Содержание

- 2. © 2010 Wiley Learning Objectives Describe the structure of supply chains Describe the bullwhip effect Describe

- 3. © 2010 Wiley Learning Objectives con’t Describe government regulation issues that affect supply chains Describe green

- 4. © 2010 Wiley Learning Objectives con’t Describe the ethics of supplier management Describe supply chain distribution

- 5. © 2010 Wiley Supply Chains & SCM Defined A supply chain is the network of all

- 6. © 2010 Wiley Components of a Supply Chain for a Manufacturer External Suppliers – source of

- 7. © 2010 Wiley Components of a Supply Chain External Distributors – transport finished products to appropriate

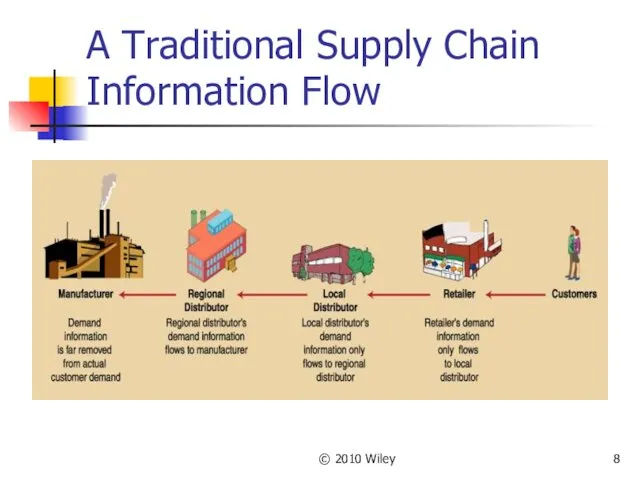

- 8. © 2010 Wiley A Traditional Supply Chain Information Flow

- 9. © 2010 Wiley The Bullwhip Effect - defined Bullwhip effect - the inaccurate or distorted demand

- 10. © 2010 Wiley The Bullwhip Effect Counteracting the Effect: Change the way suppliers forecast product demand

- 11. © 2010 Wiley Supply Chains for Service Orgs Internal Operations External Distributors

- 12. © 2010 Wiley Major Issues Affecting SCM Information technology – enablers include the Internet, Web, EDI,

- 13. © 2010 Wiley Major Issues con’t Business-to-business (B2B) E-commerce – businesses selling to and buying from

- 14. © 2010 Wiley Major Issues con’t Benefits of B2B E-Commerce Lower procurement administrative costs, Low-cost access

- 15. © 2010 Wiley Types of E-Commerce Business-to-Consumer (B2C) E-Commerce - on-line businesses sell to individual consumers:

- 16. © 2010 Wiley Types of E-Commerce con’t Sales Revenue Model – A means of selling goods,

- 17. © 2010 Wiley Major Issues con’t SCM must consider the following trends, improved capabilities, & realities:

- 18. © 2010 Wiley Global SCM Factors Managing extensive global supply chains introduces many complications Infrastructure issues

- 19. © 2010 Wiley Sourcing Issues Which products to produce in-house and which are provided by other

- 20. © 2010 Wiley The Role of Purchasing The purchasing dept plays important role in SCM and

