Слайд 2

Contents

01 Oxidation burning loss of billet

02 High temperature protection technology

03 Technical effect

04 Economic benefit

Слайд 3

01 Oxidation burning loss of billet

Слайд 4

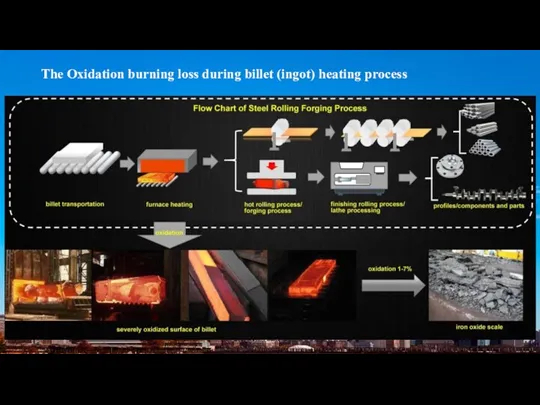

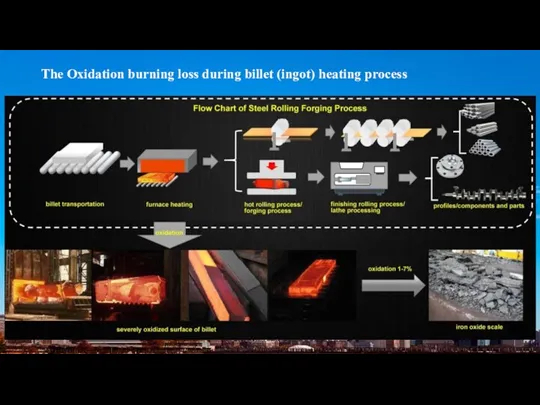

The Oxidation burning loss during billet (ingot) heating process

Слайд 5

Adverse effects of high temperature oxidation

During the heating process of rolling steel,

the oxidation burning loss accounts for about 1-1.5% of the weight of the blank. The forging heating burning loss will be higher, and the burning loss rate is as high as 3-5%.

Слайд 6

Adverse effects of high temperature oxidation

When the furnace gas or furnace temperature

is improperly controlled or the billet stays in the high temperature section for a long time, especially if the rolling failure occurs and the adjustment is not timely, the iron oxide scale of the steel will be thickened.

In general, the iron oxide scale thickness is 1-5mm, and in severe cases, it can reach 10mm.

Слайд 7

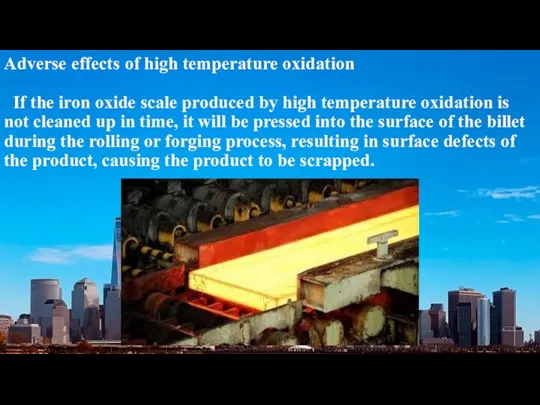

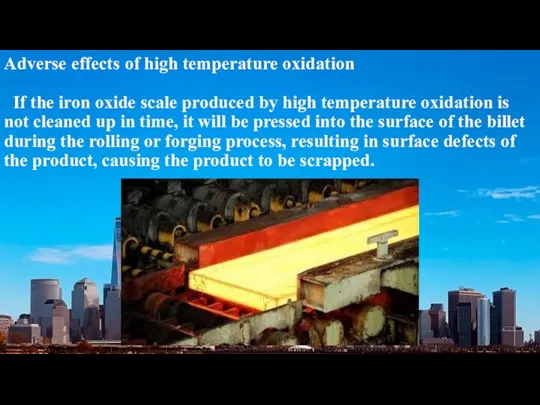

Adverse effects of high temperature oxidation

If the iron oxide scale produced by

high temperature oxidation is not cleaned up in time, it will be pressed into the surface of the billet during the rolling or forging process, resulting in surface defects of the product, causing the product to be scrapped.

