Содержание

- 2. Lecture plan Planning the layout. Single-board PCB layout. Placement of Layers for PE devices. Current loops

- 3. Current position: 1/7 Planning the layout. Single-board PCB layout. Placement of Layers for PE devices. Current

- 4. PCB design for PE devices. Why is it so important? Improper PCB design leads to: "unstable"

- 5. Planning the layout. Each PE device contains power part and control scheme. Power part - DC/DC,

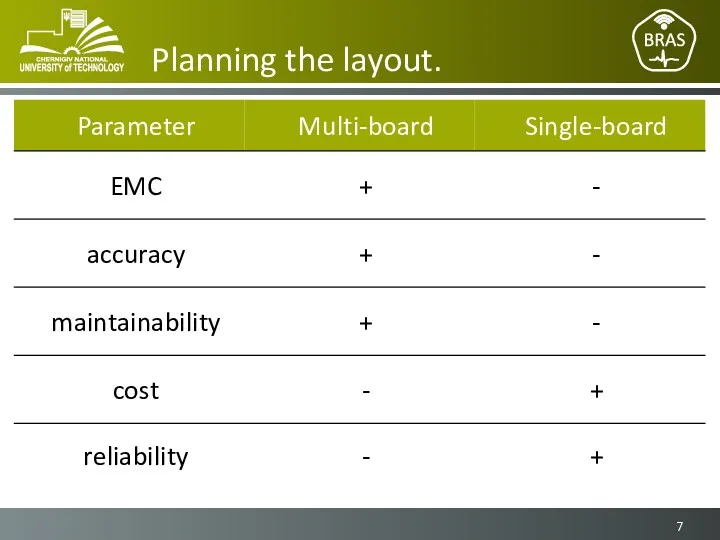

- 6. Planning the layout. Do we need to separate power and control on to two different PCB’s?

- 7. Planning the layout.

- 8. Current position: 2/7 Planning the layout. Single-board PCB layout. Placement of Layers for PE devices. Current

- 9. Single-board PCB layout. Power part location should be done at the first stage of PCB layout.

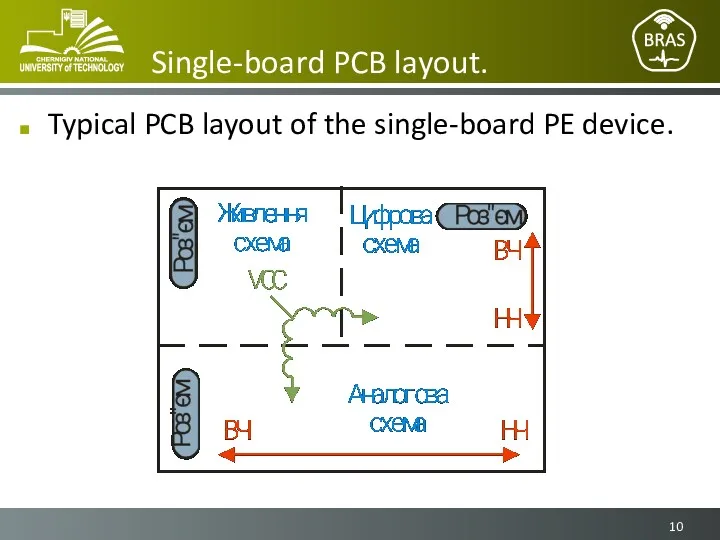

- 10. Single-board PCB layout. Typical PCB layout of the single-board PE device.

- 11. Single-board PCB layout. High speed components (both analog and digital) need to be placed as close

- 12. Current position: 3/7 Planning the layout. Single-board PCB layout. Placement of Layers for PE devices. Current

- 13. Stack of layers – 1, 2 or more? 1-layer PCB: Most sensitive to crosstalk and another

- 14. Stack of layers – 1, 2 or more? Multi-layer PCB: Better than 2-layer – more space

- 15. Stack of layers – 1, 2 or more? Conclusion: 1-layer PCBs – exceptional cases. 2-layer PCBs

