Содержание

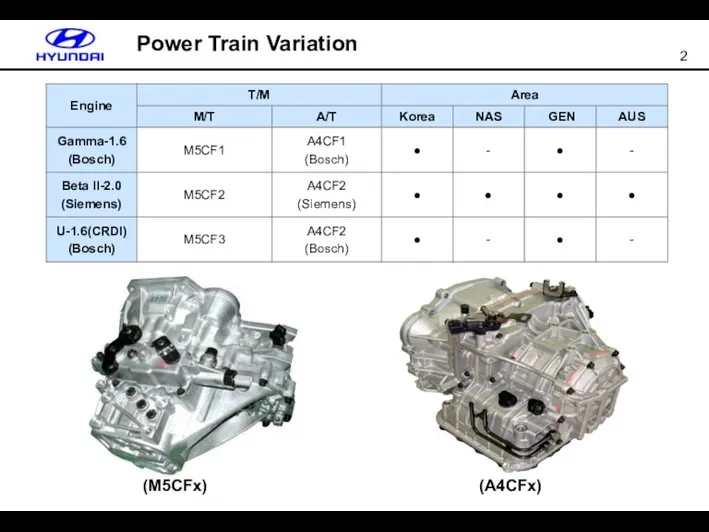

- 2. Power Train Variation (A4CFx) (M5CFx)

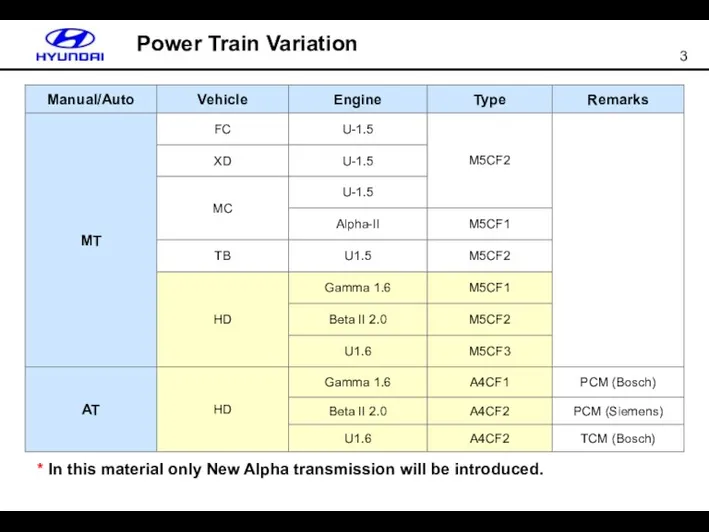

- 3. * In this material only New Alpha transmission will be introduced. Power Train Variation

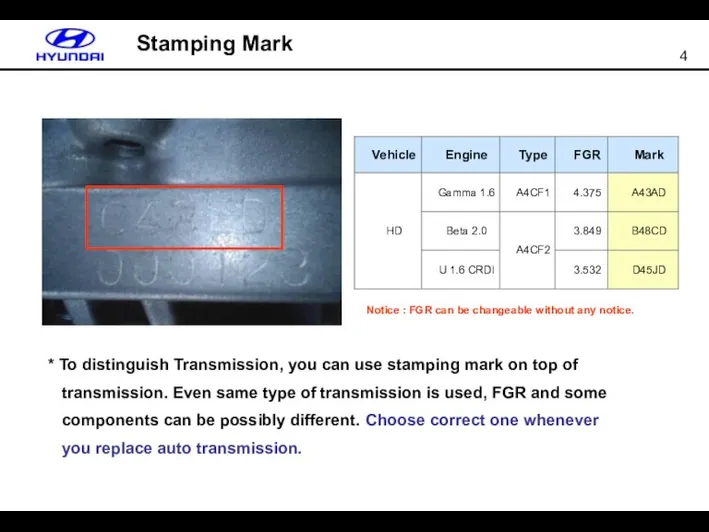

- 4. * To distinguish Transmission, you can use stamping mark on top of transmission. Even same type

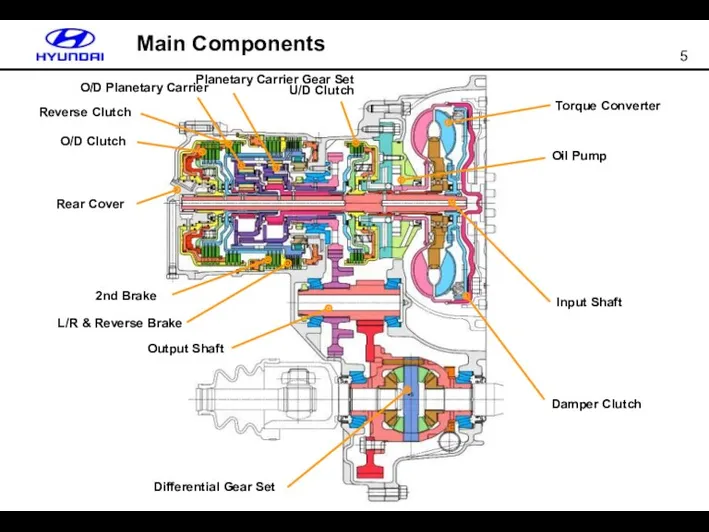

- 5. Main Components Reverse Clutch O/D Clutch Rear Cover 2nd Brake L/R & Reverse Brake Output Shaft

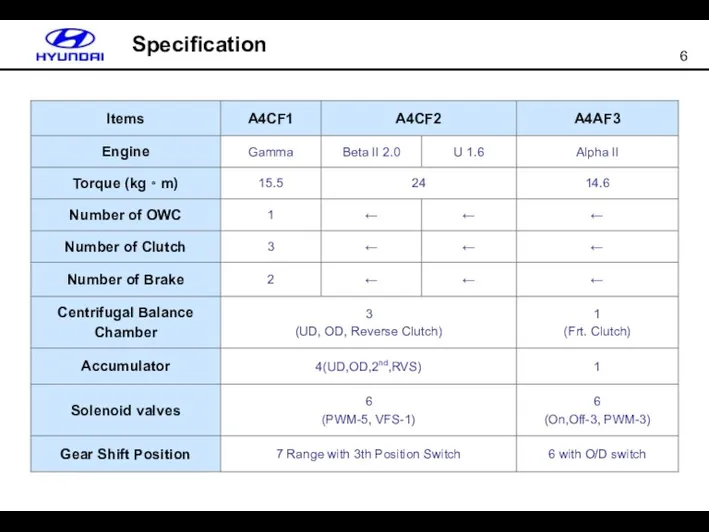

- 6. Comparison Specification

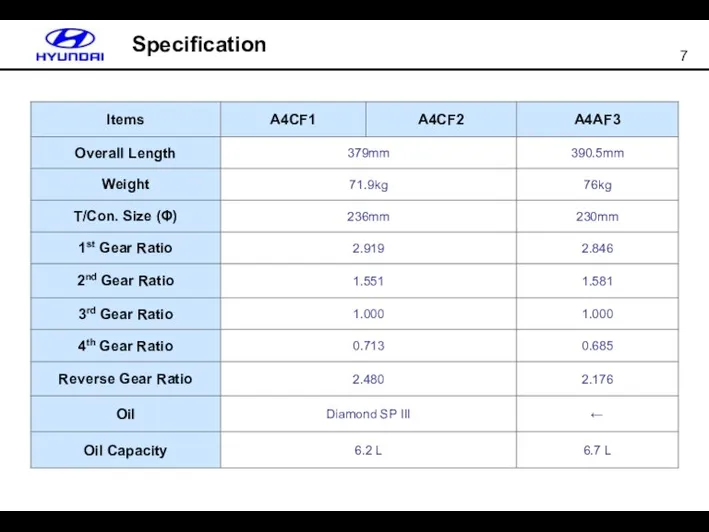

- 7. Comparison Specification

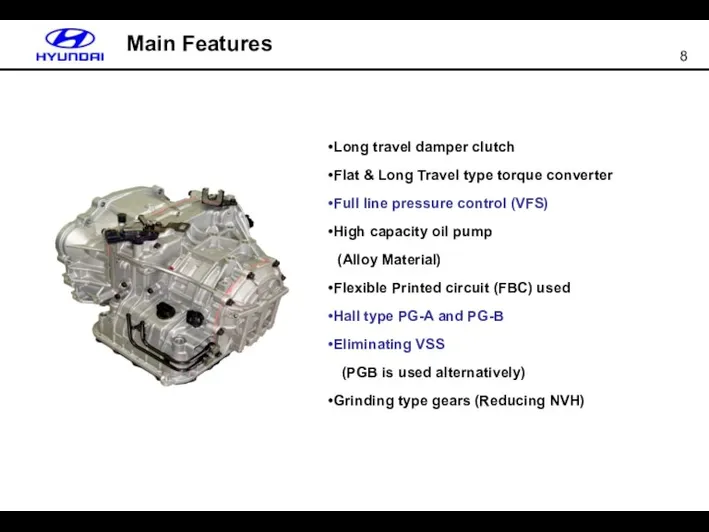

- 8. Main Features Long travel damper clutch Flat & Long Travel type torque converter Full line pressure