Слайд 8

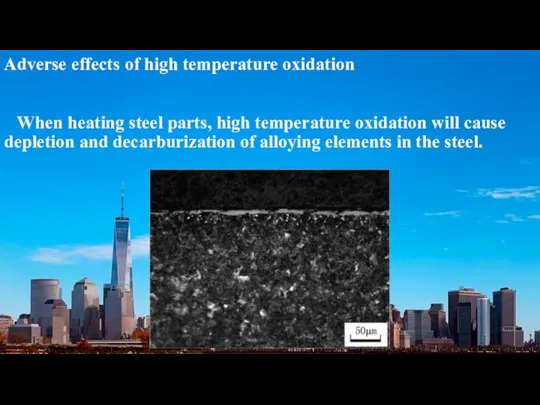

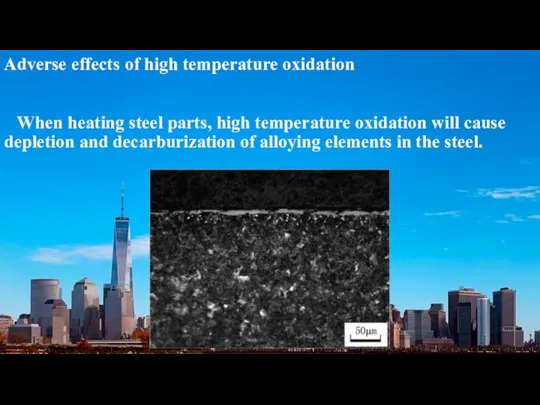

Adverse effects of high temperature oxidation

When heating steel parts, high temperature oxidation

will cause depletion and decarburization of alloying elements in the steel.

Слайд 9

Adverse effects of high temperature oxidation

The changes in the chemical composition of

the steel surface will cause a decline in the mechanical properties and corrosion resistance of the product, resulting in a reduction in the qualified rate of finished products.

