- Главная

- Английский язык

- Manufacture of cars in Russia and abroad

Содержание

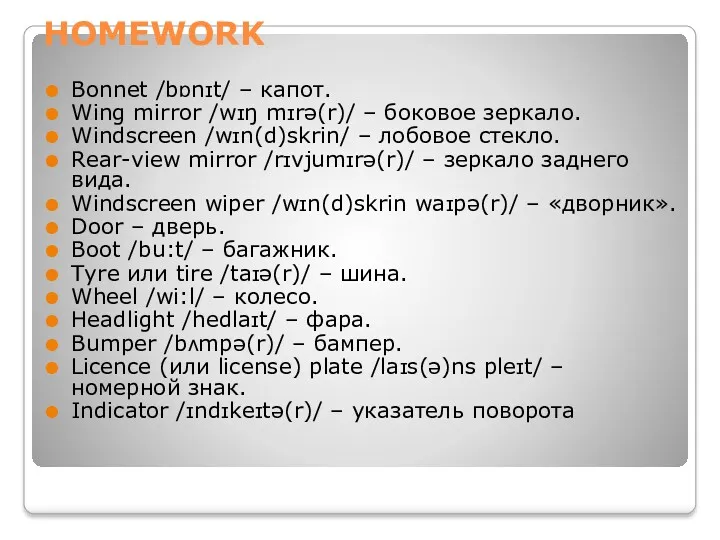

- 2. HOMEWORK Bonnet /bɒnɪt/ – капот. Wing mirror /wɪŋ mɪrə(r)/ – боковое зеркало. Windscreen /wɪn(d)skrin/ – лобовое

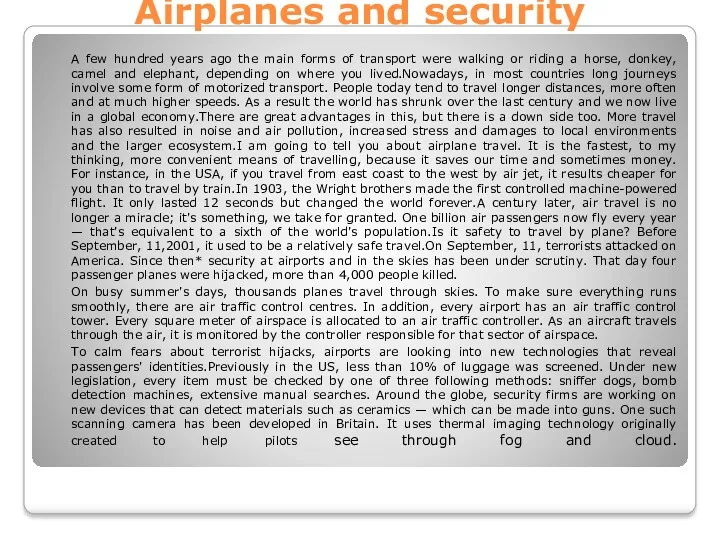

- 3. Airplanes and security A few hundred years ago the main forms of transport were walking or

- 4. Questions: 1. What was the main means of transport a few centuries ago? 2. How did

