Содержание

- 2. Society of Petroleum Engineers Distinguished Lecturer Program www.spe.org/dl Scot Buell, SPEC Waterflood Design and Operational Best

- 3. Outline Waterflood design life and injection efficiency Conformance management Injection well design Waterflood surveillance Water quality

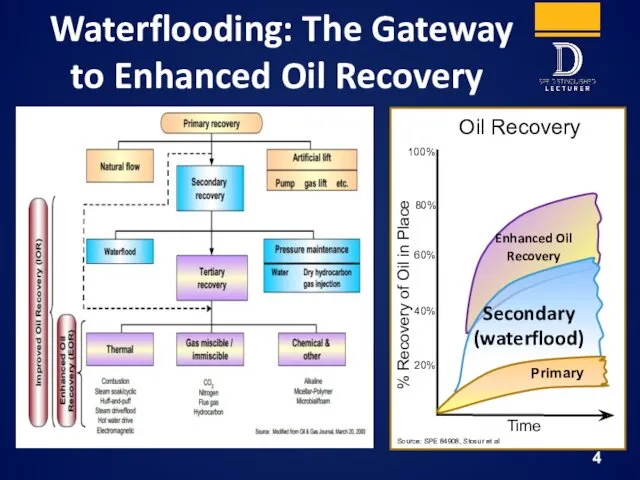

- 4. Waterflooding: The Gateway to Enhanced Oil Recovery 100% 80% 20% 40% 60% Oil Recovery Enhanced Oil

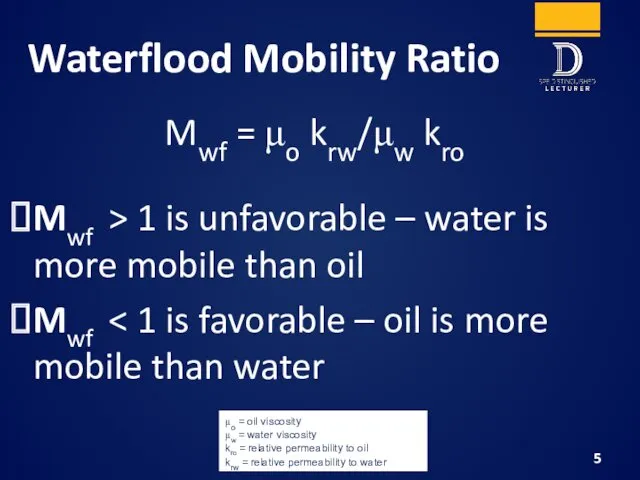

- 5. Waterflood Mobility Ratio Mwf = μo krw/μw kro Mwf > 1 is unfavorable – water is

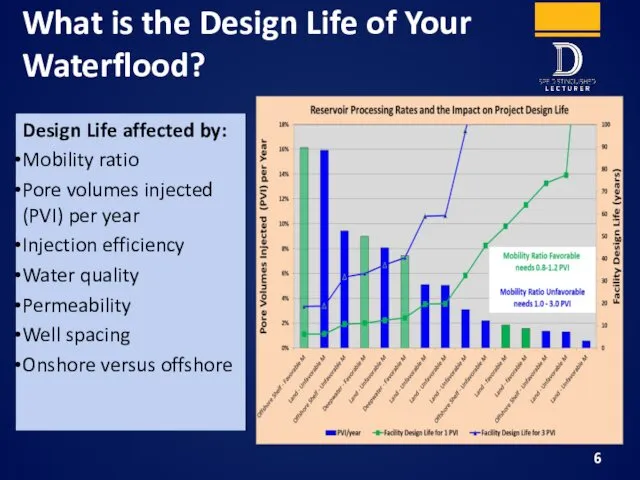

- 6. What is the Design Life of Your Waterflood? Design Life affected by: Mobility ratio Pore volumes