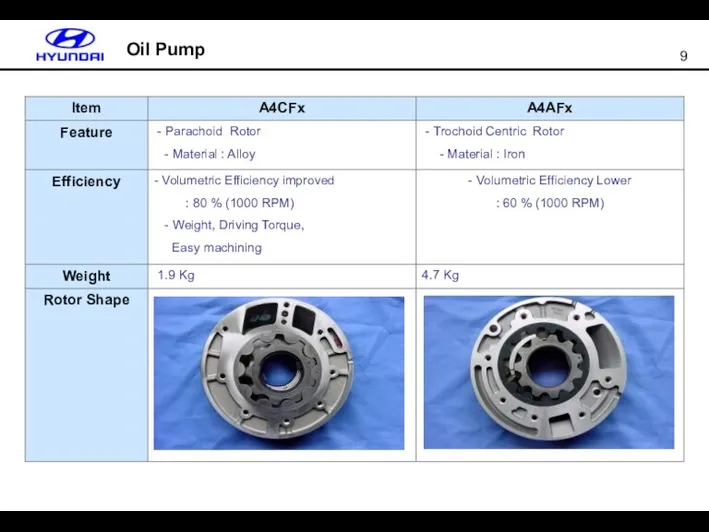

- 9. Oil Pump

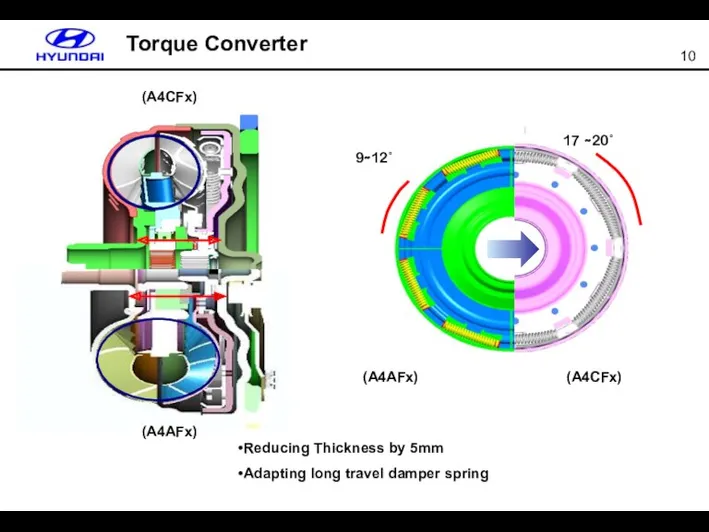

- 10. Torque Converter Reducing Thickness by 5mm Adapting long travel damper spring

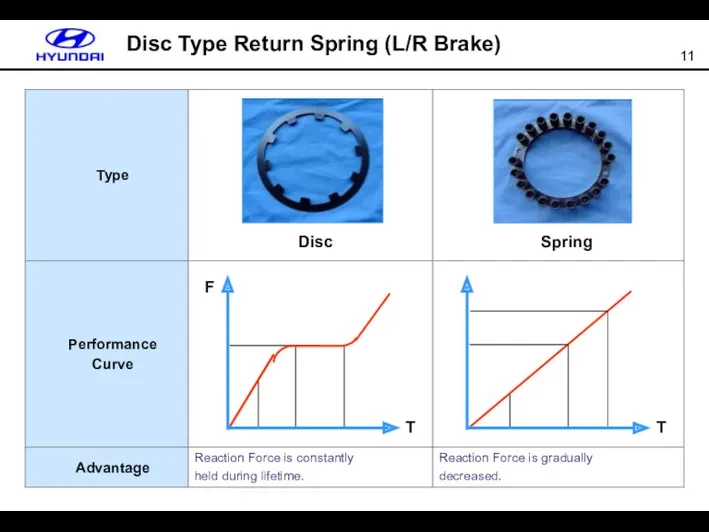

- 11. Disc Type Return Spring (L/R Brake) Disc Spring T F T

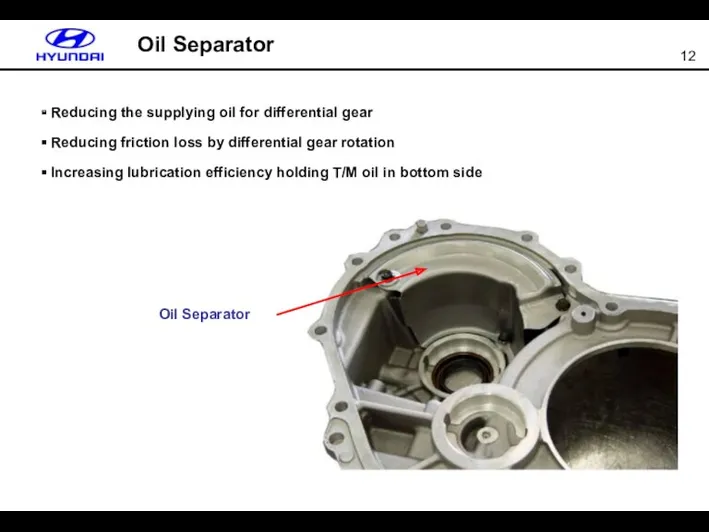

- 12. Reducing the supplying oil for differential gear Reducing friction loss by differential gear rotation Increasing lubrication

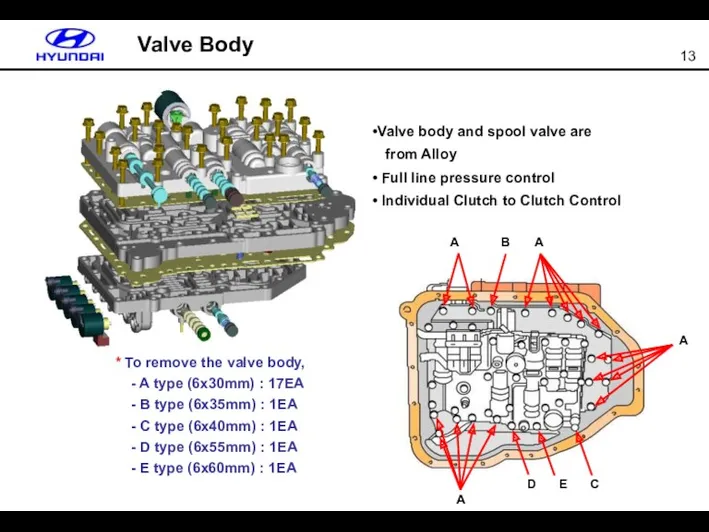

- 13. Valve Body Valve body and spool valve are from Alloy Full line pressure control Individual Clutch

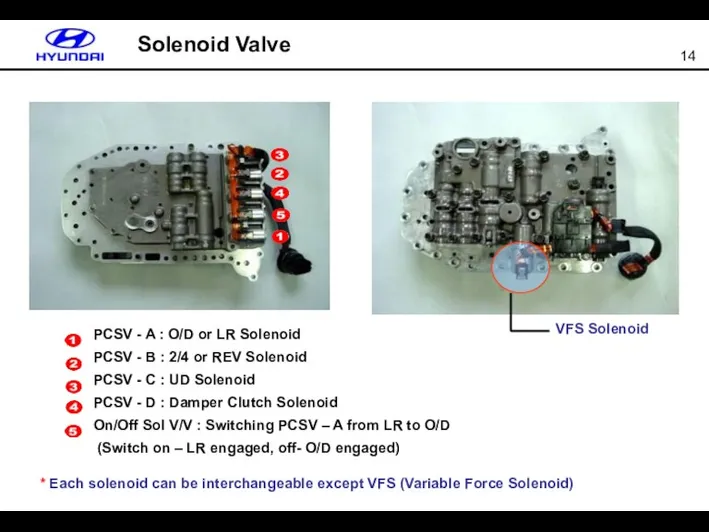

- 14. PCSV - A : O/D or LR Solenoid PCSV - B : 2/4 or REV Solenoid

- 15. Accumulator Each Spring can be interchangeable except white one ⓑ ⓒ ⓓ ⓐ UD (two springs

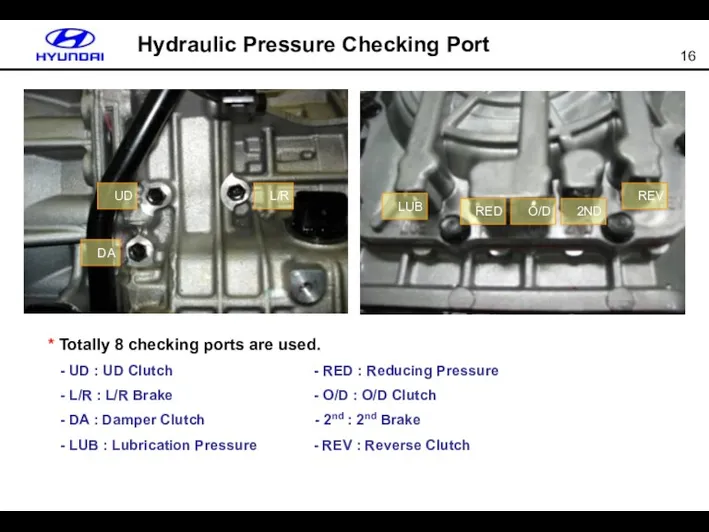

- 16. Hydraulic Pressure Checking Port * Totally 8 checking ports are used. - UD : UD Clutch

