Содержание

- 2. 1. Precaution 1. All repairs should be done in accordance with the procedures described in this

- 3. 8. Never defeat any of the B+ voltage interlocks. Do not apply AC power to the

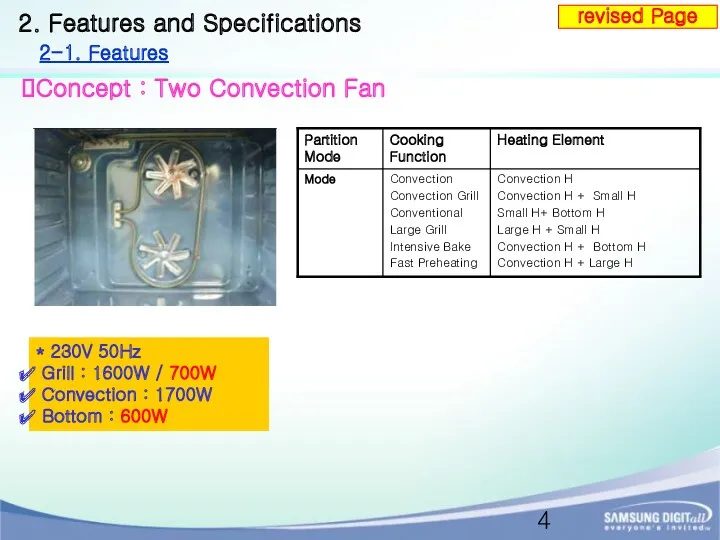

- 4. Concept : Two Convection Fan 2. Features and Specifications 2-1. Features * 230V 50Hz Grill :

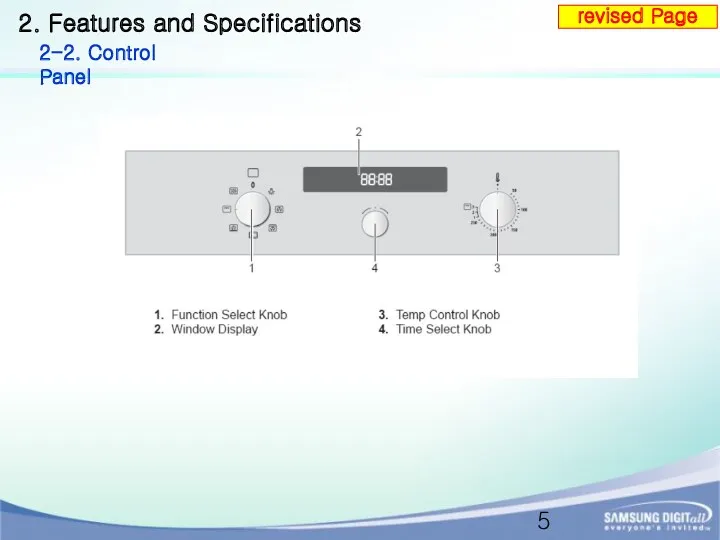

- 5. 2. Features and Specifications 2-2. Control Panel revised Page

- 6. 2. Features and Specifications 2-3. Accessory revised Page

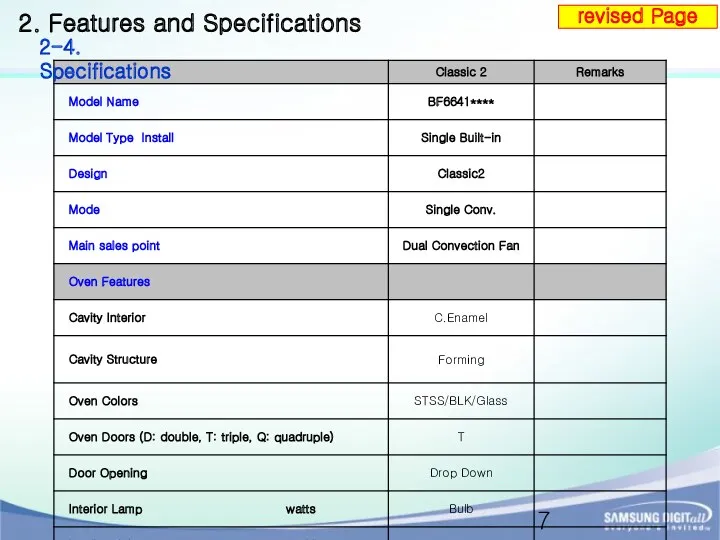

- 7. 2. Features and Specifications 2-4. Specifications revised Page

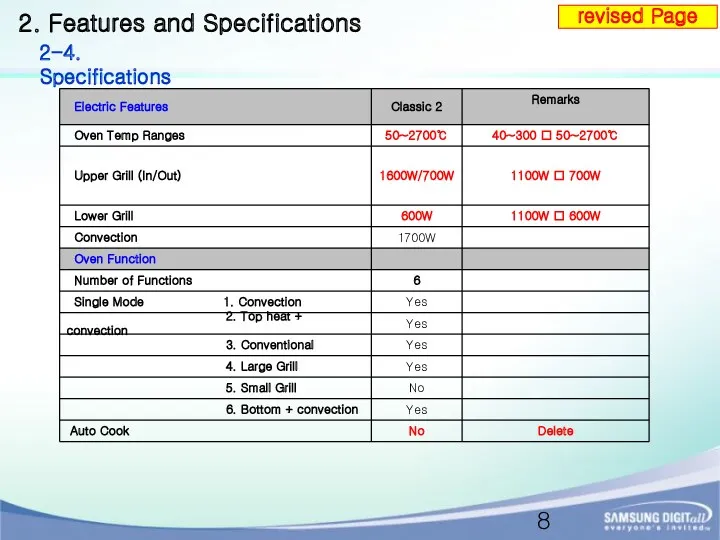

- 8. 2. Features and Specifications 2-4. Specifications revised Page

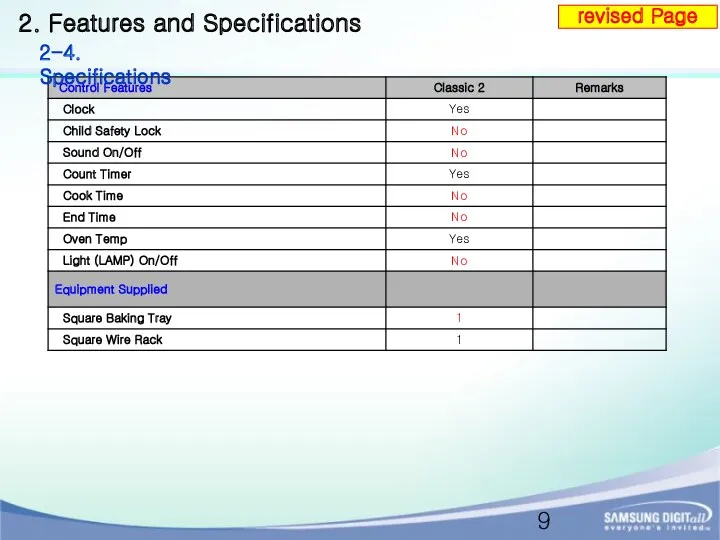

- 9. 2. Features and Specifications 2-4. Specifications revised Page

- 10. 3. Installation IMPORTANT Any electrical installation work must be carried out by a qualified electrician /

