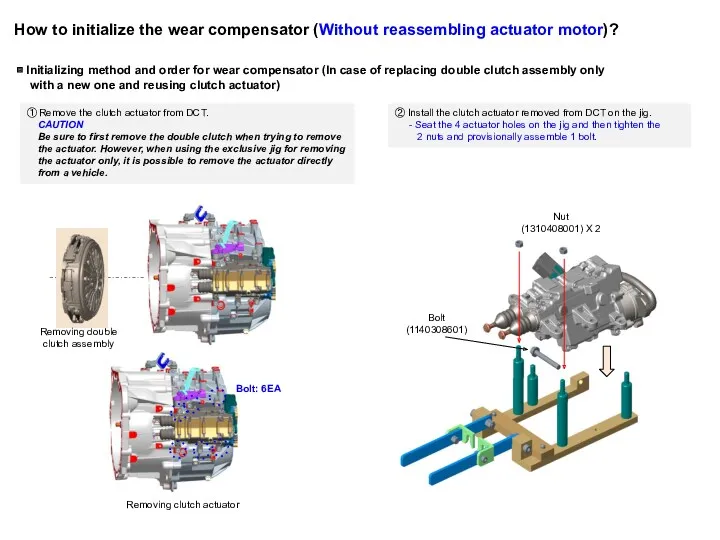

Additional instruction

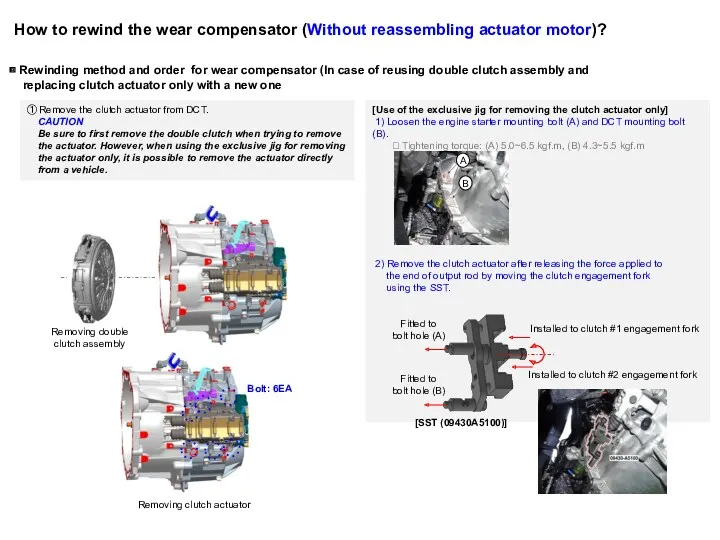

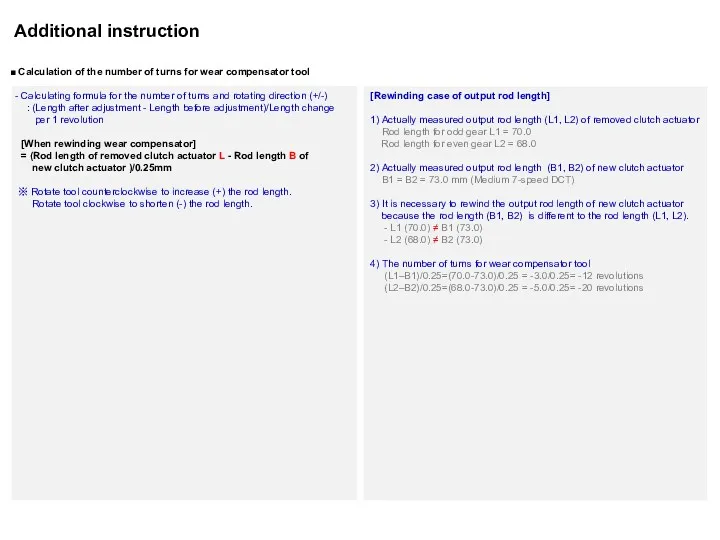

■ Calculation of the number of turns for wear compensator