Слайд 10

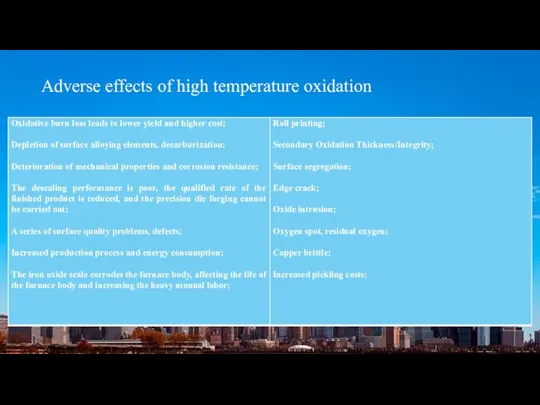

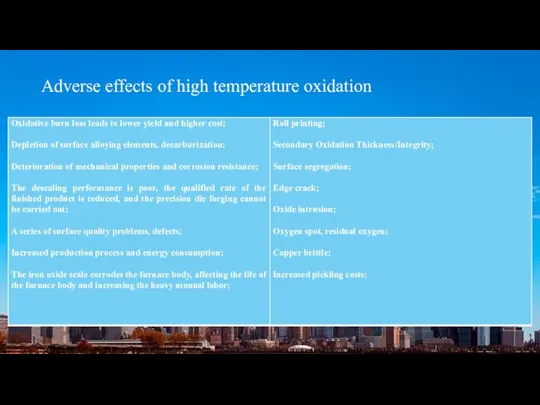

Adverse effects of high temperature oxidation

Слайд 11

02 High temperature protection technology

Слайд 12

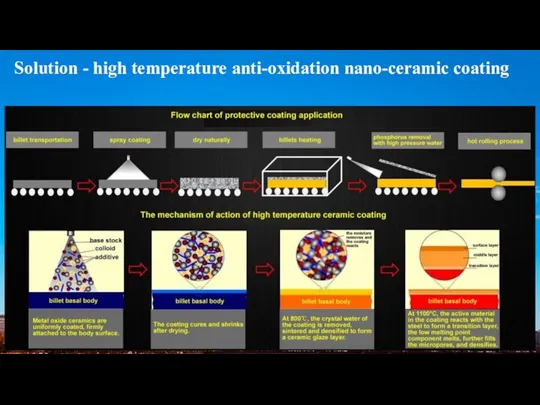

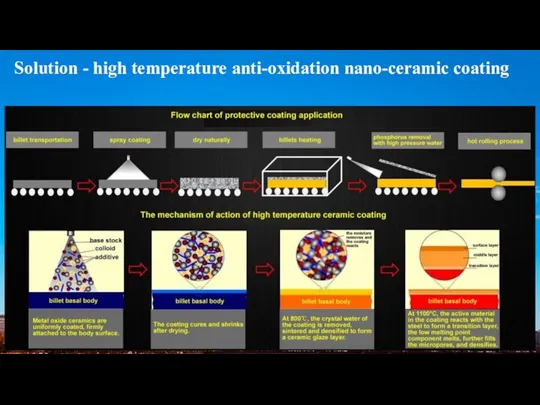

Solution - high temperature anti-oxidation nano-ceramic coating

Слайд 13

Слайд 14

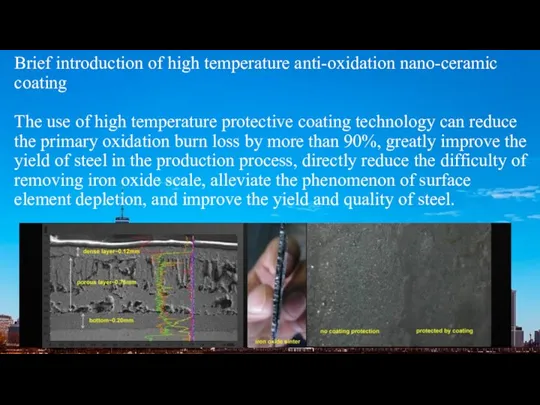

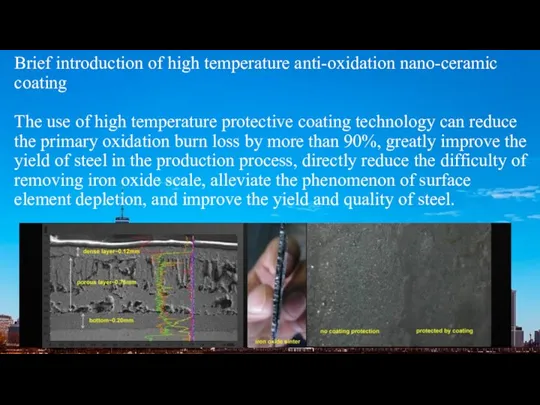

Brief introduction of high temperature anti-oxidation nano-ceramic coating

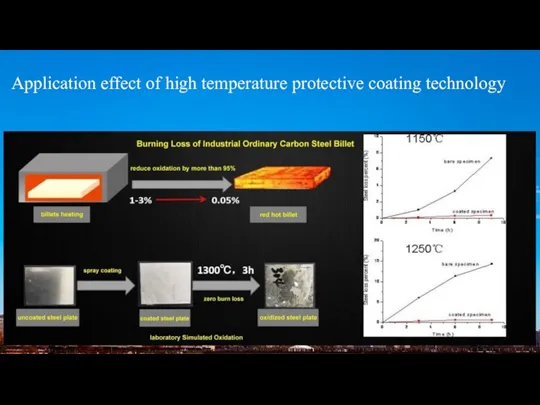

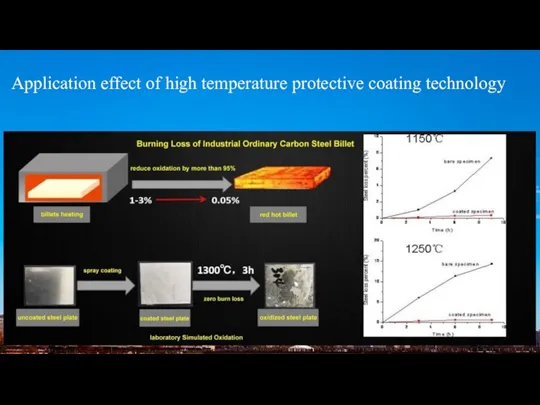

The use of high temperature protective

coating technology can reduce the primary oxidation burn loss by more than 90%, greatly improve the yield of steel in the production process, directly reduce the difficulty of removing iron oxide scale, alleviate the phenomenon of surface element depletion, and improve the yield and quality of steel.

