Содержание

- 2. Themes This Week: Business Process Improvement The Lean (Just In Time) Approach Reprise (Le)Agility Time-based Competition

- 3. What is performance improvement? Performance Improvement: A change that moves the operation towards achieving its performance

- 4. Common Themes of Business Improvement Approaches Aligning processes and people with the strategic aims of the

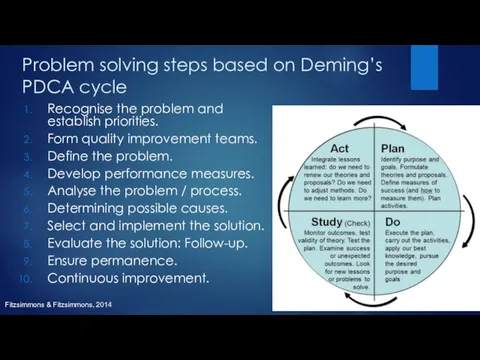

- 5. Problem solving steps based on Deming’s PDCA cycle Recognise the problem and establish priorities. Form quality

- 6. Lean Synchronization “aims to meet demand instantaneously, with perfect quality and no waste. This involves providing

- 7. ‘The key principle of lean operations is relatively straightforward to understand: it means moving towards the

- 8. Lean Manufacturing Philosophy The main objective of Lean manufacturing is to reduce throughput times by eliminating

- 9. Lean Manufacturing as Performance Improvement Origins: Manufacturing, especially the Toyota Production System (TPS). See Womack, J.P.

- 10. The ideal production situation Instantaneous order fulfilment: No need for forecasting No need for inventory Zero

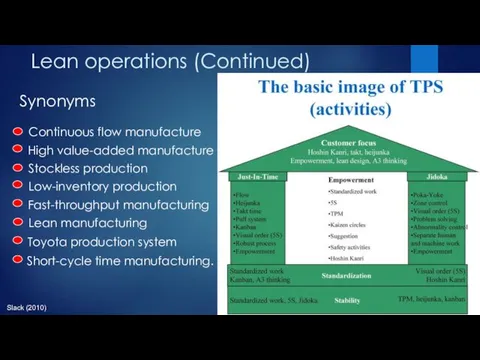

- 11. Synonyms Lean operations (Continued) Slack (2010)

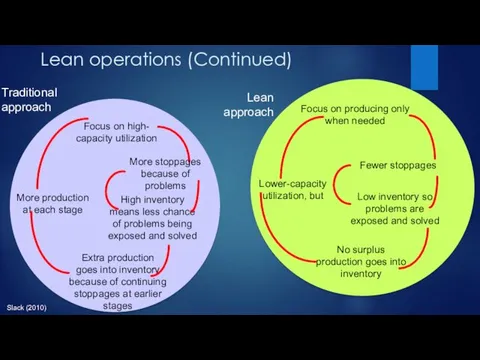

- 12. Focus on producing only when needed Focus on high- capacity utilization Lean operations (Continued) Slack (2010)

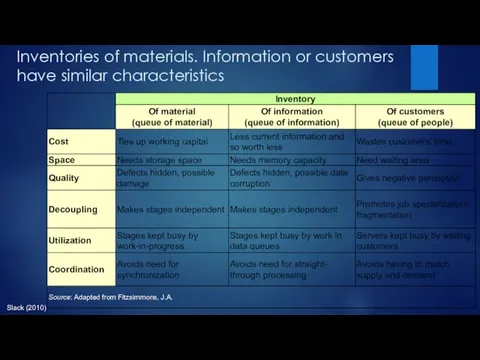

- 13. Inventories of materials. Information or customers have similar characteristics Slack (2010)

- 14. Push & Pull Scheduling Conventional production is reliant upon push scheduling: Production in response to forecast

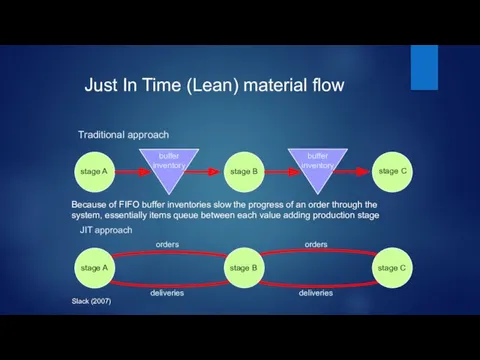

- 15. Traditional approach JIT approach Just In Time (Lean) material flow Slack (2007) Because of FIFO buffer

