Содержание

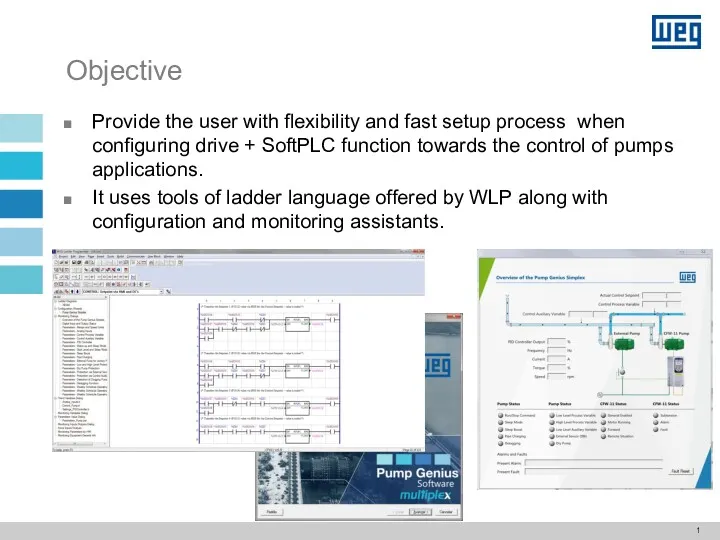

- 2. Objective Provide the user with flexibility and fast setup process when configuring drive + SoftPLC function

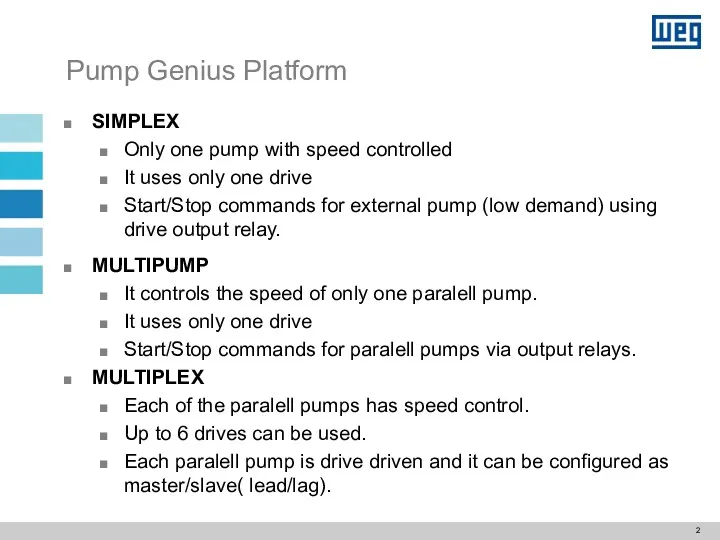

- 3. Pump Genius Platform SIMPLEX Only one pump with speed controlled It uses only one drive Start/Stop

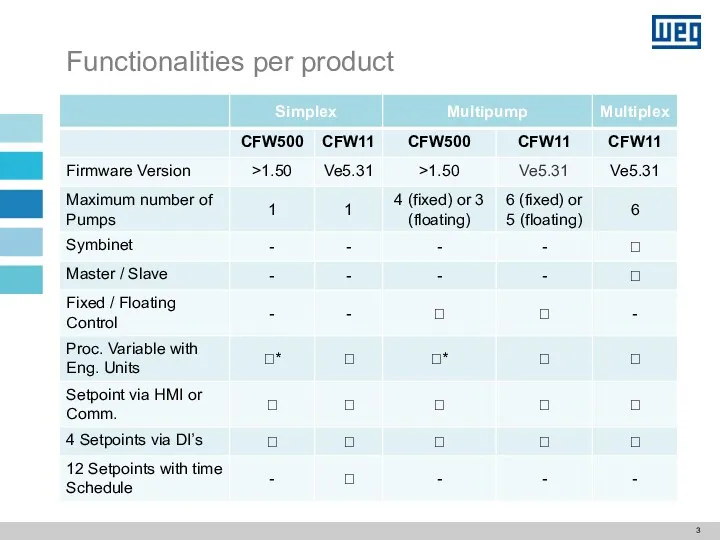

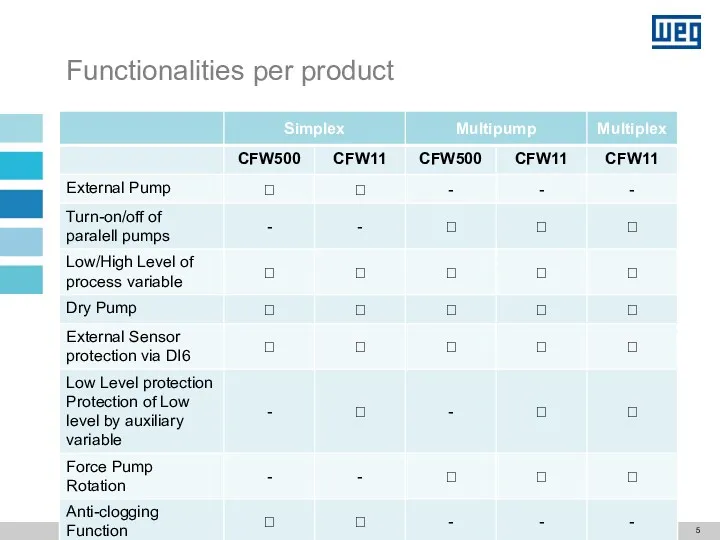

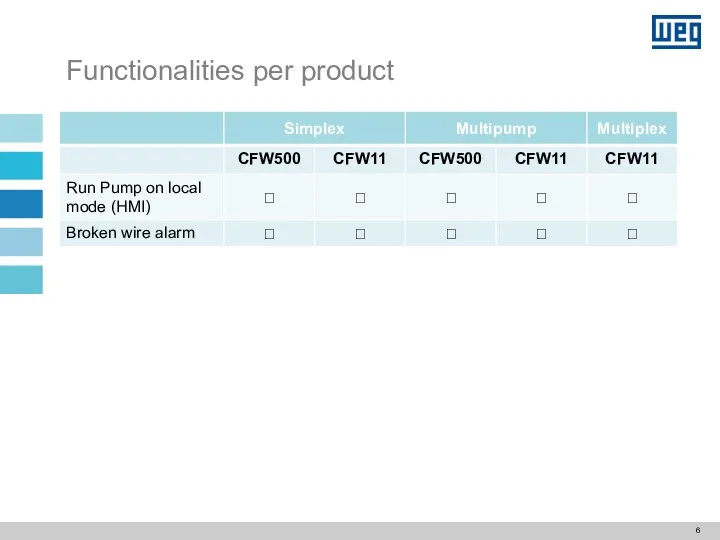

- 4. Functionalities per product

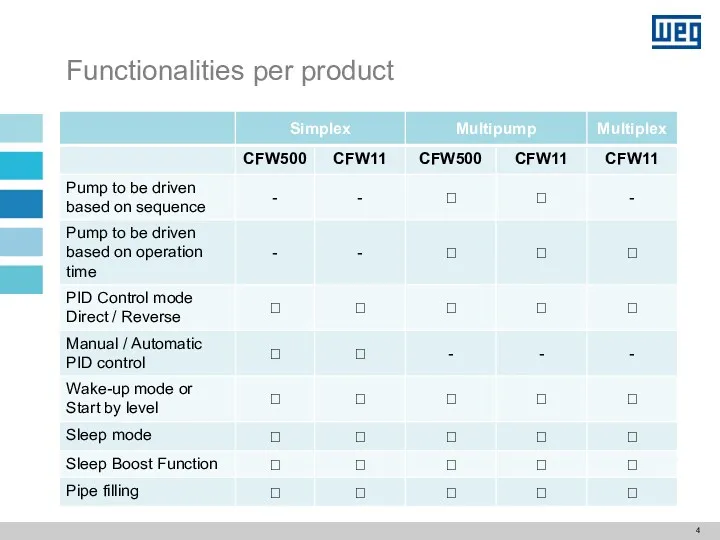

- 5. Functionalities per product

- 6. Pump Genius Software – Funcionalides para Controle de Bombas Functionalities per product

- 7. Functionalities per product

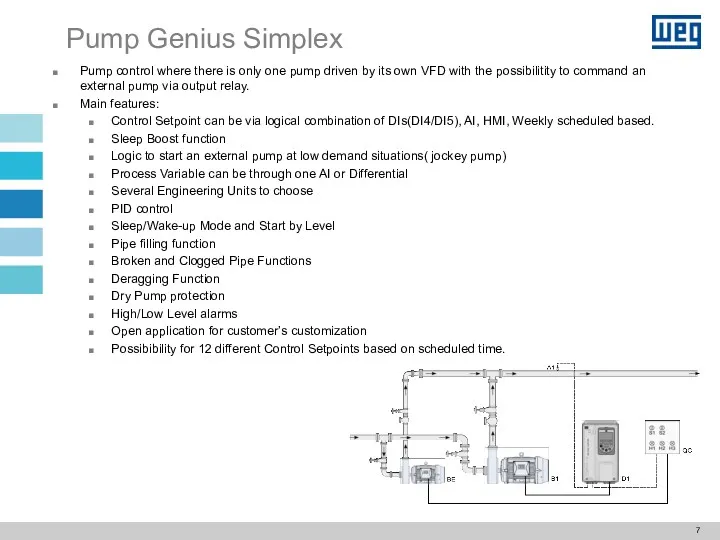

- 8. Pump Genius Simplex Pump control where there is only one pump driven by its own VFD