Слайд 15

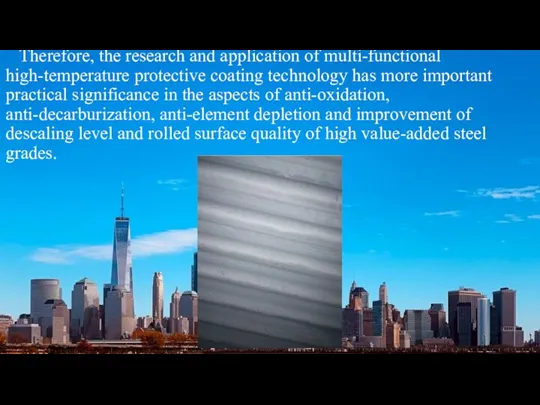

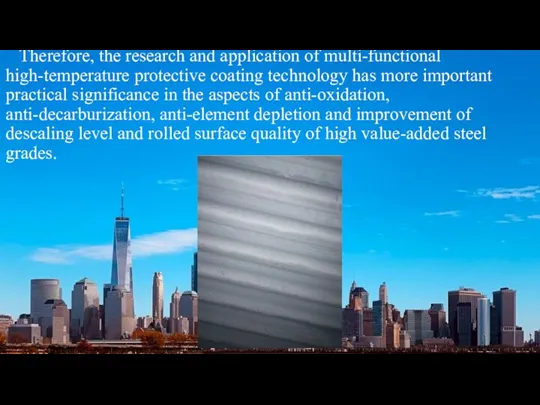

Therefore, the research and application of multi-functional high-temperature protective coating technology has

more important practical significance in the aspects of anti-oxidation, anti-decarburization, anti-element depletion and improvement of descaling level and rolled surface quality of high value-added steel grades.

Слайд 16

Characteristics of high temperature anti-oxidation nano-ceramic coating

1. The coating can reduce the surface

oxidation of the billet by more than 90%, greatly reducing the element depletion;

Слайд 17

Characteristics of high temperature anti-oxidation nano-ceramic coating

2 Good chemical compatibility, mechanical compatibility, and

CTE (coefficient of thermal expansion) matching between the coating and the substrate and between the inner layer of the coating and the layer;

Слайд 18

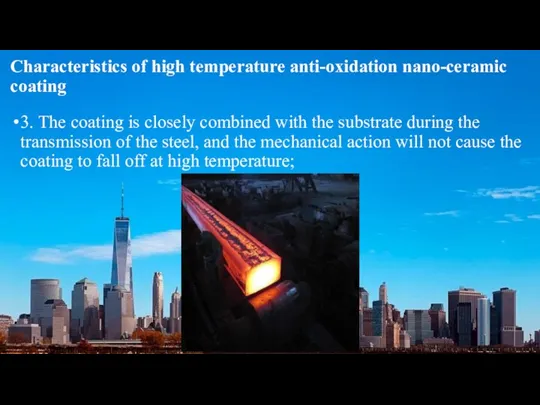

Characteristics of high temperature anti-oxidation nano-ceramic coating

3. The coating is closely combined with

the substrate during the transmission of the steel, and the mechanical action will not cause the coating to fall off at high temperature;

Слайд 19

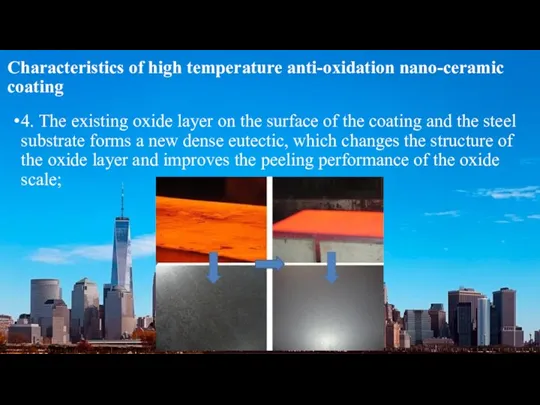

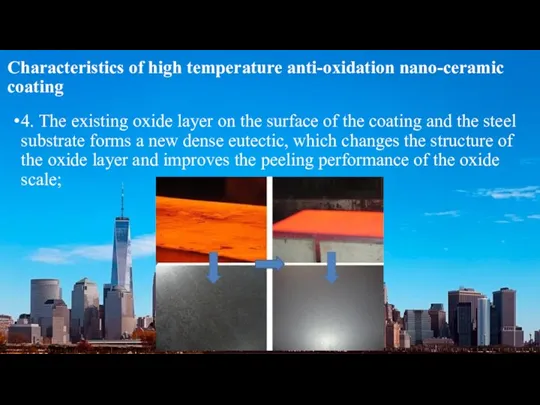

Characteristics of high temperature anti-oxidation nano-ceramic coating

4. The existing oxide layer on the

surface of the coating and the steel substrate forms a new dense eutectic, which changes the structure of the oxide layer and improves the peeling performance of the oxide scale;

