Содержание

- 2. Absorption bromistolitievye thermotransformers (ABTT) - heat-using energy-saving equipment: Refrigeration machines (ABCM) to generate artificial cold and;

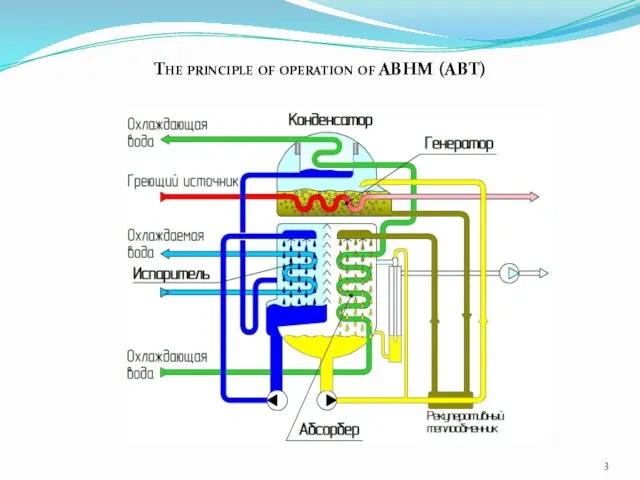

- 3. The principle of operation of ABHM (ABT)

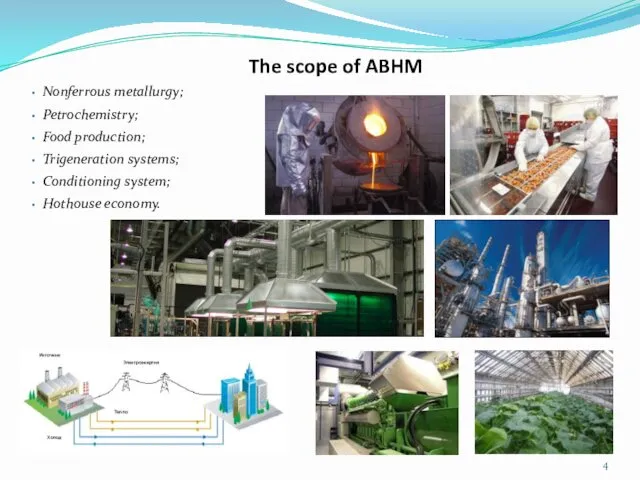

- 4. Nonferrous metallurgy; Petrochemistry; Food production; Trigeneration systems; Conditioning system; Hothouse economy. The scope of ABHM

- 5. Compression refrigerating machines (CHM) Absorption lithium bromide refrigerating machine(ABHM)

- 6. Heating system; Hot water system; Simultaneous heating and cooling in industry and heat power engineering. The

- 7. AKOR Direkt – the only one in Russia developer lithium bromide absorption thermotransformers. The company performs

- 8. In AKOR Direkt developed thirty modifications of ABTT. ABHM: with water and steam heating with single-stage

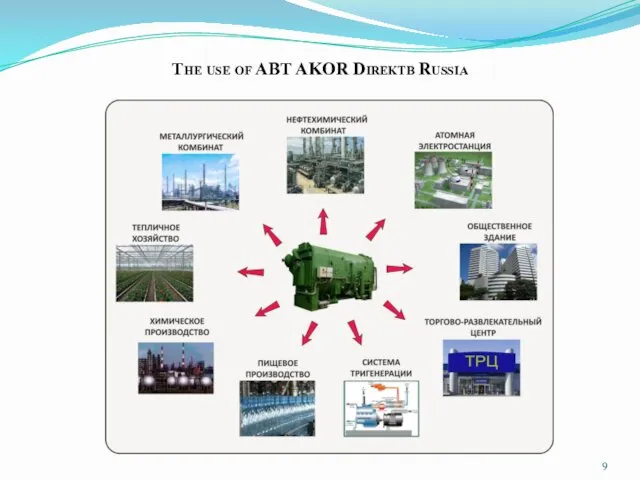

- 9. The use of ABT AKOR Direktв Russia

- 10. cooling of the blast air at the entrance to the GTU of power and gas pumping

- 11. Urgency Natural gas combustion in boilers produces up to 19-20% of water vapor by volume (12-13%