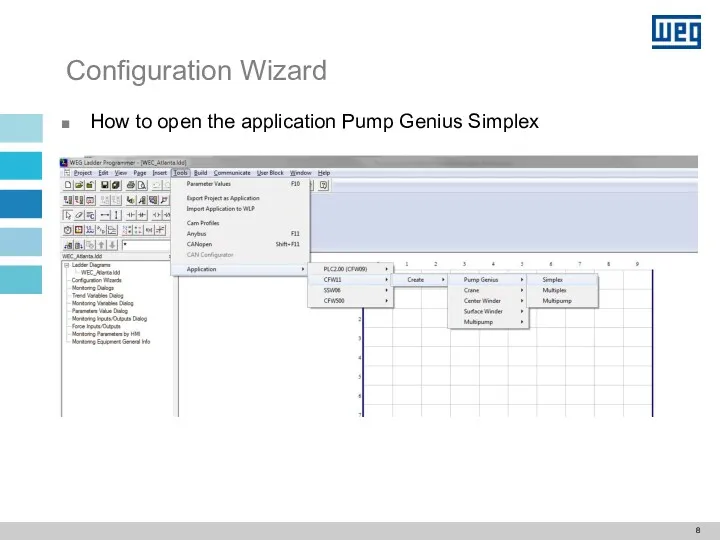

- 9. Configuration Wizard How to open the application Pump Genius Simplex

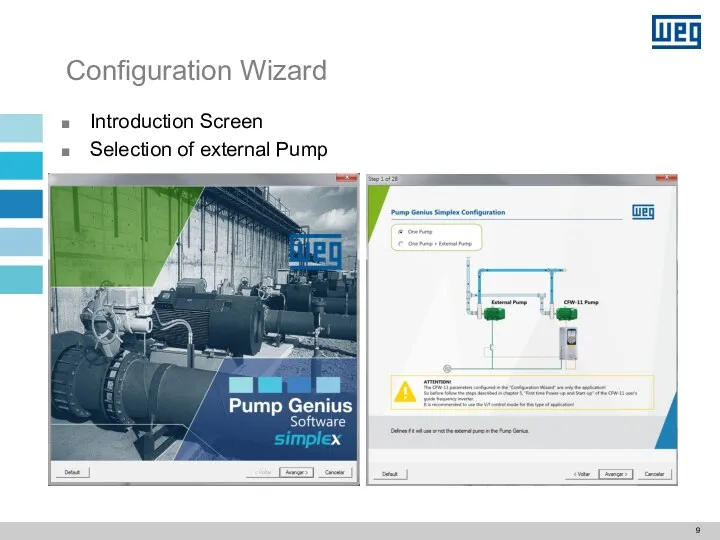

- 10. Configuration Wizard Introduction Screen Selection of external Pump

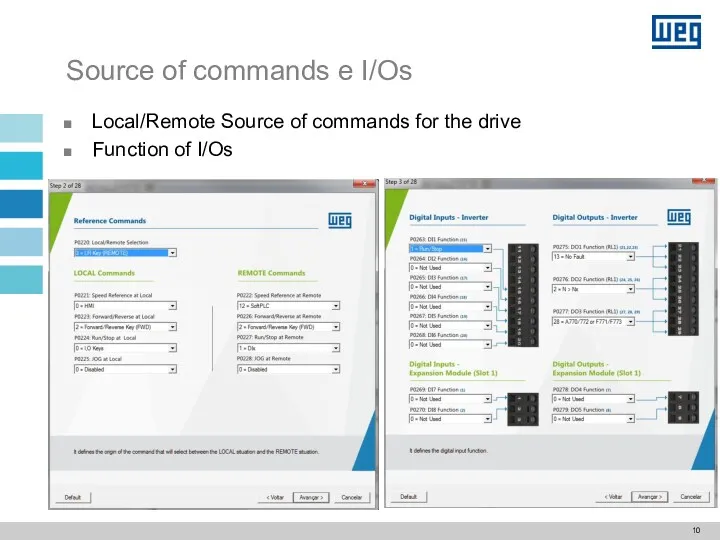

- 11. Source of commands e I/Os Local/Remote Source of commands for the drive Function of I/Os

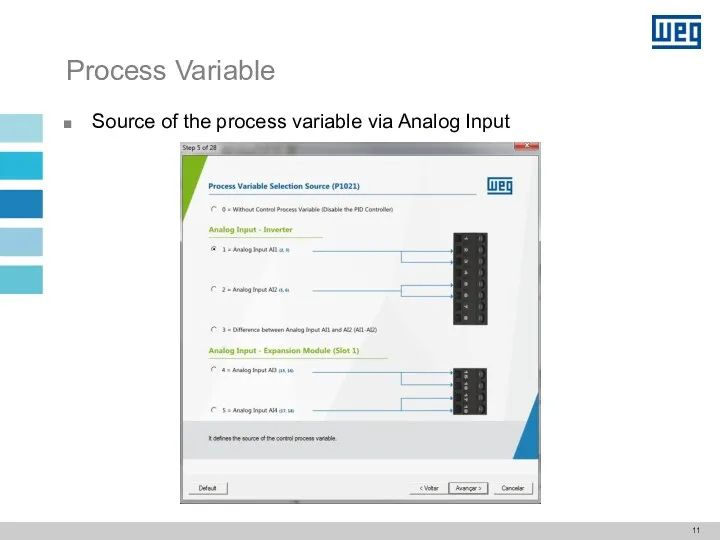

- 12. Process Variable Source of the process variable via Analog Input

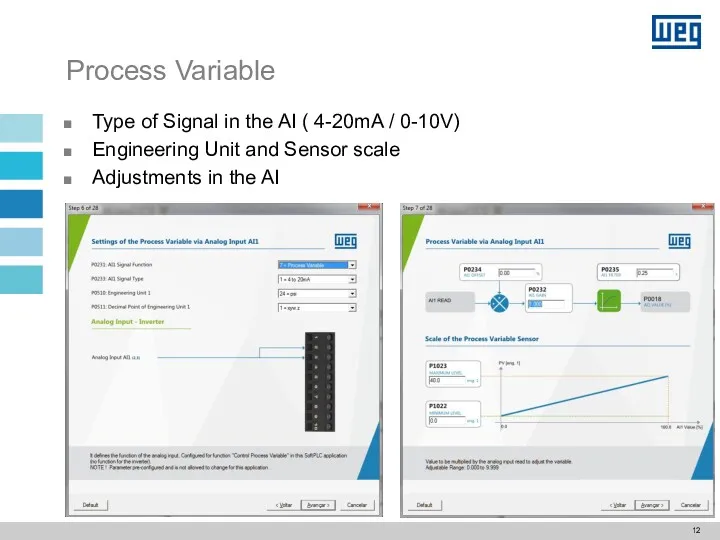

- 13. Process Variable Type of Signal in the AI ( 4-20mA / 0-10V) Engineering Unit and Sensor

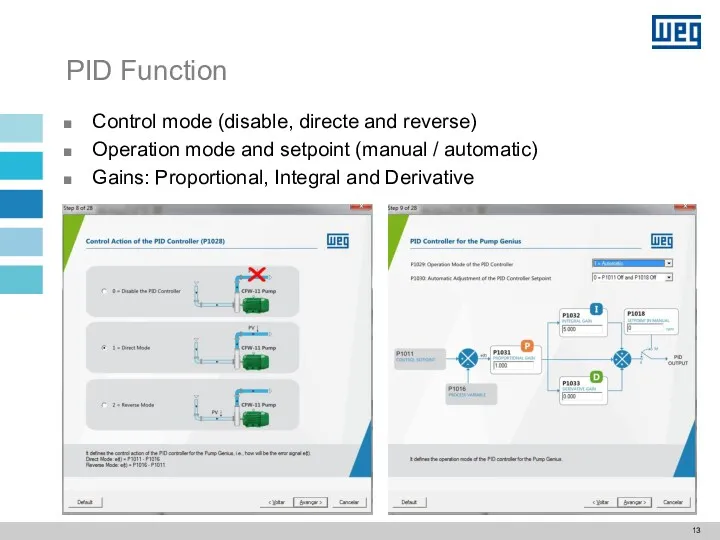

- 14. PID Function Control mode (disable, directe and reverse) Operation mode and setpoint (manual / automatic) Gains:

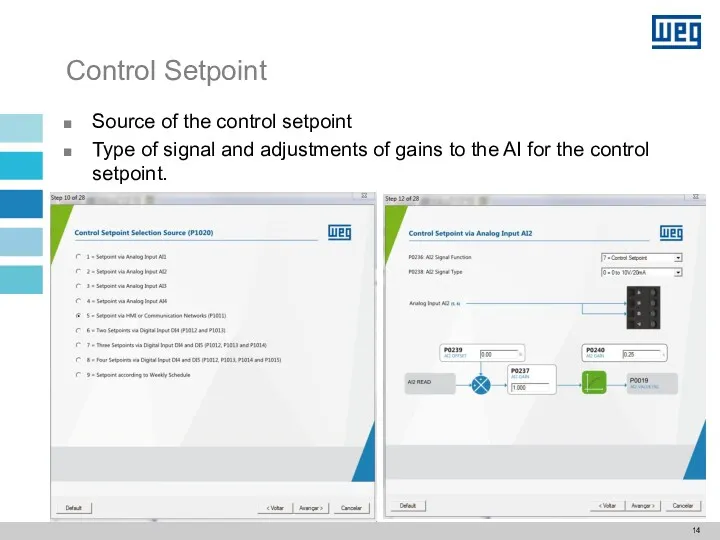

- 15. Control Setpoint Source of the control setpoint Type of signal and adjustments of gains to the