Слайд 20

Characteristics of high temperature anti-oxidation nano-ceramic coating

5. The amount of coating is small,

which does not affect the normal heating speed of the billet;

Слайд 21

Characteristics of high temperature anti-oxidation nano-ceramic coating

6. The coating can automatically heal the

cracks generated by itself in the high temperature process, ensuring the compactness and integrity of the coating;

Слайд 22

Characteristics of high temperature anti-oxidation nano-ceramic coating

7. The coating itself has anti-oxidation performance

and long protection life;

Слайд 23

Characteristics of high temperature anti-oxidation nano-ceramic coating

8. The cost of coating is low.

The existing anti-oxidation coatings for special steels are relatively expensive, while for ordinary low-carbon steels used in a large number of applications, these coatings are not practically applied, because of high cost.

Слайд 24

Application effect of high temperature protective coating technology

Слайд 25

Forging field application

Слайд 26

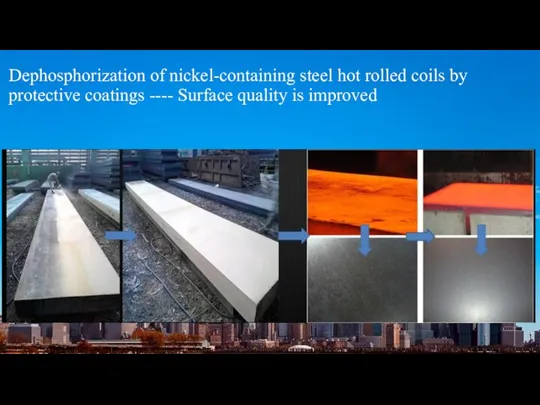

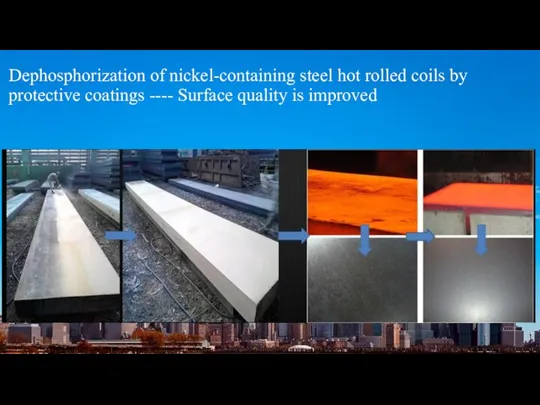

Dephosphorization of nickel-containing steel hot rolled coils by protective coatings ---- Surface quality

is improved

Слайд 27

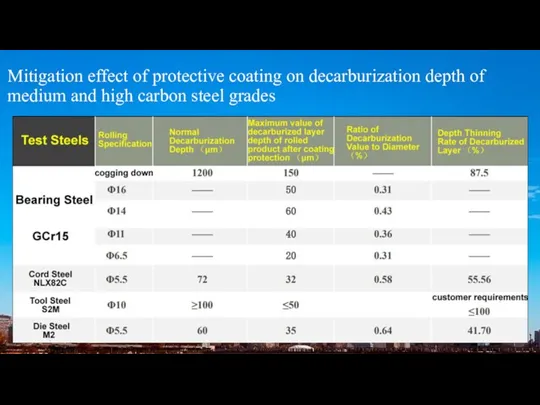

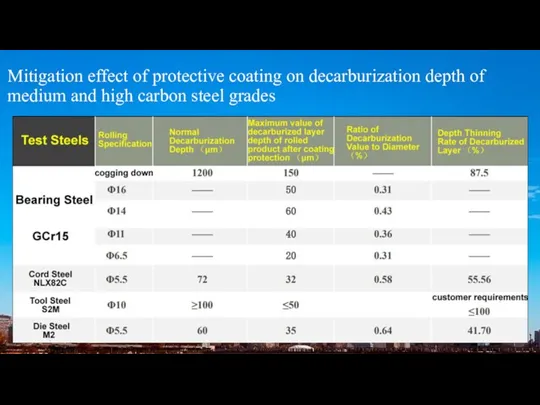

Mitigation effect of protective coating on decarburization depth of medium and high carbon