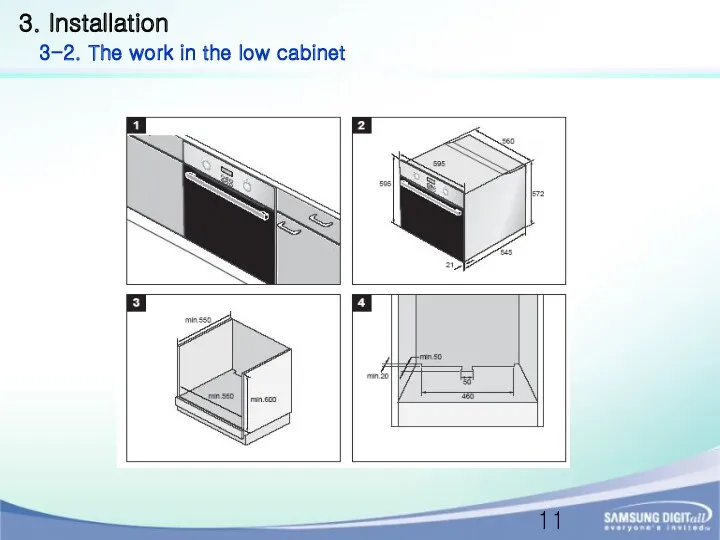

- 11. 3. Installation 3-2. The work in the low cabinet

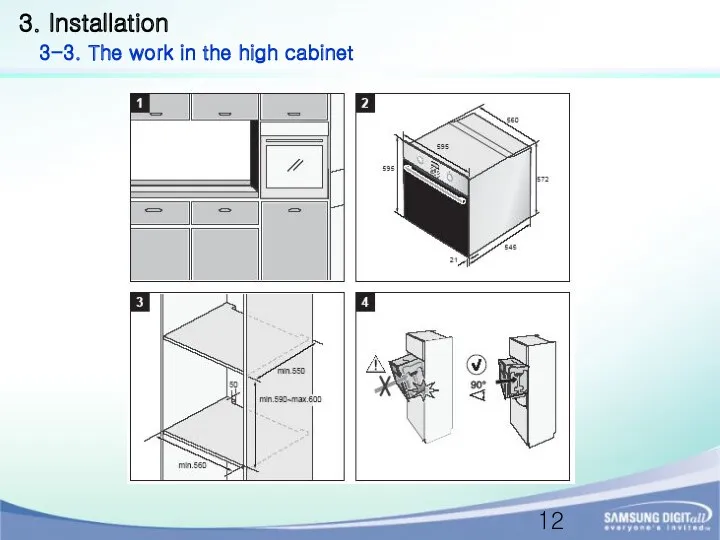

- 12. 3. Installation 3-3. The work in the high cabinet

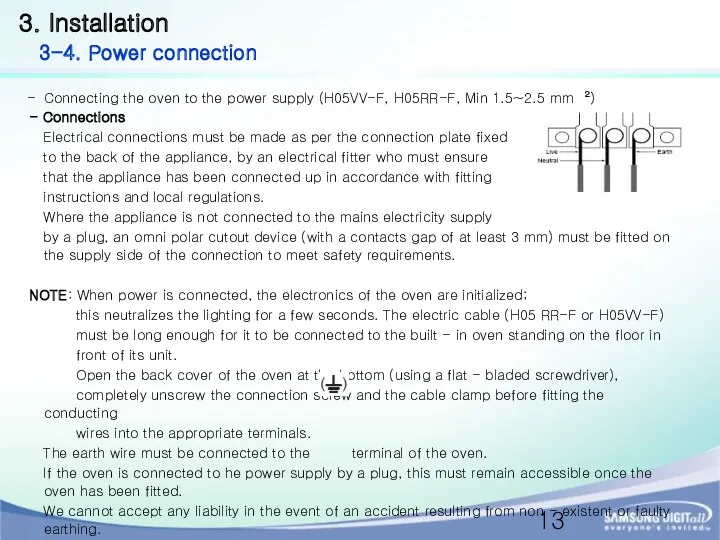

- 13. Connecting the oven to the power supply (H05VV-F, H05RR-F, Min 1.5~2.5 mm²) - Connections Electrical connections