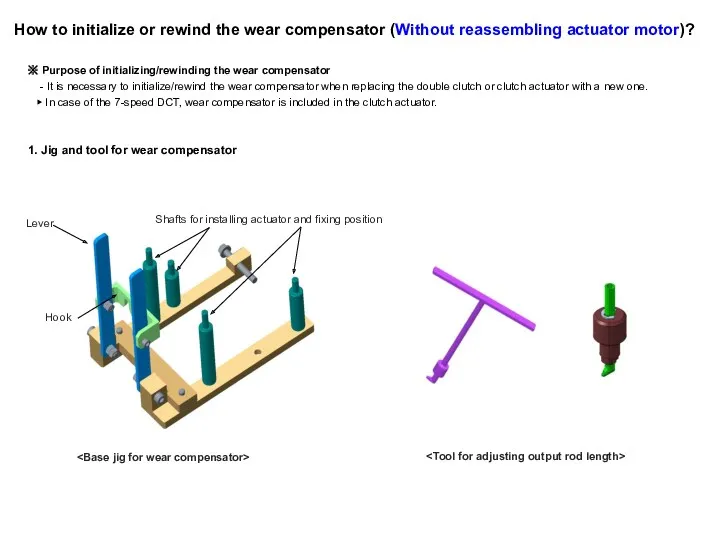

tool

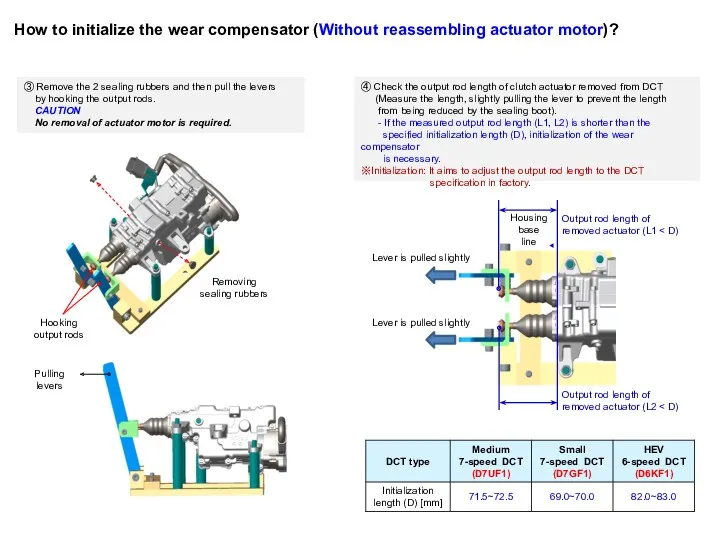

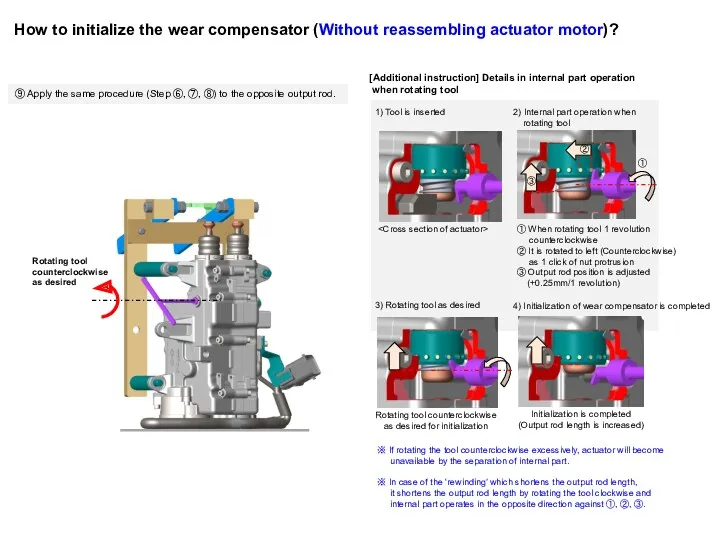

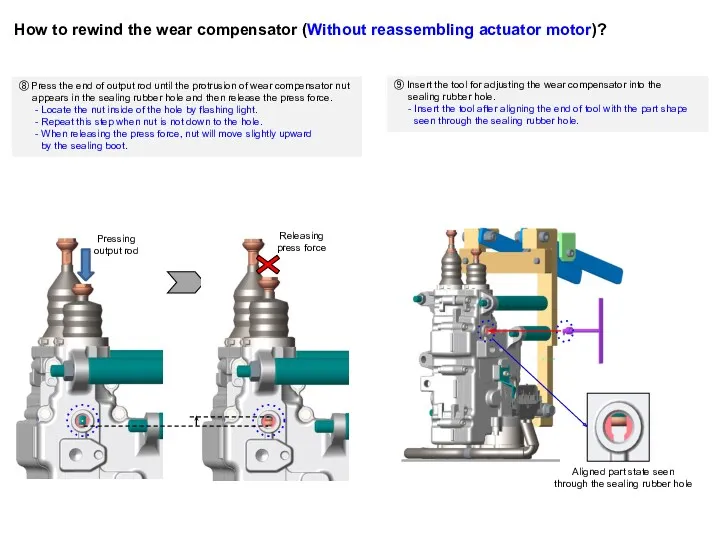

Calculating formula for the number of turns and rotating direction (+/-)

