Supply of testing roller rig for dynamic testing railroad rolling stock without traction презентация

Содержание

- 2. TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK WITHOUT TRACTION 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER

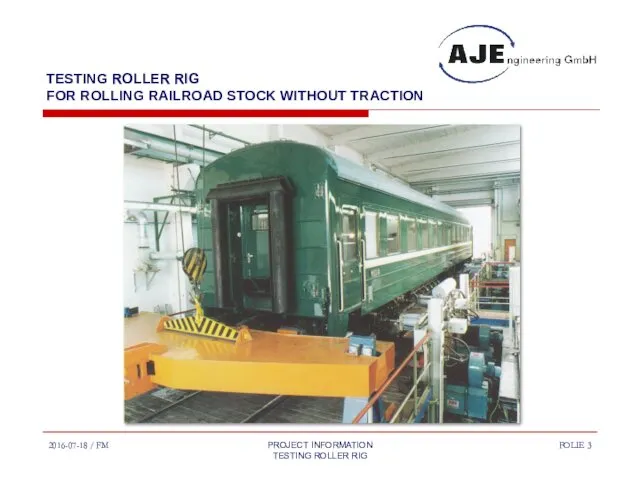

- 3. 2016-07-18/ FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK WITHOUT

- 4. 2016-07-18 / FM FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK WITHOUT TRACTION GENERAL INFORMATION(1) PROJECT

- 5. 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK

- 6. 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK

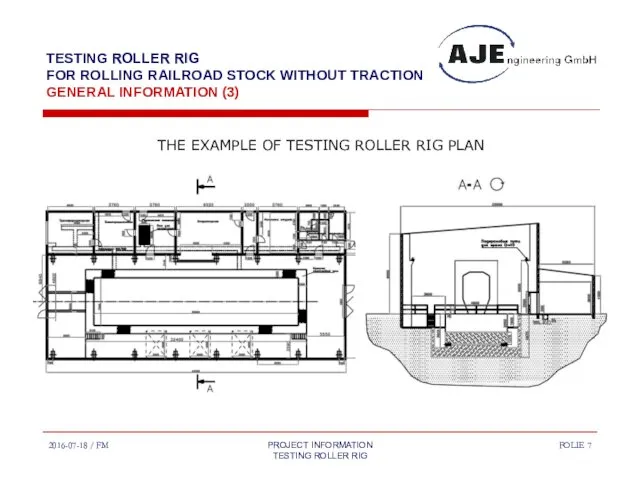

- 7. 2016-05-10 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE 2016-07-18 / FM FOLIE TESTING ROLLER RIG

- 8. 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK

- 9. 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK

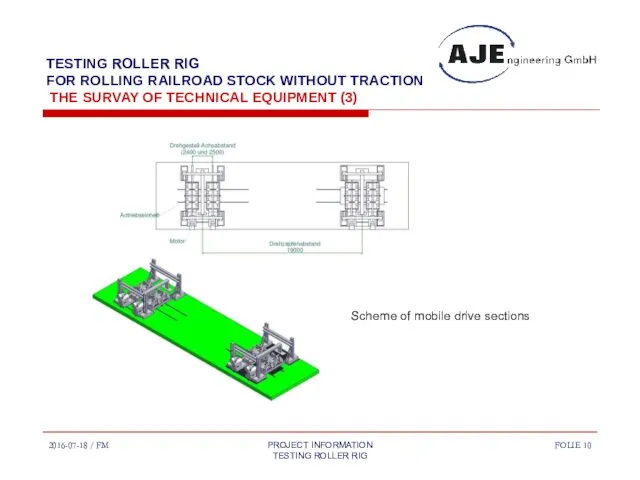

- 10. 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK

- 11. 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK

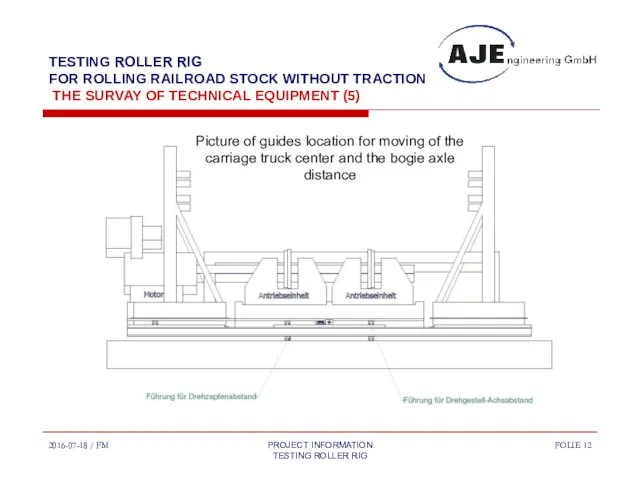

- 12. 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK

- 13. 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK

- 14. 2016-07-18/ FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK WITHOUT