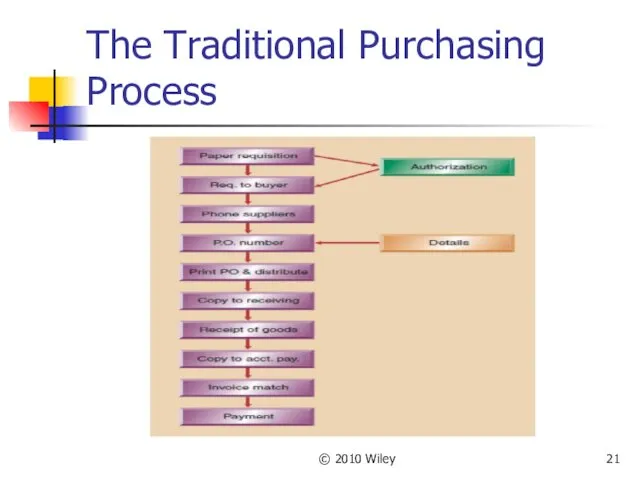

- 21. © 2010 Wiley The Traditional Purchasing Process

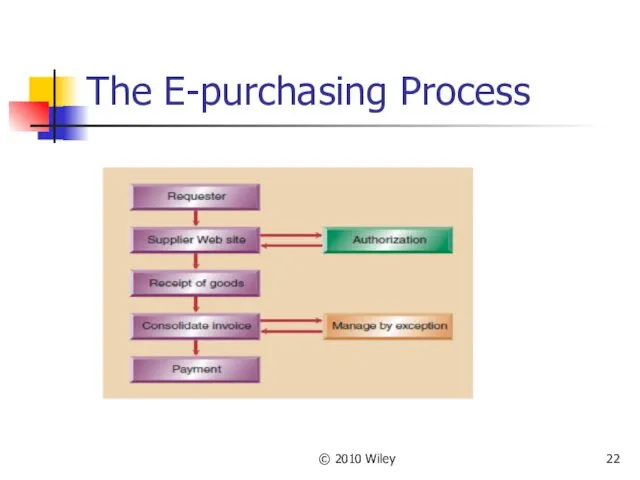

- 22. © 2010 Wiley The E-purchasing Process

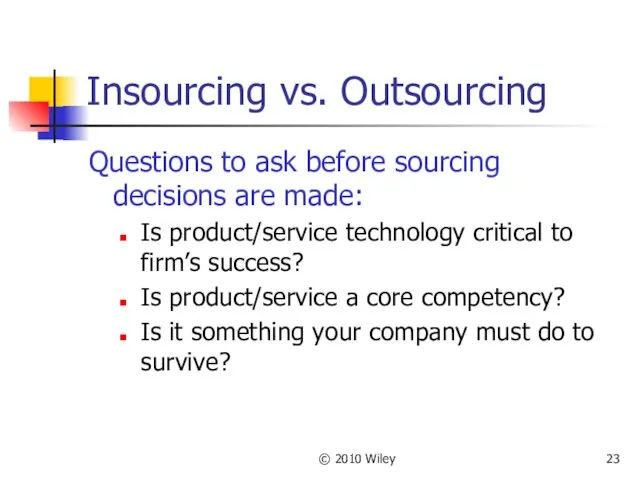

- 23. © 2010 Wiley Insourcing vs. Outsourcing Questions to ask before sourcing decisions are made: Is product/service

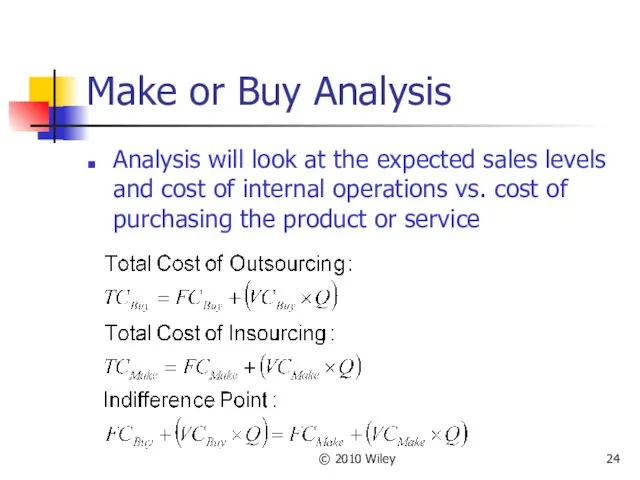

- 24. © 2010 Wiley Make or Buy Analysis Analysis will look at the expected sales levels and

- 25. © 2010 Wiley Make or Buy Example Mary and Sue decide to open a bagel shop.

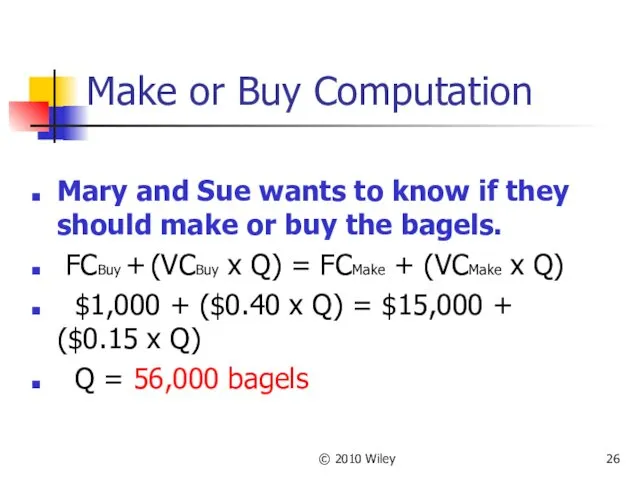

- 26. © 2010 Wiley Make or Buy Computation Mary and Sue wants to know if they should

- 27. © 2010 Wiley The Role of Purchasing Purchasing role has attained increased importance since material costs

- 28. © 2010 Wiley Developing Supplier Relationship A strong supplier base is critical to the success of

- 29. © 2010 Wiley Critical Factors in Successful Partnership Relations Critical factors in successful partnering include: Impact

- 30. © 2010 Wiley Win-Win Factors in Partnership Relations Benefits of Partnering Early supplier involvement (ESI) in

- 31. © 2010 Wiley Ethics in Supply Management Global Standards of Supply Management Conduct from ISM: Loyalty

- 32. © 2010 Wiley Supply Chain Distribution Warehouses involved in supply chain distributions and include Plant warehouses