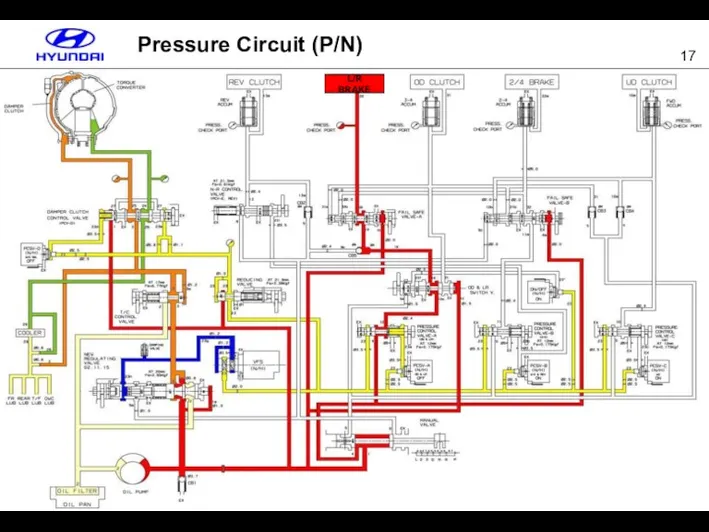

- 17. Pressure Circuit (P/N) L/R BRAKE

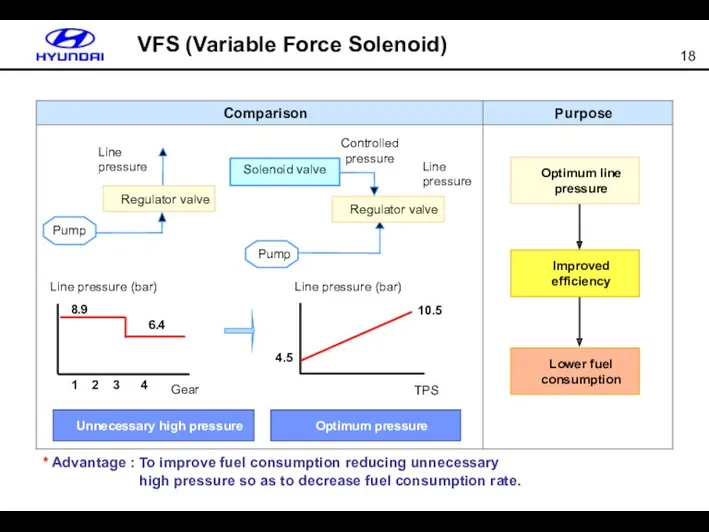

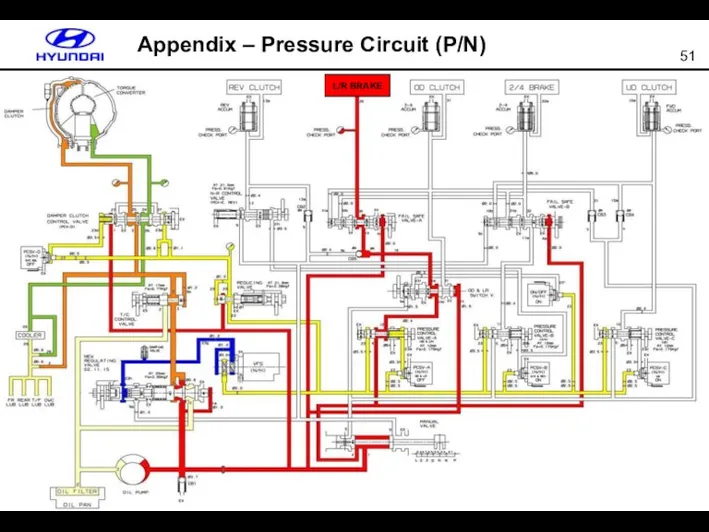

- 18. * Advantage : To improve fuel consumption reducing unnecessary high pressure so as to decrease fuel

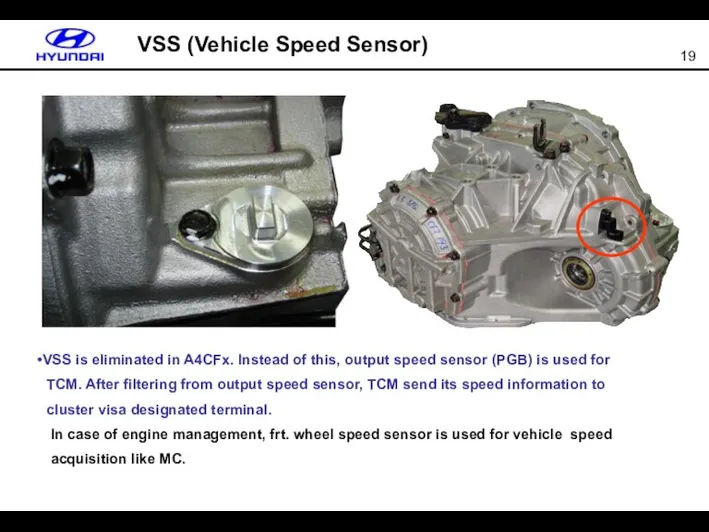

- 19. VSS (Vehicle Speed Sensor) VSS is eliminated in A4CFx. Instead of this, output speed sensor (PGB)

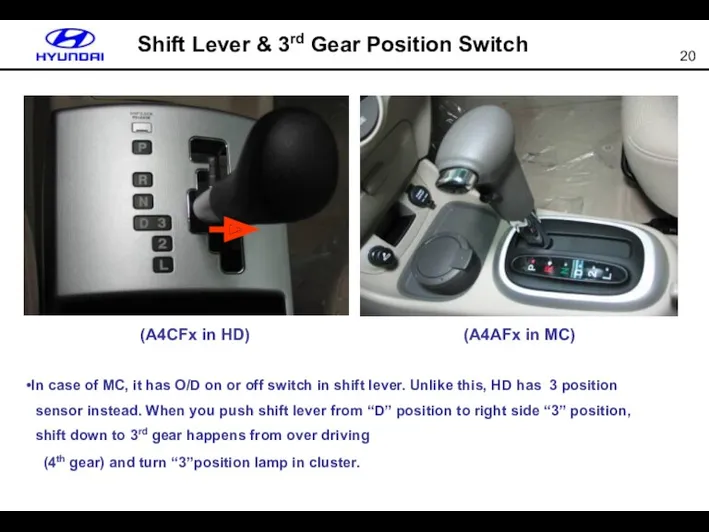

- 20. Shift Lever & 3rd Gear Position Switch (A4CFx in HD) (A4AFx in MC) In case of

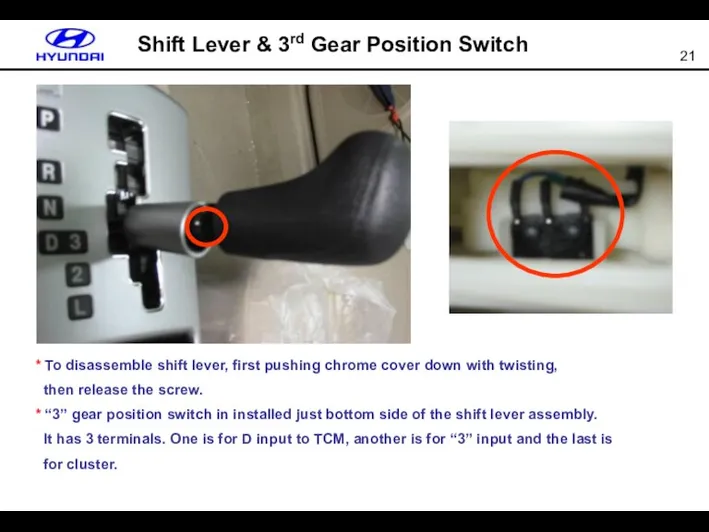

- 21. Shift Lever & 3rd Gear Position Switch * To disassemble shift lever, first pushing chrome cover

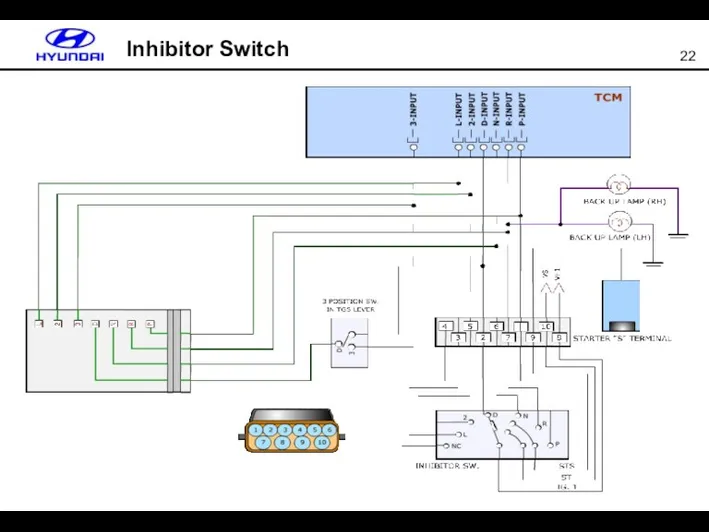

- 22. Inhibitor Switch

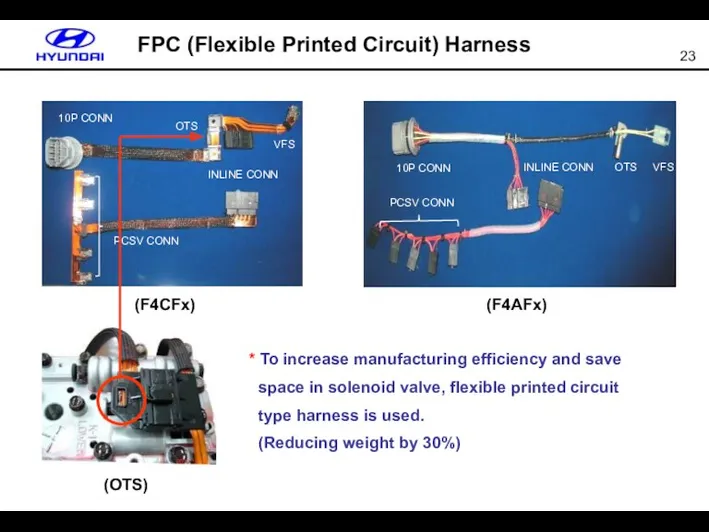

- 23. FPC (Flexible Printed Circuit) Harness 10P CONN INLINE CONN VFS PCSV CONN OTS 10P CONN INLINE