- 16. WIP Defective materials Rework Scrap Downtime Productivity problems Reduce the level of inventory (water) to reveal

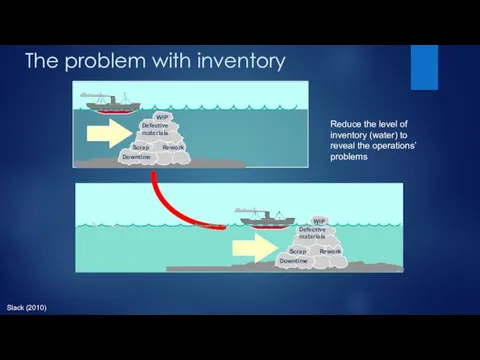

- 17. Delivering smaller quantities more often can reduce inventory levels Slack (2010)

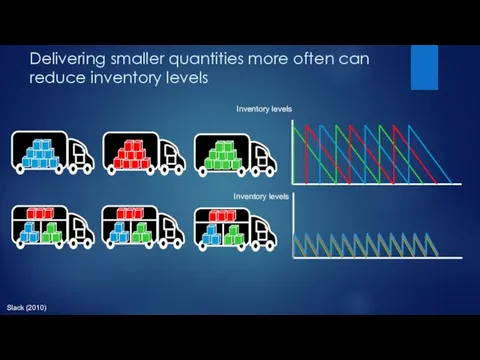

- 18. Buffers in Service Variable arrival and processing rates mean that buffers (queues) are inevitable as capacity

- 19. Eliminate Waste. Eliminate Waste: Waste can be defined as any activity which does not add value.

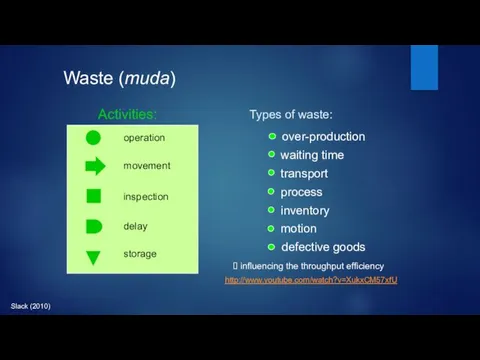

- 20. Activities: Waste (muda) influencing the throughput efficiency http://www.youtube.com/watch?v=XukxCM57xfU Types of waste: Slack (2010)

- 21. Eliminating Waste (Manuf) Make only what is needed now. Reduce waiting by coordinating flows and balancing

- 22. Lean Capacity utilisation A key objective used to be to fully utilise production capacity so that

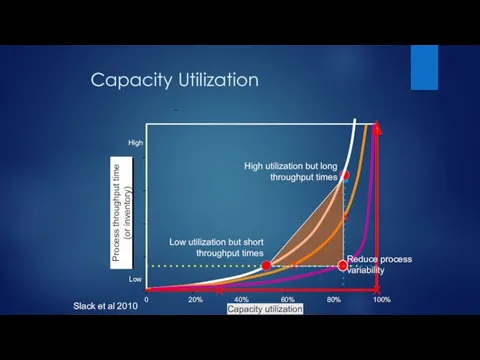

- 23. 0 20% 40% 60% 80% 100% Capacity utilization Low X X X High Average length of

- 24. Its about time! ‘Lean thinking’ is largely about reducing material and time waste so that capacity

- 25. Kaizen Continuous improvement - usually, but not always, applied to improving manufacturing performance through the elimination

- 26. Slack (2010) The Five S’s Sort (Seiri) Eliminate what is not needed and keep what is

- 27. Six Sigma “The primary means to achieving six sigma quality level is to eliminate the causes

- 28. Six Sigma Developed in 1980’s and Copyrighted by Motorola (www.motorola.com/motorolauniversity.jsp ) Disciplined data driven approach and