: (Length after adjustment - Length before adjustment)/Length change

per 1 revolution

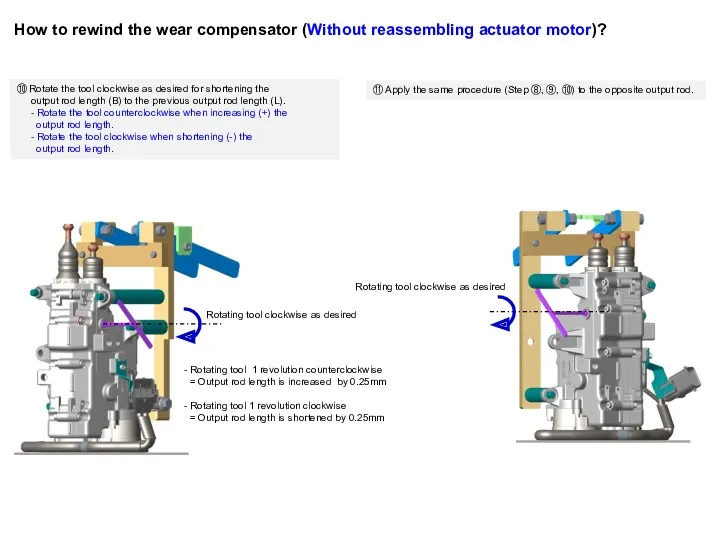

[When rewinding wear compensator]

= (Rod length of removed clutch actuator L - Rod length B of new clutch actuator )/0.25mm

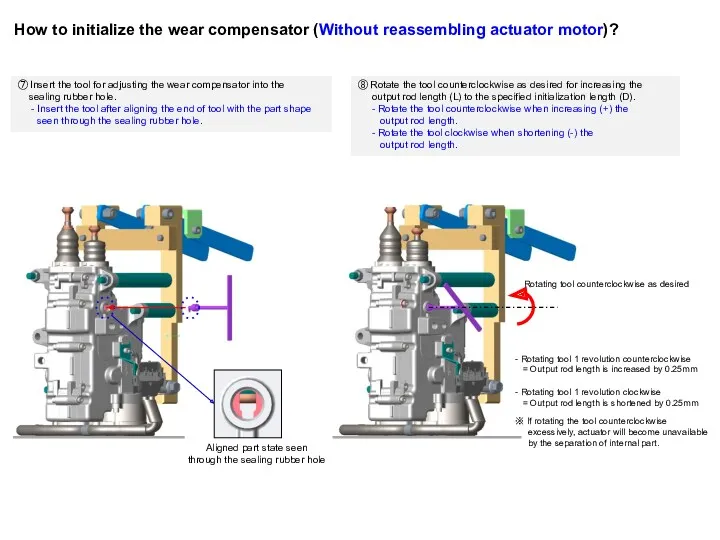

※ Rotate tool counterclockwise to increase (+) the rod length.

Rotate tool clockwise to shorten (-) the rod length.

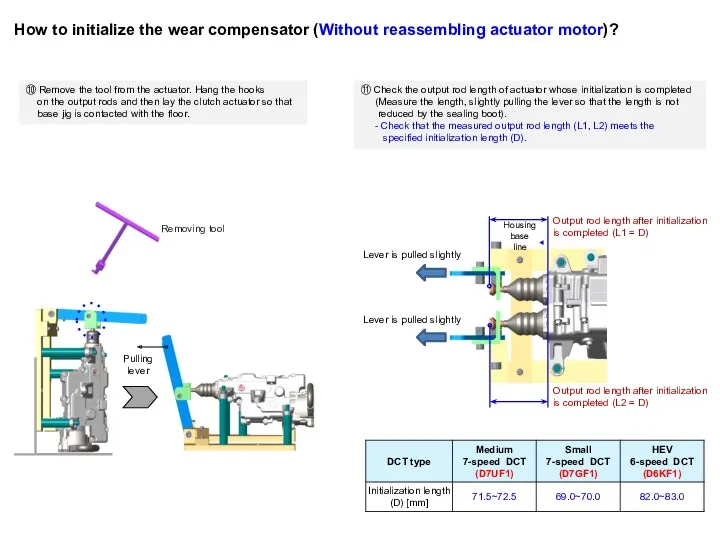

[Rewinding case of output rod length]

