Содержание

- 2. What is it ? Method validation & verification provides objective evidence that a test method is

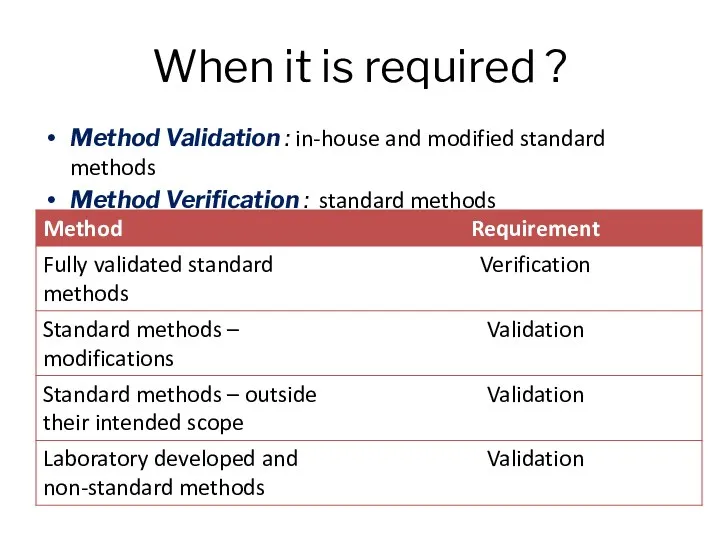

- 3. When it is required ? Method Validation : in-house and modified standard methods Method Verification :

- 4. Why it is necessary ? A test method must be shown to be fit for purpose

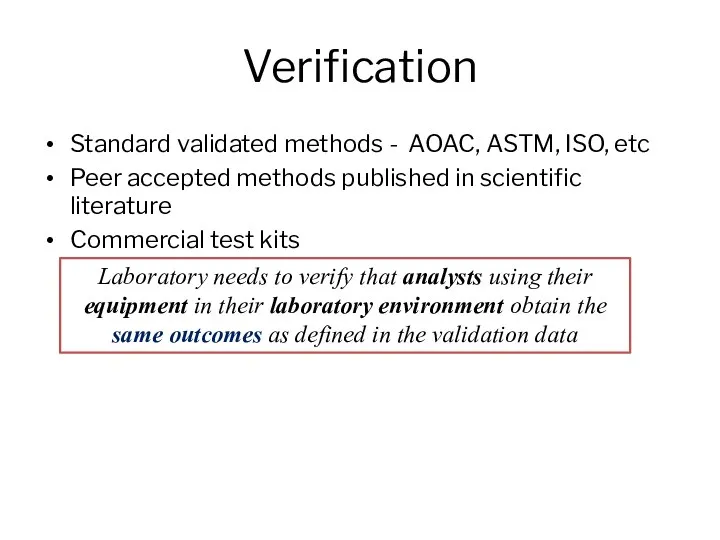

- 5. Verification Standard validated methods - AOAC, ASTM, ISO, etc Peer accepted methods published in scientific literature

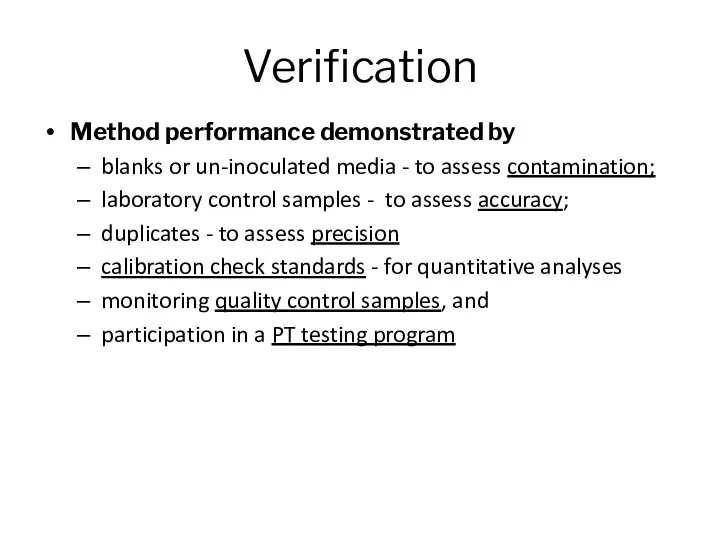

- 6. Verification Method performance demonstrated by blanks or un-inoculated media - to assess contamination; laboratory control samples