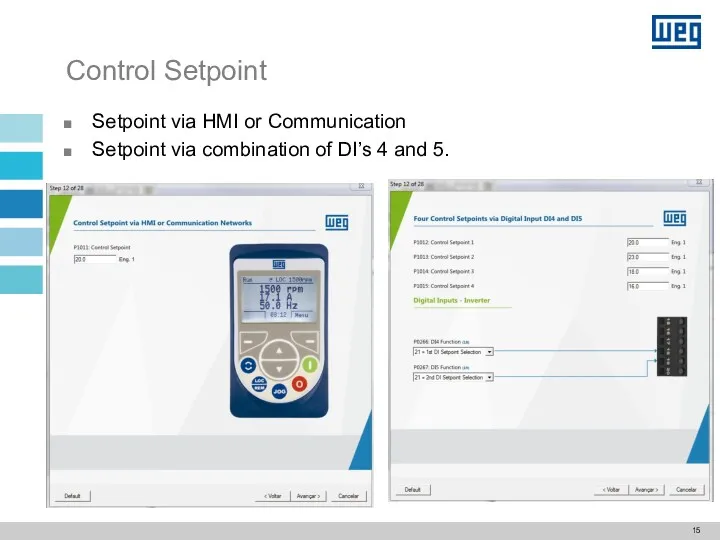

- 16. Control Setpoint Setpoint via HMI or Communication Setpoint via combination of DI’s 4 and 5.

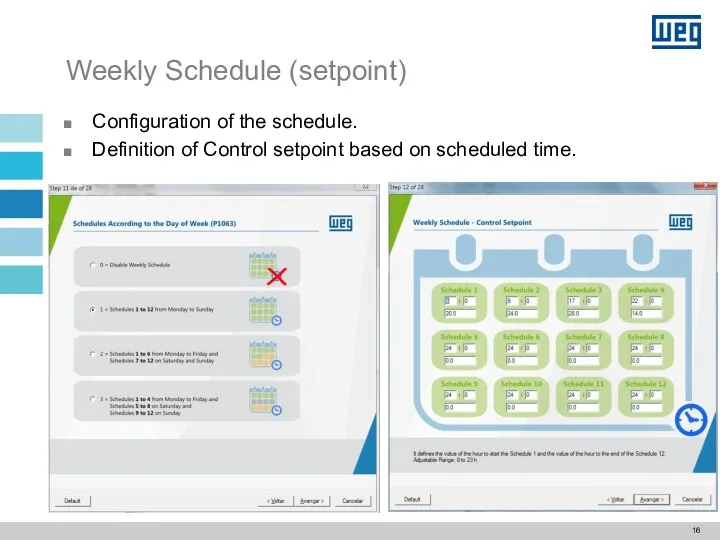

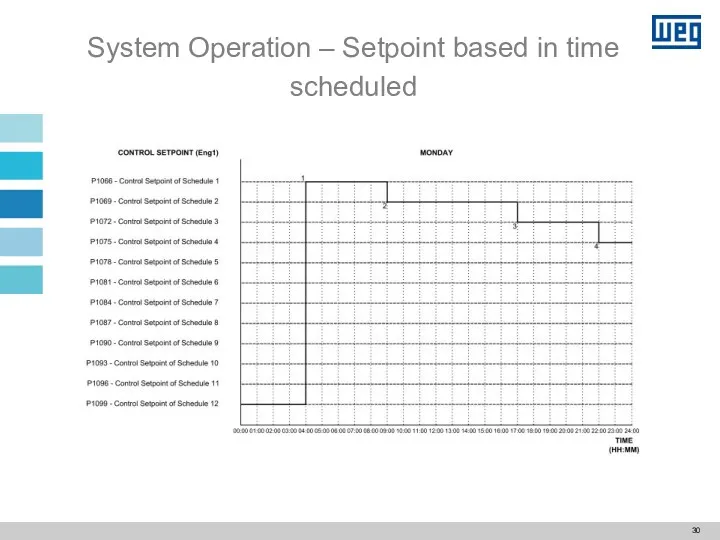

- 17. Weekly Schedule (setpoint) Configuration of the schedule. Definition of Control setpoint based on scheduled time.

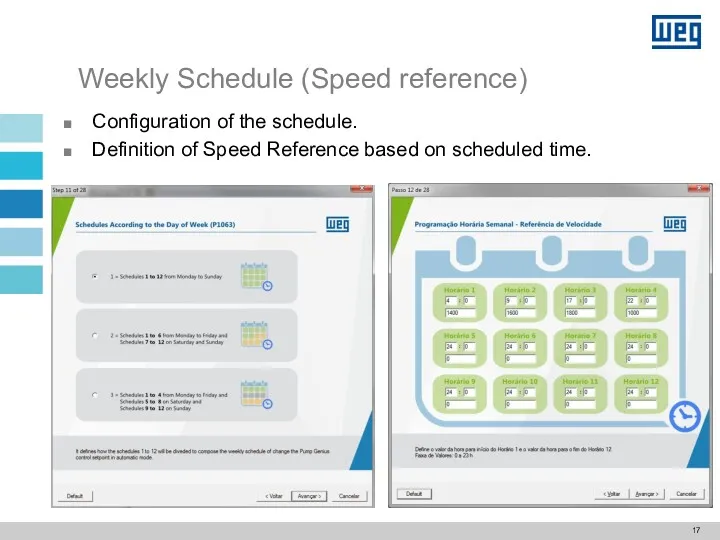

- 18. Configuration of the schedule. Definition of Speed Reference based on scheduled time. Weekly Schedule (Speed reference)

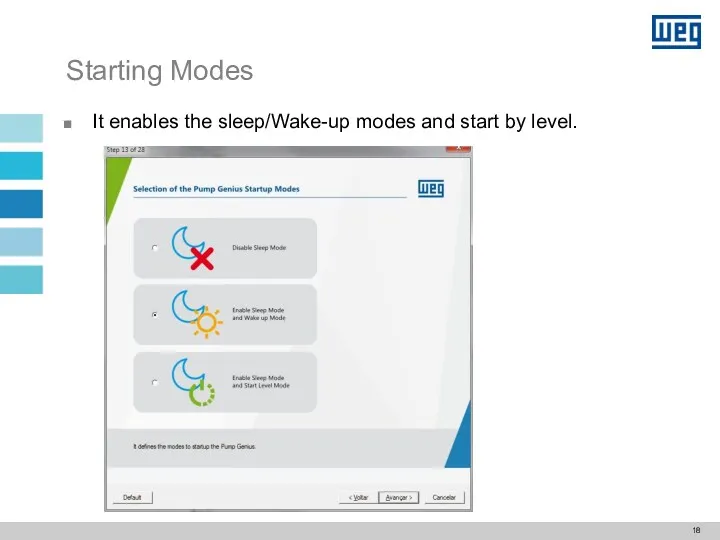

- 19. Starting Modes It enables the sleep/Wake-up modes and start by level.

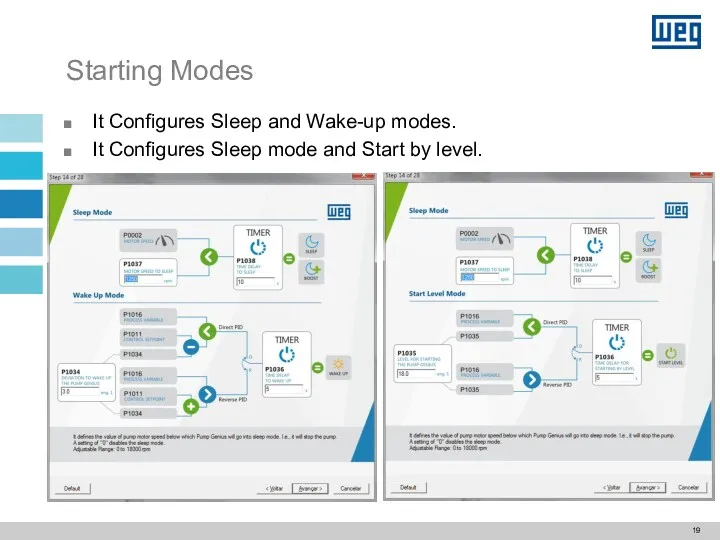

- 20. Starting Modes It Configures Sleep and Wake-up modes. It Configures Sleep mode and Start by level.