steel grades

Слайд 28

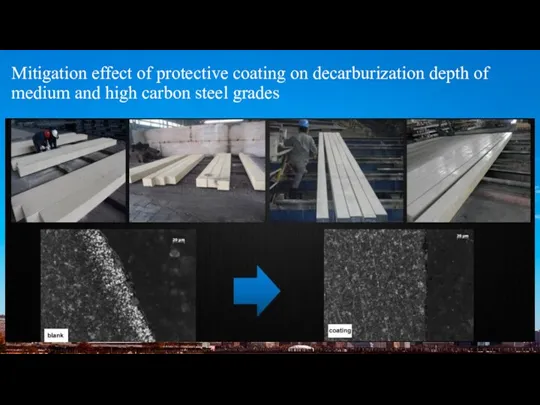

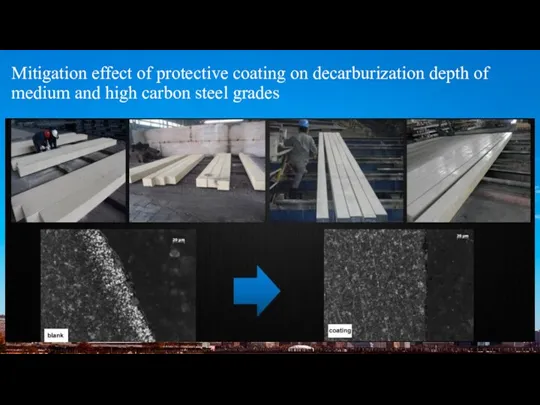

Mitigation effect of protective coating on decarburization depth of medium and high carbon

steel grades

Слайд 29

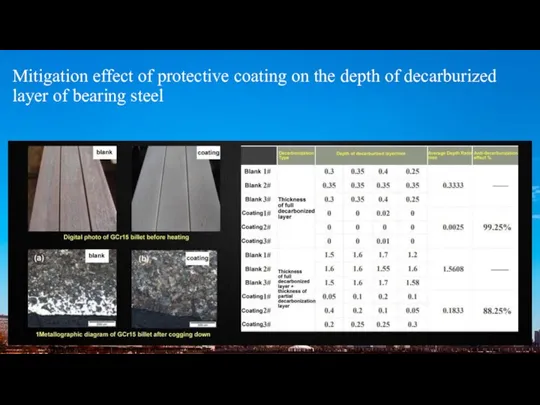

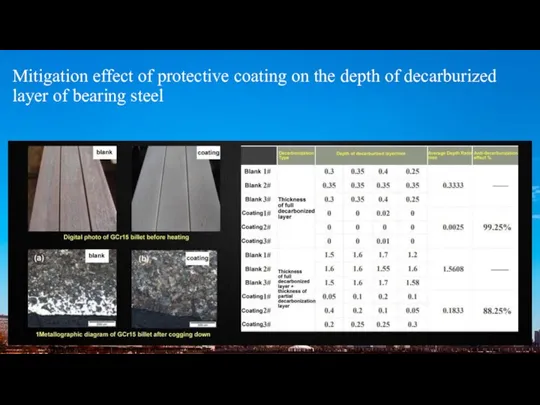

Mitigation effect of protective coating on the depth of decarburized layer of bearing

steel

Слайд 30

Practical significance of applying high temperature protective coating technology

Compared with the existing high-temperature

protective coatings, the coating increases the protective temperature, effectively reduces the high-temperature oxidation burning loss, improves the peeling performance of the iron oxide scale after it is released from the furnace, saves energy to a large extent, and improves the yield and surface quality of the billet, from the perspective of energy saving, production and efficiency of steel rolling heat treatment production, it has produced obvious benefits.

Слайд 31

Practical significance of applying high temperature protective coating technology

Most of the heating furnaces

in the rolling and forging industries in the country are at a relatively low level in the world, which is why the oxidation burning loss and surface quality of the forging industry urgently need to be improved.

