Содержание

- 2. Production planning is the planning of production and manufacturing modules in a company or industry. It

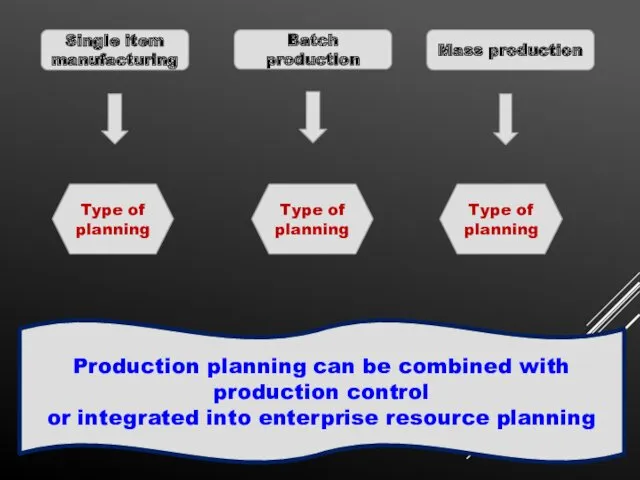

- 3. Single item manufacturing Batch production Mass production Type of planning Type of planning Type of planning

- 4. A production planning is made periodically for a specific time period, called the planning horizon. It

- 5. The planning horizon is the amount of time an organization will look into the future when

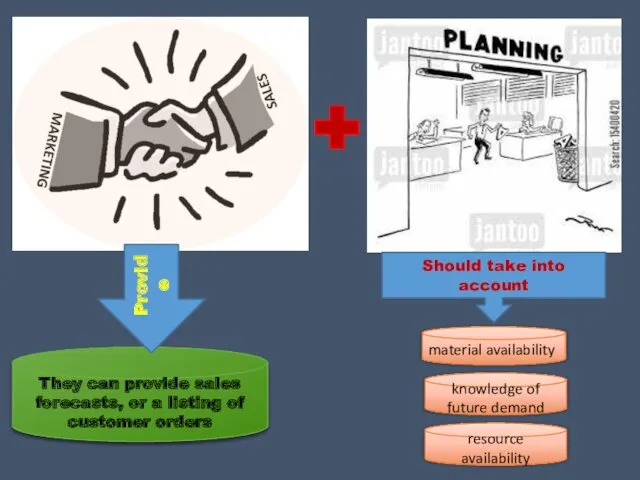

- 6. material availability They can provide sales forecasts, or a listing of customer orders Provide Should take

- 8. Elements of production planning Planning Routing Scheduling Dispatching Follow – up and expediting Inspection

- 9. Planning If you fail to plan, you are planning to fail! Benjamin Franklin

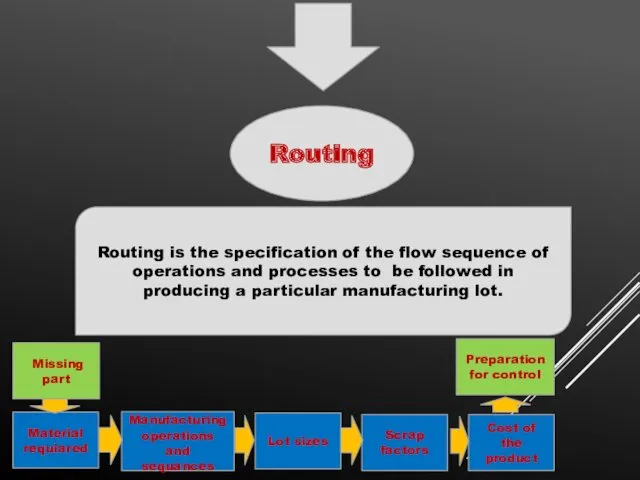

- 10. Routing Routing is the specification of the flow sequence of operations and processes to be followed