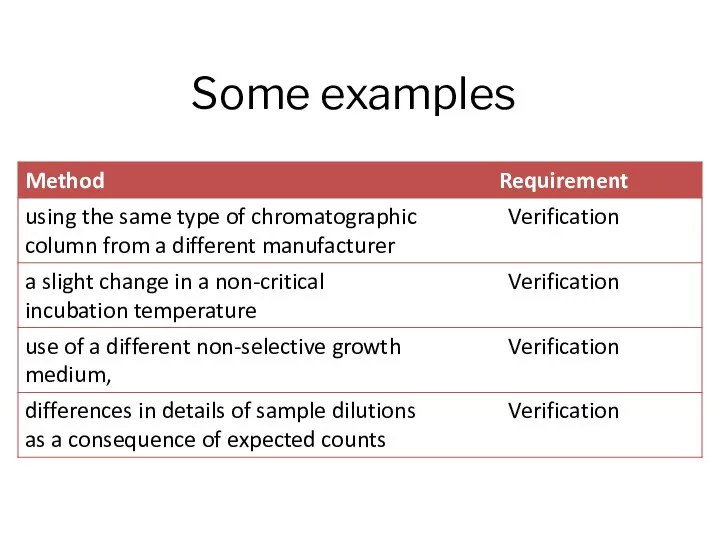

- 7. Some examples

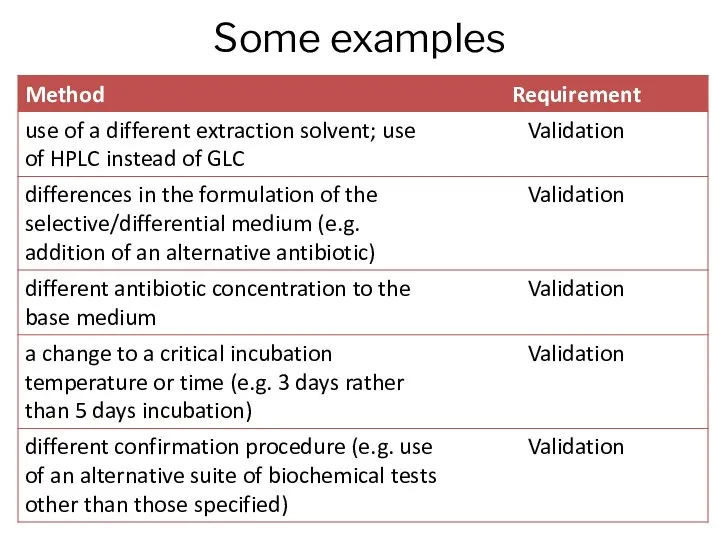

- 8. Some examples

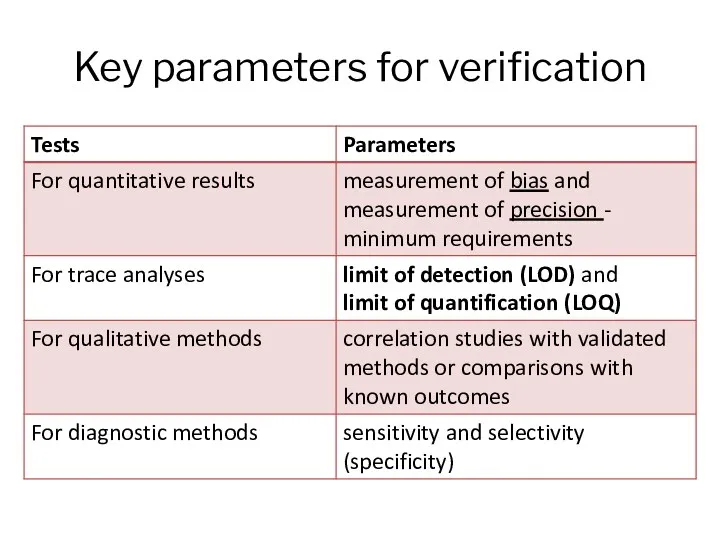

- 9. Key parameters for verification

- 10. Validation Non-standard and in-house-developed methods Scope and validation criteria to be defined and documented Tools to