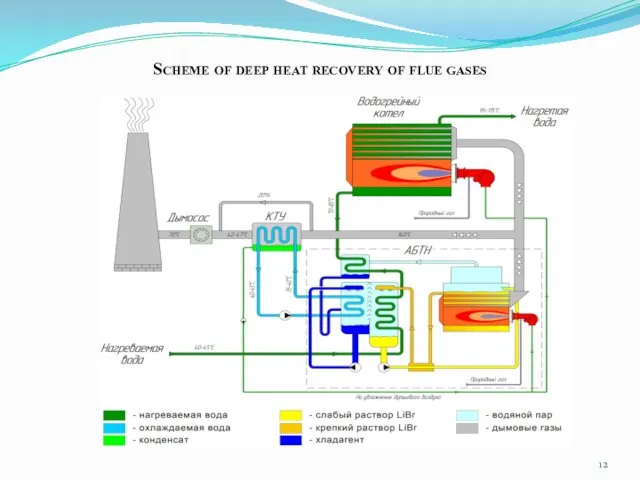

- 12. Scheme of deep heat recovery of flue gases

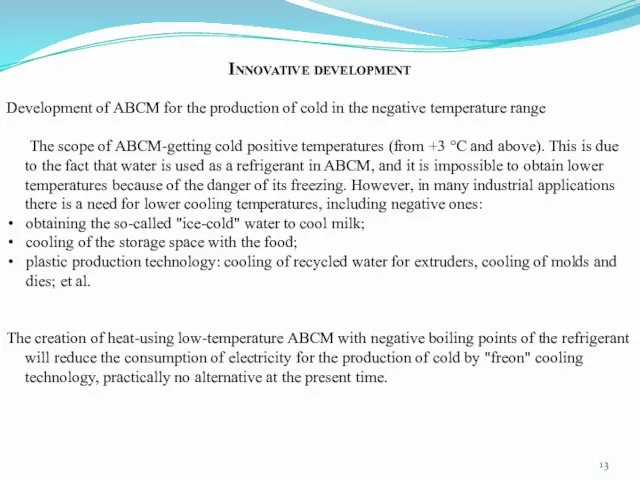

- 13. Innovative development Development of ABCM for the production of cold in the negative temperature range The

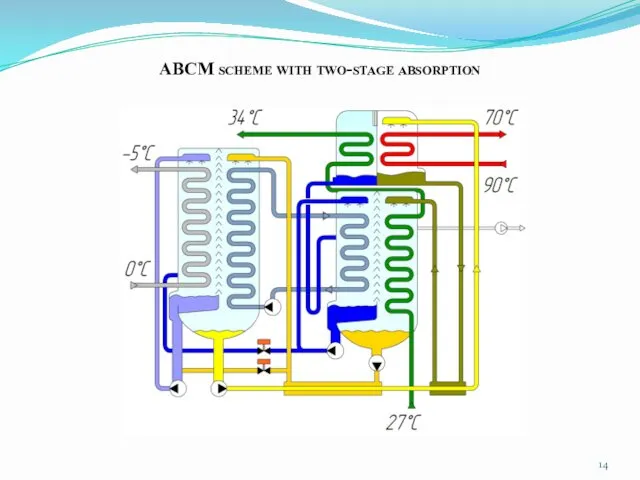

- 14. ABCM scheme with two-stage absorption

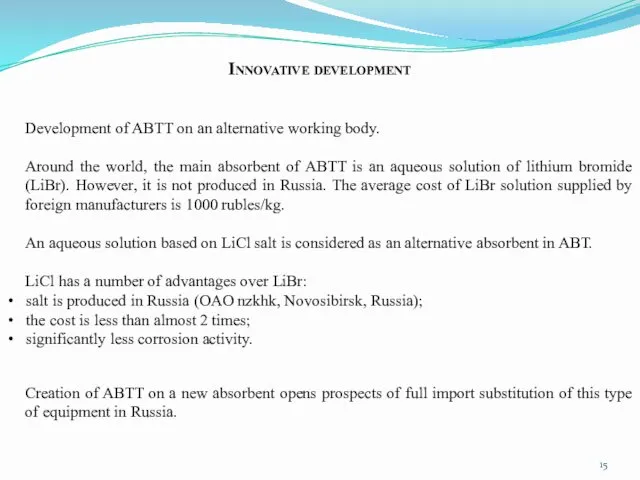

- 15. Innovative development Development of ABTT on an alternative working body. Around the world, the main absorbent

- 16. Thank you for your attention!