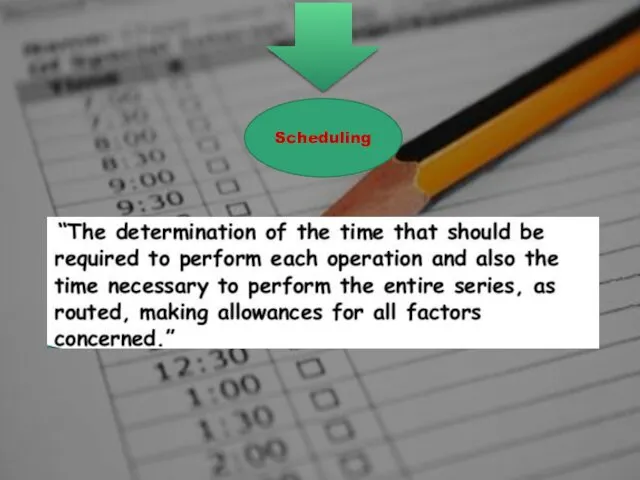

- 11. Scheduling

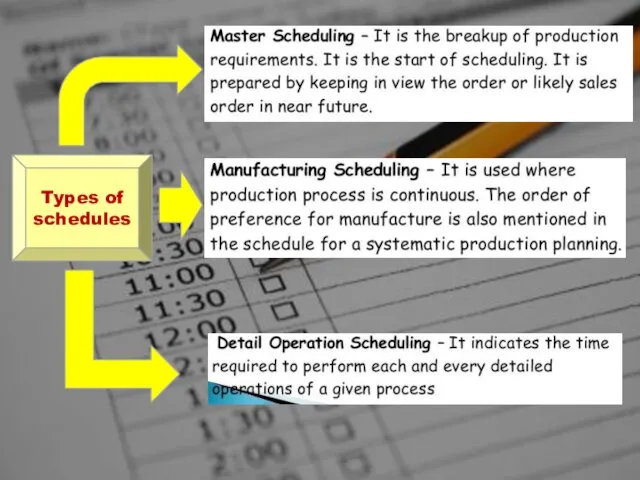

- 12. Types of schedules

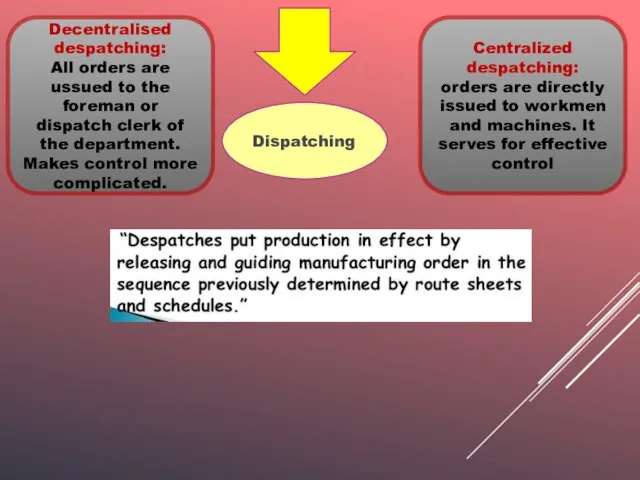

- 13. Dispatching Centralized despatching: orders are directly issued to workmen and machines. It serves for effective control

- 14. Follow – up and expediting Follow up or expediting is that branch of production control procedure,

- 15. Inspection Inspection is the process of ensuring whether the products manufactured are requisite quality or not.

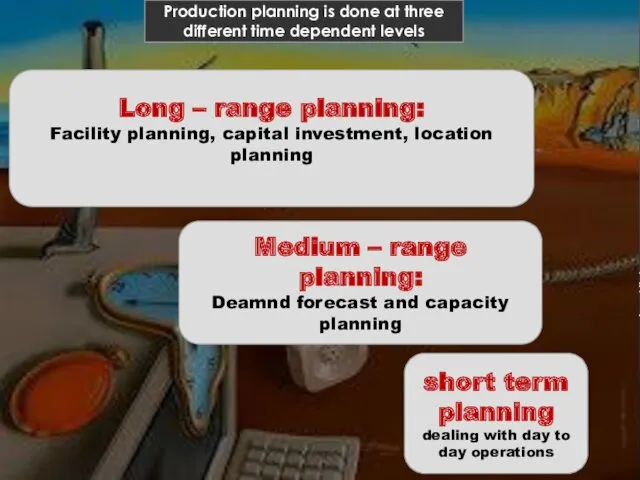

- 16. short term planning dealing with day to day operations Medium – range planning: Deamnd forecast and

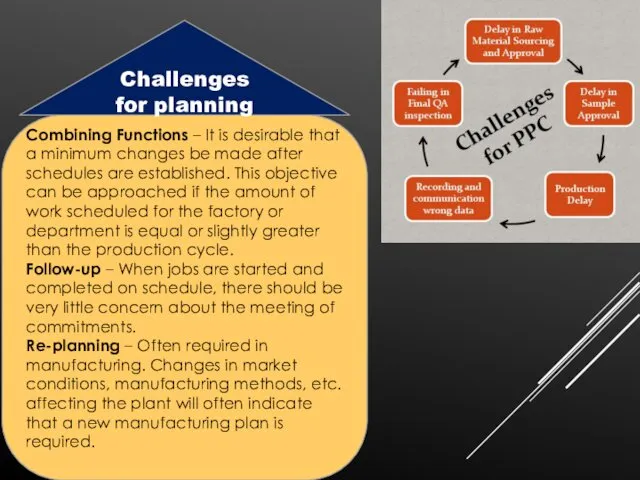

- 17. Combining Functions – It is desirable that a minimum changes be made after schedules are established.