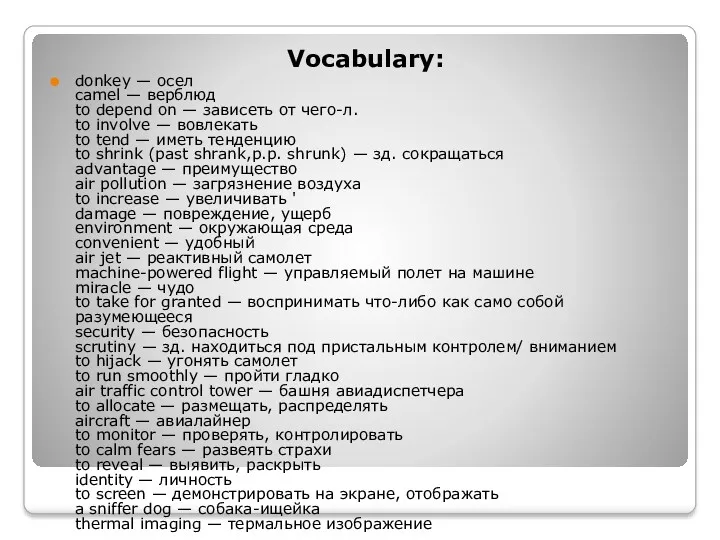

- 5. Vocabulary: donkey — осел camel — верблюд to depend on — зависеть от чего-л. to involve

- 6. History The Russian EmpireIn pre-Soviet times, Russia had no automobile industry as a specialized industry. The

- 7. The automotive industry of the USSR USSRThe development of automotive industry of the USSR passed several

- 8. After the war, along with reconstruction and expansion of the existing plants built and started production

- 9. From 1947-1948, the car manufacturers started the development of new types of vehicles instead of the

- 10. Automotive industry in Russia Since 1991In 2002 in Vsevolozhsk (Leningrad region) opened the car company FordIn

- 11. In July 2008, was laid the first stone at the construction site of the plant PSMA

- 12. Assembly production of foreign cars Assembly production of foreign cars began to appear in Russia in

- 13. Mass opening in Russia of factories of foreign automakers contributed to the introduction in mid-2000-ies the

- 14. In 2006, automotive components, intended for industrial Assembly of cars was introduced a zero rate of

- 15. In St. Petersburg began to produce the company's products companies General Motors and Toyota, and in

- 17. Скачать презентацию

HOMEWORK

Bonnet /bɒnɪt/ – капот.

Wing mirror /wɪŋ mɪrə(r)/ – боковое зеркало.

Windscreen /wɪn(d)skrin/ – лобовое стекло.

Rear-view

HOMEWORK

Bonnet /bɒnɪt/ – капот.

Wing mirror /wɪŋ mɪrə(r)/ – боковое зеркало.

Windscreen /wɪn(d)skrin/ – лобовое стекло.

Rear-view

Windscreen wiper /wɪn(d)skrin waɪpə(r)/ – «дворник».

Door – дверь.

Boot /bu:t/ – багажник.

Tyre или tire /taɪə(r)/ – шина.

Wheel /wi:l/ – колесо.

Headlight /hedlaɪt/ – фара.

Bumper /bʌmpə(r)/ – бампер.

Licence (или license) plate /laɪs(ə)ns pleɪt/ – номерной знак.

Indicator /ɪndɪkeɪtə(r)/ – указатель поворота

Airplanes and security

A few hundred years ago the main forms of

Airplanes and security

A few hundred years ago the main forms of

On busy summer's days, thousands planes travel through skies. To make sure everything runs smoothly, there are air traffic control centres. In addition, every airport has an air traffic control tower. Every square meter of airspace is allocated to an air traffic controller. As an aircraft travels through the air, it is monitored by the controller responsible for that sector of airspace.

To calm fears about terrorist hijacks, airports are looking into new technologies that reveal passengers' identities.Previously in the US, less than 10% of luggage was screened. Under new legislation, every item must be checked by one of three following methods: sniffer dogs, bomb detection machines, extensive manual searches. Around the globe, security firms are working on new devices that can detect materials such as ceramics — which can be made into guns. One such scanning camera has been developed in Britain. It uses thermal imaging technology originally created to help pilots see through fog and cloud.