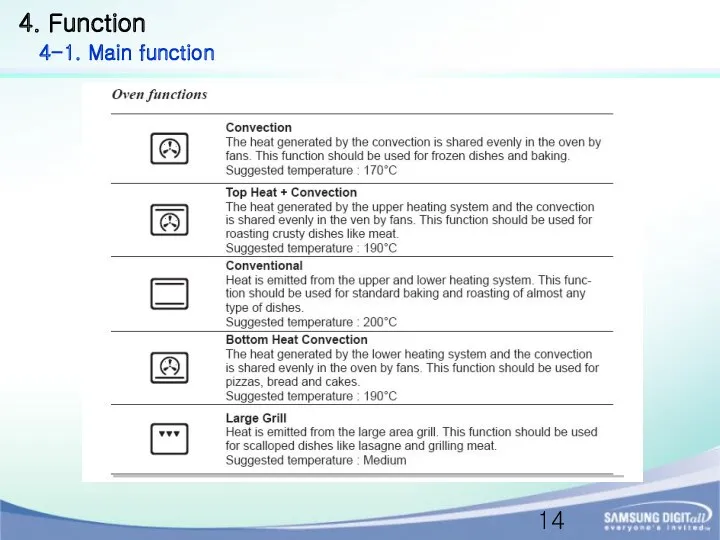

- 14. 4. Function 4-1. Main function

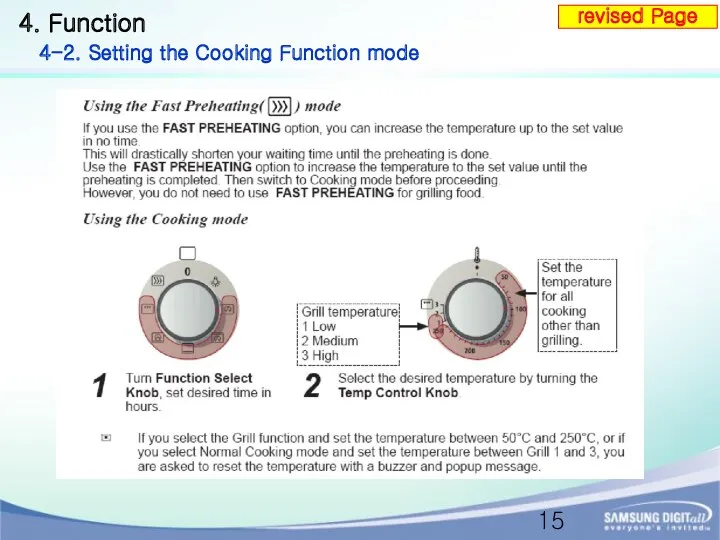

- 15. 4. Function 4-2. Setting the Cooking Function mode revised Page

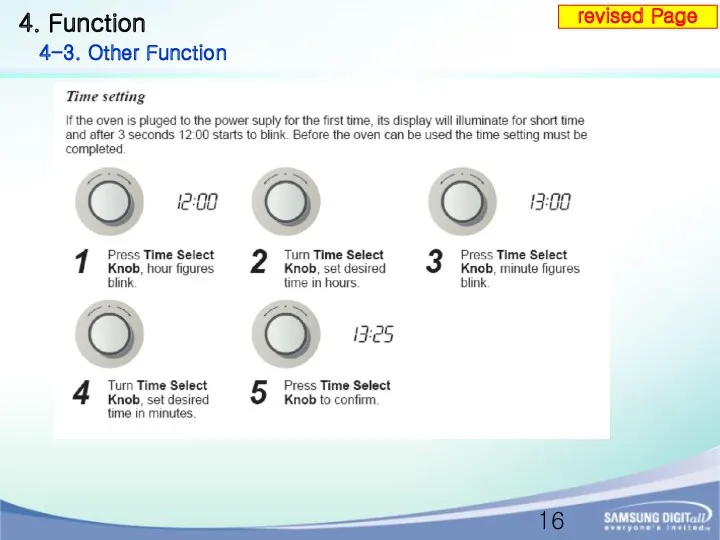

- 16. 4. Function 4-3. Other Function revised Page

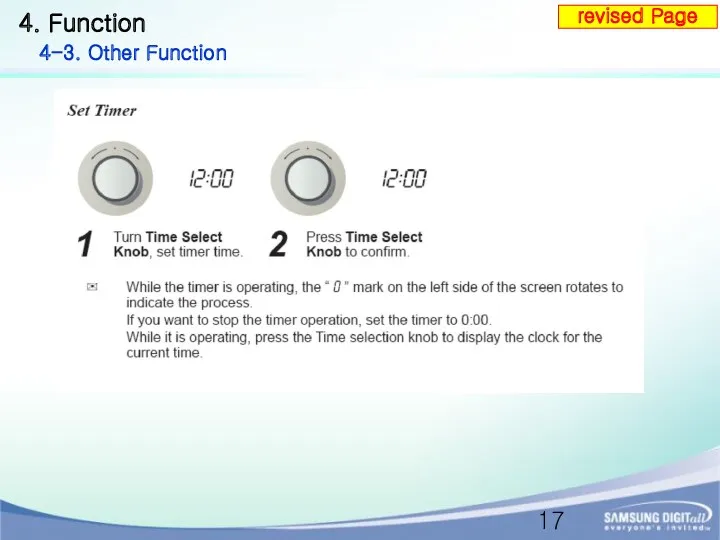

- 17. 4. Function 4-3. Other Function revised Page

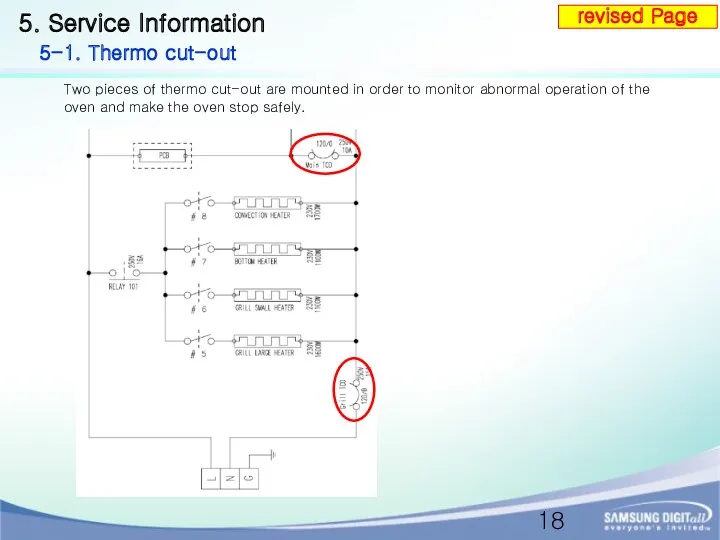

- 18. 5. Service Information 5-1. Thermo cut-out Two pieces of thermo cut-out are mounted in order to

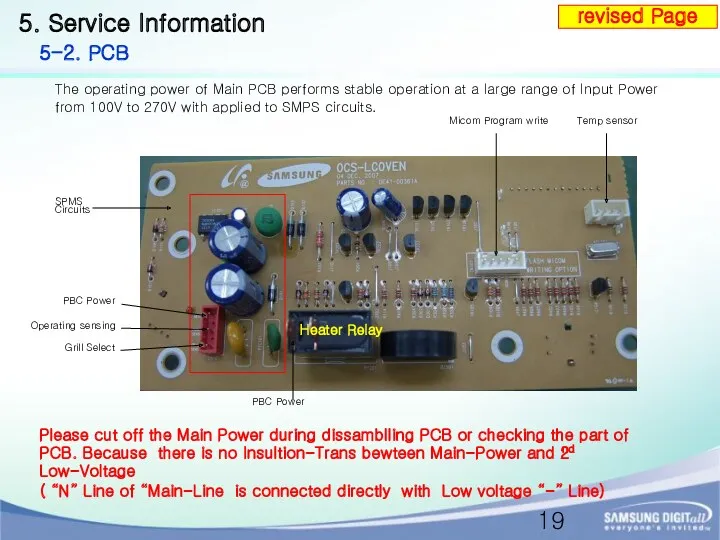

- 19. 5. Service Information 5-2. PCB The operating power of Main PCB performs stable operation at a

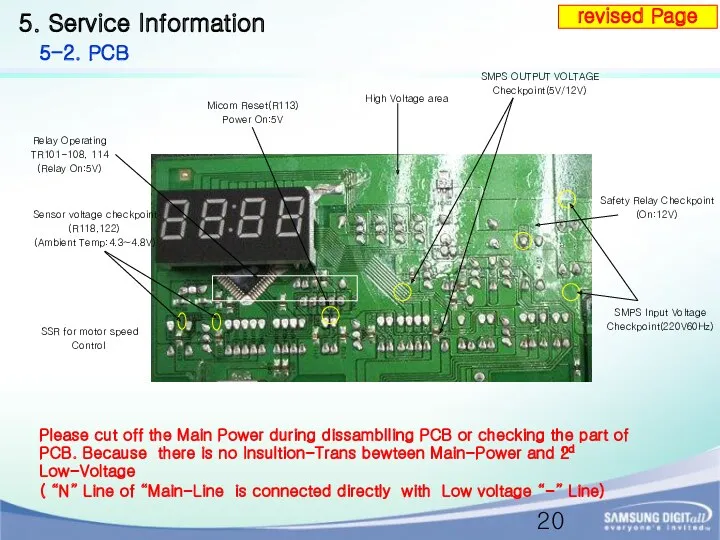

- 20. 5. Service Information 5-2. PCB SMPS OUTPUT VOLTAGE Checkpoint(5V/12V) High Voltage area SSR for motor speed