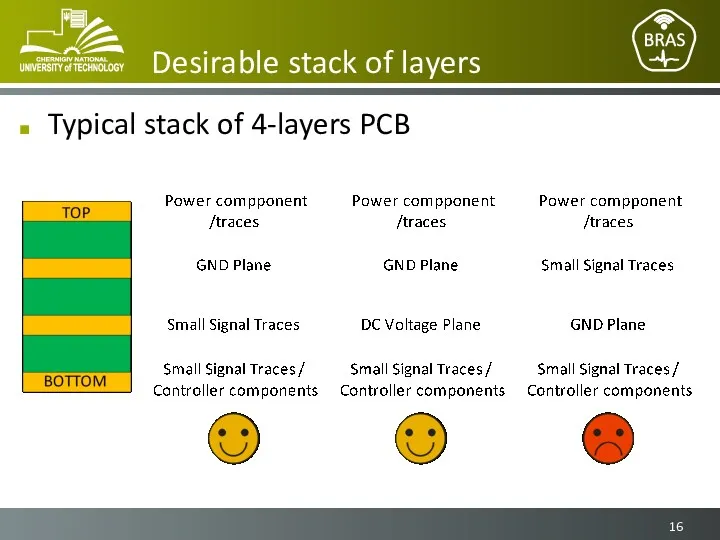

- 16. Desirable stack of layers Typical stack of 4-layers PCB

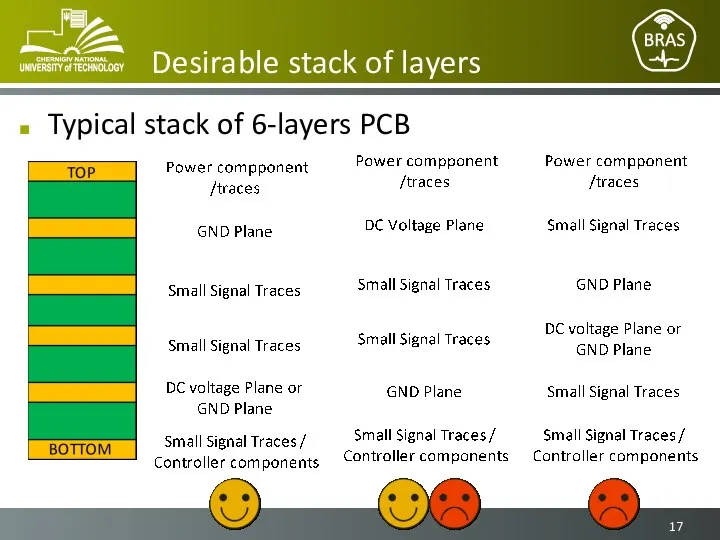

- 17. Desirable stack of layers Typical stack of 6-layers PCB

- 18. Current position: 4/7 Planning the layout. Single-board PCB layout. Placement of Layers for PE devices. Current

- 19. Important features of power part Highest currents and voltages in the device What ever – mA

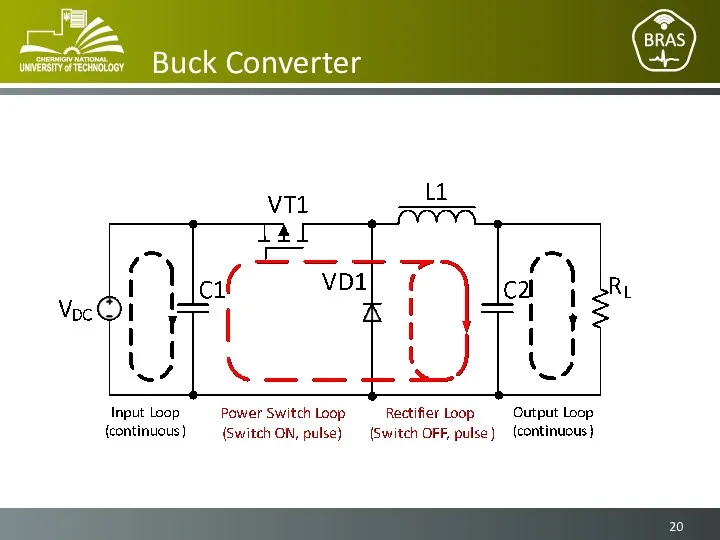

- 20. Buck Converter

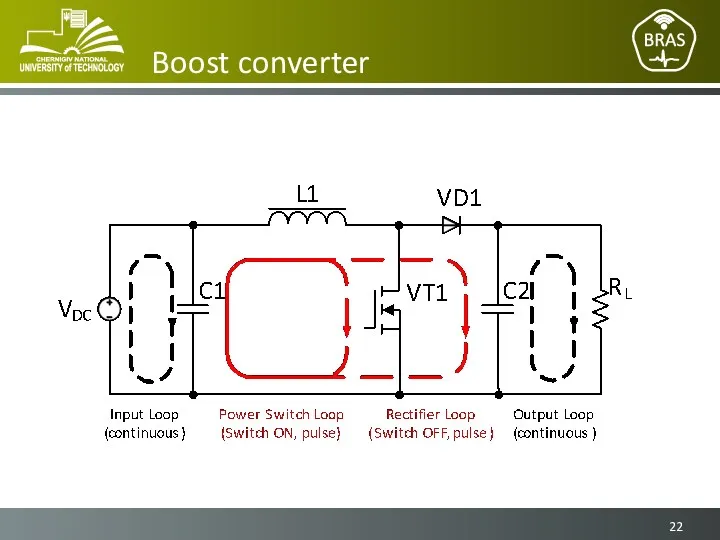

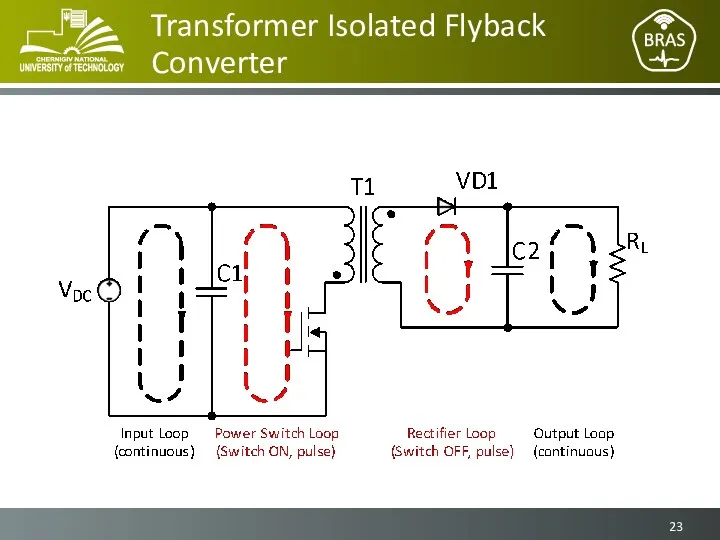

- 21. Current loops ordered by EMI generation in power conv. 1. Power switch loop – maximum attention!