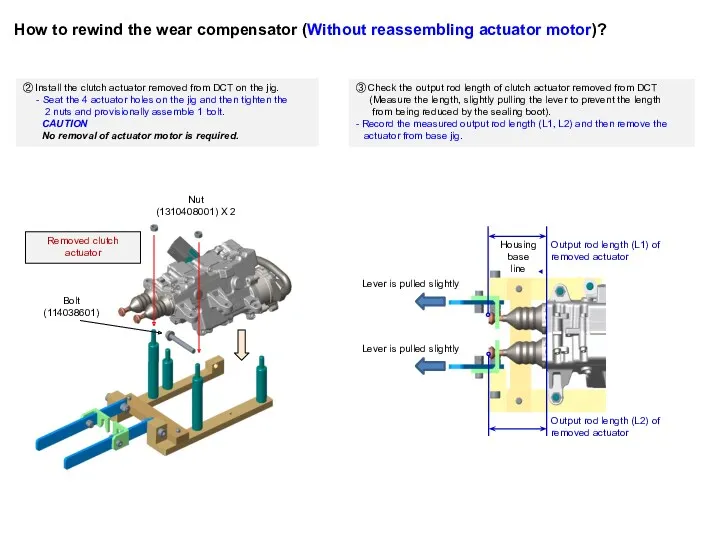

1) Actually measured output rod length (L1, L2) of removed clutch actuator

Rod length for odd gear L1 = 70.0

Rod length for even gear L2 = 68.0

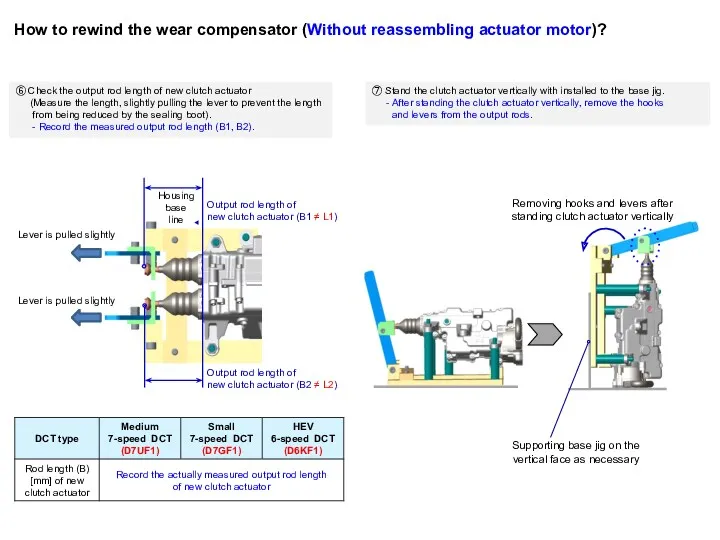

2) Actually measured output rod length (B1, B2) of new clutch actuator

B1 = B2 = 73.0 mm (Medium 7-speed DCT)

3) It is necessary to rewind the output rod length of new clutch actuator

because the rod length (B1, B2) is different to the rod length (L1, L2).

- L1 (70.0) ≠ B1 (73.0) - L2 (68.0) ≠ B2 (73.0)

4) The number of turns for wear compensator tool

(L1–B1)/0.25=(70.0-73.0)/0.25 = -3.0/0.25= -12 revolutions

(L2–B2)/0.25=(68.0-73.0)/0.25 = -5.0/0.25= -20 revolutions

![[Additional instruction]](/_ipx/f_webp&q_80&fit_contain&s_1440x1080/imagesDir/jpg/205416/slide-11.jpg)

Структурные уровни организации материи. Лекция 6 (1ч)

Структурные уровни организации материи. Лекция 6 (1ч) Diesel engine. Cooling. The coolants

Diesel engine. Cooling. The coolants Ремонт остова тягового электродвигателя ЭД-118 А(Б)

Ремонт остова тягового электродвигателя ЭД-118 А(Б) Изучение конструкций и методов расчета подъемно-транспортных машин

Изучение конструкций и методов расчета подъемно-транспортных машин Выбор оборудования для участка ремонта и заряда АКБ легкового автотранспорта