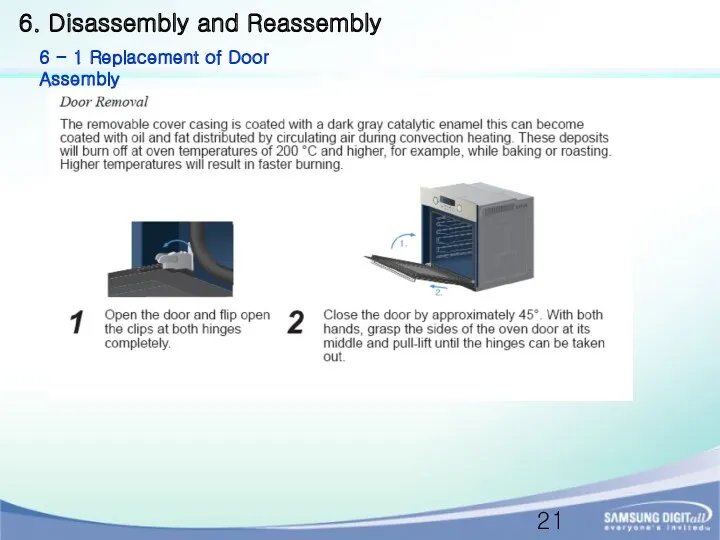

- 21. 6. Disassembly and Reassembly 6 - 1 Replacement of Door Assembly

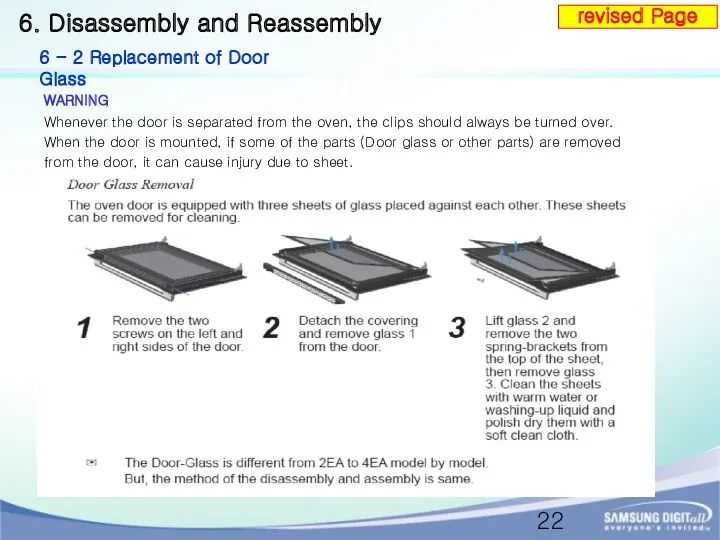

- 22. WARNING Whenever the door is separated from the oven, the clips should always be turned over.

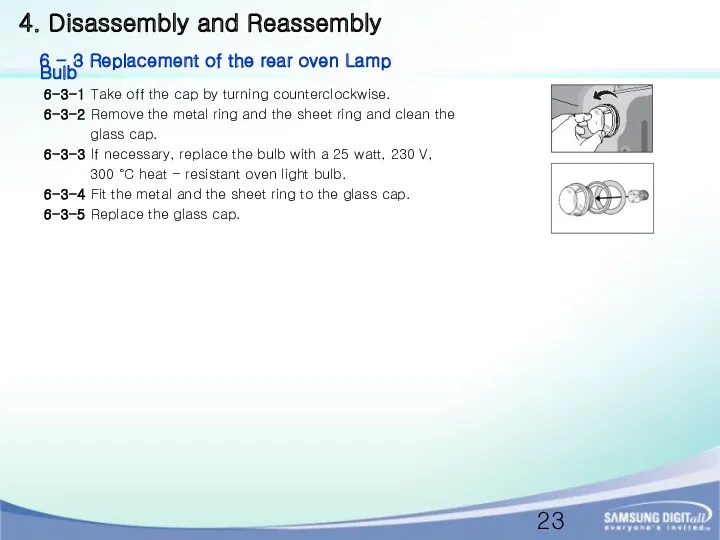

- 23. 6-3-1 Take off the cap by turning counterclockwise. 6-3-2 Remove the metal ring and the sheet

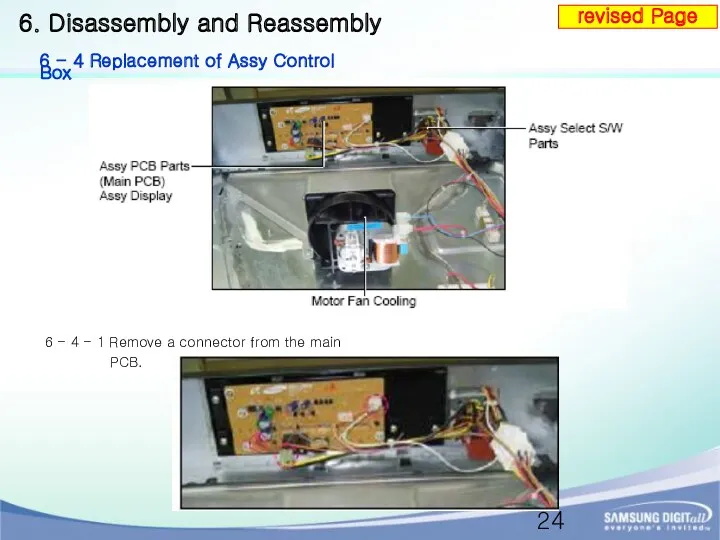

- 24. 6 - 4 - 1 Remove a connector from the main PCB. 6. Disassembly and Reassembly

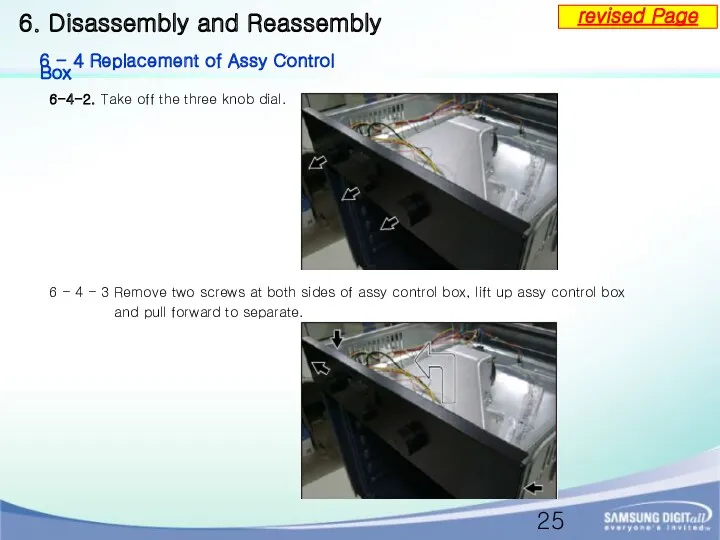

- 25. 6-4-2. Take off the three knob dial. 6. Disassembly and Reassembly 6 - 4 Replacement of