Слайд 32

Practical significance of applying high temperature protective coating technology

The improvement of surface quality

has played a significant role in improving the equipment life of downstream processes such as rolling process, pickling process and other supporting links, and reducing material consumption.

Слайд 33

Practical significance of applying high temperature protective coating technology

The improvement of product quality

also increases the added value of products and enhances the strategic competitiveness of enterprises themselves.

Слайд 34

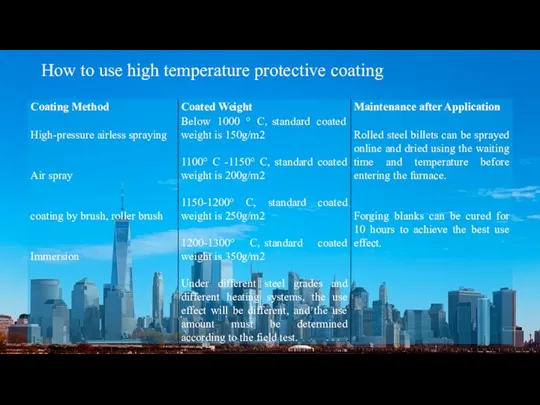

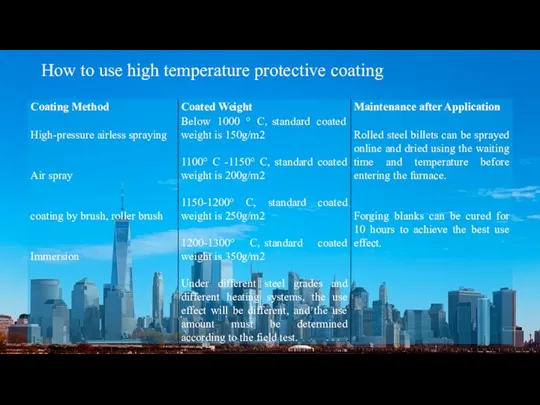

How to use high temperature protective coating

Слайд 35

Слайд 36

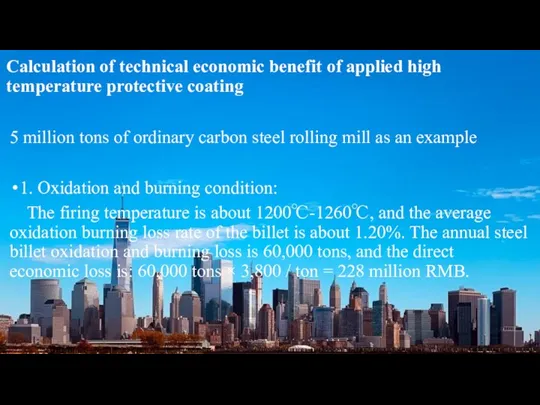

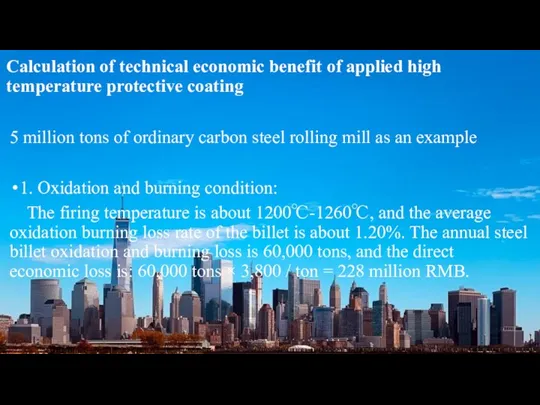

Calculation of technical economic benefit of applied high temperature protective coating

5 million tons

of ordinary carbon steel rolling mill as an example

1. Oxidation and burning condition:

The firing temperature is about 1200℃-1260℃, and the average oxidation burning loss rate of the billet is about 1.20%. The annual steel billet oxidation and burning loss is 60,000 tons, and the direct economic loss is: 60,000 tons × 3,800 / ton = 228 million RMB.