- 29. Sub-methodologies DMAIC Define, Measure, Analyse, Improve, Control

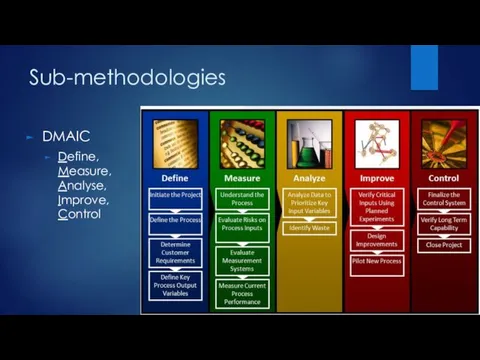

- 30. DMAIC Tool Examples Define: Brainstorming, Importance Performance matrix, Pareto. Measure: Data collection. Analyse: Data analysis, 5-whys,

- 31. Lean or Six Sigma? Lean: Waste elimination, quality improvements are a factor here. Immediate benefits, not

- 32. Developments from Lean LEAN / AGILE MANUFACTURING QUICK RESPONSE MANUFACTURING

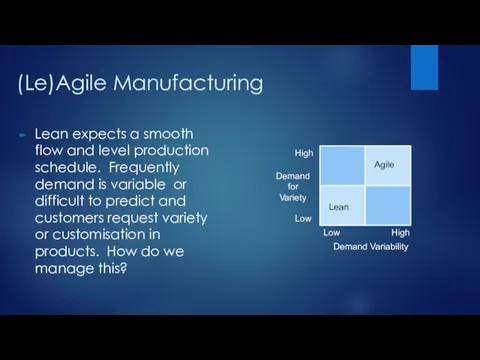

- 33. (Le)Agile Manufacturing Lean expects a smooth flow and level production schedule. Frequently demand is variable or

- 34. Agile Manufacturing (a variant of Lean) To remain agile (responsive) some waste is inevitable – labour,

- 35. The decoupling point represents the point of differentiation , where raw materials or part finished goods