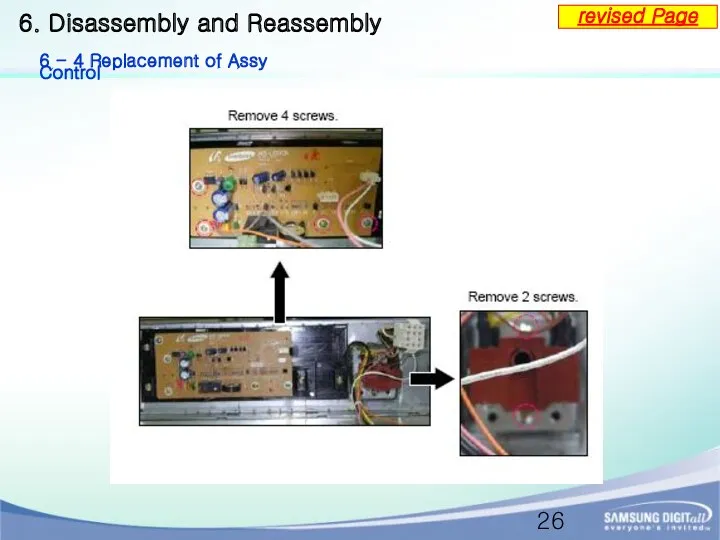

- 26. 6. Disassembly and Reassembly 6 - 4 Replacement of Assy Control revised Page

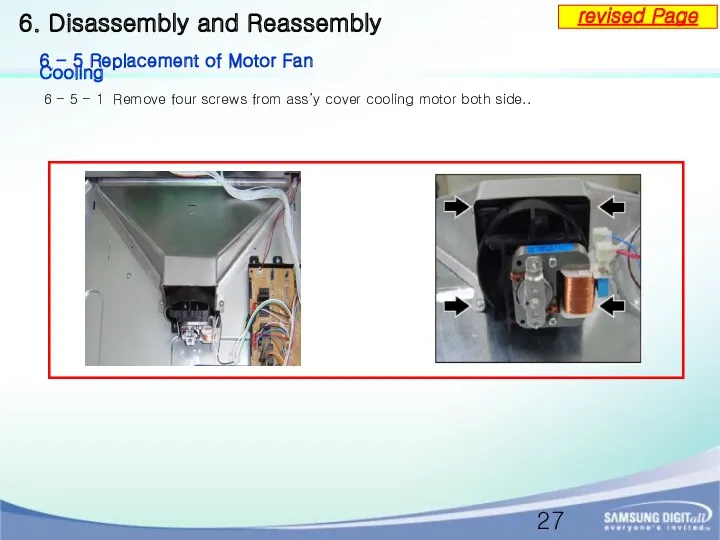

- 27. 6 - 5 - 1 Remove four screws from ass’y cover cooling motor both side.. 6.

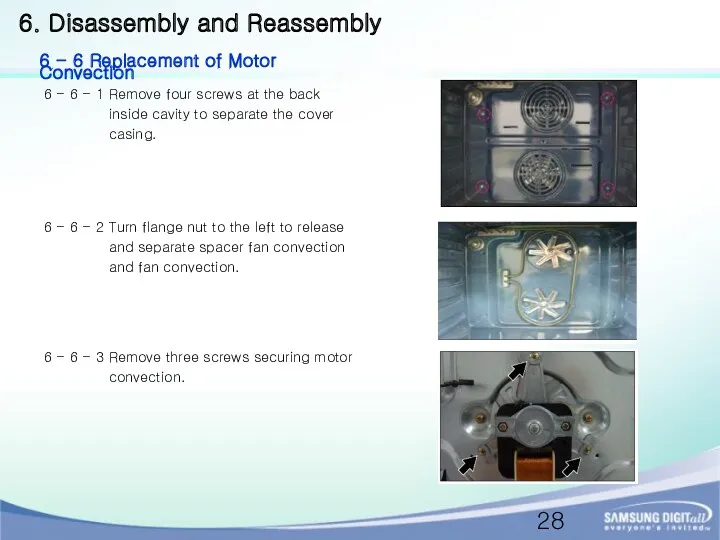

- 28. 6 - 6 - 1 Remove four screws at the back inside cavity to separate the

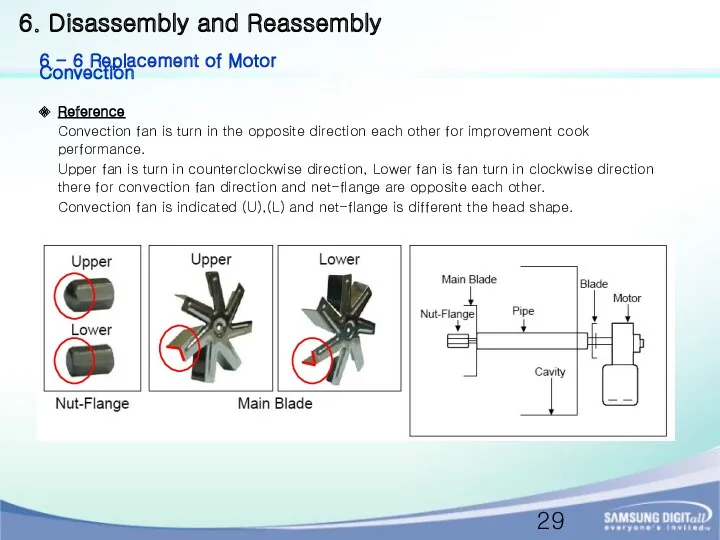

- 29. 6. Disassembly and Reassembly 6 - 6 Replacement of Motor Convection Reference Convection fan is turn

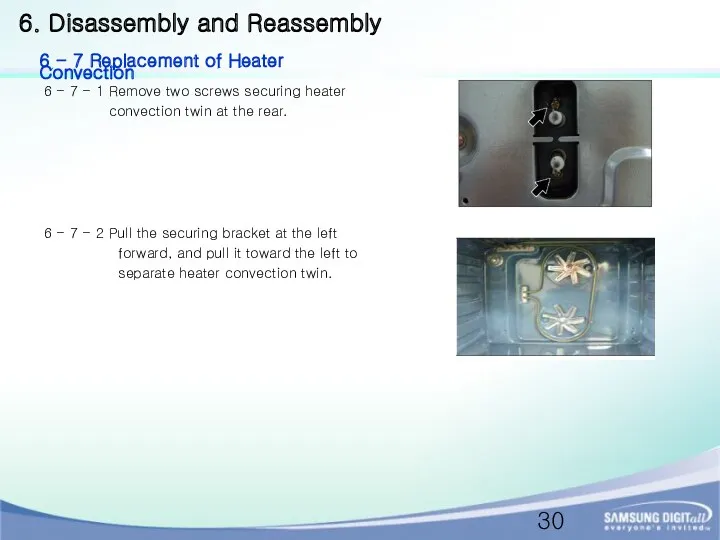

- 30. 6 - 7 - 1 Remove two screws securing heater convection twin at the rear. 6

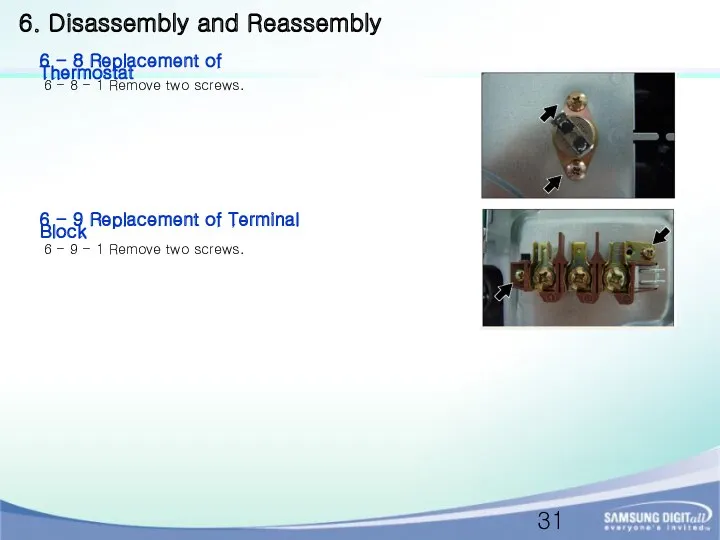

- 31. 6 - 8 - 1 Remove two screws. 6 - 9 - 1 Remove two screws.