- 11. Types of Validation Comparative Validation To demonstrate equivalent performance between two methods (validated and revised analytical

- 12. Validation Two steps to specify what you intend to identify or measure to determine selected performance

- 13. Validation Parameters Linearity range Measuring interval Matrix effects Selectivity Sensitivity Accuracy . Precision Repeatability Reproducibility Trueness

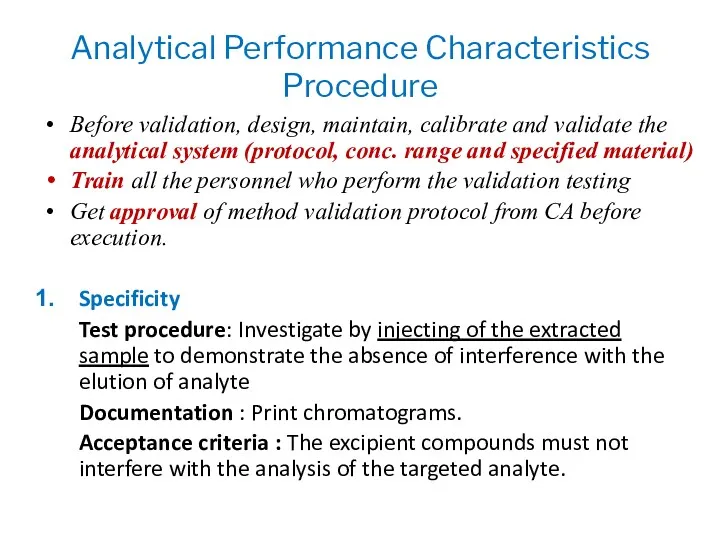

- 14. Analytical Performance Characteristics Procedure Before validation, design, maintain, calibrate and validate the analytical system (protocol, conc.

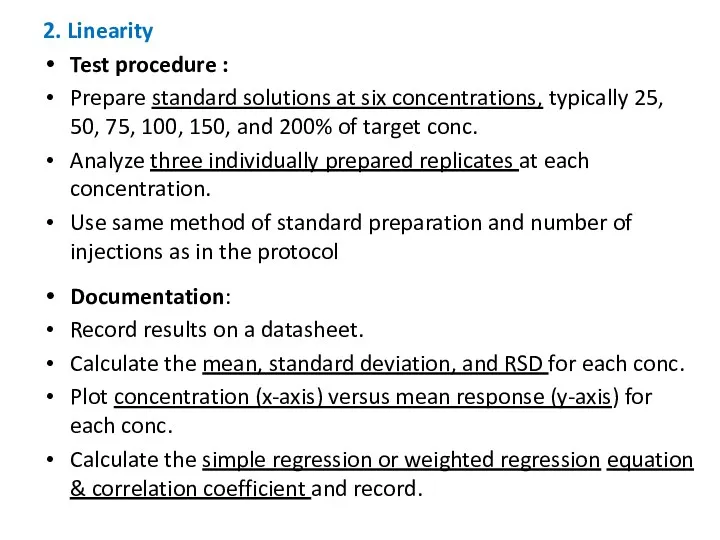

- 15. 2. Linearity Test procedure : Prepare standard solutions at six concentrations, typically 25, 50, 75, 100,