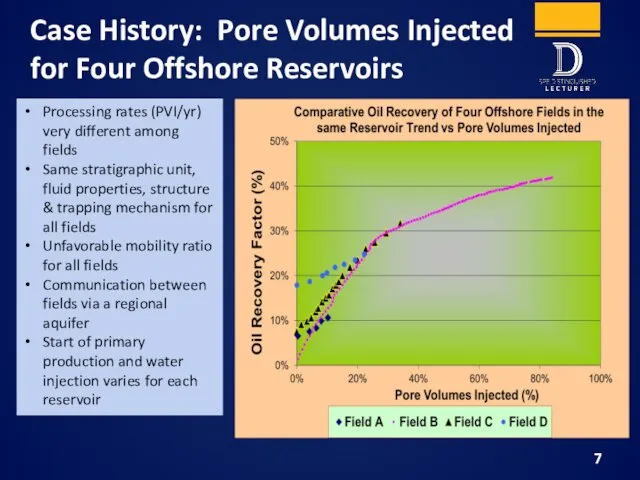

- 7. Case History: Pore Volumes Injected for Four Offshore Reservoirs Processing rates (PVI/yr) very different among fields

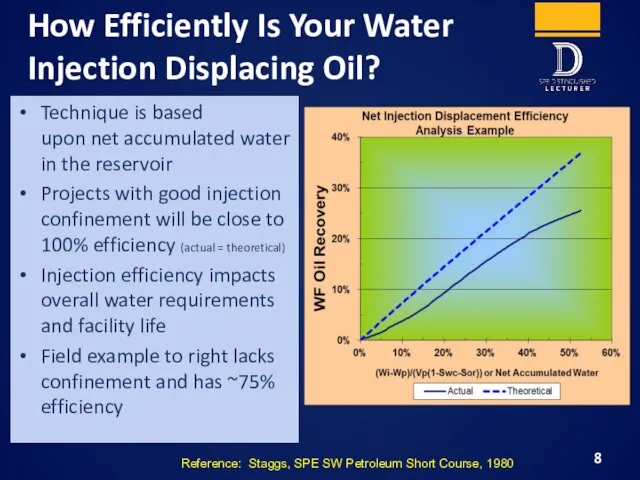

- 8. How Efficiently Is Your Water Injection Displacing Oil? Technique is based upon net accumulated water in

- 9. Voidage Replacement Ratio (VRR) VRR is used as a leading indicator to achieve target reservoir pressure

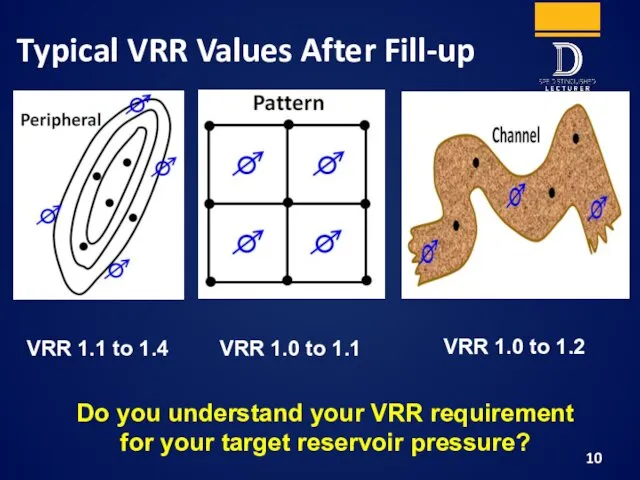

- 10. Typical VRR Values After Fill-up VRR 1.1 to 1.4 VRR 1.0 to 1.1 VRR 1.0 to

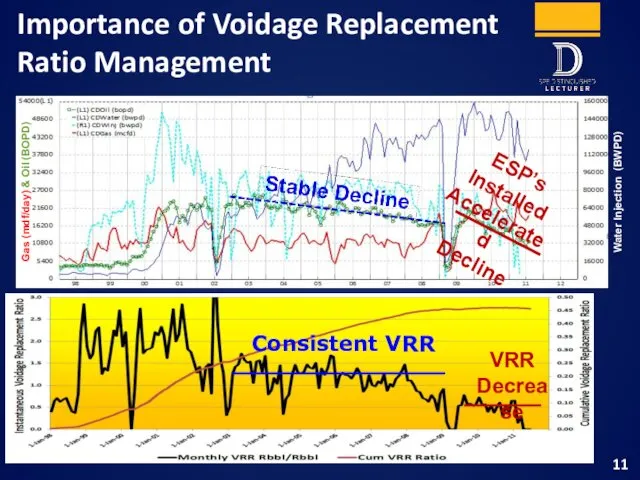

- 11. Consistent VRR Importance of Voidage Replacement Ratio Management VRR Decrease Gas (mdf/day) & Oil (BOPD) Water