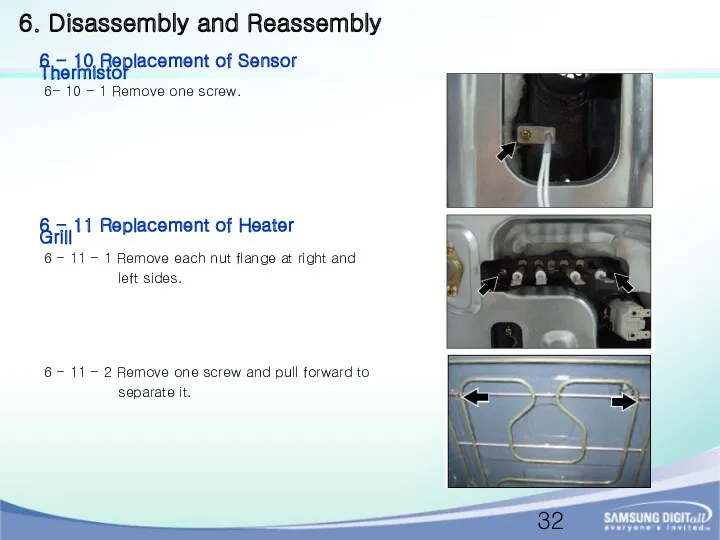

- 32. 6- 10 - 1 Remove one screw. 6 - 11 - 1 Remove each nut flange

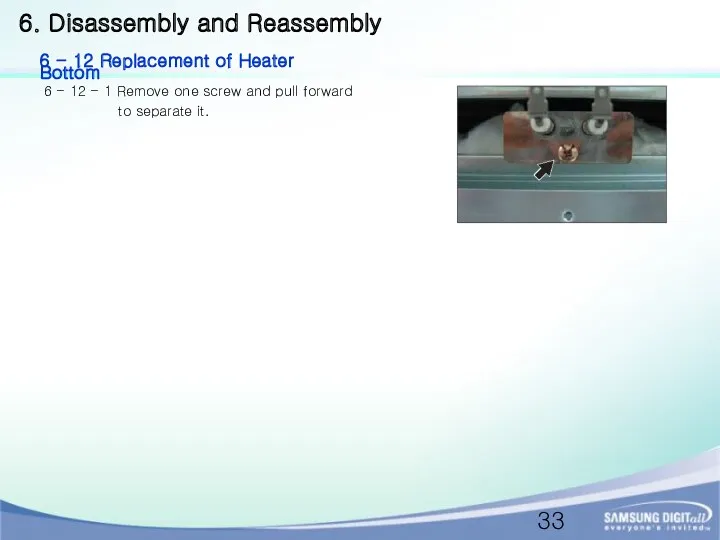

- 33. 6 - 12 - 1 Remove one screw and pull forward to separate it. 6. Disassembly

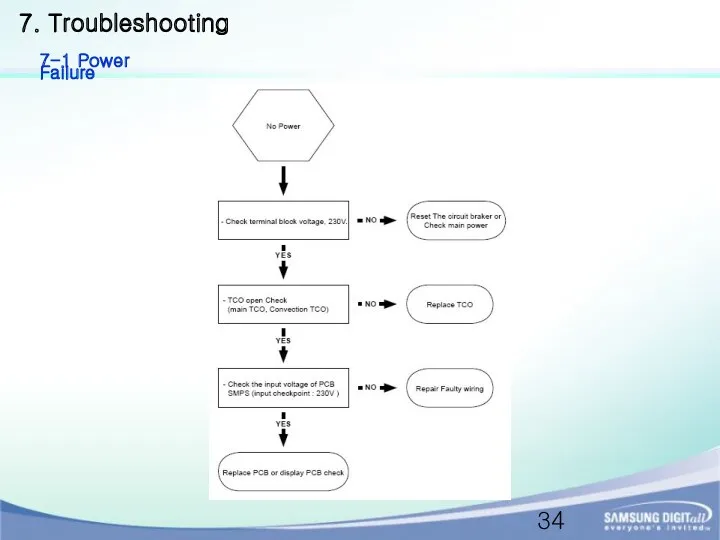

- 34. 7. Troubleshooting 7-1 Power Failure

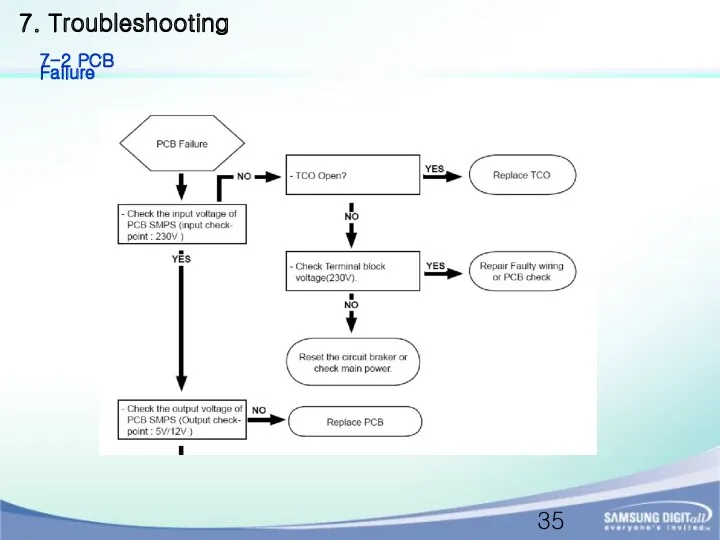

- 35. 7. Troubleshooting 7-2 PCB Failure

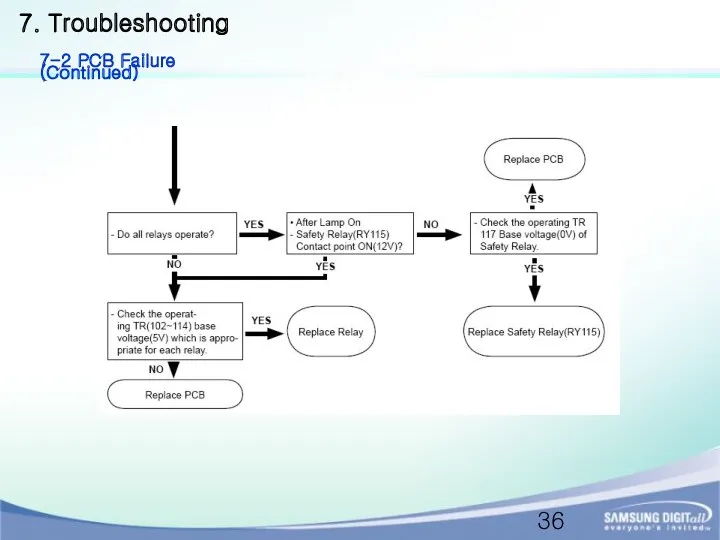

- 36. 7. Troubleshooting 7-2 PCB Failure (Continued)