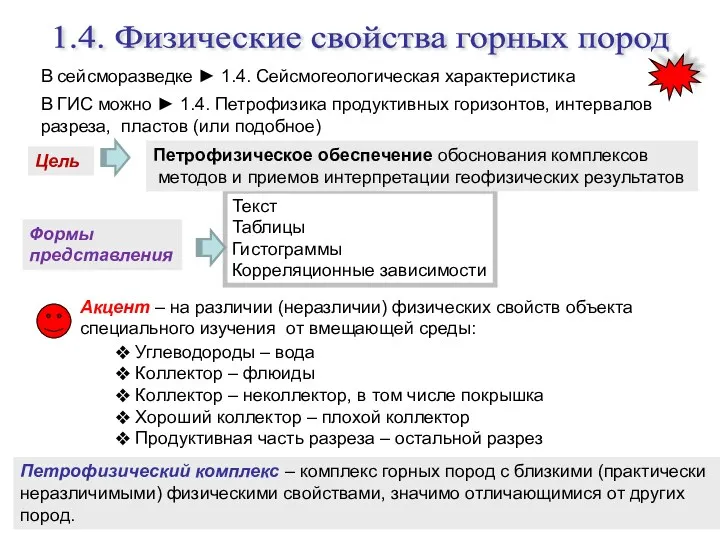

Выбор оборудования для участка ремонта и заряда АКБ легкового автотранспорта Физические свойства горных пород

Физические свойства горных пород Газовые законы. Урок физики в 10 классе

Газовые законы. Урок физики в 10 классе Создание кроссвордов c триггерами в PowerPoint

Создание кроссвордов c триггерами в PowerPoint Кінематика

Кінематика Своя игра по физике

Своя игра по физике Газовые законы

Газовые законы Магнитные материалы. Классификация

Магнитные материалы. Классификация Теория возникновения вещества

Теория возникновения вещества Шкала электромагнитных излучений

Шкала электромагнитных излучений Операциялық жүйелер және қолданбалы бағдарламалар пакеті

Операциялық жүйелер және қолданбалы бағдарламалар пакеті Лекция 8. Магнитоэлектрические приборы

Лекция 8. Магнитоэлектрические приборы Межпредметный учебный проект Физика+информатика

Межпредметный учебный проект Физика+информатика Научные фокусы. Электрические тени

Научные фокусы. Электрические тени Експлуатація навчального вертольота. Експлуатація гідравлічної і пневматичної систем в польоті

Експлуатація навчального вертольота. Експлуатація гідравлічної і пневматичної систем в польоті Теоремы динамики механической системы. Масса механической системы. (Лекция 4)

Теоремы динамики механической системы. Масса механической системы. (Лекция 4) Солнечная радиация как альтернативный источник энергии. Способы получения энергии

Солнечная радиация как альтернативный источник энергии. Способы получения энергии Ядерные реакции. Радиоактивность

Ядерные реакции. Радиоактивность Электрический ток

Электрический ток Радиоприёмные устройства. Часть 2. Помехи

Радиоприёмные устройства. Часть 2. Помехи ВКР: Ремонт трансмиссии автомобиля ВАЗ 2192 Калина

ВКР: Ремонт трансмиссии автомобиля ВАЗ 2192 Калина Звездный час: Сила Архимеда

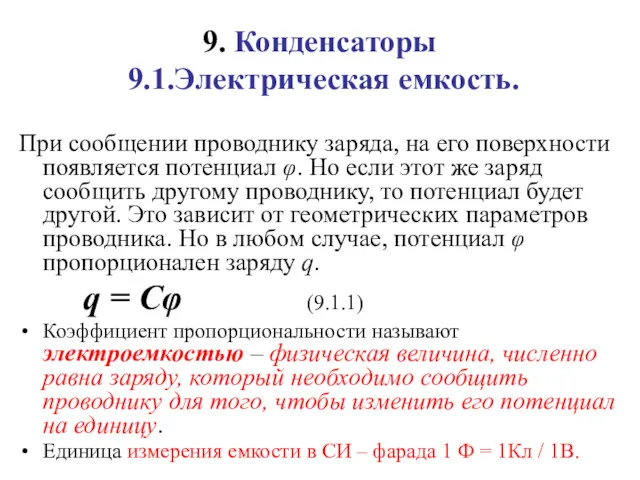

Звездный час: Сила Архимеда Конденсаторы. Электрическая емкость

Конденсаторы. Электрическая емкость Точность и погрешность измерений

Точность и погрешность измерений