- 22. Boost converter

- 23. Transformer Isolated Flyback Converter

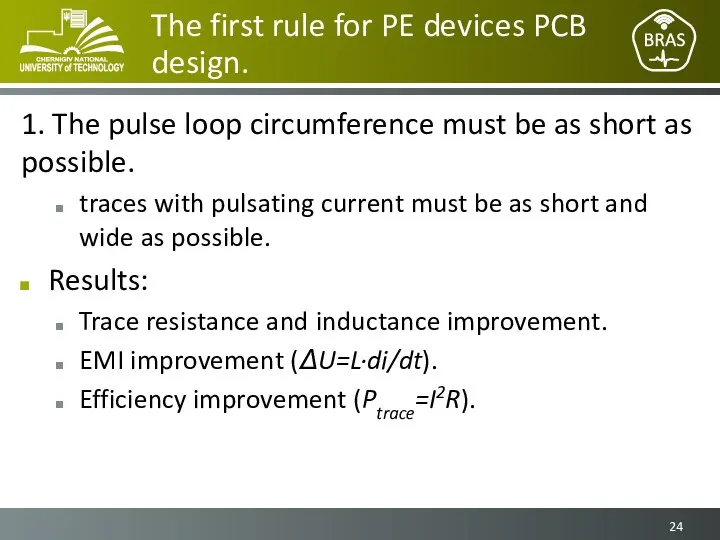

- 24. The first rule for PE devices PCB design. 1. The pulse loop circumference must be as

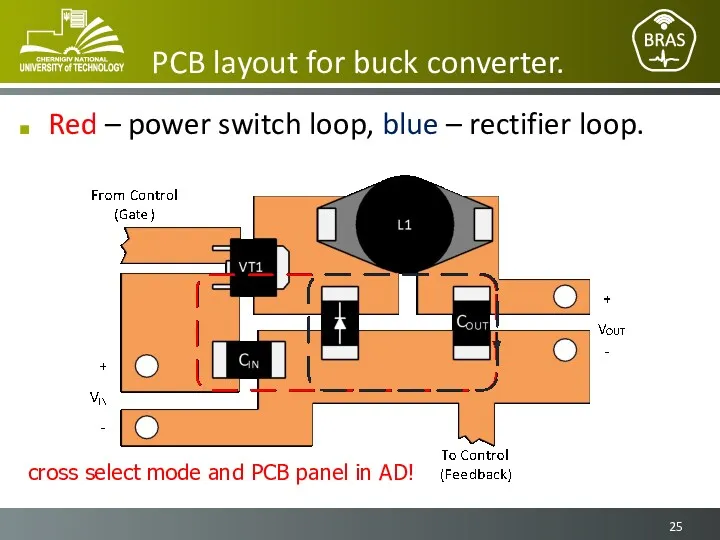

- 25. PCB layout for buck converter. Red – power switch loop, blue – rectifier loop. cross select

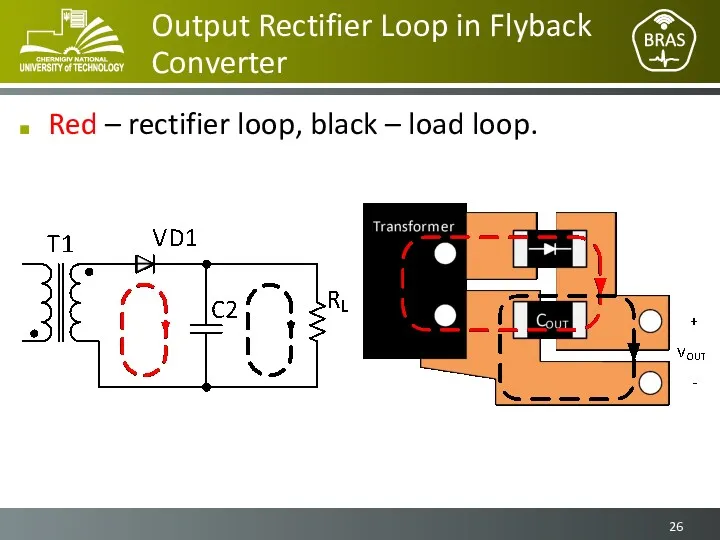

- 26. Red – rectifier loop, black – load loop. Output Rectifier Loop in Flyback Converter