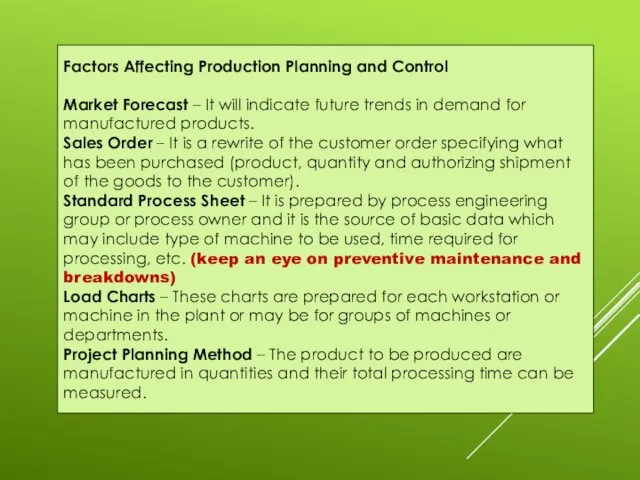

- 18. Factors Affecting Production Planning and Control Market Forecast – It will indicate future trends in demand

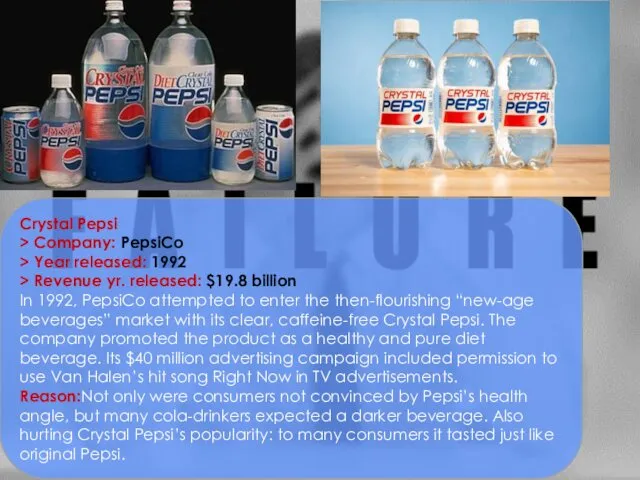

- 19. Crystal Pepsi > Company: PepsiCo > Year released: 1992 > Revenue yr. released: $19.8 billion In

- 23. Скачать презентацию

Бизнес-план: Производство топливных пеллет

Бизнес-план: Производство топливных пеллет Виды и формы бизнеса. Урок 18

Виды и формы бизнеса. Урок 18 Gucci (Russ. Gucci) Russ. Gucci)) - Italian brand, specializing in the creaton of clothing, luxury shoes and accessories

Gucci (Russ. Gucci) Russ. Gucci)) - Italian brand, specializing in the creaton of clothing, luxury shoes and accessories Обучение за % от профита

Обучение за % от профита Бизнес-план открытия кофейни

Бизнес-план открытия кофейни Проект консалтинговой компании EMS ABC

Проект консалтинговой компании EMS ABC Маркетинг-план компании Amway

Маркетинг-план компании Amway Шаблон SWOT анализа

Шаблон SWOT анализа Программа Бизнес класс

Программа Бизнес класс Изготовление изделий из дерева

Изготовление изделий из дерева Производство пирожков от компании “АнДи”

Производство пирожков от компании “АнДи” Проблемы молодых и начинающих предпринимателей и их решения

Проблемы молодых и начинающих предпринимателей и их решения Бизнес-планирование на предприятии АПК

Бизнес-планирование на предприятии АПК Основы бизнеса в информационной сфере

Основы бизнеса в информационной сфере Бизнес идея

Бизнес идея Бизнес-планирование

Бизнес-планирование Прохождение курса в Like-центре. Цель на время прохождения курса

Прохождение курса в Like-центре. Цель на время прохождения курса “PenMan”. Магазин канцтоваров

“PenMan”. Магазин канцтоваров Бизнес не для всех. Какими навыками нужно обладать для старта

Бизнес не для всех. Какими навыками нужно обладать для старта Установка для получения пресной воды из атмосферного воздуха в прибрежных районах, а также условиях морского транспорта

Установка для получения пресной воды из атмосферного воздуха в прибрежных районах, а также условиях морского транспорта Бизнес-план. Компьютерный клуб Интер

Бизнес-план. Компьютерный клуб Интер Рынок окон ПВХ сегодня. Завтра. Стратегия

Рынок окон ПВХ сегодня. Завтра. Стратегия Архитектура предприятия. Стандарт гильдии бизнес-архитекторов. (Тема 7)

Архитектура предприятия. Стандарт гильдии бизнес-архитекторов. (Тема 7) Крупный и венчурный бизнес

Крупный и венчурный бизнес Путь предпринимателя в IT

Путь предпринимателя в IT Становись партнером Dream&Gift

Становись партнером Dream&Gift Бізнес-план

Бізнес-план Основы системного бизнес-анализа

Основы системного бизнес-анализа