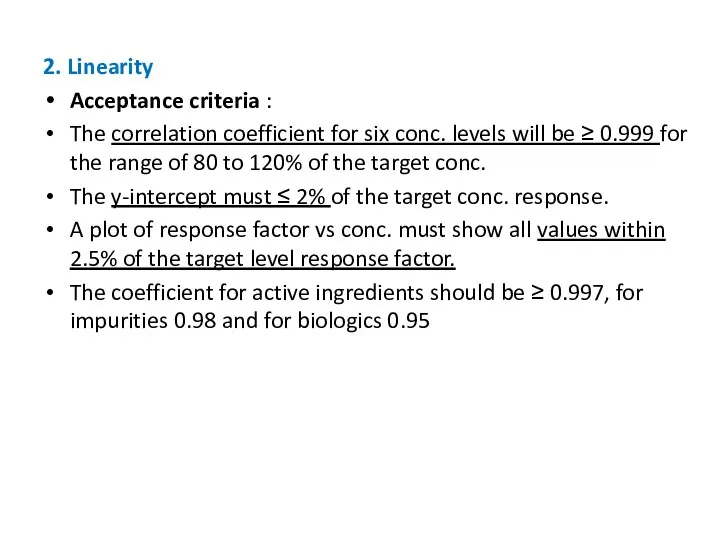

- 16. 2. Linearity Acceptance criteria : The correlation coefficient for six conc. levels will be ≥ 0.999

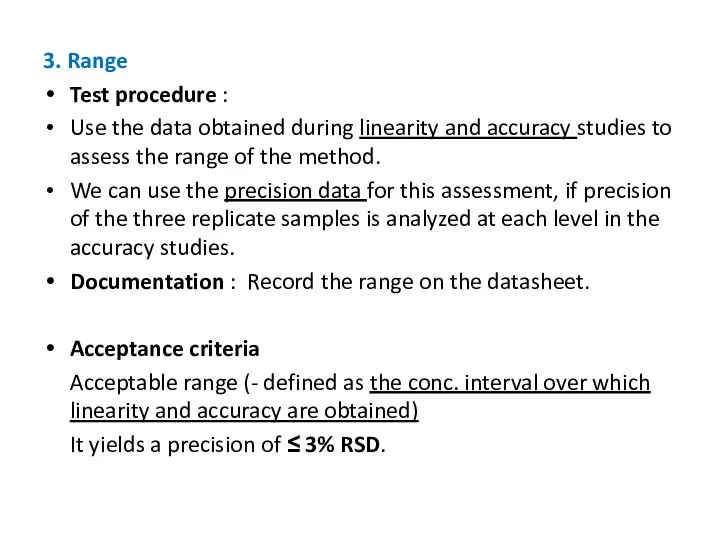

- 17. 3. Range Test procedure : Use the data obtained during linearity and accuracy studies to assess

- 18. 4. Accuracy Test procedure Prepare spiked samples at three conc. over the range of 50 to

- 19. 4. Accuracy Acceptance criteria The mean recovery will be within 90 to 110% of the theoretical

- 20. 5. Precision - Repeatability Test procedure: Prepare one sample solution containing the target level of analyte

- 21. 6. Intermediate Precision Test procedure: Demonstrate Intermediate precision (within-laboratory variation) by two analysts, using two HPLC

- 22. 7. Limit of Detection Test procedure Determine the lowest concentration of the standard solution by sequentially

- 23. 8. Limit of Quantitation Test procedure Determine the lowest concentration at which an analyte in the

- 24. 8. Limit of Quantitation Acceptance criteria: The limit of quantitation for chromatographic methods is described as

- 25. 9. System Suitability Test procedure Perform system suitability tests on both HPLC systems to determine the

- 26. 9. System Suitability Acceptance criteria: Retention factor (k): the peak of interest be well resolved from

- 27. 10. Robustness Measures the capacity of an analytical method to remain unaffected by small but deliberate

- 28. 10. Robustness Compare the chromatography obtained for a sample containing representative impurities, when using modified parameter(s),

- 29. 11. Measurement Uncertainty Calculation of measurement uncertainty by mathematical model according to law of propagation of