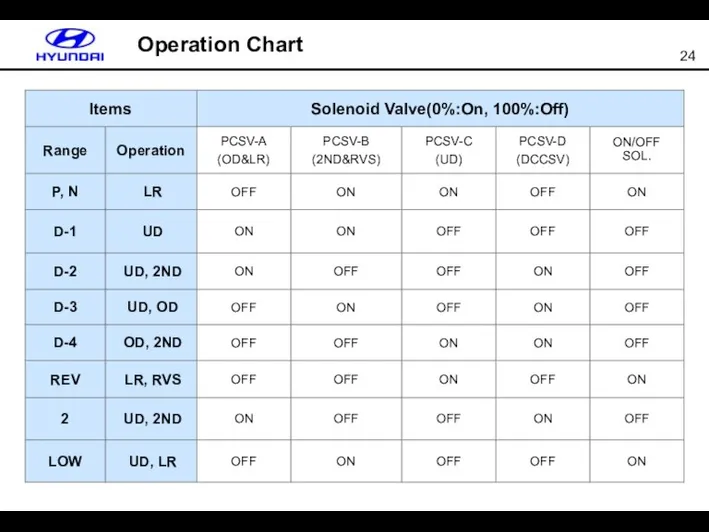

- 24. Operation Chart

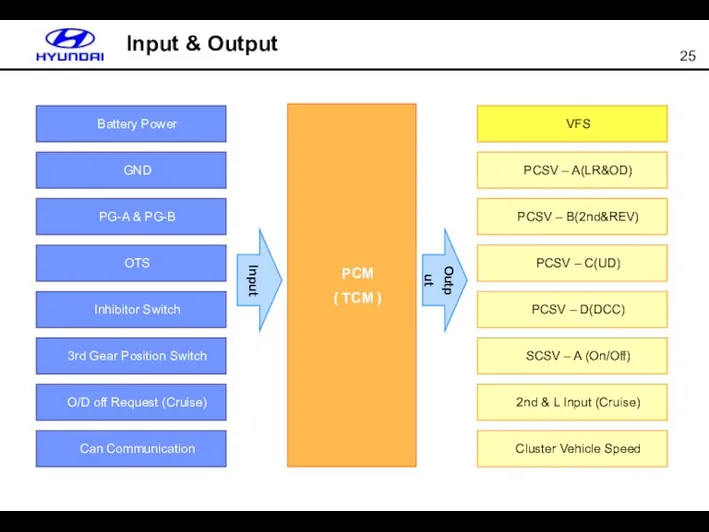

- 25. Input & Output Input PCM ( TCM ) Battery Power GND PG-A & PG-B OTS Inhibitor

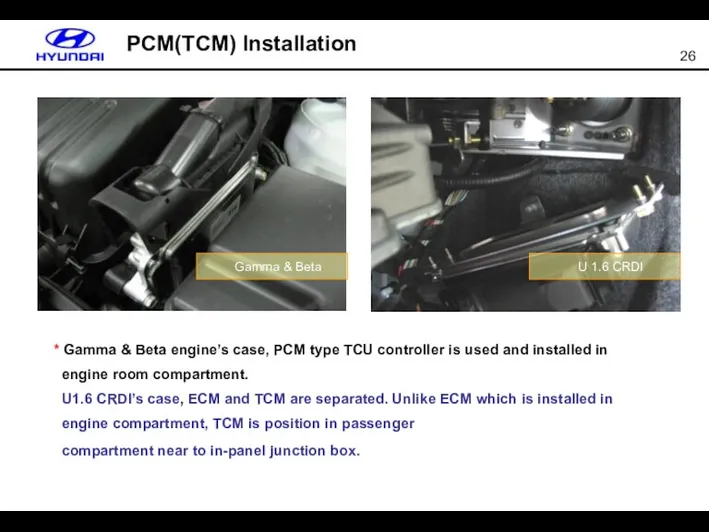

- 26. PCM(TCM) Installation * Gamma & Beta engine’s case, PCM type TCU controller is used and installed

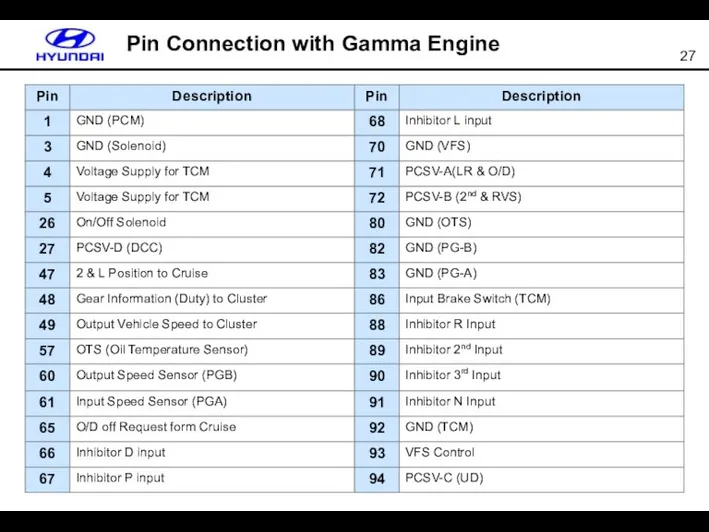

- 27. Pin Connection with Gamma Engine

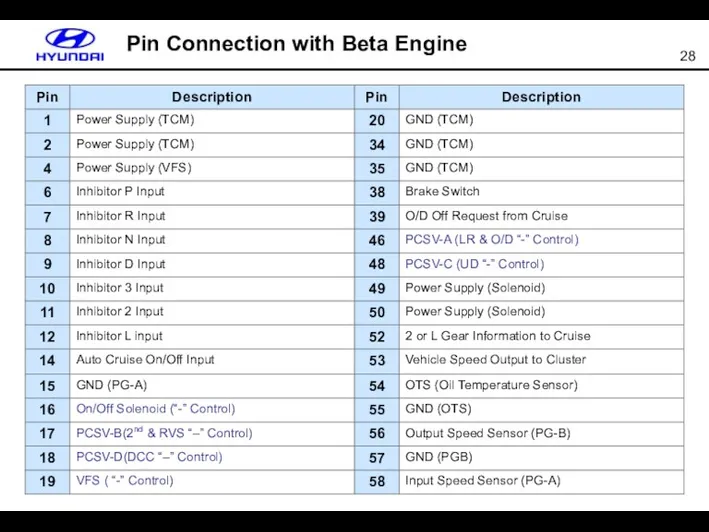

- 28. Pin Connection with Beta Engine

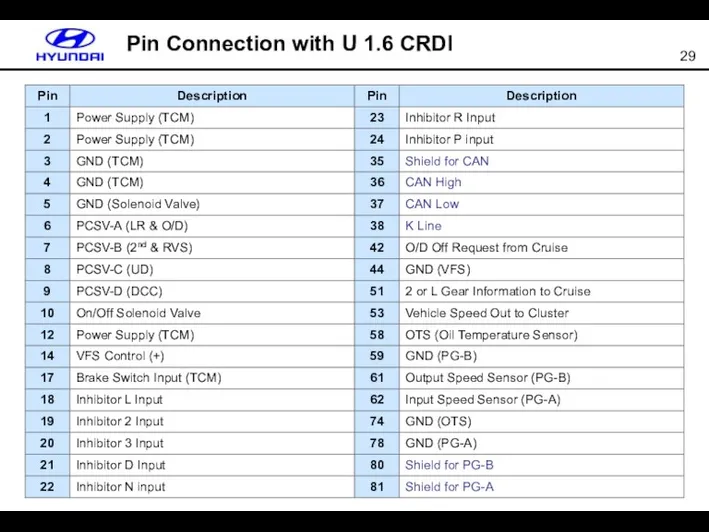

- 29. Pin Connection with U 1.6 CRDI

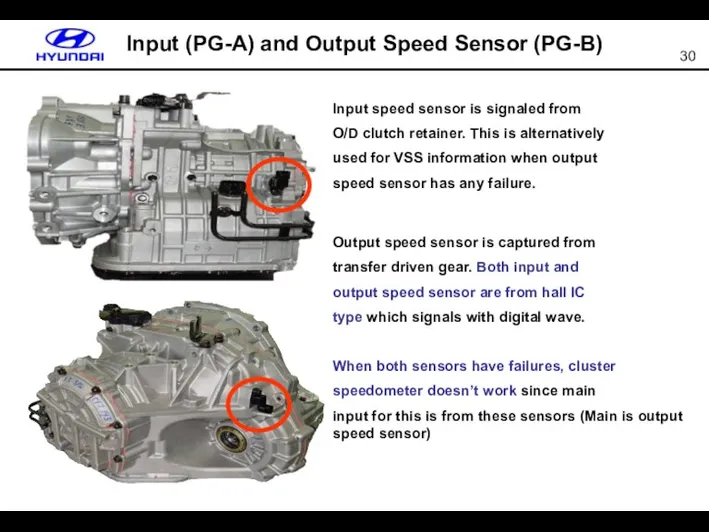

- 30. Input (PG-A) and Output Speed Sensor (PG-B) Input speed sensor is signaled from O/D clutch retainer.