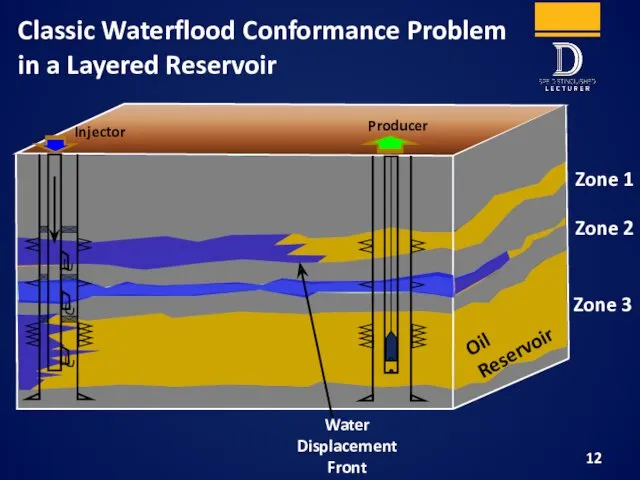

- 12. Zone 3 Zone 2 Zone 1 Water Displacement Front Oil Reservoir Classic Waterflood Conformance Problem in

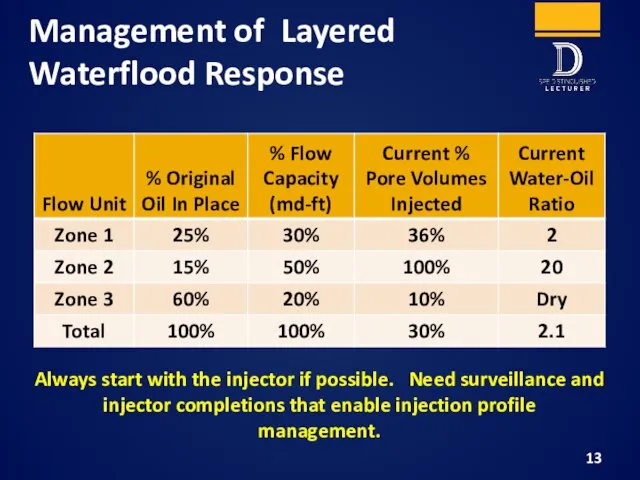

- 13. Management of Layered Waterflood Response Always start with the injector if possible. Need surveillance and injector

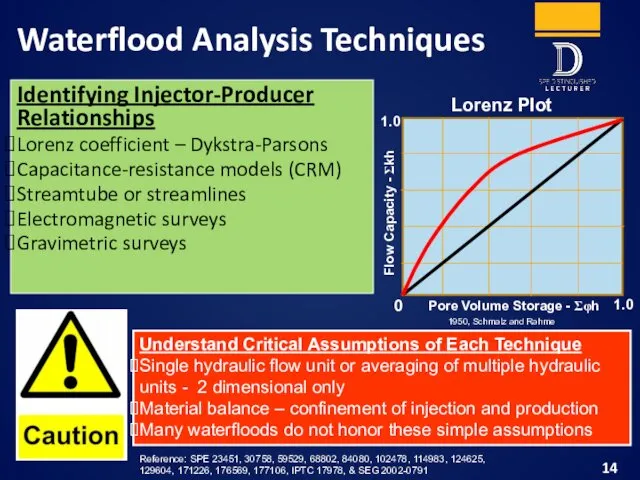

- 14. Waterflood Analysis Techniques Identifying Injector-Producer Relationships Lorenz coefficient – Dykstra-Parsons Capacitance-resistance models (CRM) Streamtube or streamlines