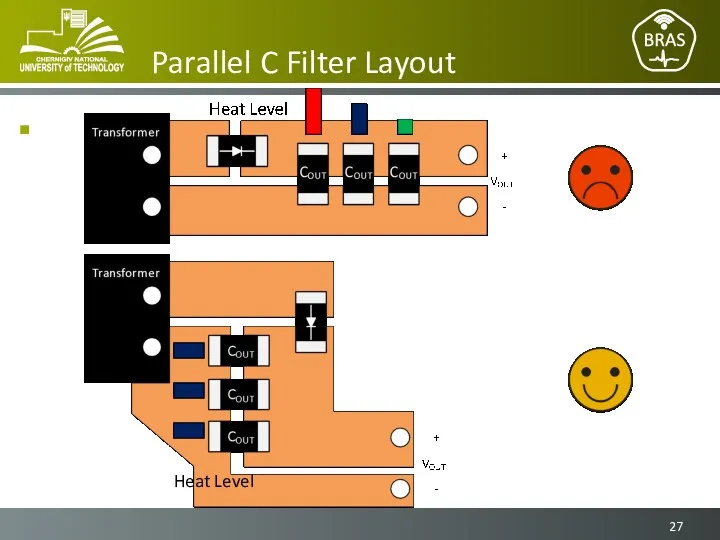

- 27. Parallel C Filter Layout

- 28. Parallel C Filter Layout PCB layout between each capacitor and source in multi-component filter must be

- 29. Current position: 5/7 Planning the layout. Single-board PCB layout. Placement of Layers for PE devices. Current

- 30. Grounding in the PE devices. Types of ground in power convertor devices: Power ground with high

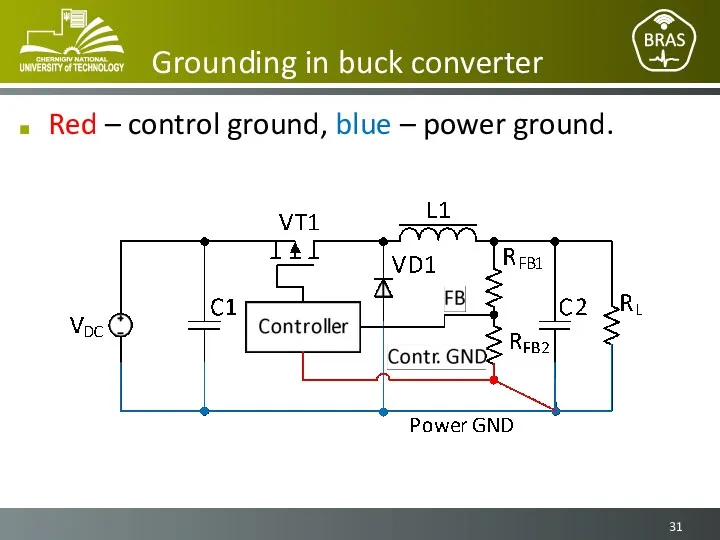

- 31. Grounding in buck converter Red – control ground, blue – power ground.

- 32. Control and power ground connection. Rules of thumb for grounding in PE devices: Feedback ground must

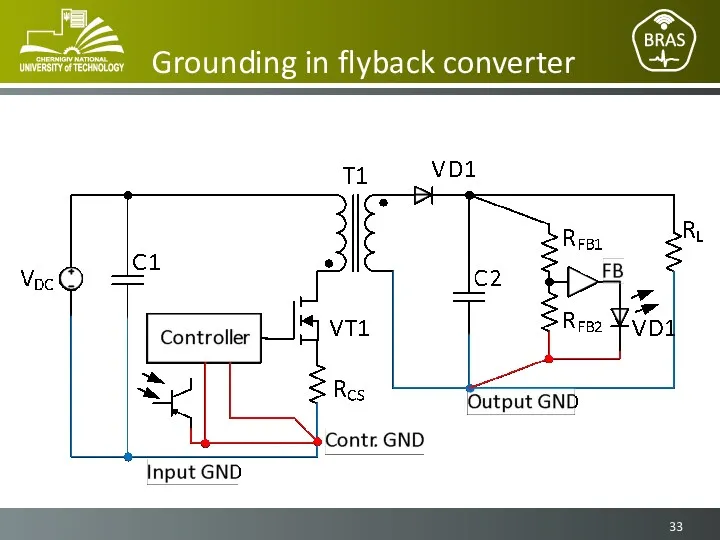

- 33. Grounding in flyback converter

- 34. Current position: 6/7 Planning the layout. Single-board PCB layout. Placement of Layers for PE devices. Current

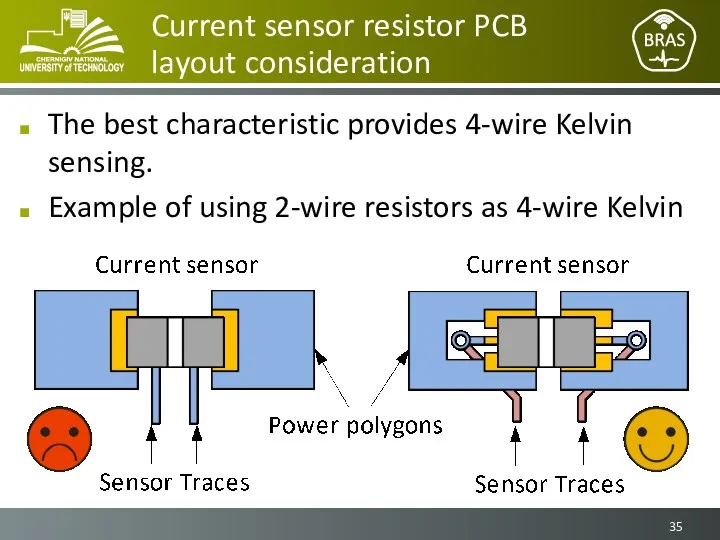

- 35. Current sensor resistor PCB layout consideration The best characteristic provides 4-wire Kelvin sensing. Example of using