Слайд 37

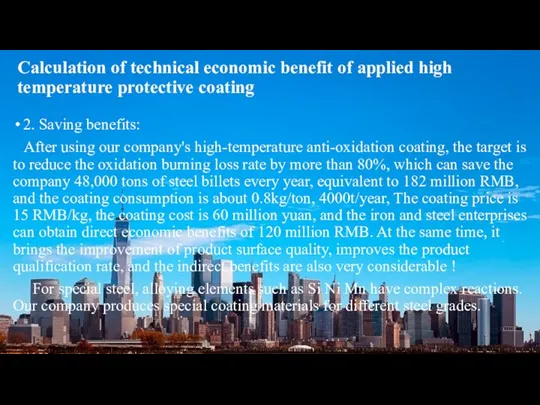

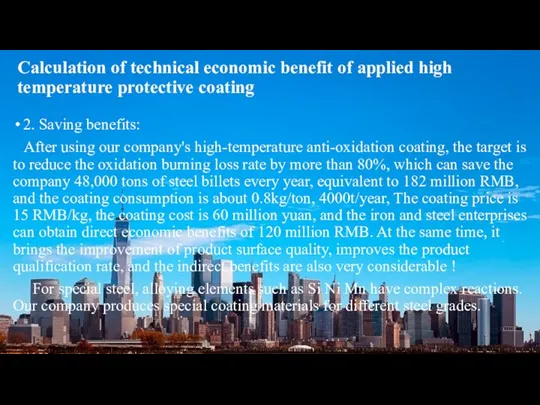

Calculation of technical economic benefit of applied high temperature protective coating

2. Saving benefits:

After using our company's high-temperature anti-oxidation coating, the target is to reduce the oxidation burning loss rate by more than 80%, which can save the company 48,000 tons of steel billets every year, equivalent to 182 million RMB, and the coating consumption is about 0.8kg/ton, 4000t/year, The coating price is 15 RMB/kg, the coating cost is 60 million yuan, and the iron and steel enterprises can obtain direct economic benefits of 120 million RMB. At the same time, it brings the improvement of product surface quality, improves the product qualification rate, and the indirect benefits are also very considerable !

For special steel, alloying elements such as Si Ni Mn have complex reactions. Our company produces special coating materials for different steel grades.

Паронимы

Паронимы Презентация к занятию на тему: Форма, цвет, размер

Презентация к занятию на тему: Форма, цвет, размер Выбор вспомогательного оборудования. Компоновка котельных

Выбор вспомогательного оборудования. Компоновка котельных Обобщение опыта

Обобщение опыта ИСТОРИЯ ОДЕЖДЫ

ИСТОРИЯ ОДЕЖДЫ Былинные богатыри.

Былинные богатыри. Обучение младших школьников приемам работы с текстовой информацией

Обучение младших школьников приемам работы с текстовой информацией Модуль Календарное планирование

Модуль Календарное планирование Геохронологічна таблиця

Геохронологічна таблиця Ог - тыва чоннун амыдыралынын ундезини

Ог - тыва чоннун амыдыралынын ундезини Двойное размножения у цветковых растений

Двойное размножения у цветковых растений Светофорная сигнализация, назначение сигналов и их классификация. Основные сигнальные цвета и их значения

Светофорная сигнализация, назначение сигналов и их классификация. Основные сигнальные цвета и их значения Развитие познавательно - исследовательской деятельности детей старшего возраста

Развитие познавательно - исследовательской деятельности детей старшего возраста Стадии проектирования и содержание проектной документации на строительство здания или сооружения

Стадии проектирования и содержание проектной документации на строительство здания или сооружения bet_game

bet_game Детское экспериментирование - путь познания окружающего мира

Детское экспериментирование - путь познания окружающего мира Устройство реактора

Устройство реактора Презентация Мелодекламация Шар

Презентация Мелодекламация Шар Презентация для педагогов Методы и приемы обучения детей с ОНР диалогической речи.

Презентация для педагогов Методы и приемы обучения детей с ОНР диалогической речи. Мультимедийный тест по теме Шахматная Ладья

Мультимедийный тест по теме Шахматная Ладья Герои Великой Отечественной войны, уроженцы Тихвинского края

Герои Великой Отечественной войны, уроженцы Тихвинского края Презентация 6 простых опытов

Презентация 6 простых опытов О плане работы студенческого научного общества

О плане работы студенческого научного общества Земля и космос

Земля и космос Стабилизаторы напряжения и тока

Стабилизаторы напряжения и тока Физика. Передача электроэнергии

Физика. Передача электроэнергии Дидактический синквейн как средство развития творческого развития речи у детей с ОВЗ

Дидактический синквейн как средство развития творческого развития речи у детей с ОВЗ Песня далекая и близкая

Песня далекая и близкая