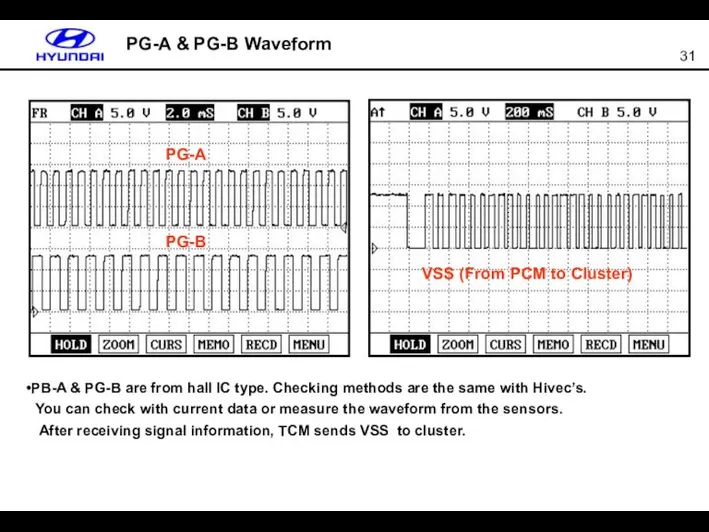

- 31. PG-A & PG-B Waveform PG-A PG-B PB-A & PG-B are from hall IC type. Checking methods

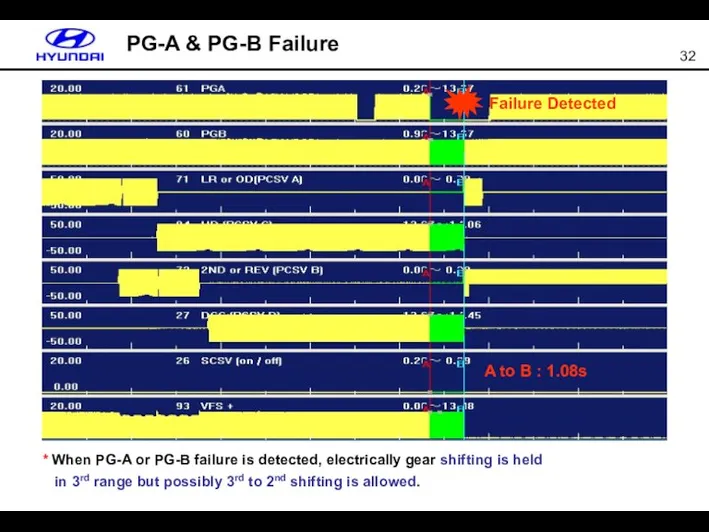

- 32. PG-A & PG-B Failure * When PG-A or PG-B failure is detected, electrically gear shifting is

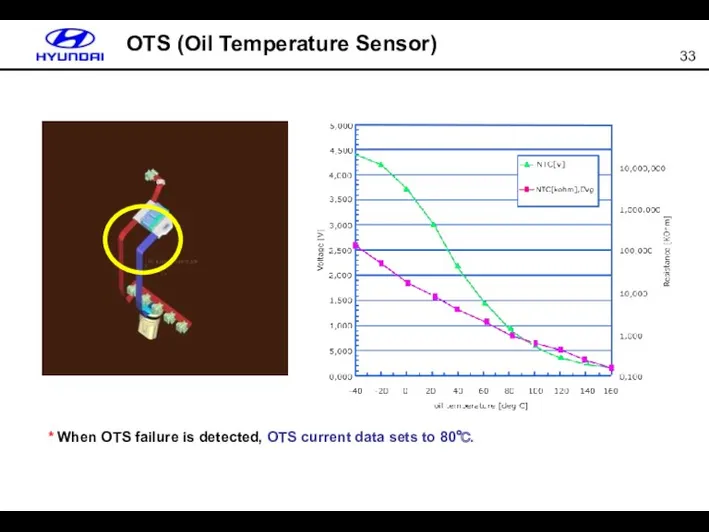

- 33. OTS (Oil Temperature Sensor) * When OTS failure is detected, OTS current data sets to 80℃.

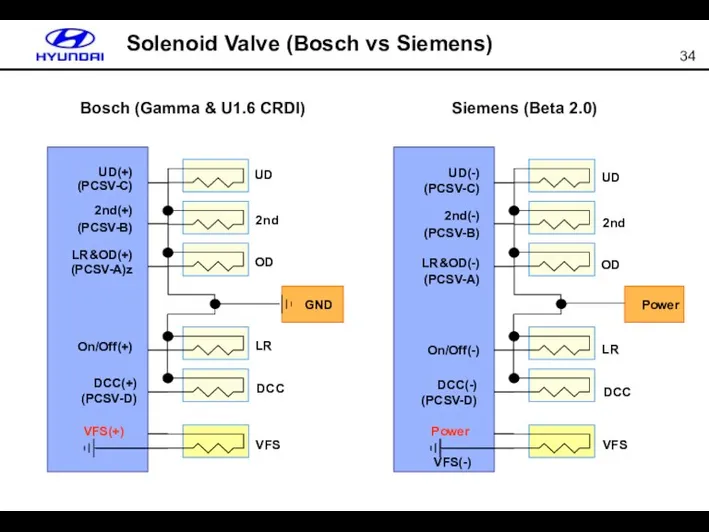

- 34. GND Solenoid Valve (Bosch vs Siemens) UD 2nd OD LR DCC VFS UD(-) (PCSV-C) 2nd(-) (PCSV-B)

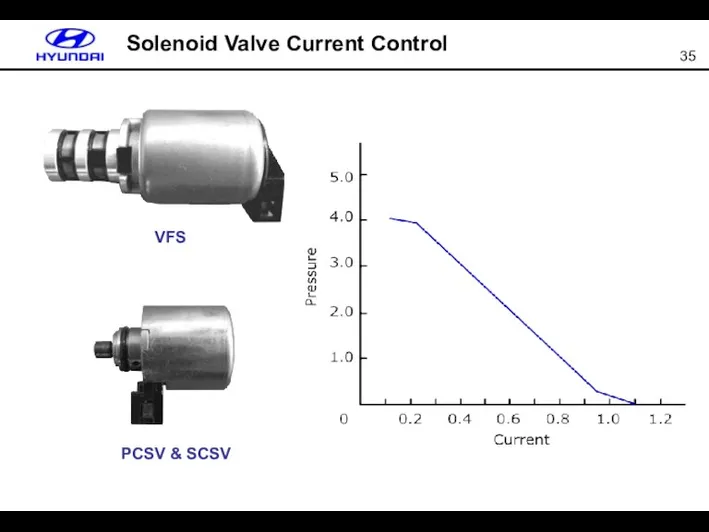

- 35. Solenoid Valve Current Control VFS PCSV & SCSV

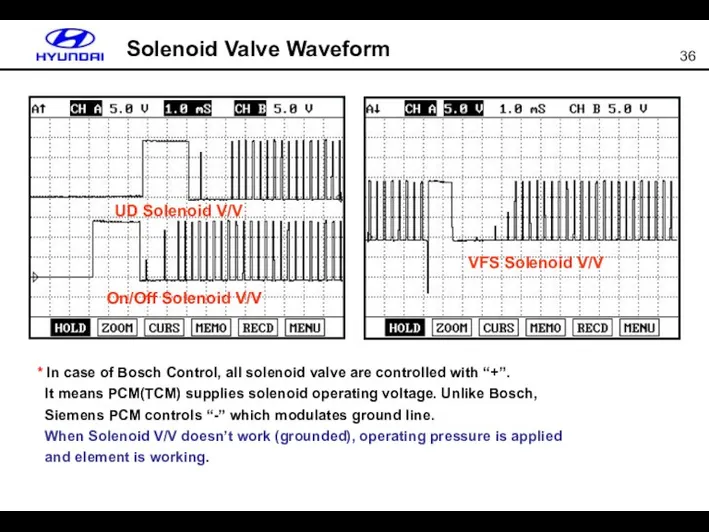

- 36. UD Solenoid V/V On/Off Solenoid V/V VFS Solenoid V/V Solenoid Valve Waveform * In case of