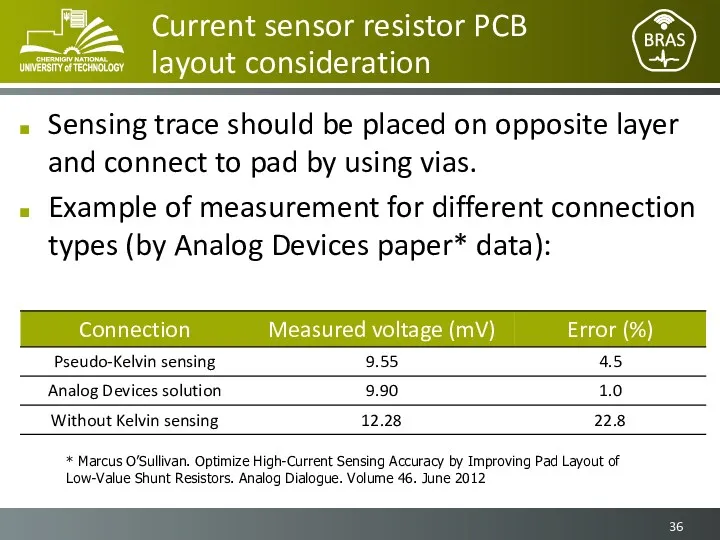

- 36. Current sensor resistor PCB layout consideration Sensing trace should be placed on opposite layer and connect

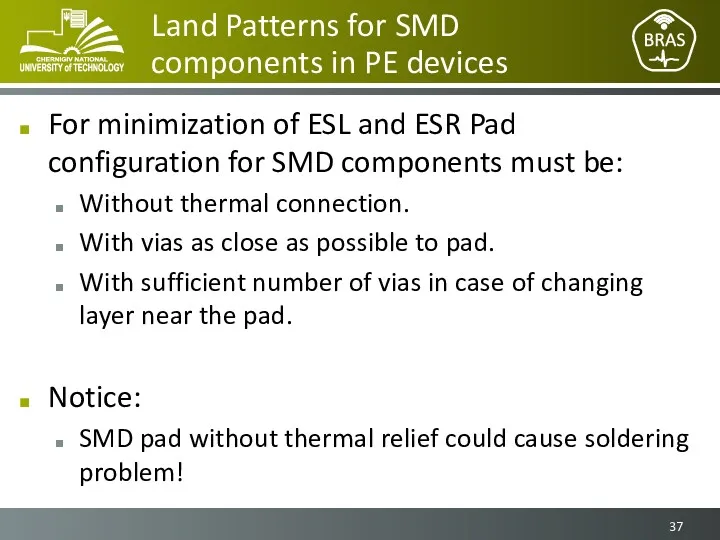

- 37. Land Patterns for SMD components in PE devices For minimization of ESL and ESR Pad configuration

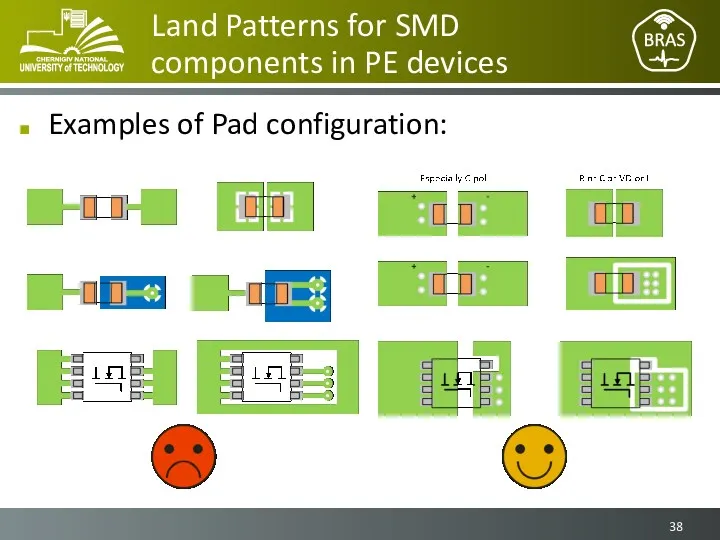

- 38. Land Patterns for SMD components in PE devices Examples of Pad configuration:

- 39. Current position: 7/7 Planning the layout. Single-board PCB layout. Placement of Layers for PE devices. Current

- 40. Mixed-signal grounding Mixed-signal components: External DAC and ADC, MCU with DAC/ADC on board. Ground in mixed-signal

- 41. Mixed-signal grounding Mixed-signal components: External DAC and ADC, MCU with DAC/ADC on board. Ground in mixed-signal