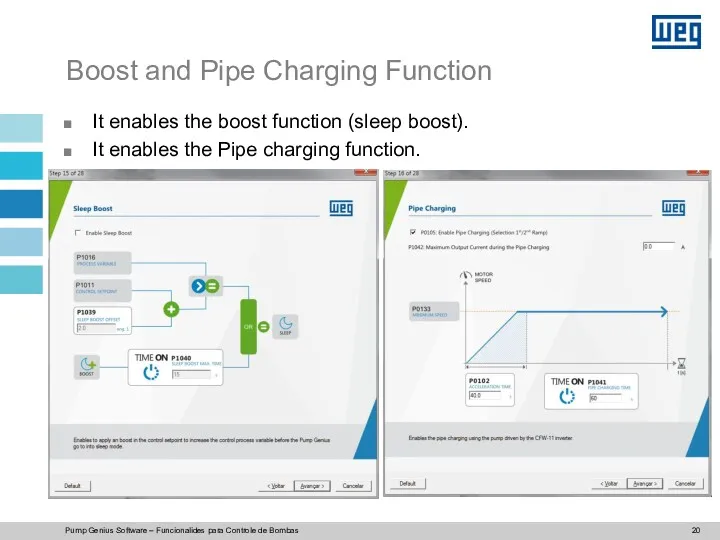

- 21. Pump Genius Software – Funcionalides para Controle de Bombas Boost and Pipe Charging Function It enables

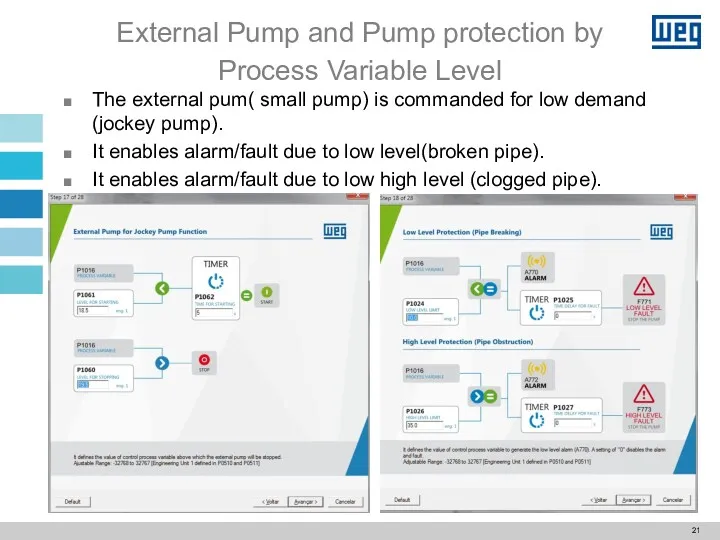

- 22. External Pump and Pump protection by Process Variable Level The external pum( small pump) is commanded

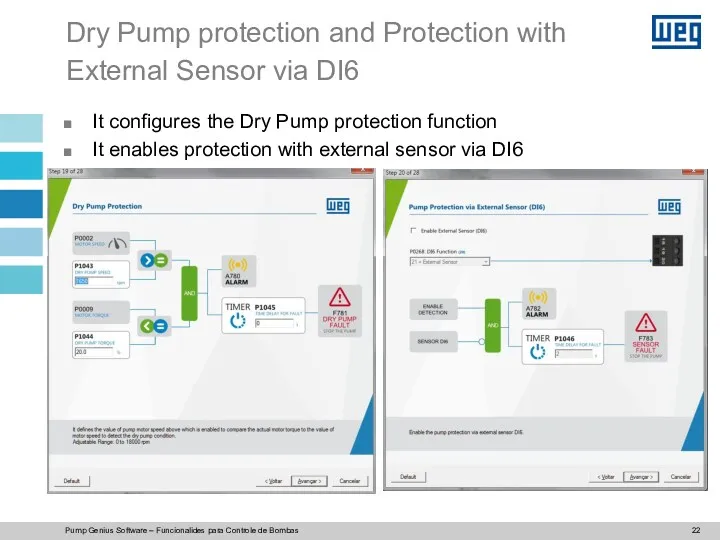

- 23. Pump Genius Software – Funcionalides para Controle de Bombas Dry Pump protection and Protection with External

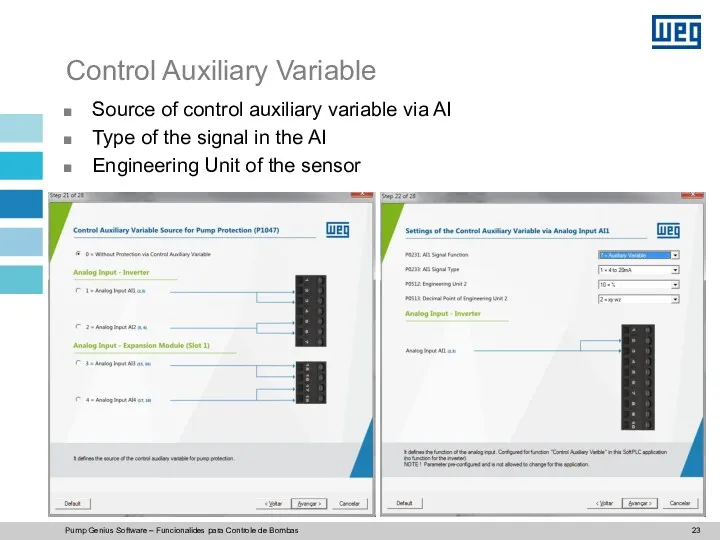

- 24. Pump Genius Software – Funcionalides para Controle de Bombas Control Auxiliary Variable Source of control auxiliary

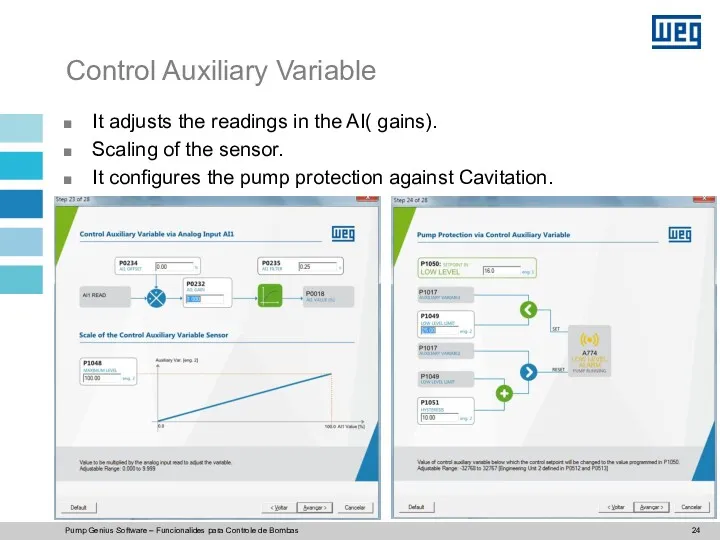

- 25. Pump Genius Software – Funcionalides para Controle de Bombas Control Auxiliary Variable It adjusts the readings

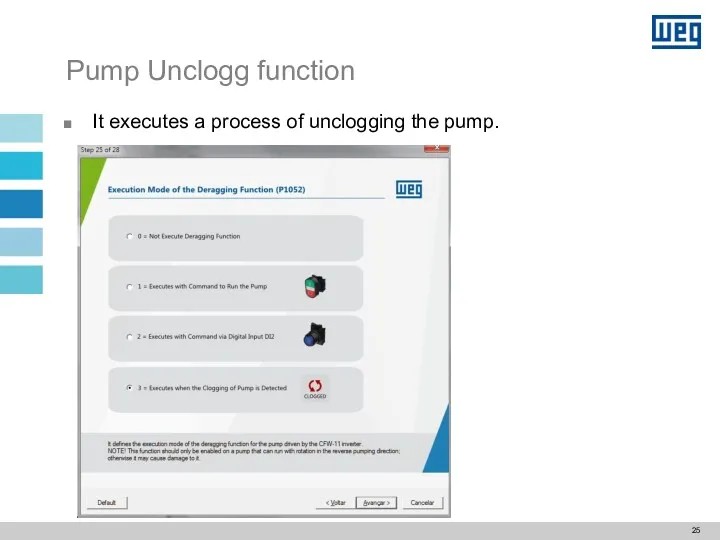

- 26. Pump Unclogg function It executes a process of unclogging the pump.

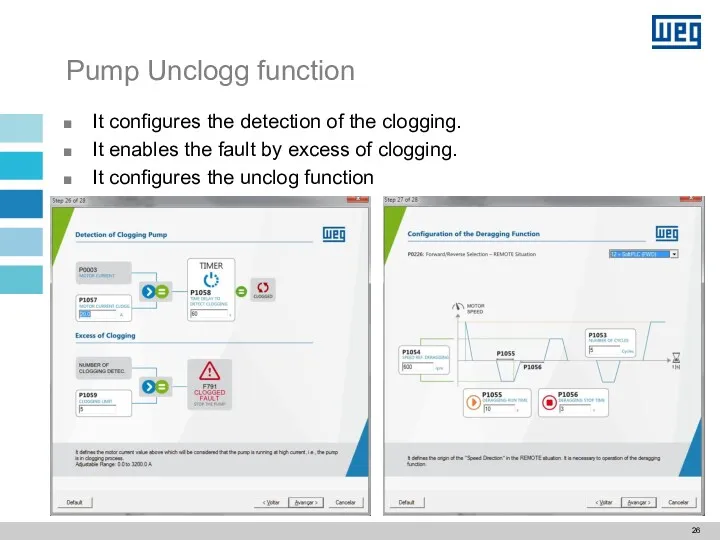

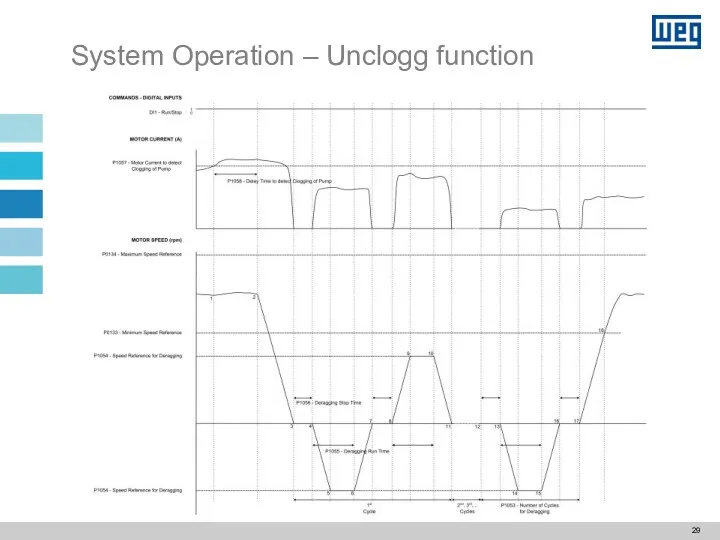

- 27. Pump Unclogg function It configures the detection of the clogging. It enables the fault by excess

