельность. Сочинение на тему, связанную с анализом текста (сочинение 15.2)

Сочинение на тему, связанную с анализом текста (сочинение 15.2) Подходы к измерению информации

Подходы к измерению информации Русские народные сказки. Сказители

Русские народные сказки. Сказители Методология, теория и методы психологических исследований

Методология, теория и методы психологических исследований Распространение дезинформации в мессенджере whatsapp и проблема ее влияния на общественное мнение

Распространение дезинформации в мессенджере whatsapp и проблема ее влияния на общественное мнение Функции в языке программирования QBasic. Арифметические, строковые и логические выражения

Функции в языке программирования QBasic. Арифметические, строковые и логические выражения Диагностические возможности социально-психологического анамнеза в коррекции нарушений речи у детей

Диагностические возможности социально-психологического анамнеза в коррекции нарушений речи у детей Экономикалық ақпарат

Экономикалық ақпарат Форстеритовая и кордиеритовая керамика

Форстеритовая и кордиеритовая керамика