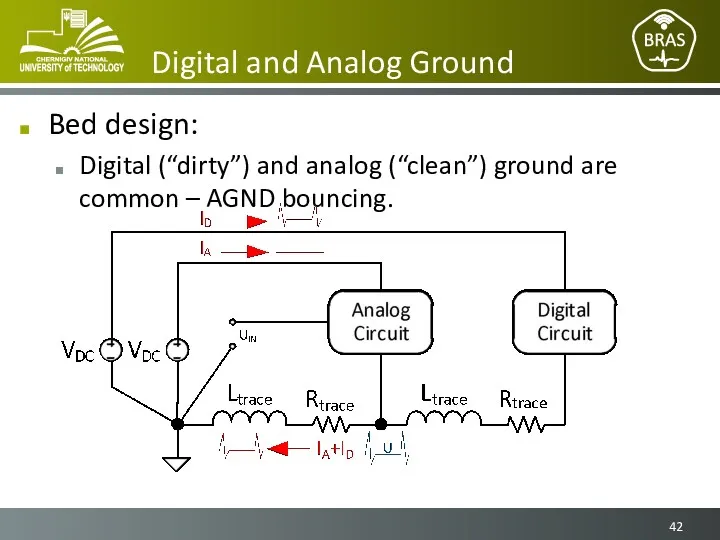

- 42. Digital and Analog Ground Bed design: Digital (“dirty”) and analog (“clean”) ground are common – AGND

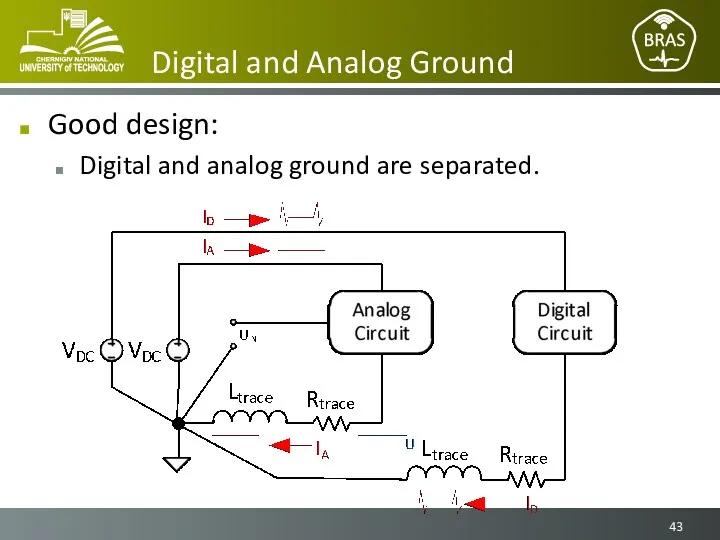

- 43. Digital and Analog Ground Good design: Digital and analog ground are separated.

- 44. Digital and Analog Ground Planes for ground in control circuits of power electronic devices should improve

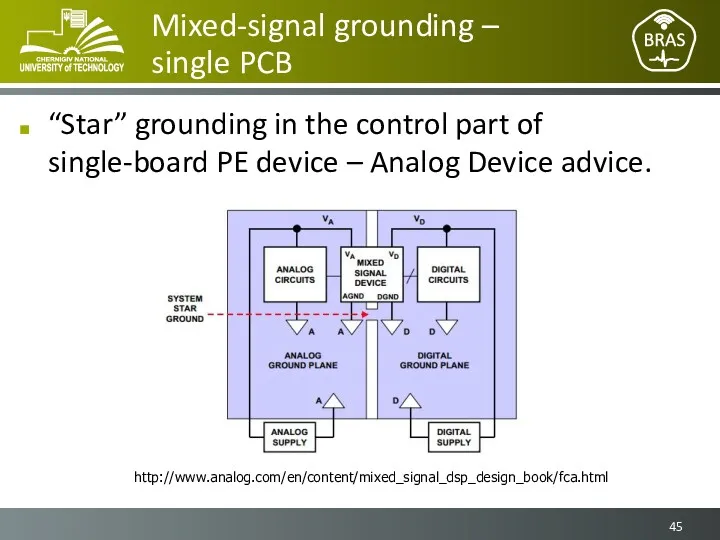

- 45. Mixed-signal grounding – single PCB “Star” grounding in the control part of single-board PE device –

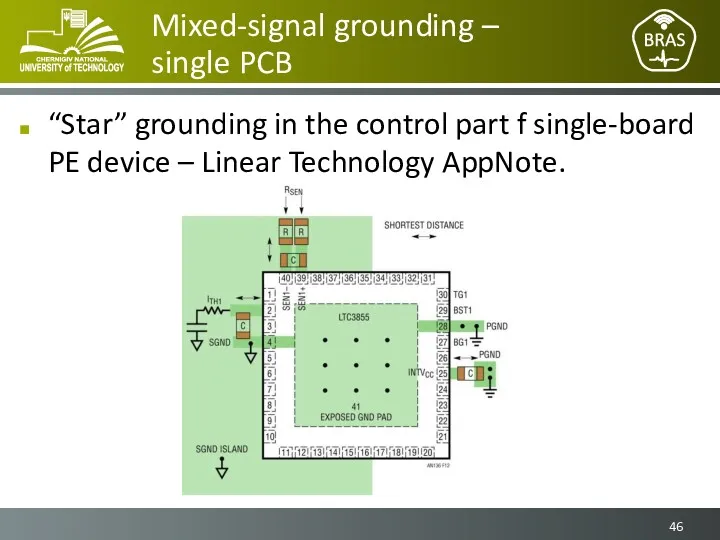

- 46. Mixed-signal grounding – single PCB “Star” grounding in the control part f single-board PE device –

