HSE Networking 2016

Basic cause:

• The end switch was broken. The end switch

was not fastened on protection door.

Another causes:

• lack of safety discipline on the shop floor level

• violation of the safety requirements by operator

• low control for technical safety equipments

Corrective measures:

• The end switchs was fasten on protection door and checked another end switchs on lines. (This was done immediately after accident.)

• All end switchs was fasten reliably , with out opportunities to take off it easy with simple equipment (e.g. screwdriver).

• All employees of production department were instructed

• Process and procedures of tecnical maintenance was reviewed and improved

Словообразование при помощи суффиксов в английском языке. 9 класс

Словообразование при помощи суффиксов в английском языке. 9 класс The 10 Golden Rules of Customer Service

The 10 Golden Rules of Customer Service Christmas

Christmas Famous Person: Marilyn Monroe

Famous Person: Marilyn Monroe ОГЭ. Интерактивный тренажёр. Word formation. Tasks 29-34. 5 variants

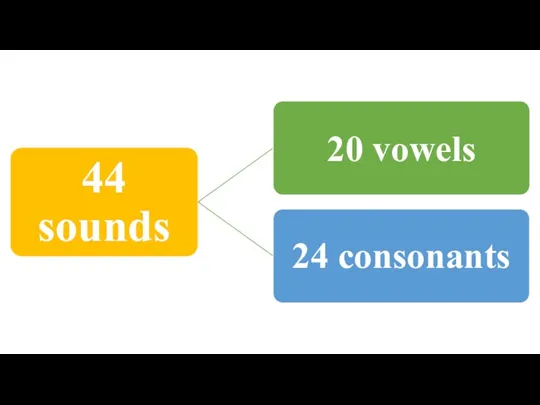

ОГЭ. Интерактивный тренажёр. Word formation. Tasks 29-34. 5 variants 44 sounds. 20 vowels. 24 consonants

44 sounds. 20 vowels. 24 consonants Legalese in Legal English Usage

Legalese in Legal English Usage CANADA

CANADA Irregular verbs

Irregular verbs A lesson about jobs (part 1)

A lesson about jobs (part 1) Spotlight 3. Module 2 (Unit 4). Family moments

Spotlight 3. Module 2 (Unit 4). Family moments Английский Алфавит. Alphabet

Английский Алфавит. Alphabet Lecture 3 old english grammar. The nominal system

Lecture 3 old english grammar. The nominal system My Diary

My Diary Zero Article in English Grammar

Zero Article in English Grammar English pronouns

English pronouns Basketball is a team sport with a ball

Basketball is a team sport with a ball Грамматические приемы перевода

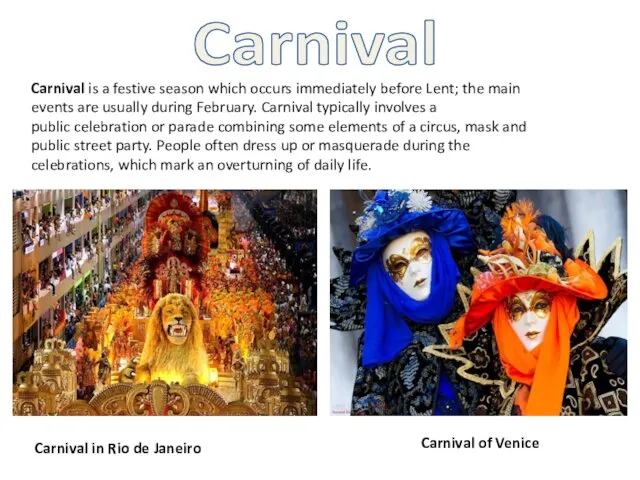

Грамматические приемы перевода Carnival of Venice. Carnival in Rio de Janeiro

Carnival of Venice. Carnival in Rio de Janeiro Требования к современному уроку английского языка

Требования к современному уроку английского языка Methods of teaching grammar. Types of grammatical skills

Methods of teaching grammar. Types of grammatical skills Talented women, prepositions

Talented women, prepositions Do or make game. Teacher switcher

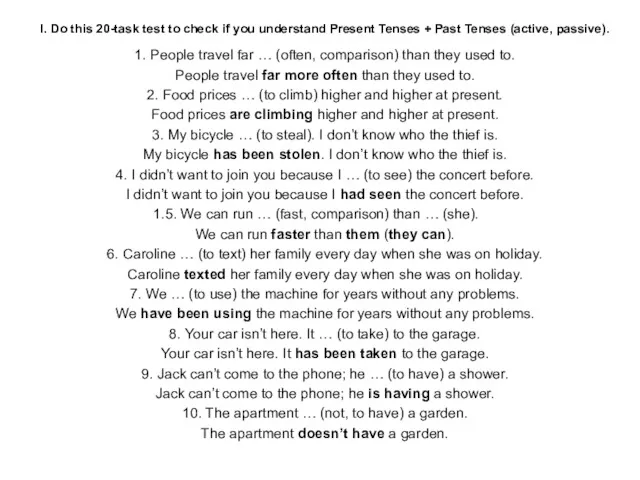

Do or make game. Teacher switcher Do this 20-task test to check if you understand Present Tenses + Past Tenses (active, passive)

Do this 20-task test to check if you understand Present Tenses + Past Tenses (active, passive) In the bath!

In the bath! Who is who

Who is who Do what you can, with what you have, where you are

Do what you can, with what you have, where you are My favorite holiday

My favorite holiday