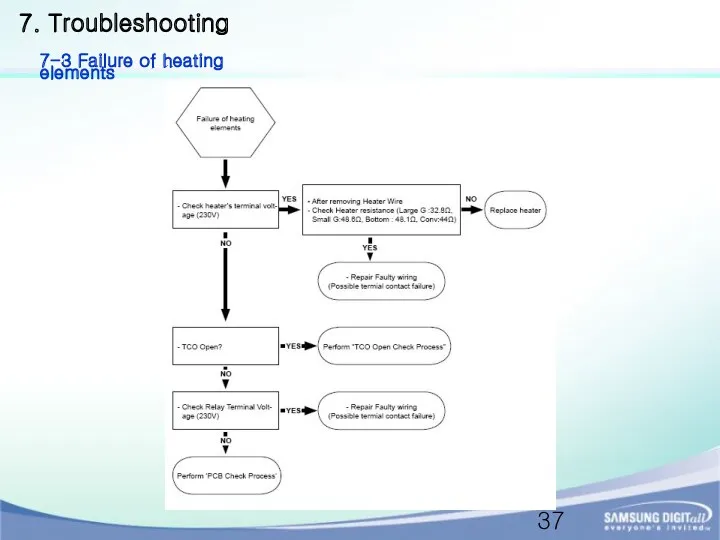

- 37. 7. Troubleshooting 7-3 Failure of heating elements

- 38. 8. Schematic Diagram 8-1 Main PCB revised Page Please cut off the Main Power during dissamblling