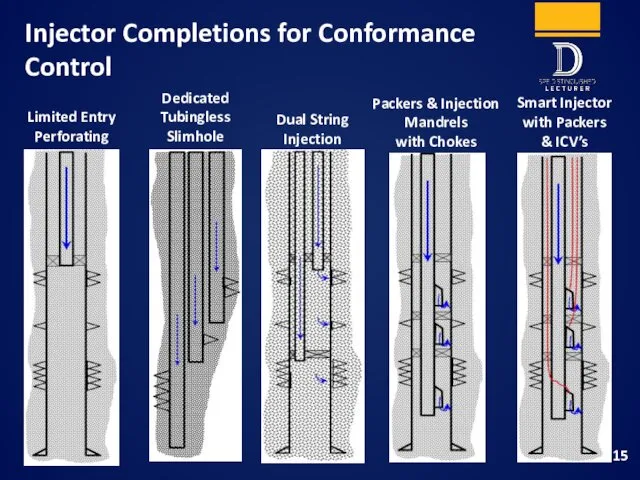

- 15. Injector Completions for Conformance Control Limited Entry Perforating Dedicated Tubingless Slimhole Packers & Injection Mandrels with

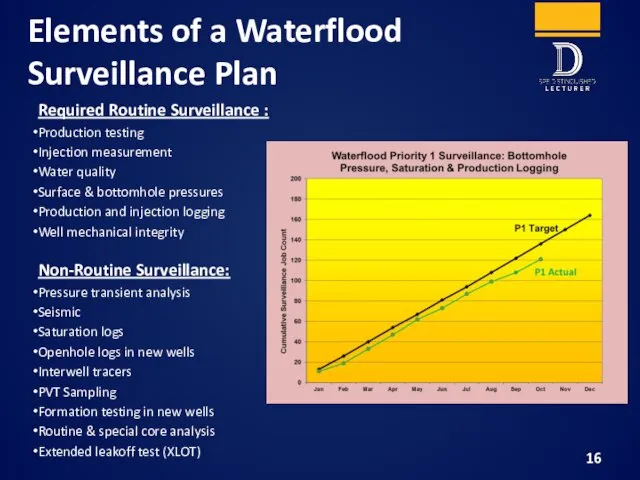

- 16. Elements of a Waterflood Surveillance Plan Required Routine Surveillance : Production testing Injection measurement Water quality

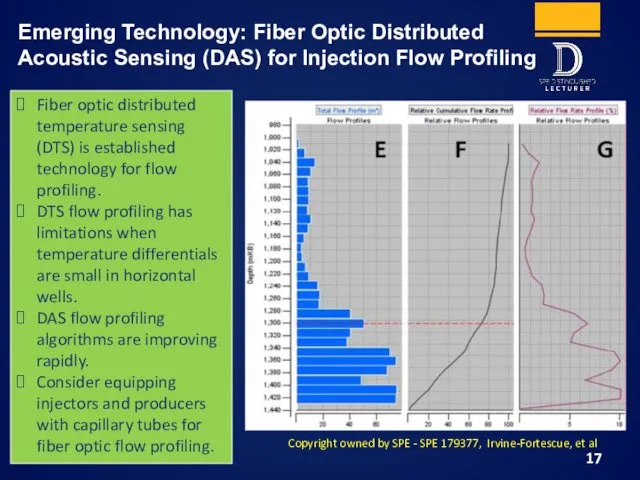

- 17. Emerging Technology: Fiber Optic Distributed Acoustic Sensing (DAS) for Injection Flow Profiling Copyright owned by SPE

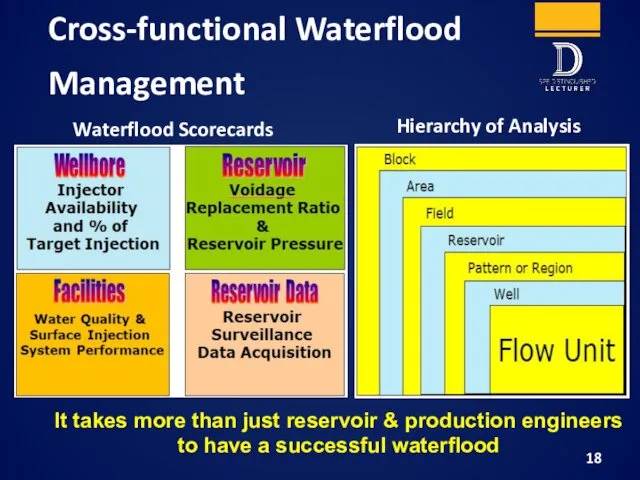

- 18. Cross-functional Waterflood Management Hierarchy of Analysis Waterflood Scorecards It takes more than just reservoir & production