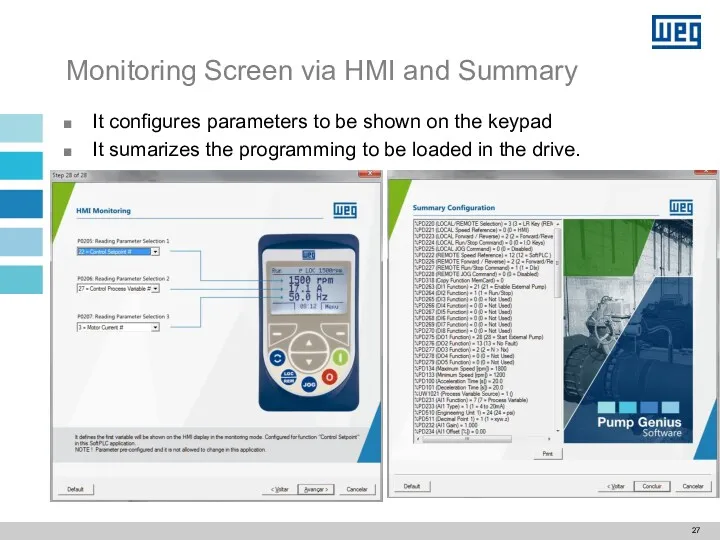

- 28. Monitoring Screen via HMI and Summary It configures parameters to be shown on the keypad It

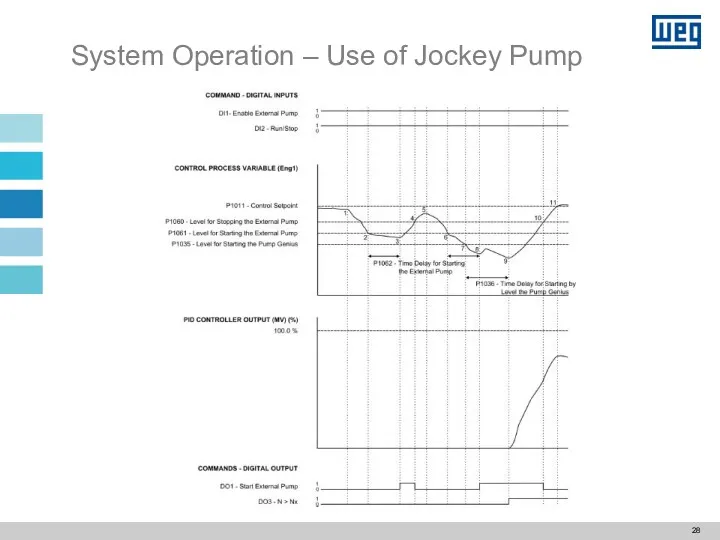

- 29. System Operation – Use of Jockey Pump

- 30. System Operation – Unclogg function

- 31. System Operation – Setpoint based in time scheduled

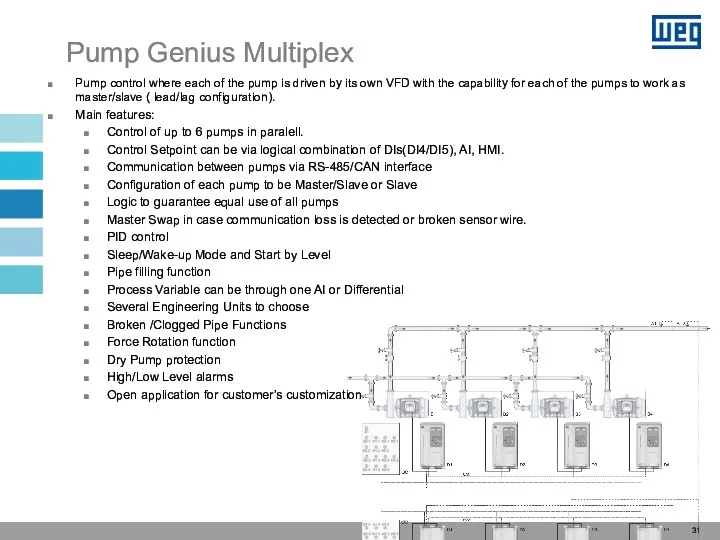

- 32. Pump Genius Multiplex Pump control where each of the pump is driven by its own VFD

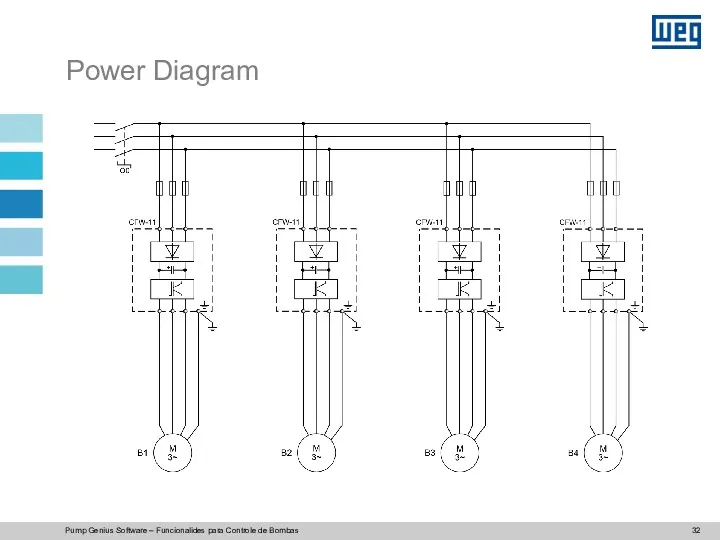

- 33. Pump Genius Software – Funcionalides para Controle de Bombas Power Diagram

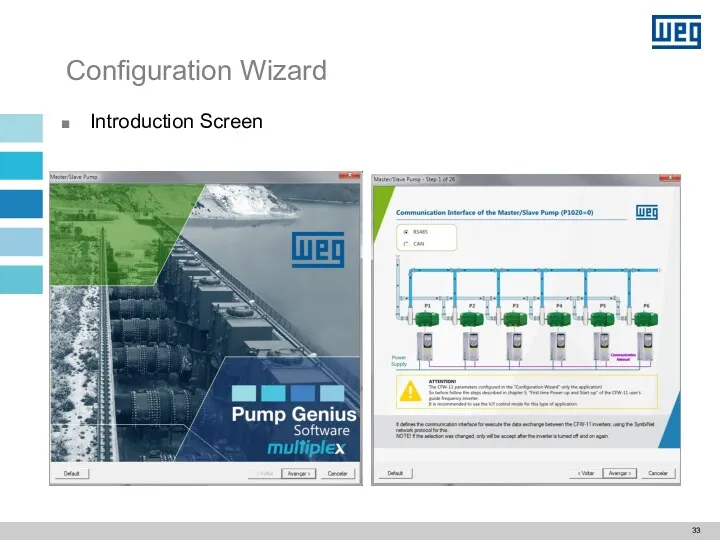

- 34. Configuration Wizard Introduction Screen

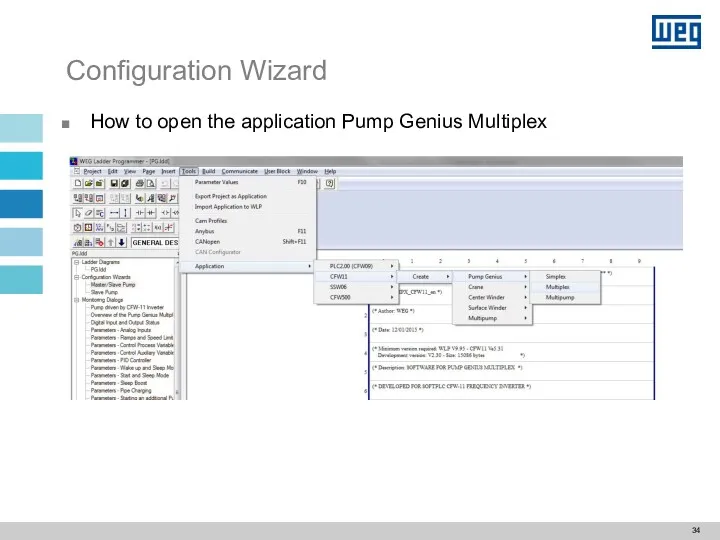

- 35. Configuration Wizard How to open the application Pump Genius Multiplex

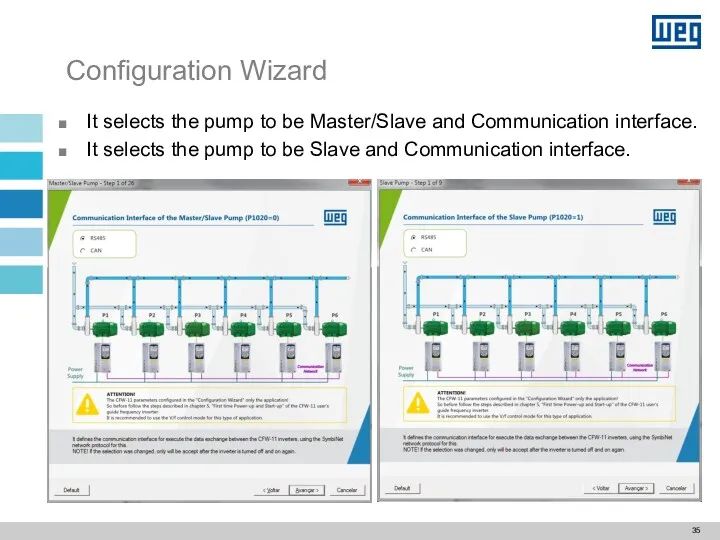

- 36. Configuration Wizard It selects the pump to be Master/Slave and Communication interface. It selects the pump