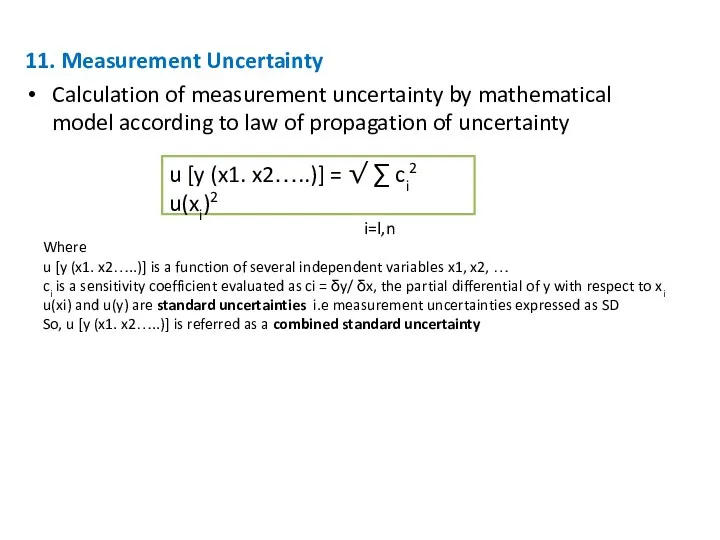

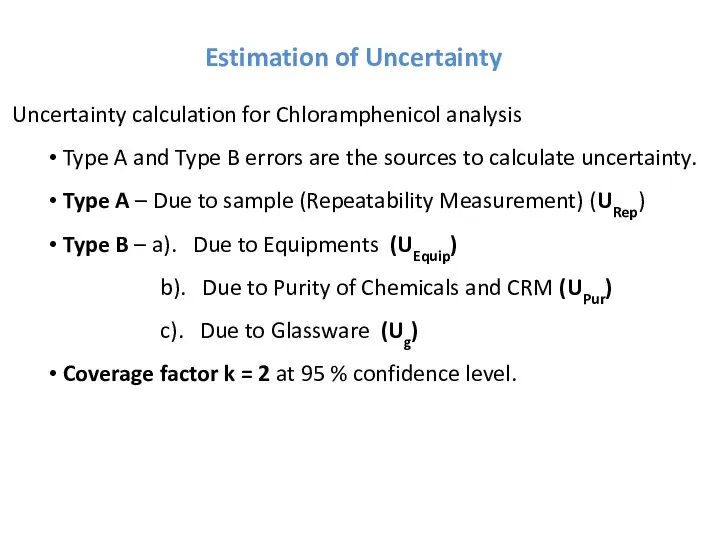

- 30. Estimation of Uncertainty Uncertainty calculation for Chloramphenicol analysis Type A and Type B errors are the