- 15. 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK

- 16. 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK

- 17. 2016-07-18/ FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK WITHOUT

- 18. 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK

- 19. 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK

- 20. 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK

- 21. 2016-07-18 / FM PROJECT INFORMATION TESTING ROLLER RIG FOLIE TESTING ROLLER RIG FOR ROLLING RAILROAD STOCK

- 23. Скачать презентацию

Наше радио

Наше радио Буква О

Буква О Спортсмены Краснодарского края

Спортсмены Краснодарского края Кодирование информации

Кодирование информации Реформы управления Петра I

Реформы управления Петра I Публичное выступление

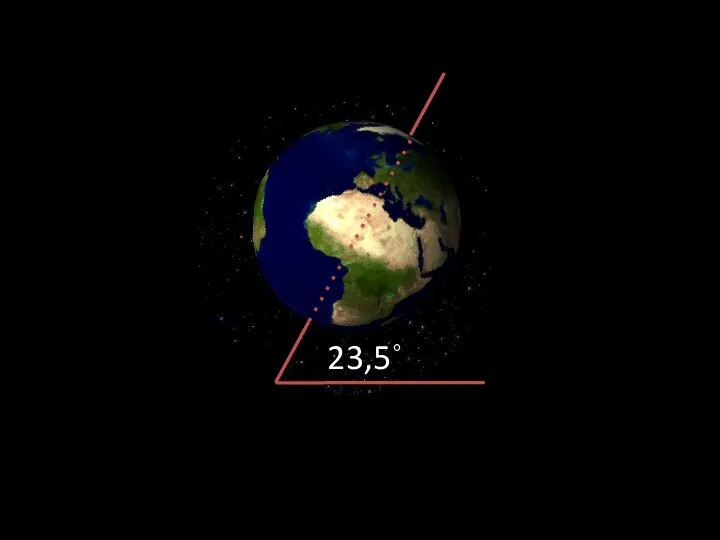

Публичное выступление Презентация. Солнечный свет на Земле

Презентация. Солнечный свет на Земле Работа с иллюстративным материалом в процессе подготовки к ЕГЭ и олимпиаде

Работа с иллюстративным материалом в процессе подготовки к ЕГЭ и олимпиаде Виды предложений. 3 класс

Виды предложений. 3 класс Процессы с участием нуклеиновых кислот

Процессы с участием нуклеиновых кислот Финансовые рынки и финансовые институты

Финансовые рынки и финансовые институты Адекватность, эквивалентность и переводимость, как качественные характеристики процесса перевода

Адекватность, эквивалентность и переводимость, как качественные характеристики процесса перевода Игра Доскажи словечко

Игра Доскажи словечко Причины и условия возникновения патологических процессов. Роль реактивности организма при патологии

Причины и условия возникновения патологических процессов. Роль реактивности организма при патологии Сокращение и нераспространение оружия массового поражения. (Тема 7)

Сокращение и нераспространение оружия массового поражения. (Тема 7) Презентация по теме Квиллинг

Презентация по теме Квиллинг Цифровая схемотехника. Классификация регистров

Цифровая схемотехника. Классификация регистров Крымская война 1853 - 1856 годов

Крымская война 1853 - 1856 годов Внутренняя изоляция высоковольтного электроэнергетического оборудования. (Лекция 8)

Внутренняя изоляция высоковольтного электроэнергетического оборудования. (Лекция 8) Graphic Аrts

Graphic Аrts Ведение мяча в баскетболе

Ведение мяча в баскетболе Дополнения к XML. Пространства имен. (Лекция 4)

Дополнения к XML. Пространства имен. (Лекция 4) Пермский государственный национальный исследовательский университет

Пермский государственный национальный исследовательский университет Развитие нефтегазовой отрасли в мире и в России

Развитие нефтегазовой отрасли в мире и в России Меры государственной поддержки бизнеса на территории Вологодской области, инвестиционная политика в области

Меры государственной поддержки бизнеса на территории Вологодской области, инвестиционная политика в области Раны. Классификация ран

Раны. Классификация ран Удивительный мир насекомых. Игра для дошкольников

Удивительный мир насекомых. Игра для дошкольников Бизнес-планирование и анализ инвестиционных проектов

Бизнес-планирование и анализ инвестиционных проектов