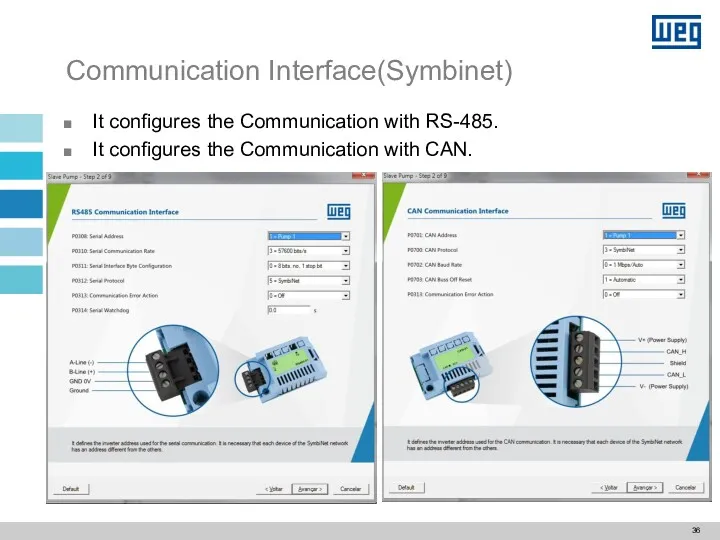

- 37. Communication Interface(Symbinet) It configures the Communication with RS-485. It configures the Communication with CAN.

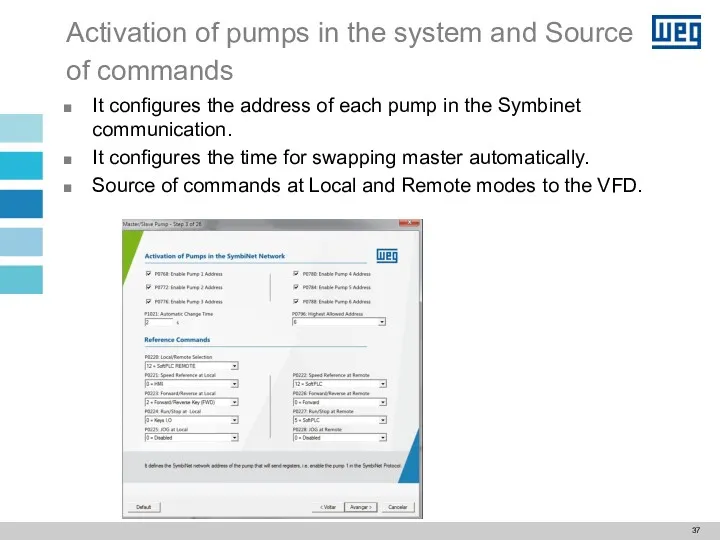

- 38. Activation of pumps in the system and Source of commands It configures the address of each

- 39. Pump Genius Software – Funcionalides para Controle de Bombas Master Pump Swapping In case there is

- 40. Pump Genius Software – Funcionalides para Controle de Bombas Turn on/off Paralell Pumps Conditions to turn

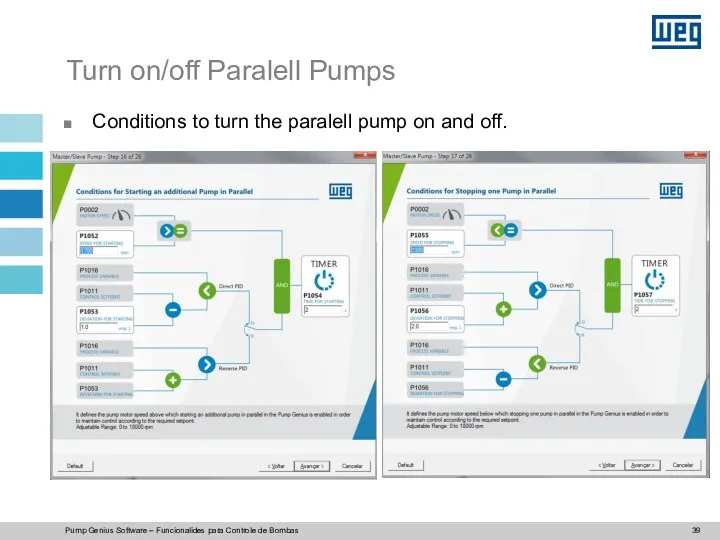

- 41. Force Rotation of Pumps It configures the conditions to force rotation of the pumps. All the

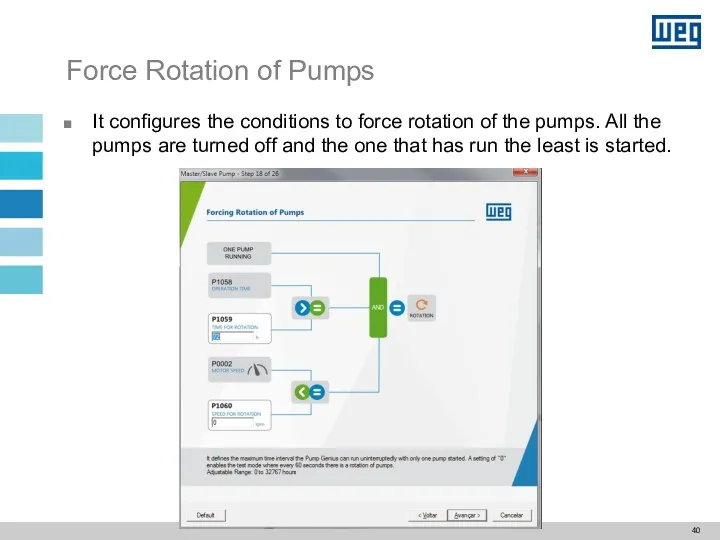

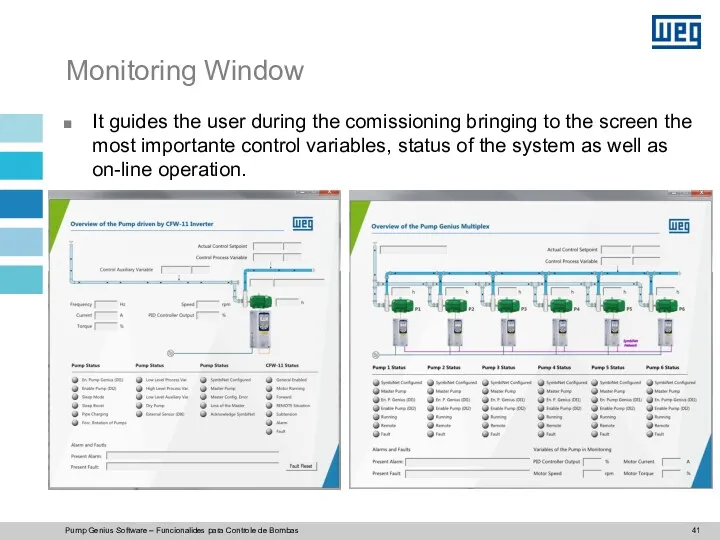

- 42. Pump Genius Software – Funcionalides para Controle de Bombas Monitoring Window It guides the user during

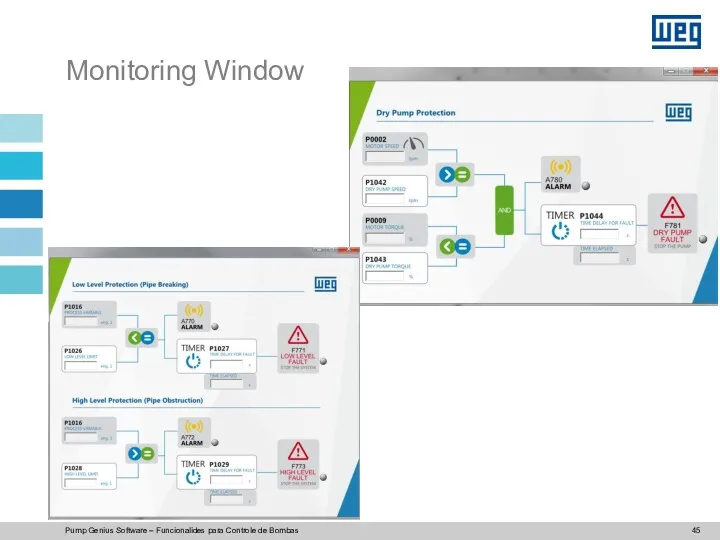

- 43. Pump Genius Software – Funcionalides para Controle de Bombas Monitoring Window