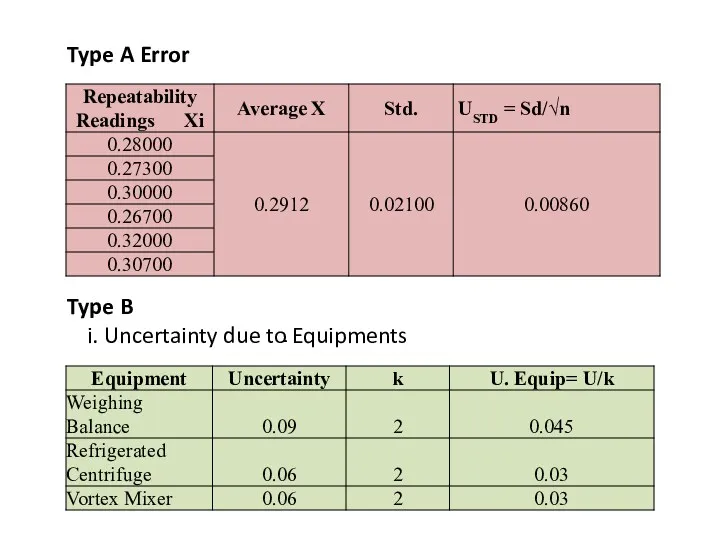

- 31. Type A Error Type B Uncertainty due to Equipments

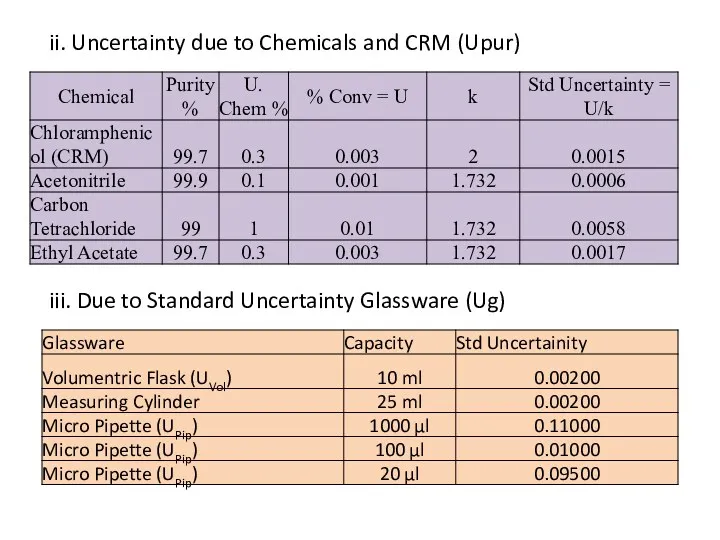

- 32. ii. Uncertainty due to Chemicals and CRM (Upur) iii. Due to Standard Uncertainty Glassware (Ug)

- 34. Скачать презентацию

Gerund and Infinitive

Gerund and Infinitive The present indefinite tense

The present indefinite tense English. Oral texts

English. Oral texts Уровни перевода

Уровни перевода Comparatives and Superlatives

Comparatives and Superlatives Beautiful places

Beautiful places Teenagers and their problem

Teenagers and their problem Good and bad habits

Good and bad habits READ and LEARN

READ and LEARN Speakout Pre - Intermediate. Question forms

Speakout Pre - Intermediate. Question forms Instructions for writing the solution paragraph

Instructions for writing the solution paragraph Impressionizm

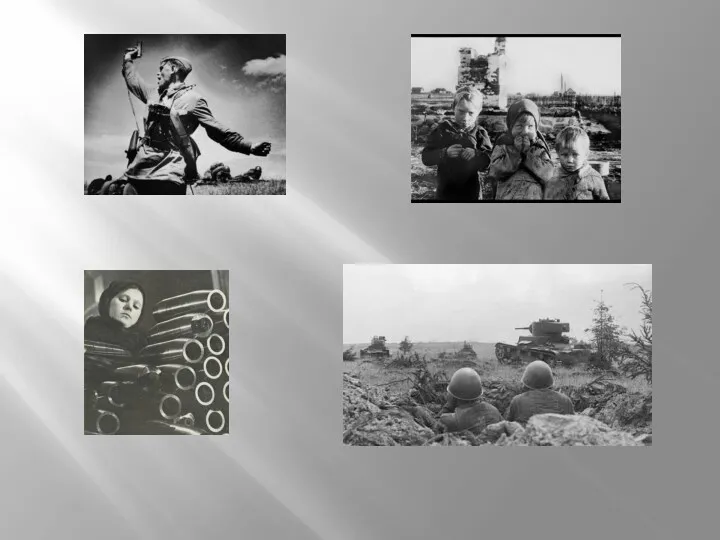

Impressionizm Young Heroes of the War 1941-1945

Young Heroes of the War 1941-1945 Snow

Snow Habits. Used to

Habits. Used to Verb to have got

Verb to have got Education abroad I had like

Education abroad I had like TV programmes

TV programmes Sport facilities of my university

Sport facilities of my university School What is school for you?

School What is school for you? Police of the Russian Federation

Police of the Russian Federation Present perfect tense

Present perfect tense Choice of profession

Choice of profession Peter’s family

Peter’s family Animals and parts of the body

Animals and parts of the body Customs and traditions in Great Britain. Обычаи и традиции

Customs and traditions in Great Britain. Обычаи и традиции About the person that is writing in this place. Something about

About the person that is writing in this place. Something about Yale university

Yale university