- 47. Mixed-signal grounding – multi-board PCB Grounding techniques for single-board PE devices are not optimum for multi-board

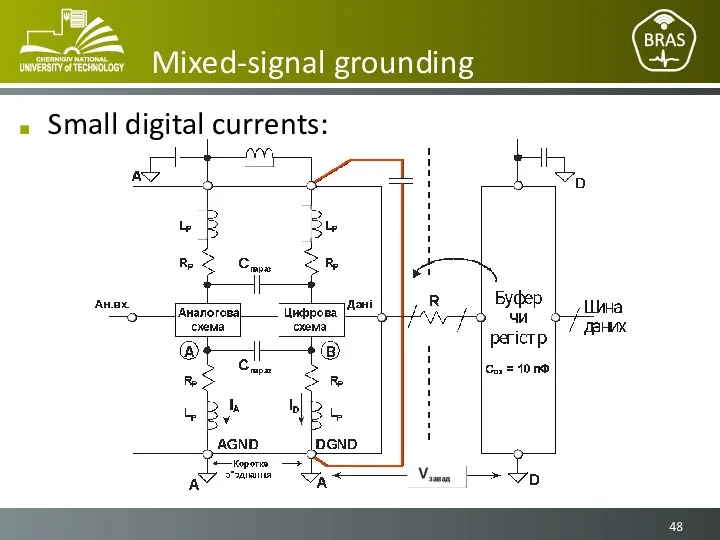

- 48. Mixed-signal grounding Small digital currents:

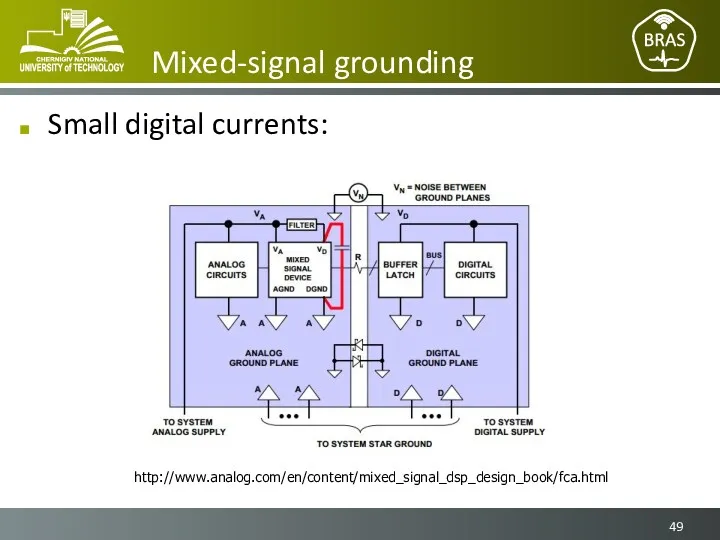

- 49. Mixed-signal grounding Small digital currents: http://www.analog.com/en/content/mixed_signal_dsp_design_book/fca.html

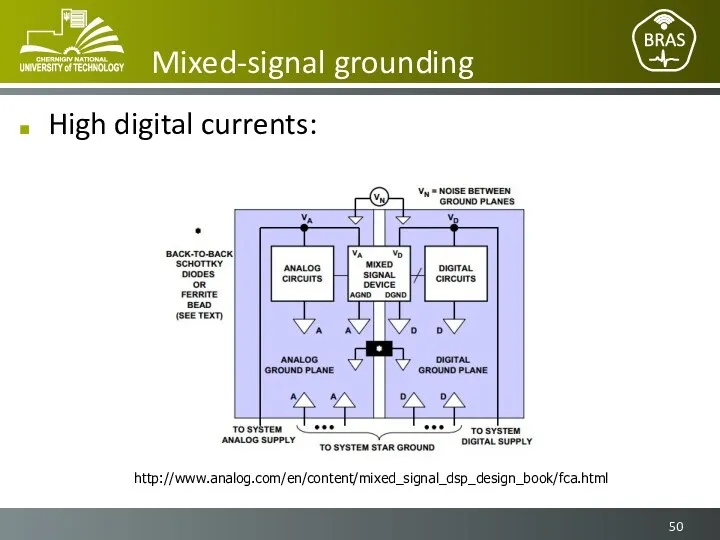

- 50. Mixed-signal grounding High digital currents: http://www.analog.com/en/content/mixed_signal_dsp_design_book/fca.html