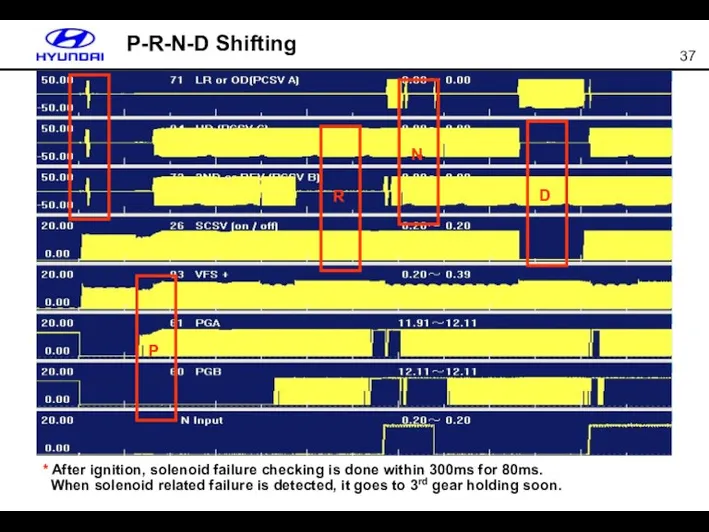

- 37. P-R-N-D Shifting P R N D * After ignition, solenoid failure checking is done within 300ms

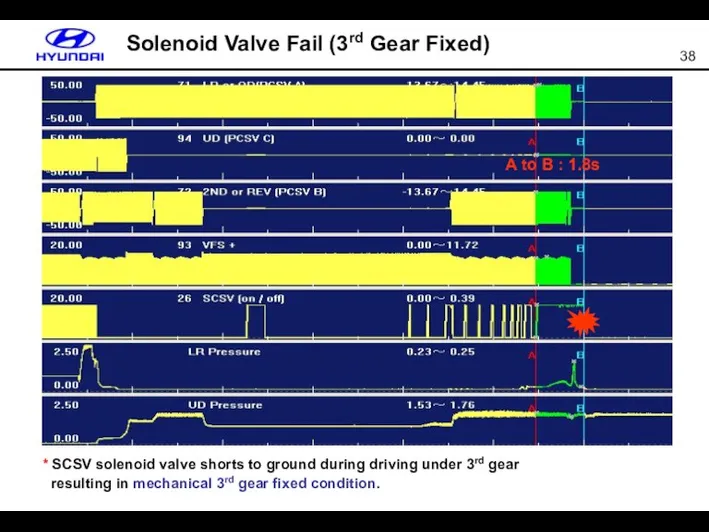

- 38. Solenoid Valve Fail (3rd Gear Fixed) A to B : 1.8s * SCSV solenoid valve shorts

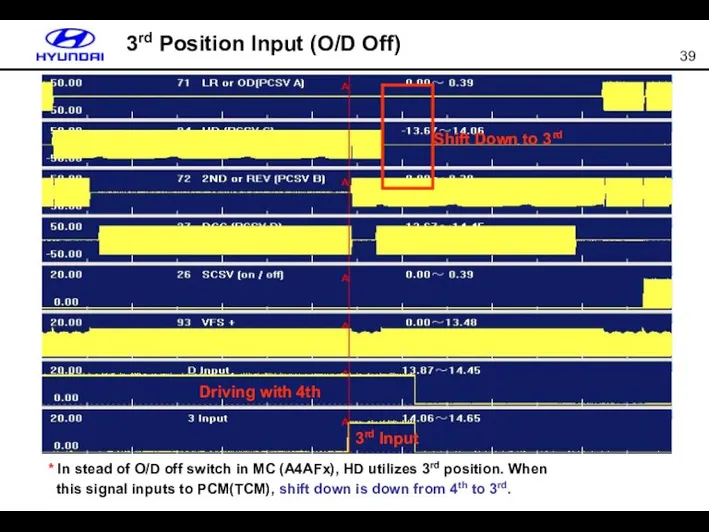

- 39. 3rd Position Input (O/D Off) * In stead of O/D off switch in MC (A4AFx), HD

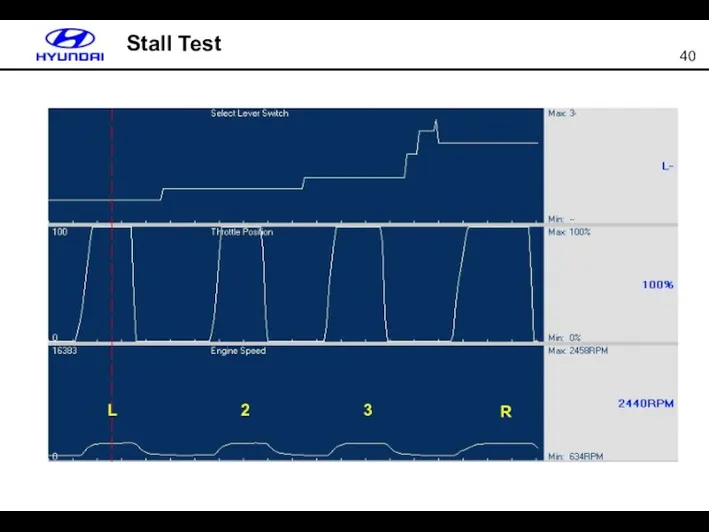

- 40. Stall Test L 2 3 R

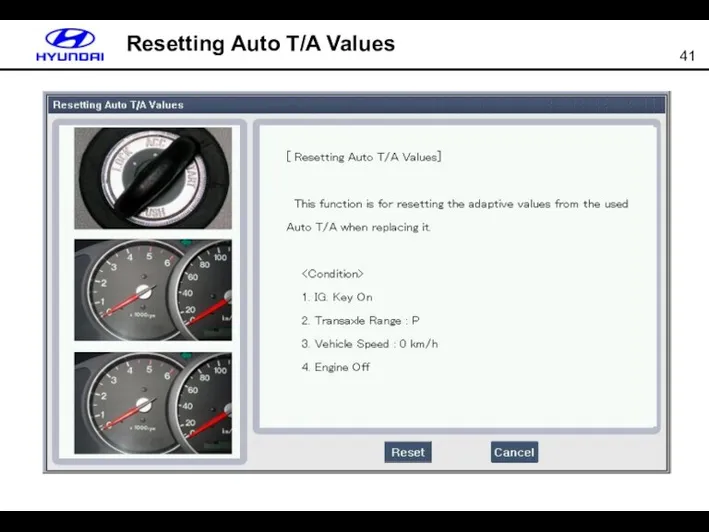

- 41. Resetting Auto T/A Values

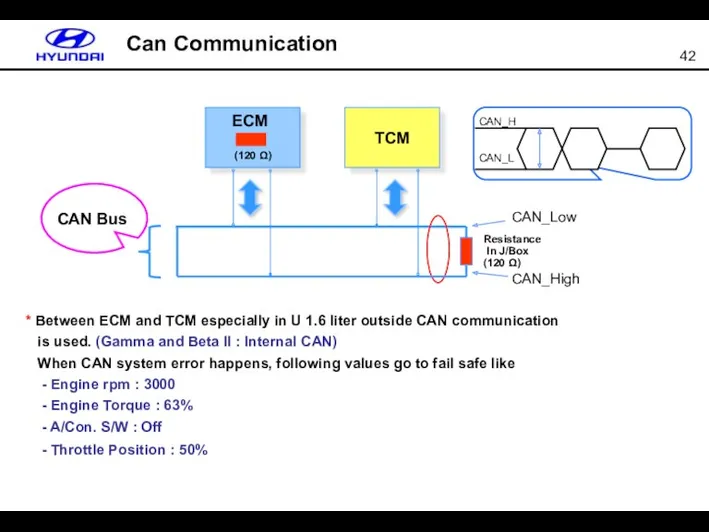

- 42. TCM CAN Bus CAN_Low CAN_High CAN_L CAN_H Resistance In J/Box (120 Ω) ECM (120 Ω) Can

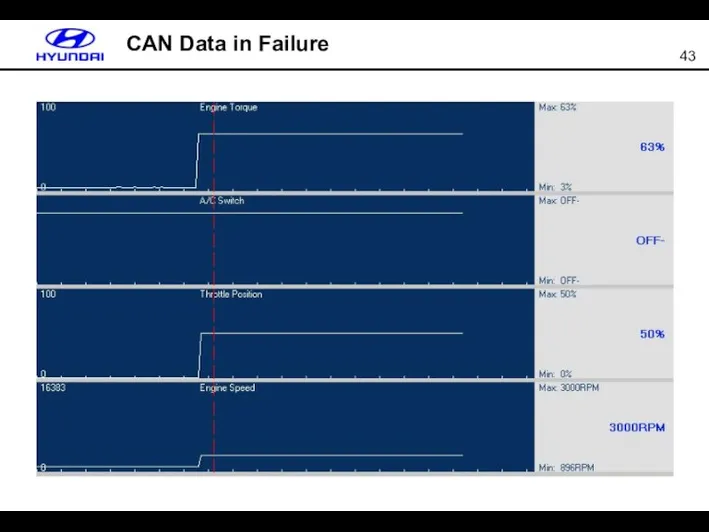

- 43. CAN Data in Failure

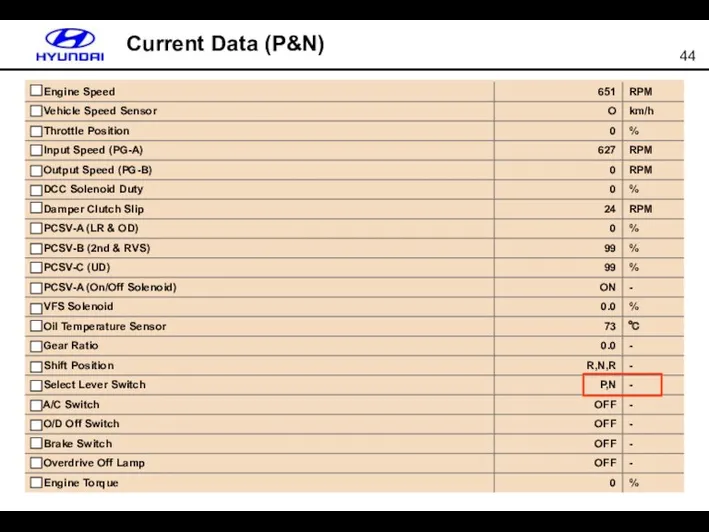

- 44. Current Data (P&N)