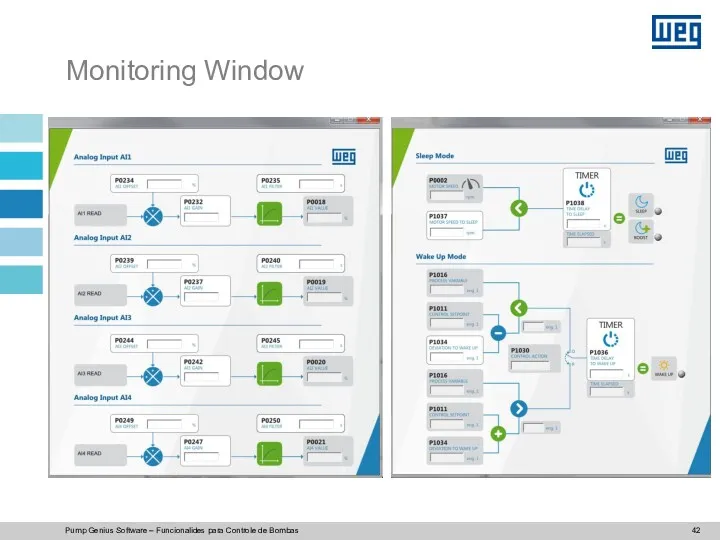

- 44. Pump Genius Software – Funcionalides para Controle de Bombas Monitoring Window

- 45. Pump Genius Software – Funcionalides para Controle de Bombas Monitoring Window

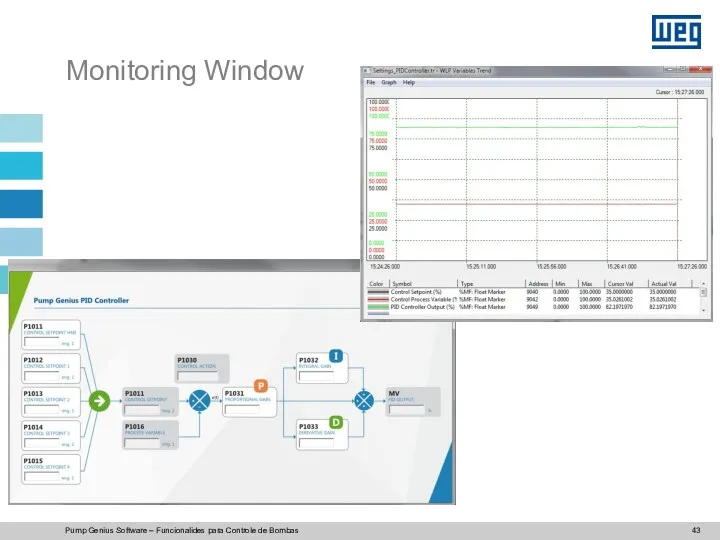

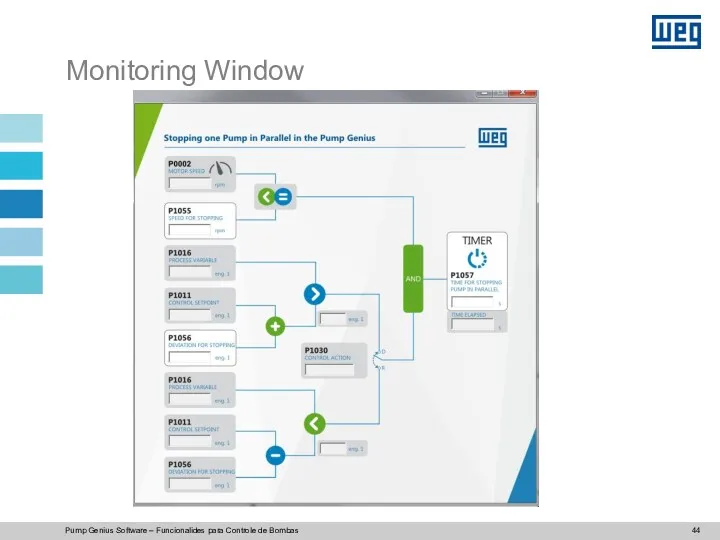

- 46. Pump Genius Software – Funcionalides para Controle de Bombas Monitoring Window

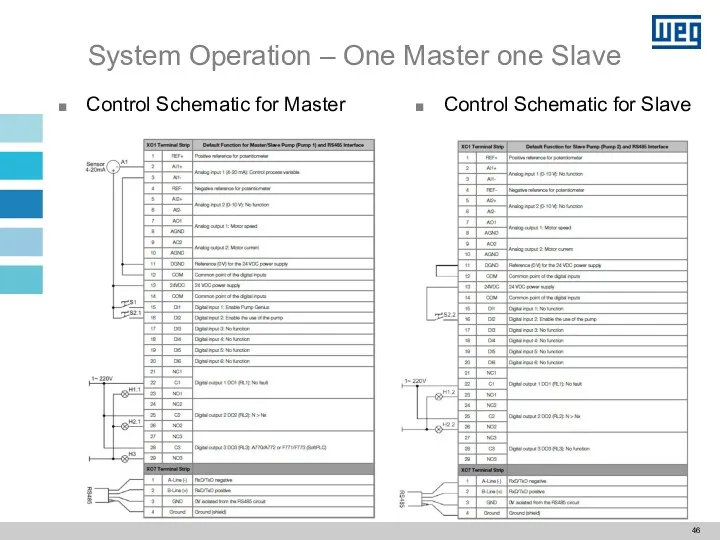

- 47. System Operation – One Master one Slave Control Schematic for Master Control Schematic for Slave

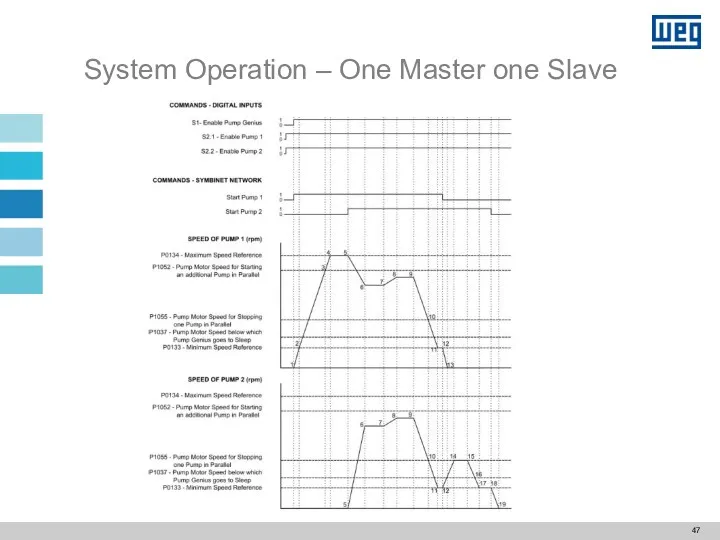

- 48. System Operation – One Master one Slave

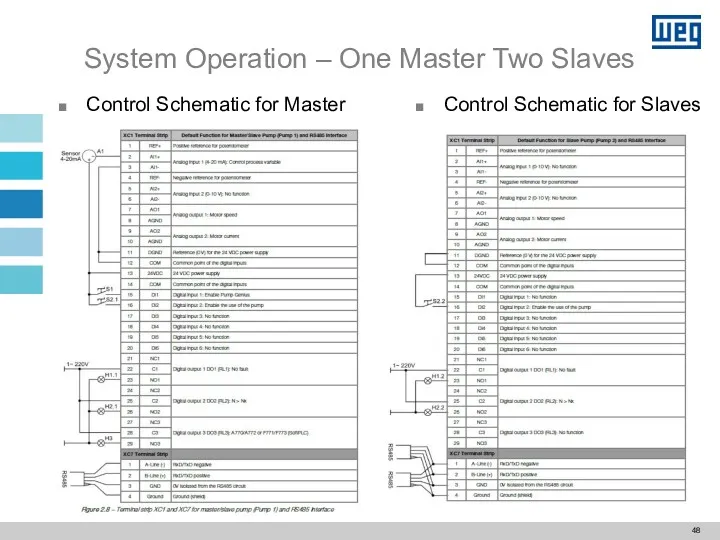

- 49. System Operation – One Master Two Slaves Control Schematic for Master Control Schematic for Slaves