- 33. © 2010 Wiley Supply Chain Distribution con’t Transportation consolidation – warehouses consolidate less-than-truckload (LTL) quantities into

- 34. © 2010 Wiley Supply Chain Distribution con’t Services are offered can improve customer service by moving

- 35. © 2010 Wiley Supply Chain Distribution con’t Radio Frequency Identification Technology (RFID) – automated data collection

- 36. © 2010 Wiley Integrated SCM Implementing integrated SCM requires: Analyzing the whole supply chain Starting by

- 37. © 2010 Wiley Integrated SCM con’t Manufacturer’s Goals Reduce costs Reduce duplication of effort Improve quality

- 38. © 2010 Wiley Leveraging SCM: A List Regularly assess your SC network to ensure continued suitability

- 39. © 2010 Wiley Leveraging SCM: A List con’t Expand your visibility. Know what happens, when it

- 40. © 2010 Wiley Eliminating Sources of Waste in Supply Chain Overproduction: don’t build product before needed

- 41. © 2010 Wiley Eliminating Sources of Waste in Supply Chain con’t Unnecessary movement of people: includes

- 42. © 2010 Wiley Supply Chain Metrics Measuring supply chain performance Traditional measures include: Return on investment

- 43. © 2010 Wiley Supply Chain Performance Metrics con’t Customer demands for better-quality requires company’s to develop

- 44. © 2010 Wiley Current Trends in SCM Increased use of electronic marketplace such as: E-distributors –

- 45. © 2010 Wiley Current Trends in SCM – con’t Value chain management – automation of a

- 46. © 2010 Wiley SCM Across the Organization SCM changes the way companies do business. Accounting shares

- 47. © 2010 Wiley Chapter 4 Highlights Every organization is part of a supply chain, either as

- 48. © 2010 Wiley Chapter 4 Highlights con’t Many issues affect supply chain management. The Internet, the

- 49. © 2010 Wiley Chapter 4 Highlights con’t Global supply chains increase geographic distances between members, causing

- 50. © 2010 Wiley Chapter 4 Highlights con’t Companies make insourcing and outsourcing decisions. These make-or-buy decisions

- 51. © 2010 Wiley Chapter 4 Highlights con’t Supply chain distribution requires effective warehousing operations. The warehouses

- 52. © 2010 Wiley Chapter 4 Highlights con’t The emergence of net marketplaces has significantly affected SCM.

- 54. Скачать презентацию

Пансионаты в Евпатории

Пансионаты в Евпатории Номерной фонд. Классификация гостиничных номеров

Номерной фонд. Классификация гостиничных номеров Бизнес-план по открытию салона-парикмахерской Карина

Бизнес-план по открытию салона-парикмахерской Карина Бизнес как проект

Бизнес как проект Сеть студий косметических услуг Epilier

Сеть студий косметических услуг Epilier Уверенный взлет вашего бизнеса. Международный аэропорт Сочи

Уверенный взлет вашего бизнеса. Международный аэропорт Сочи Открытие барбершопа Renome

Открытие барбершопа Renome Jey CAMP. Программа на английском языке в Олимпийской деревне Сочи

Jey CAMP. Программа на английском языке в Олимпийской деревне Сочи Проект генерального плана изменений в землепользовании и застройке территории города

Проект генерального плана изменений в землепользовании и застройке территории города Бизнес-игра

Бизнес-игра Туристские ресурсы Самарской области

Туристские ресурсы Самарской области Поддержка малого предпринимательства в республике Башкортостан

Поддержка малого предпринимательства в республике Башкортостан Бизнес-план Прокат автомобилей

Бизнес-план Прокат автомобилей Кафе “COFFEE TEA”

Кафе “COFFEE TEA” Бизнес жоспар. Қонақ үй мен антикафе

Бизнес жоспар. Қонақ үй мен антикафе Рекламное агентство Аравт

Рекламное агентство Аравт Календарь 2019 год свиньи

Календарь 2019 год свиньи Домашнее задание для школы молодых предпринимателей. Шаблон

Домашнее задание для школы молодых предпринимателей. Шаблон Конно-спортивный клуб АС (ООО)

Конно-спортивный клуб АС (ООО) техники эффективных продаж

техники эффективных продаж Бизнес-кейс Экстремал

Бизнес-кейс Экстремал Реинжиниринг бизнес-процессов

Реинжиниринг бизнес-процессов Прокат мужских костюмов в г. Томске. Бизнес-план

Прокат мужских костюмов в г. Томске. Бизнес-план Requirements (BABOK)

Requirements (BABOK) Деятельность индивидуальных предпринимателей

Деятельность индивидуальных предпринимателей Основы подготовки бизнес-плана. Лекция 5

Основы подготовки бизнес-плана. Лекция 5 Модель бизнеса

Модель бизнеса Слагаемые успеха в бизнесе

Слагаемые успеха в бизнесе