- 17. Refrigerating machine ABHM-3000П capacity of 3000 kW FKP "Anoit", Kuibyshev, NSO, 2008 Purpose: process water cooling

- 18. Refrigerating machine ABHM-1000vn with capacity of 960 kW OOO "Basket-6", Lipetsk, 2012 Purpose: for air-conditioning of

- 20. Скачать презентацию

Реактивное движение

Реактивное движение Тест Формулы за 7 класс

Тест Формулы за 7 класс Презентация Метод проектов на уроках физики

Презентация Метод проектов на уроках физики Автосцепное устройство

Автосцепное устройство разработка к уроку на тему Электролизация тел 8 класс

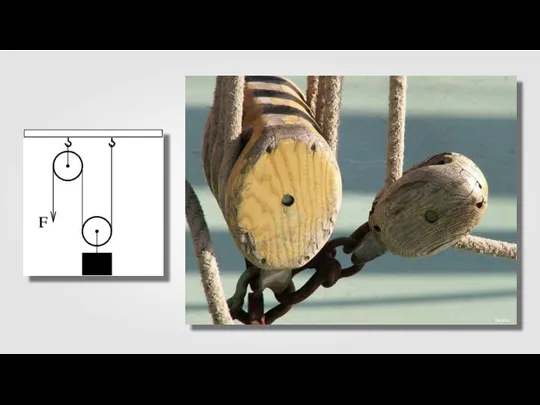

разработка к уроку на тему Электролизация тел 8 класс Применение правила равновесия рычага к блоку

Применение правила равновесия рычага к блоку Кинематика вращательного движения. Плоское движение. Лекция 2

Кинематика вращательного движения. Плоское движение. Лекция 2 Виды излучений. Инфракрасное излучение

Виды излучений. Инфракрасное излучение Интерференция, дифракция, поляризация

Интерференция, дифракция, поляризация Приборы для измерения атмосферного давления. Билет 23. Барометры

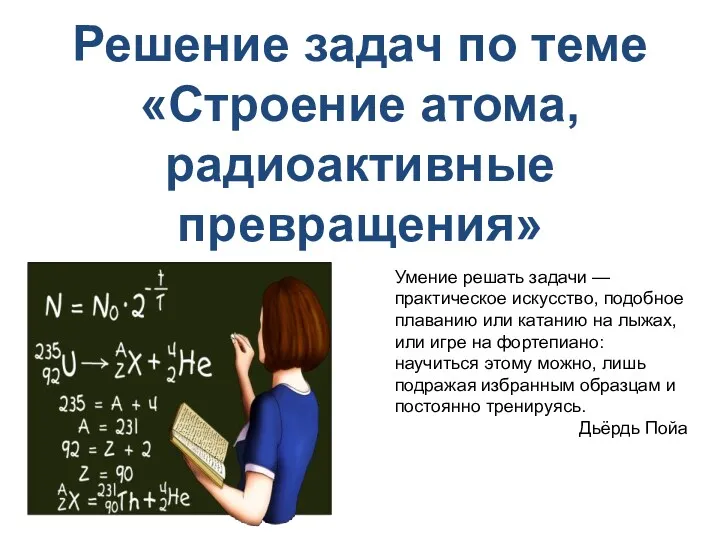

Приборы для измерения атмосферного давления. Билет 23. Барометры Решение задач по теме Строение атома, радиоактивные превращения

Решение задач по теме Строение атома, радиоактивные превращения Первичные измерительные преобразователи

Первичные измерительные преобразователи Айналмалы тоқ және трансформатор

Айналмалы тоқ және трансформатор Резание металла слесарной ножовкой

Резание металла слесарной ножовкой Трансмісія Об.447А. Системи гідроуправління та змащення трансмісії. (Тема 3.5)

Трансмісія Об.447А. Системи гідроуправління та змащення трансмісії. (Тема 3.5) Лекция 38. Дисперсия, поляризация света

Лекция 38. Дисперсия, поляризация света Теория механизмов и машин. Кинематический анализ механизмов

Теория механизмов и машин. Кинематический анализ механизмов Управление ядерным реактором

Управление ядерным реактором Свободные электромагнитные колебания

Свободные электромагнитные колебания Пара сил и момент силы относительно точки

Пара сил и момент силы относительно точки Неразветвленные цепи однофазного тока. Лекция №3

Неразветвленные цепи однофазного тока. Лекция №3 Исследование характеристик ККЛ

Исследование характеристик ККЛ Что изучает физика. Физические термины

Что изучает физика. Физические термины Қатты дененің қозғалысы

Қатты дененің қозғалысы дополнение к уроку физики Испарение- вопросы почемучки

дополнение к уроку физики Испарение- вопросы почемучки Силы в механике: сила упругости, сила сухого и вязкого трения.

Силы в механике: сила упругости, сила сухого и вязкого трения. Радиоактивность

Радиоактивность Теплові насоси та кондиціонери

Теплові насоси та кондиціонери