Questions:

1. What was the main means of transport a few centuries

Questions:

1. What was the main means of transport a few centuries

Vocabulary:

donkey — осел

camel — верблюд

to depend on — зависеть от чего-л.

to

Vocabulary:

donkey — осел

camel — верблюд

to depend on — зависеть от чего-л.

to

History

The Russian EmpireIn pre-Soviet times, Russia had no automobile industry

History

The Russian EmpireIn pre-Soviet times, Russia had no automobile industry

The first Russian cars Yakovlev-the mill (1896)

The automotive industry of the USSR

USSRThe development of automotive industry of

The automotive industry of the USSR

USSRThe development of automotive industry of

After the war, along with reconstruction and expansion of the existing

After the war, along with reconstruction and expansion of the existing

In 1932 started production of cars GAZ-the Gorky automobile plant (1936 — cars M-1. In 1936 he started manufacturing cars 6 seater cars ZIS-101 at the Moscow automobile plant. Moscow car Assembly plant. KIM (1930) in 1938-1939, was enlarged and reconstructed for mass production mini-cars, may 1, 1940, was released the first 3 samples before the beginning of the great Patriotic war — about 500 cars, named KIM-10. In 1933, the Moscow automobile plant released 21-seater bus ZIS-8 in 1934 — improved bus ZIS-12, and before the war — bus for 26 passengers ZIS-16. Along with the development of production two-axle trucks were produced off-road vehicles, 1933 — three-axle trucks ZIS-6 with a capacity of 2.5 tons (4 tons — on the paved roads), in 1935 at the Gorky automobile plant — a three-axle truck GAZ-30 in lifting capacity 2 t During these years, was started the production of cars, trucks and chassis for special cars for different purposes.[During the great Patriotic war was built by the Ural automobile plant in Miass (Chelyabinsk region) and components of its plants — forging in Chelyabinsk and aggregate in Shadrinsk (Kurgan oblast). In 1942-1943, the Ural plant supplying car engines and the gearbox Moscow and other plants in July 1944 produced 3-ton trucks.

From 1947-1948, the car manufacturers started the development of new types

From 1947-1948, the car manufacturers started the development of new types

Automotive industry in Russia

Since 1991In 2002 in Vsevolozhsk (Leningrad region)

Automotive industry in Russia

Since 1991In 2002 in Vsevolozhsk (Leningrad region)

In July 2008, was laid the first stone at the construction

In July 2008, was laid the first stone at the construction

Assembly production of foreign cars

Assembly production of foreign cars began

Assembly production of foreign cars

Assembly production of foreign cars began

Mass opening in Russia of factories of foreign automakers contributed to

Mass opening in Russia of factories of foreign automakers contributed to

In 2006, automotive components, intended for industrial Assembly of cars was

In 2006, automotive components, intended for industrial Assembly of cars was

In St. Petersburg began to produce the company's products companies General

In St. Petersburg began to produce the company's products companies General

Gerund and Infinitive

Gerund and Infinitive The present indefinite tense

The present indefinite tense English. Oral texts

English. Oral texts Уровни перевода

Уровни перевода Comparatives and Superlatives

Comparatives and Superlatives Beautiful places

Beautiful places Teenagers and their problem

Teenagers and their problem Good and bad habits

Good and bad habits READ and LEARN

READ and LEARN Speakout Pre - Intermediate. Question forms

Speakout Pre - Intermediate. Question forms Instructions for writing the solution paragraph

Instructions for writing the solution paragraph Impressionizm

Impressionizm Young Heroes of the War 1941-1945

Young Heroes of the War 1941-1945 Snow

Snow Habits. Used to

Habits. Used to Verb to have got

Verb to have got Education abroad I had like

Education abroad I had like TV programmes

TV programmes Sport facilities of my university

Sport facilities of my university School What is school for you?

School What is school for you? Police of the Russian Federation

Police of the Russian Federation Present perfect tense

Present perfect tense Choice of profession

Choice of profession Peter’s family

Peter’s family Animals and parts of the body

Animals and parts of the body Customs and traditions in Great Britain. Обычаи и традиции

Customs and traditions in Great Britain. Обычаи и традиции About the person that is writing in this place. Something about

About the person that is writing in this place. Something about Yale university

Yale university