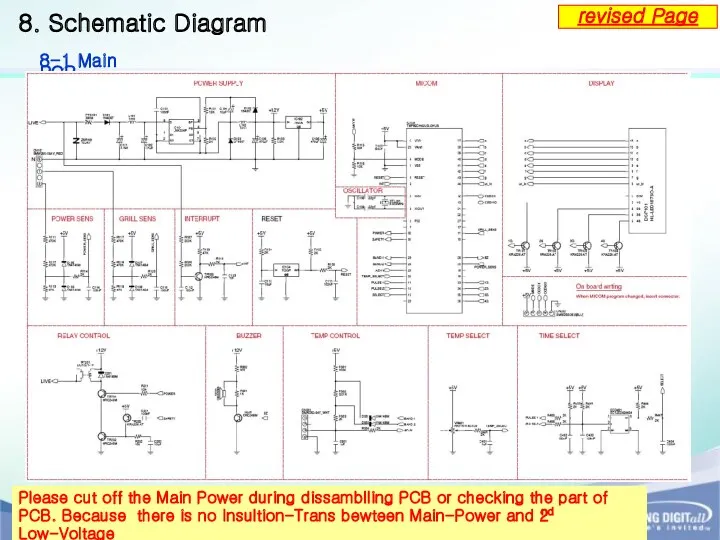

- 39. 8. Schematic Diagram 8-2 SMPS Diagram revised Page

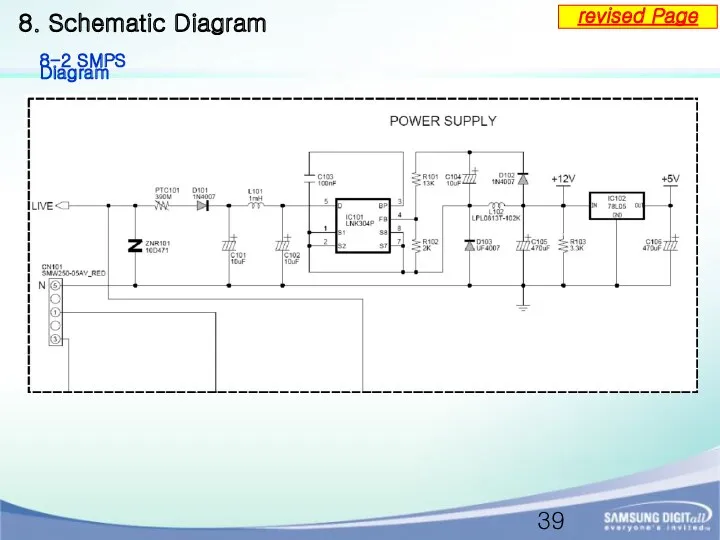

- 40. 8. Schematic Diagram 8-3 Temp Sensor revised Page

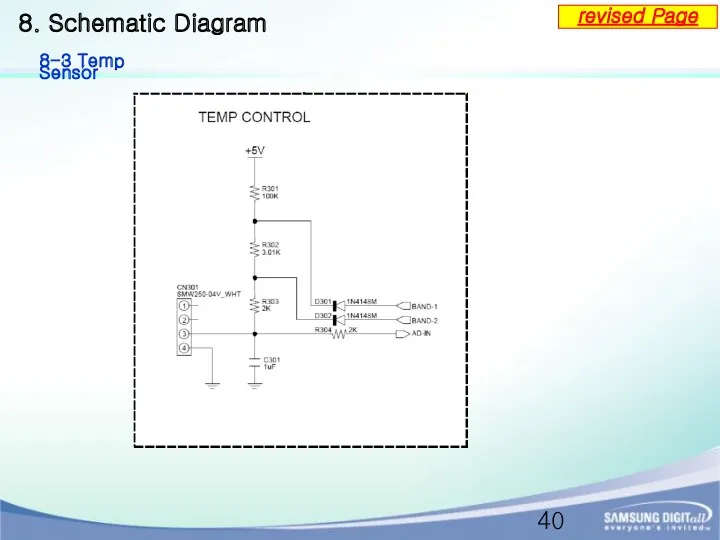

- 41. 8. Schematic Diagram 8-4 Relay Operation Diagram revised Page

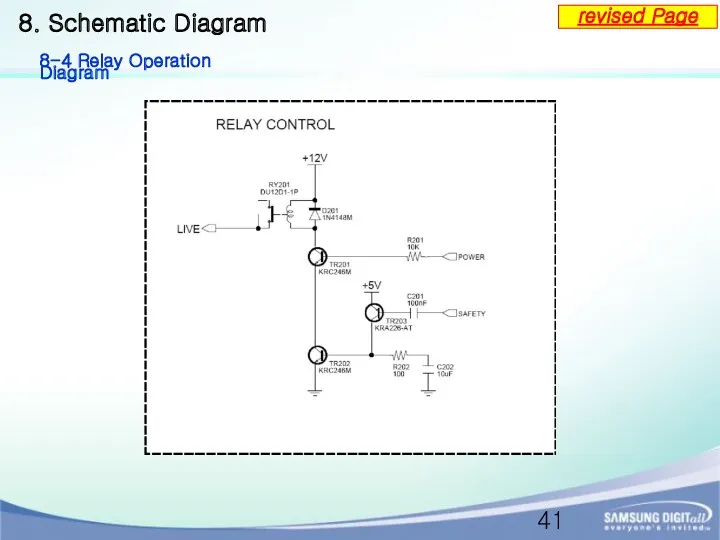

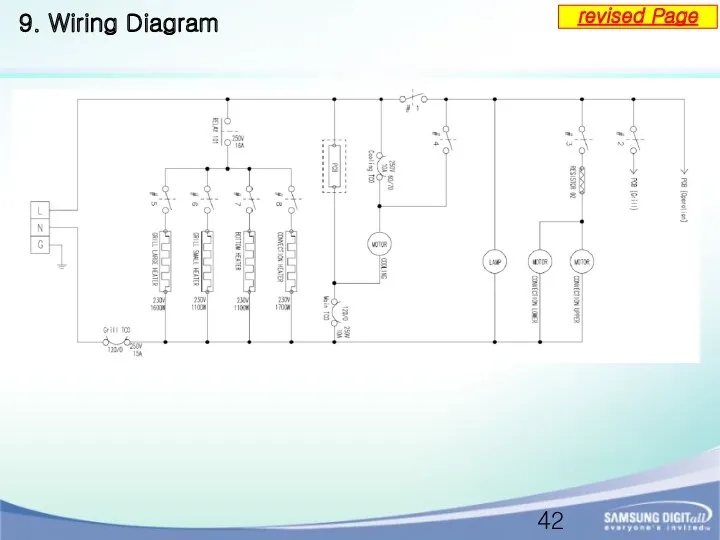

- 42. 9. Wiring Diagram revised Page

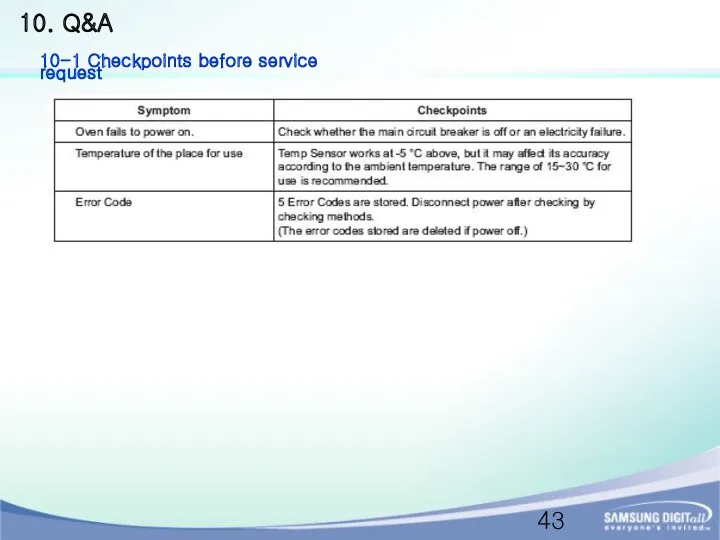

- 43. 10. Q&A 10-1 Checkpoints before service request

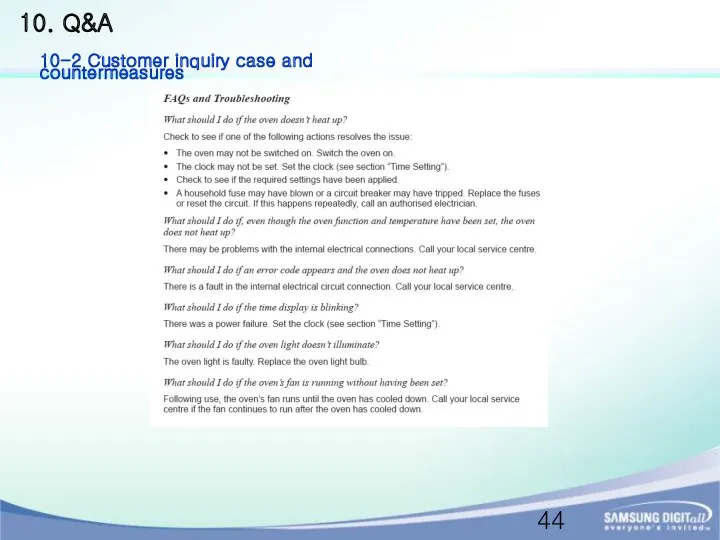

- 44. 10. Q&A 10-2 Customer inquiry case and countermeasures

- 46. Скачать презентацию

Озон. Строение молекулы озона

Озон. Строение молекулы озона Приборы и устройства безопасности кранов

Приборы и устройства безопасности кранов Игры нашего поселка

Игры нашего поселка Лекарственные формы для инъекций

Лекарственные формы для инъекций Презентация Развитие личности ребенка в процессе приобщения к культурно-историческому наследию казачества

Презентация Развитие личности ребенка в процессе приобщения к культурно-историческому наследию казачества Чрезвычайные ситуации и их характеристика. Основные понятия и определения

Чрезвычайные ситуации и их характеристика. Основные понятия и определения Презентация Многоатомные спирты 10 класс

Презентация Многоатомные спирты 10 класс Презентация к празднику Прощай, АЗБУКА!

Презентация к празднику Прощай, АЗБУКА! Вплив війни на психічне здоров'я 2

Вплив війни на психічне здоров'я 2 Фестиваль народного творчества Донбасса

Фестиваль народного творчества Донбасса Из истории наших предков. Боги славян.

Из истории наших предков. Боги славян. Колесо оценки урока.

Колесо оценки урока. Беспроводные локальные сети

Беспроводные локальные сети Творчий проект Переборні задачі Паскаль

Творчий проект Переборні задачі Паскаль Презентация Зимушка-Зима.

Презентация Зимушка-Зима. Эти слайды описывают любовь к тебе

Эти слайды описывают любовь к тебе Николай Иванович Сладков

Николай Иванович Сладков Театральное искусство XVII - XVIII вв и его виды

Театральное искусство XVII - XVIII вв и его виды Аргументы Шепли в большом споре

Аргументы Шепли в большом споре Развитие произвольной памяти у детей старшего дошкольного возраста через дидактические игры

Развитие произвольной памяти у детей старшего дошкольного возраста через дидактические игры Формирование простых запросов к готовой базе данных. (9 класс)

Формирование простых запросов к готовой базе данных. (9 класс) ПРЕЗЕНТАЦИЯ по познавательному развитию ФЦКМ ДОРОГА ЖИЗНИ

ПРЕЗЕНТАЦИЯ по познавательному развитию ФЦКМ ДОРОГА ЖИЗНИ Первая медицинская помощь при кровотечении

Первая медицинская помощь при кровотечении Программа технологических расчетов трубопроводов

Программа технологических расчетов трубопроводов Внеурочная деятельность в младшей школе как важное условие реализации деятельности ФГОС нового поколения

Внеурочная деятельность в младшей школе как важное условие реализации деятельности ФГОС нового поколения  РАБОТЫ УЧАЩИХСЯ 7А класса по математике, информатике и ИКТ

РАБОТЫ УЧАЩИХСЯ 7А класса по математике, информатике и ИКТ Покормите птиц зимой!!!

Покормите птиц зимой!!! Гавриил Романович Державин (1743-1816). Творчество Г. Р. Державина

Гавриил Романович Державин (1743-1816). Творчество Г. Р. Державина