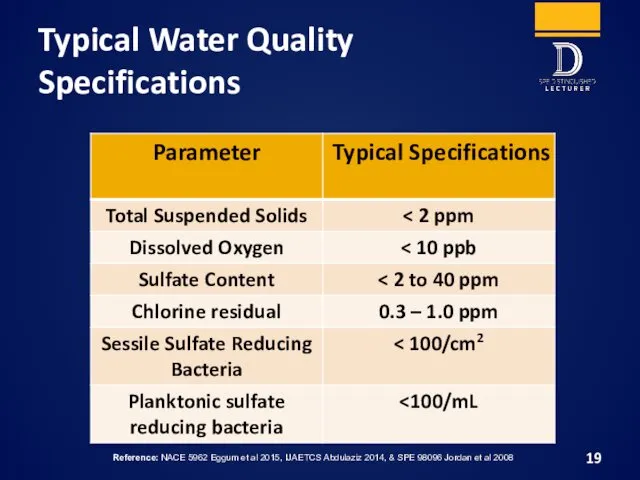

- 19. Typical Water Quality Specifications Reference: NACE 5962 Eggum et al 2015, IJAETCS Abdulaziz 2014, & SPE

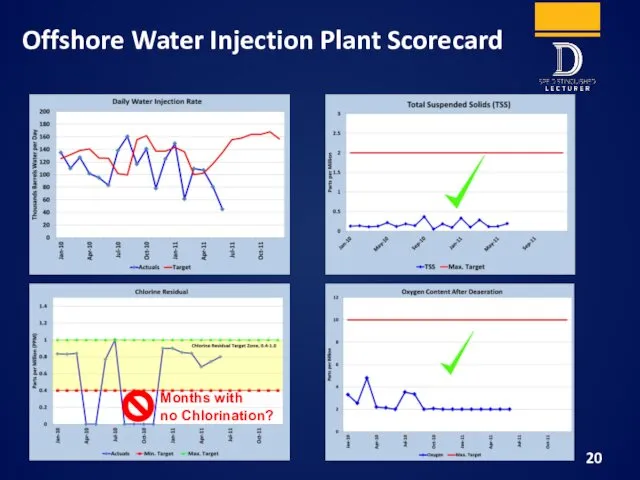

- 20. Offshore Water Injection Plant Scorecard Months with no Chlorination?

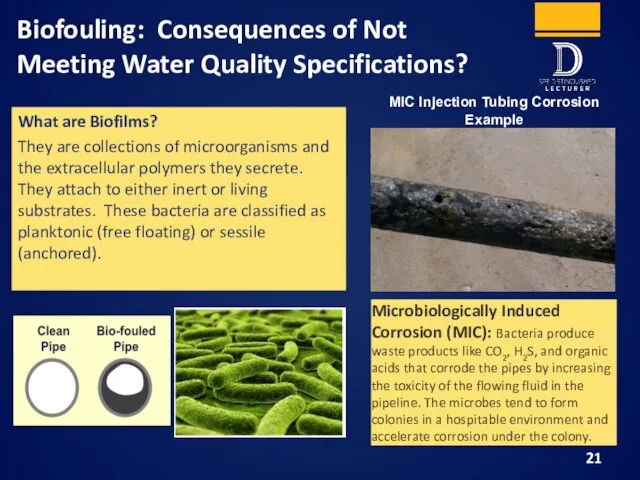

- 21. Biofouling: Consequences of Not Meeting Water Quality Specifications? What are Biofilms? They are collections of microorganisms