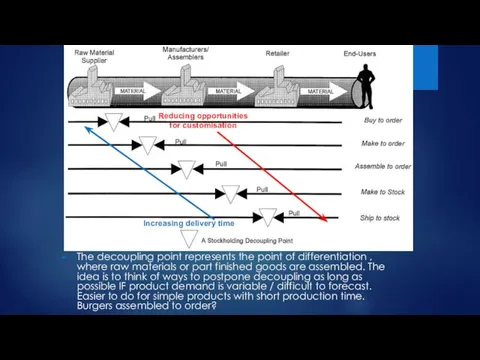

- 37. Скачать презентацию

Гостиничный сервис

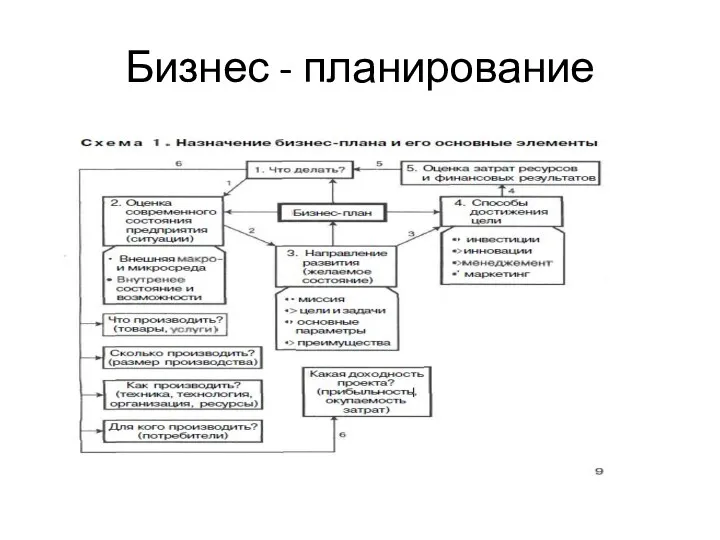

Гостиничный сервис Бизнес - планирование

Бизнес - планирование ООО АвтоТехно. Реконструкция

ООО АвтоТехно. Реконструкция Цветочный бутик ООО Цветущий дом

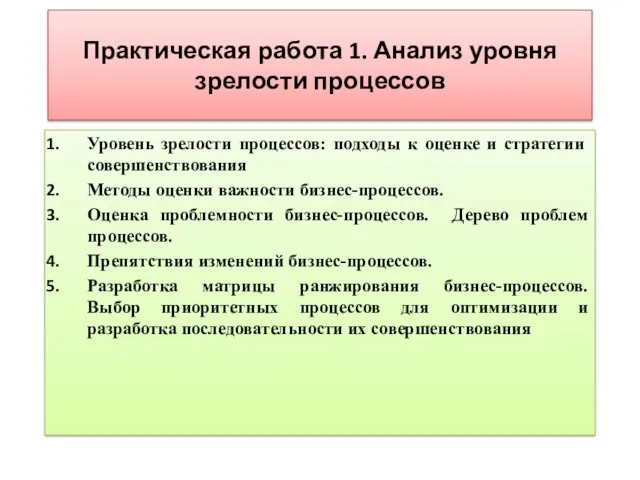

Цветочный бутик ООО Цветущий дом Практическая работа 1. Анализ уровня зрелости процессов

Практическая работа 1. Анализ уровня зрелости процессов Об основных результатах реформы контроля и надзора

Об основных результатах реформы контроля и надзора Корпоративтік мәдениеттің компоненттері. Ресми компоненттер. Бейресми компоненттер

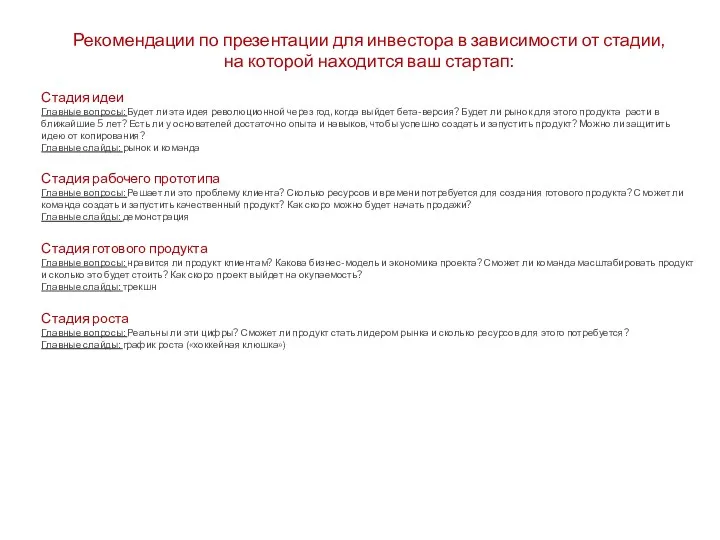

Корпоративтік мәдениеттің компоненттері. Ресми компоненттер. Бейресми компоненттер Рекомендации для инвестора в зависимости от стадии, на которой находится ваш стартап

Рекомендации для инвестора в зависимости от стадии, на которой находится ваш стартап Бизнес-план. Компьютерный клуб Интер

Бизнес-план. Компьютерный клуб Интер Проект ООО Новый город

Проект ООО Новый город Бизнес-план открытия кофейни

Бизнес-план открытия кофейни Организация IT-компании

Организация IT-компании Задание 4 недели проекта

Задание 4 недели проекта Открытие золотодобывающего предприятия

Открытие золотодобывающего предприятия Проект Частный детский сад Звёздочка

Проект Частный детский сад Звёздочка Стартап-тинейджер

Стартап-тинейджер Дизайн-проект магазина женской одежды Merci Store

Дизайн-проект магазина женской одежды Merci Store Организация автомобильный курсов для начинающих водителей и автоледи

Организация автомобильный курсов для начинающих водителей и автоледи Виды малого бизнеса

Виды малого бизнеса Бизнес-план фитнес-клуба

Бизнес-план фитнес-клуба Всё самое главное, что вам нужно знать про Customer Development

Всё самое главное, что вам нужно знать про Customer Development Дом.ru

Дом.ru Разработка бизнес-плана Организация и планирование управления кафе Блинная

Разработка бизнес-плана Организация и планирование управления кафе Блинная Добро пожаловать на Ларри Вильямса

Добро пожаловать на Ларри Вильямса Дело не в вине. Винный Бар

Дело не в вине. Винный Бар Основы рекрутирования

Основы рекрутирования Проектирование отдельных видов туристско-рекреационных продуктов

Проектирование отдельных видов туристско-рекреационных продуктов Семейный центр Legacy

Семейный центр Legacy