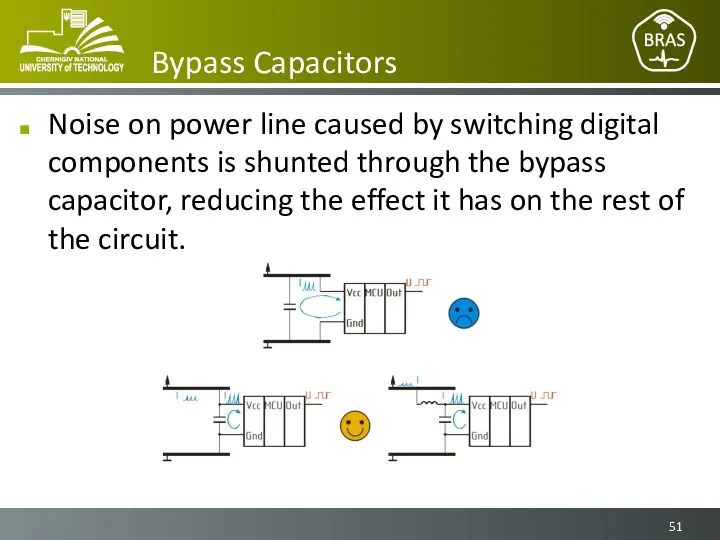

- 51. Bypass Capacitors Noise on power line caused by switching digital components is shunted through the bypass

- 52. Bypass Capacitors Bypass capacitor should be connected to the power pins of the digital components as

- 54. Скачать презентацию

Развивающие компьютерные игры для детей

Развивающие компьютерные игры для детей Проектирование информационных систем. Обследование и анализ информационной системы предприятия. (Лекция 1)

Проектирование информационных систем. Обследование и анализ информационной системы предприятия. (Лекция 1) Mac OS — семейство операционных систем производства корпорации Apple

Mac OS — семейство операционных систем производства корпорации Apple Учет межпредметных связей на уроках информатики

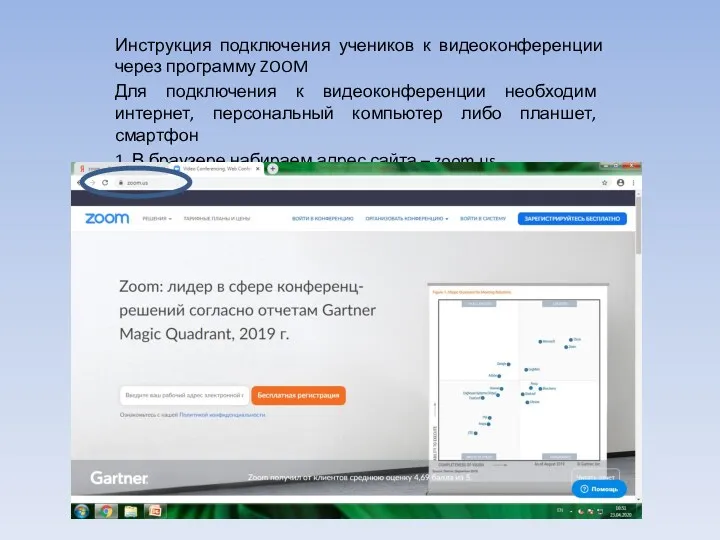

Учет межпредметных связей на уроках информатики Инструкция подключения учеников к видеоконференции через программу ZOOM

Инструкция подключения учеников к видеоконференции через программу ZOOM Урок по созданию диаграмм в Excel для финансовых отчетов

Урок по созданию диаграмм в Excel для финансовых отчетов Види і типи сайтів. Цільова аудиторія (урок 1)

Види і типи сайтів. Цільова аудиторія (урок 1) Презентация У истоков компьютерной революции

Презентация У истоков компьютерной революции Тестирование и жизненный цикл ПО. CMM. Лекция 2

Тестирование и жизненный цикл ПО. CMM. Лекция 2 Путешествие в страну информатики

Путешествие в страну информатики Действия с информацией. Тест

Действия с информацией. Тест Классы вычислительных машин (тема 1.1)

Классы вычислительных машин (тема 1.1) Как создать свой сайт?

Как создать свой сайт? Кодирование текстовой информации

Кодирование текстовой информации Общие сведения о языке программирования Паскаль. Начала программирования. Информатика. 8 класс

Общие сведения о языке программирования Паскаль. Начала программирования. Информатика. 8 класс Аддитивные технологии

Аддитивные технологии Разработка информационной системы для учета продаж билетов в авиакассах

Разработка информационной системы для учета продаж билетов в авиакассах Введение в web-программирование

Введение в web-программирование Сапр AutoCAD - основные понятия и приемы работы

Сапр AutoCAD - основные понятия и приемы работы Алгоритм создания и развития интернет ресурса

Алгоритм создания и развития интернет ресурса Виды графики

Виды графики Интересные факты в сфере информационных технологий

Интересные факты в сфере информационных технологий 20231004_prilozhenie_1

20231004_prilozhenie_1 Компьютерные технологии в обучении: определение, разновидности, этапы

Компьютерные технологии в обучении: определение, разновидности, этапы Лайфхаки Word

Лайфхаки Word Алгоритмы и исполнители

Алгоритмы и исполнители Все программы от Adobe

Все программы от Adobe Сеть Ethernet. Построение коммутируемой сети

Сеть Ethernet. Построение коммутируемой сети