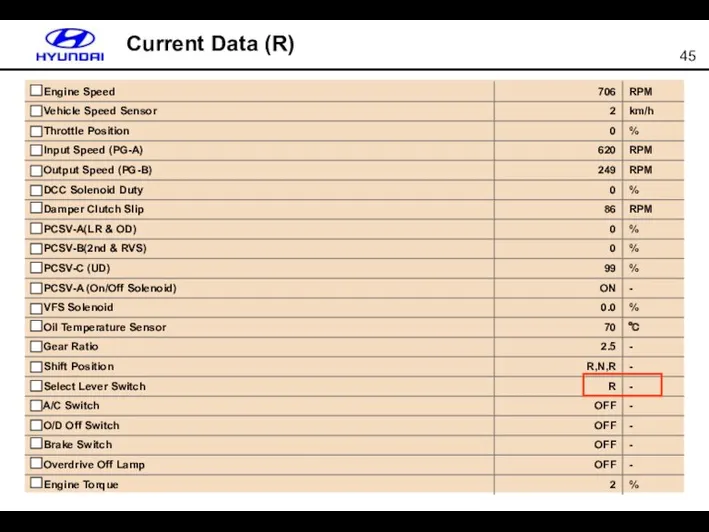

- 45. Current Data (R)

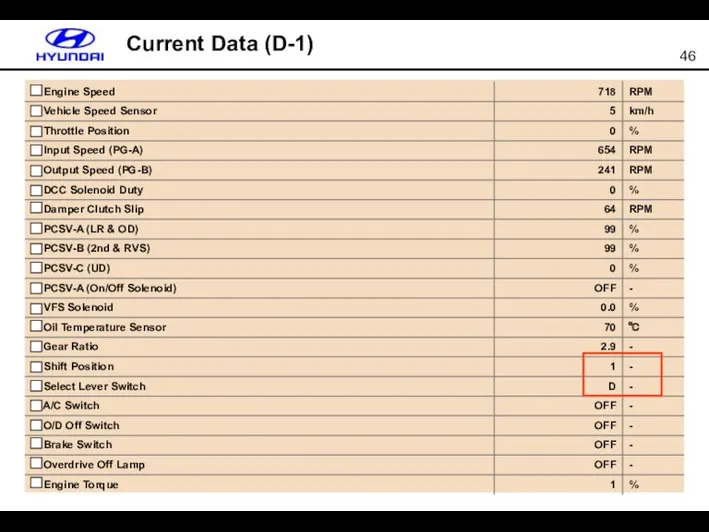

- 46. Current Data (D-1)

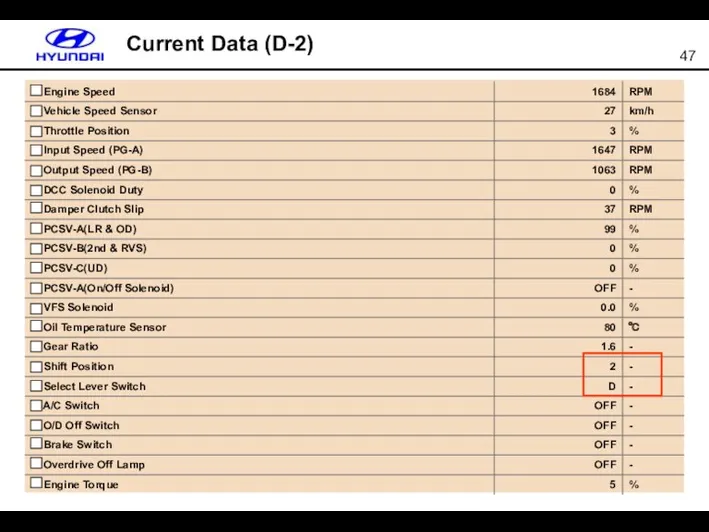

- 47. Current Data (D-2)

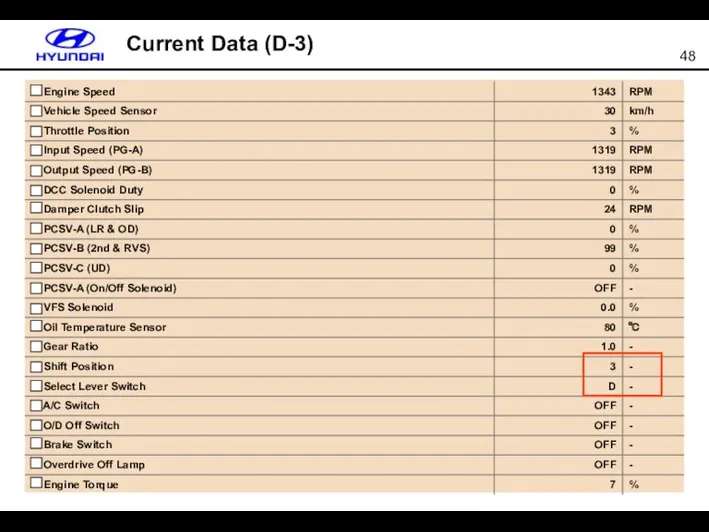

- 48. Current Data (D-3)

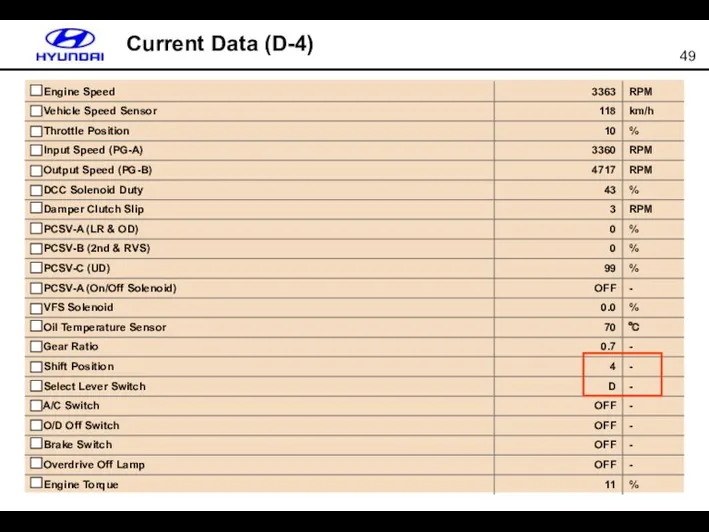

- 49. Current Data (D-4)

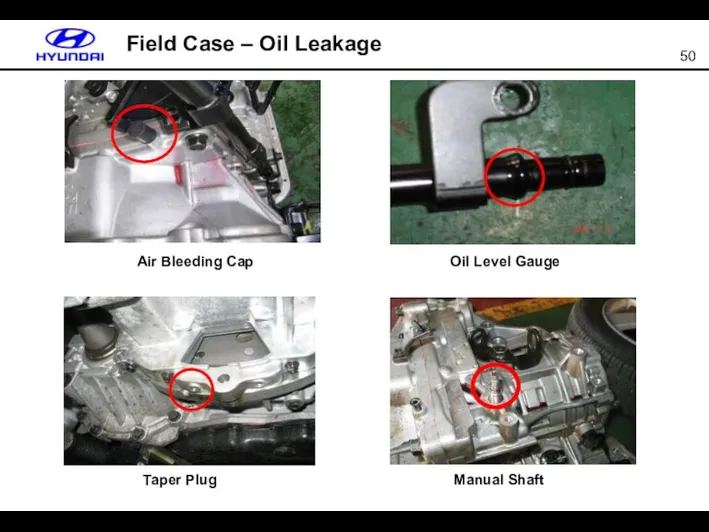

- 50. Field Case – Oil Leakage Air Bleeding Cap Oil Level Gauge Taper Plug Manual Shaft