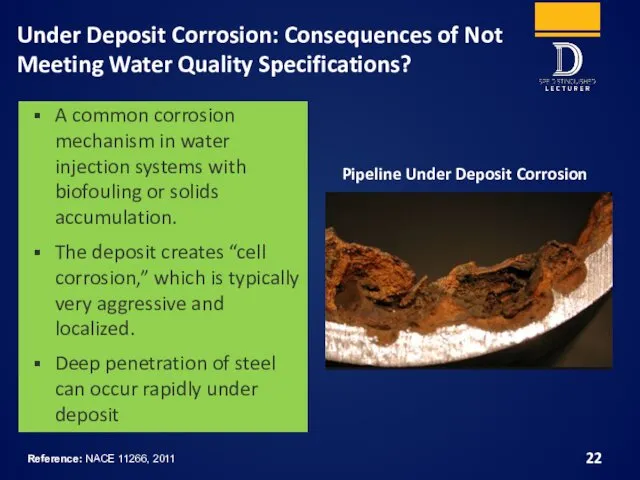

- 22. Under Deposit Corrosion: Consequences of Not Meeting Water Quality Specifications? A common corrosion mechanism in water

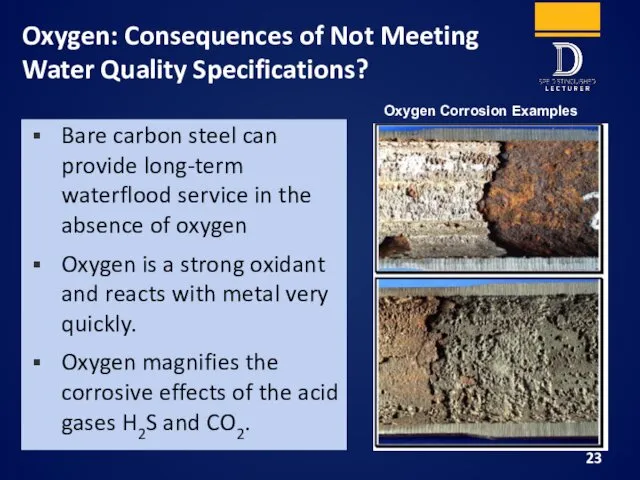

- 23. Oxygen: Consequences of Not Meeting Water Quality Specifications? Oxygen Corrosion Examples Bare carbon steel can provide

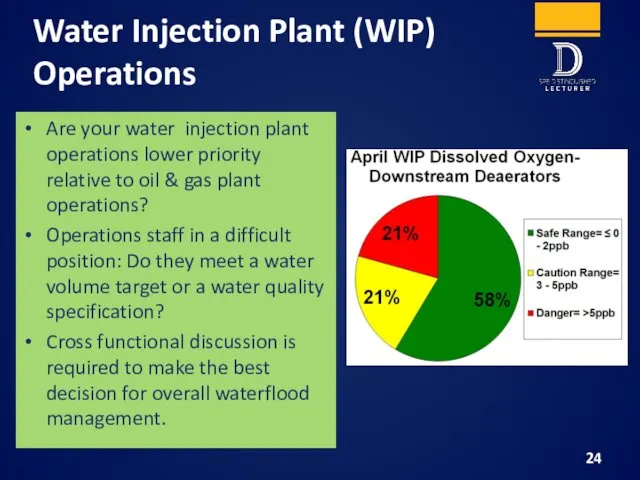

- 24. Water Injection Plant (WIP) Operations Are your water injection plant operations lower priority relative to oil

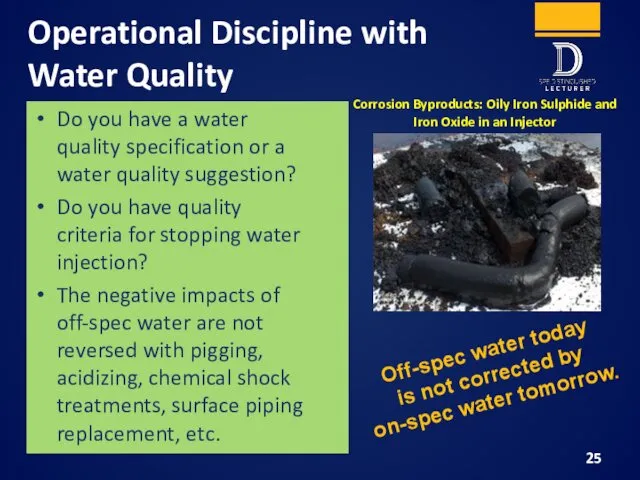

- 25. Operational Discipline with Water Quality Do you have a water quality specification or a water quality