- 51. Appendix – Pressure Circuit (P/N) L/R BRAKE

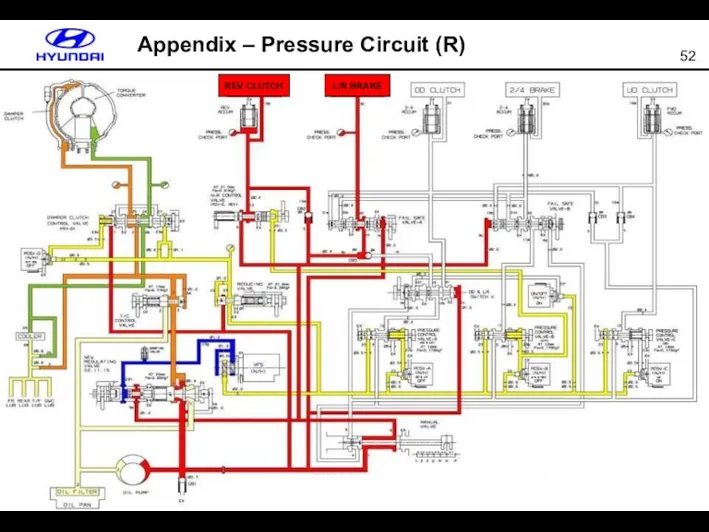

- 52. Appendix – Pressure Circuit (R) L/R BRAKE REV CLUTCH

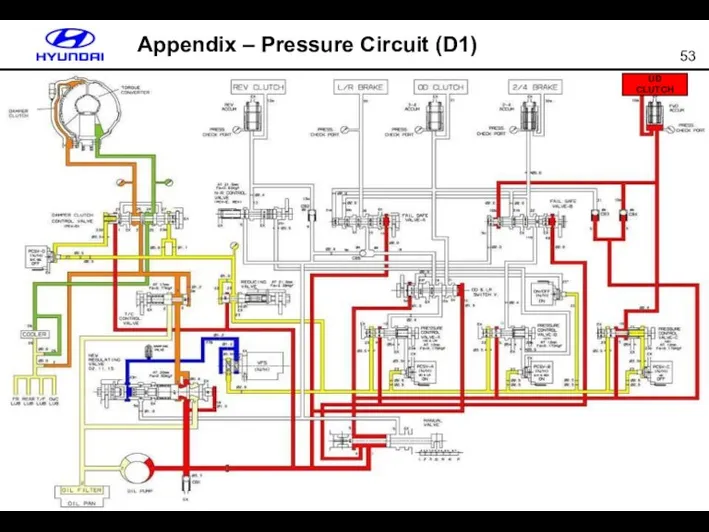

- 53. Appendix – Pressure Circuit (D1) UD CLUTCH

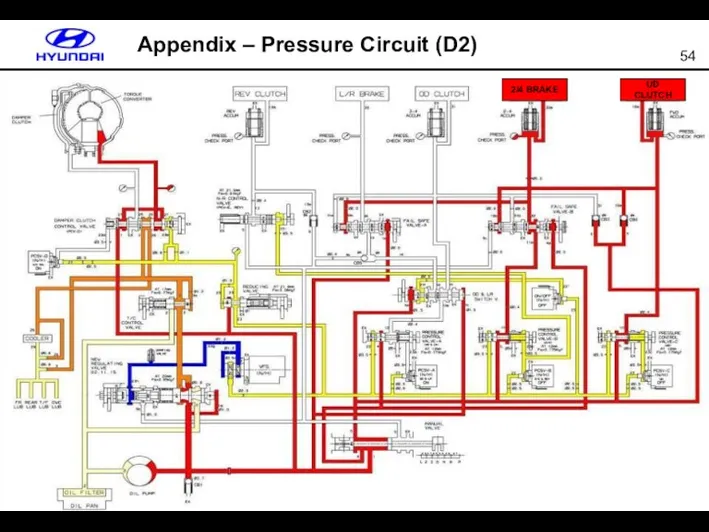

- 54. Appendix – Pressure Circuit (D2) UD CLUTCH 2/4 BRAKE

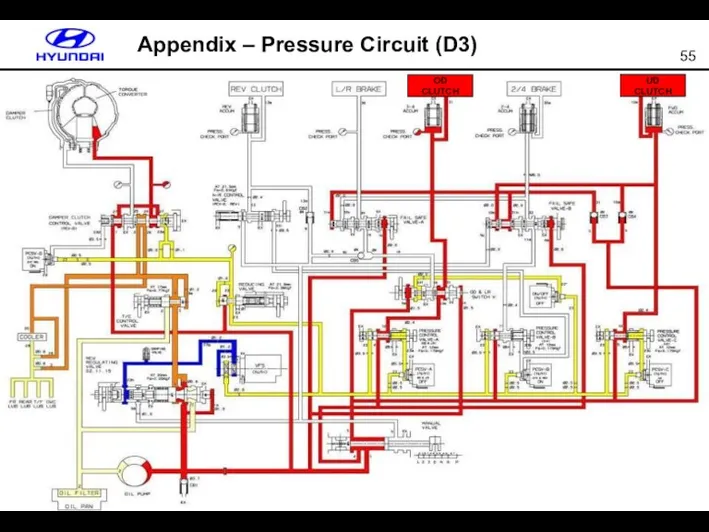

- 55. Appendix – Pressure Circuit (D3) UD CLUTCH OD CLUTCH

- 57. Скачать презентацию

Механическая работа

Механическая работа Модуляция и детектирование

Модуляция и детектирование Тележка электровоза ВЛ80р

Тележка электровоза ВЛ80р Расчет сложных электрических цепей постоянного тока

Расчет сложных электрических цепей постоянного тока Физические основы гемодинамики

Физические основы гемодинамики Резка металла

Резка металла Законы сохранения в механике

Законы сохранения в механике Электрические машины постоянного тока

Электрические машины постоянного тока Расчет потенциалов простейших электростатических полей

Расчет потенциалов простейших электростатических полей Лазеры. Лазерное излучение

Лазеры. Лазерное излучение Сақталу заңдары

Сақталу заңдары Механические волны

Механические волны Методы люминисцентного анализа

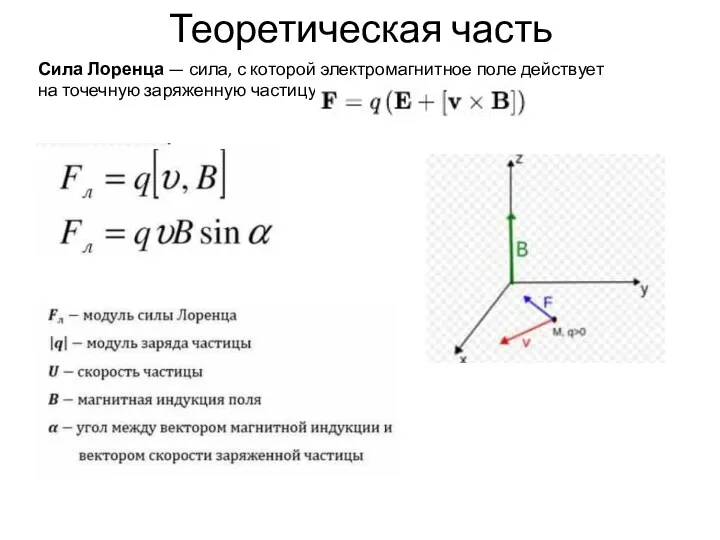

Методы люминисцентного анализа Сила Лоренца. Теоретическая часть

Сила Лоренца. Теоретическая часть Гидравлика. Основные свойства жидкостей

Гидравлика. Основные свойства жидкостей Совершенствование ГБЦ двигателя МеМЗ 307

Совершенствование ГБЦ двигателя МеМЗ 307 Адсорбция изотермалары

Адсорбция изотермалары Что такое электричество?

Что такое электричество? Гидравлический удар. Описание процесса

Гидравлический удар. Описание процесса Масса. Взаимодействие тел

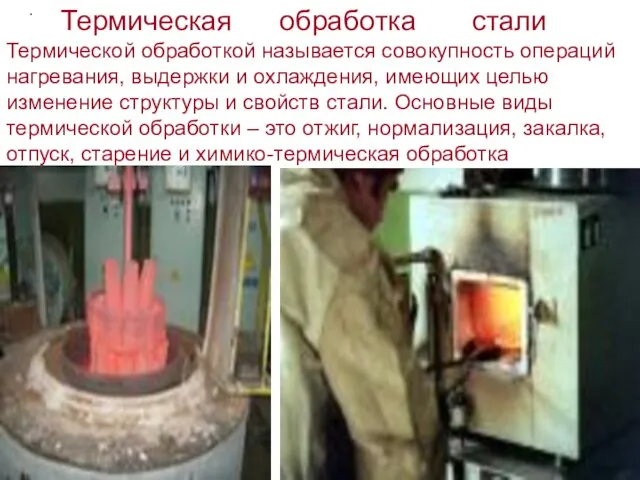

Масса. Взаимодействие тел Термическая обработка стали

Термическая обработка стали Физические методы исследования в химии

Физические методы исследования в химии Преподавание физики в 2012-13 уч.году

Преподавание физики в 2012-13 уч.году Система питания дизельного двигателя

Система питания дизельного двигателя Технологии получения полимерных нанокомпозитов

Технологии получения полимерных нанокомпозитов Магні́тне по́ле

Магні́тне по́ле Простые механизмы. Рычаг. Равновесие сил на рычаге

Простые механизмы. Рычаг. Равновесие сил на рычаге Кванттық теорияның бастаулары

Кванттық теорияның бастаулары