- 26. Matrix Injection Myth in Waterfloods Long term matrix injection cannot be achieved with practical water quality

- 27. Subsurface Integrity Management for Waterfloods Subsurface integrity management ensures injected fluids are confined to targeted and

- 28. Key Takeaways Understand the design life and processing rate of your reservoir (PVI/year) Understand how much

- 30. Скачать презентацию

Елементи біофізики при вивченні електрики

Елементи біофізики при вивченні електрики Молочнокислые бактерии

Молочнокислые бактерии Нарушения КОС организма

Нарушения КОС организма Химический состав клетки

Химический состав клетки Классификация животного мира. 7 класс

Классификация животного мира. 7 класс Клетка. Структура клетки. Органоиды клетки

Клетка. Структура клетки. Органоиды клетки Задачи и методы генетики. Подготовка к ЕГЭ

Задачи и методы генетики. Подготовка к ЕГЭ Эволюция кровеносной системы животных

Эволюция кровеносной системы животных Зрительный анализатор

Зрительный анализатор Antioxidants

Antioxidants Популяция. Свойства популяций

Популяция. Свойства популяций Вегетативная нервная система

Вегетативная нервная система Зоология позвоночных. Разнообразие млекопитающих. (Лекция 11)

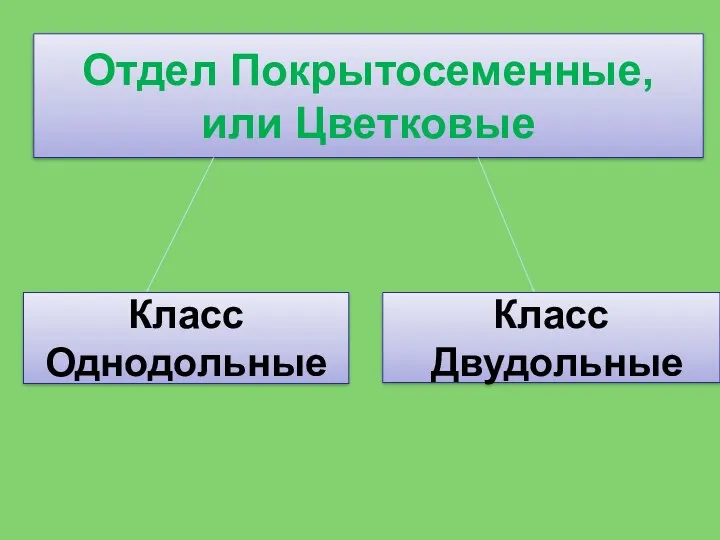

Зоология позвоночных. Разнообразие млекопитающих. (Лекция 11) Отдел покрытосеменные, или цветковые. Класс однодольные. Класс двудольные

Отдел покрытосеменные, или цветковые. Класс однодольные. Класс двудольные Adaptation and natural selection

Adaptation and natural selection Анализирующее скрещивание. Промежуточный характер наследования

Анализирующее скрещивание. Промежуточный характер наследования Биоэнергетика. Современное представление о биологическом окислении

Биоэнергетика. Современное представление о биологическом окислении презентация к теме Эволюционное учение

презентация к теме Эволюционное учение Вредители и болезни культурных растений

Вредители и болезни культурных растений Насекомые. Отличительные признаки насекомых (1 класса)

Насекомые. Отличительные признаки насекомых (1 класса) Вода. Роль воды в жизни человека

Вода. Роль воды в жизни человека Самые ядовитые животные в мире

Самые ядовитые животные в мире Суточная активность попугаев

Суточная активность попугаев Скелет человека. Осевой скелет. 8 класс

Скелет человека. Осевой скелет. 8 класс Қан ферменттерін анықтаудың клиникалық маңызы

Қан ферменттерін анықтаудың клиникалық маңызы Этимология названий лекарственных растений. Мифы и легенды

Этимология названий лекарственных растений. Мифы и легенды Биохимия нервной ткани

Биохимия нервной ткани Экологические группы птиц

Экологические группы птиц