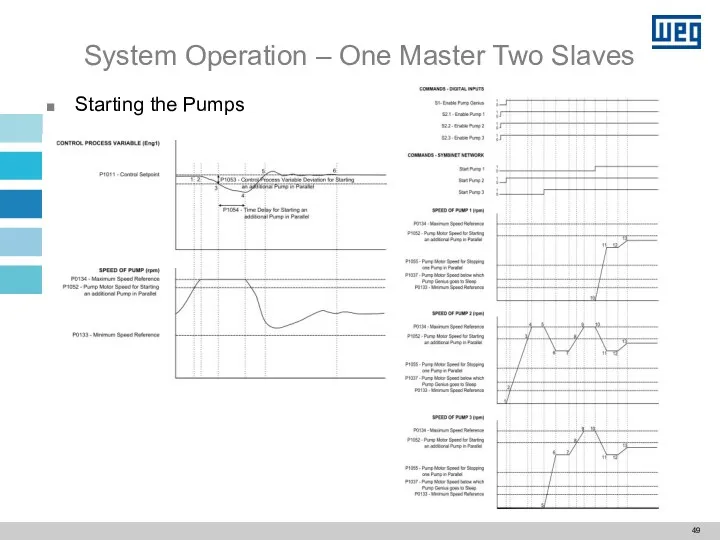

- 50. System Operation – One Master Two Slaves Starting the Pumps

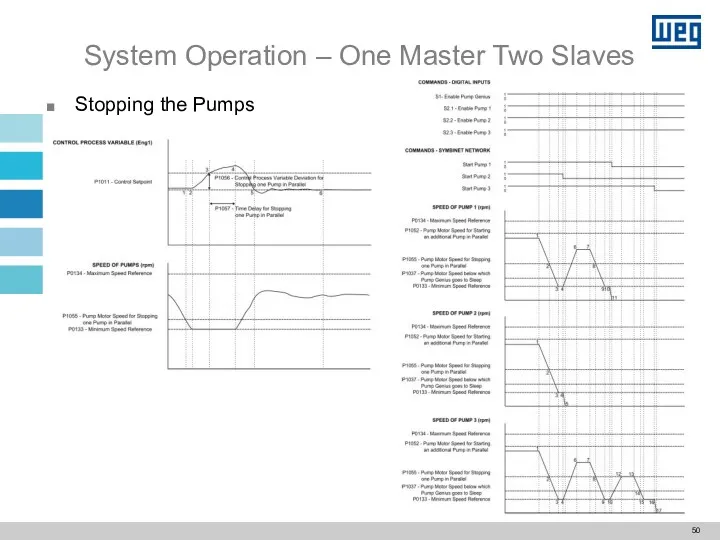

- 51. System Operation – One Master Two Slaves Stopping the Pumps

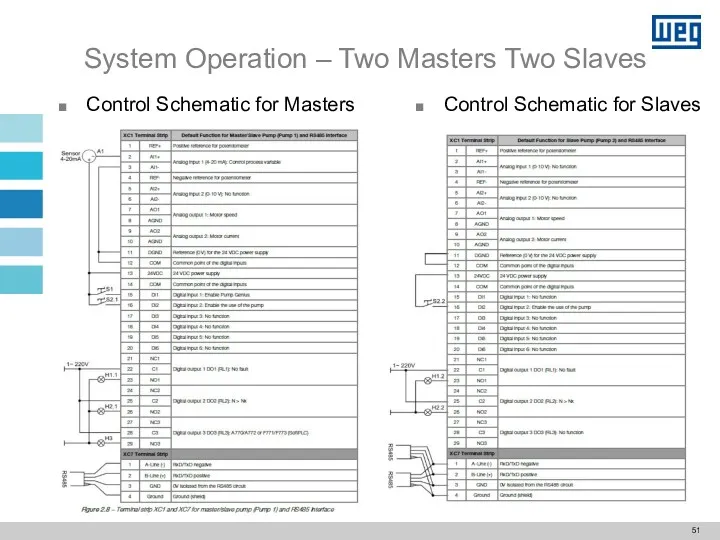

- 52. System Operation – Two Masters Two Slaves Control Schematic for Masters Control Schematic for Slaves

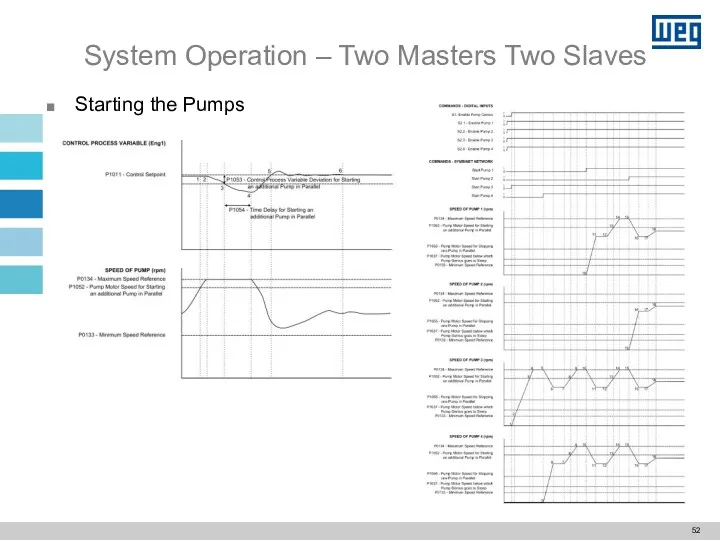

- 53. System Operation – Two Masters Two Slaves Starting the Pumps

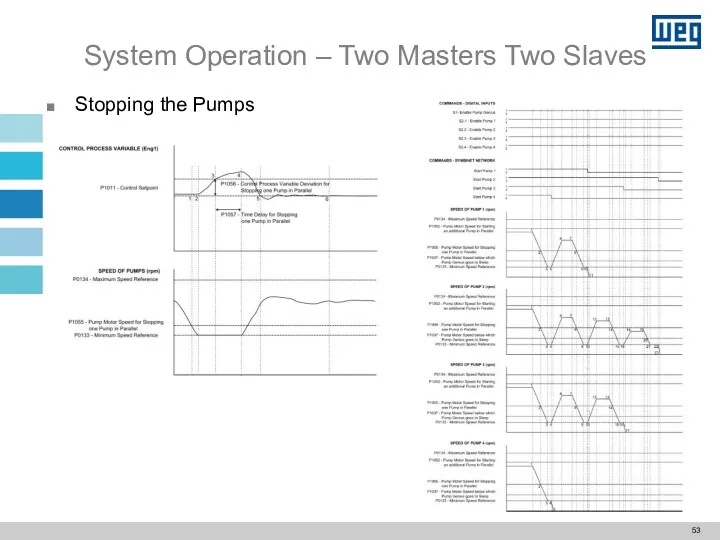

- 54. System Operation – Two Masters Two Slaves Stopping the Pumps

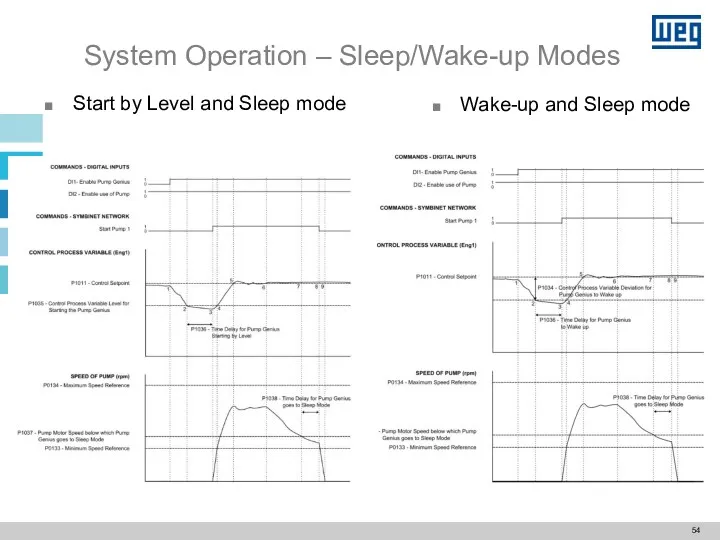

- 55. System Operation – Sleep/Wake-up Modes Start by Level and Sleep mode Wake-up and Sleep mode

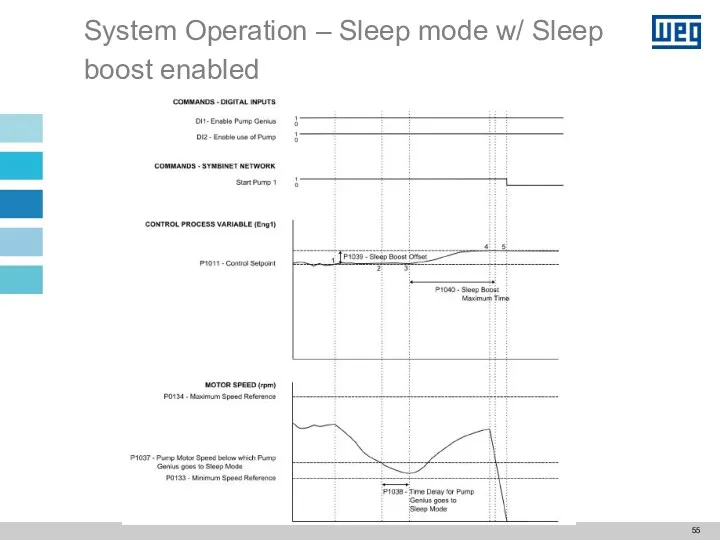

- 56. System Operation – Sleep mode w/ Sleep boost enabled

- 58. Скачать презентацию

Безопасность в интернете

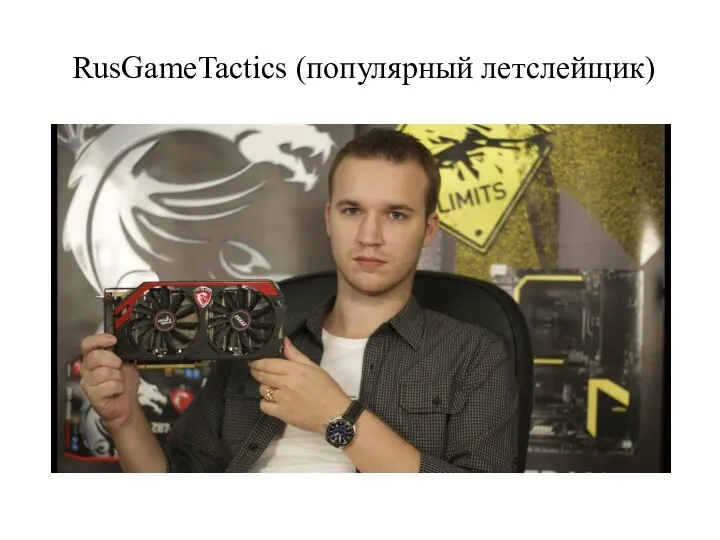

Безопасность в интернете RusGameTactics (популярный летслейщик)

RusGameTactics (популярный летслейщик) Основы искусственного интеллекта. Языки логического программирования

Основы искусственного интеллекта. Языки логического программирования Методологии разработки ПО

Методологии разработки ПО Основы СУБД в ACCESS

Основы СУБД в ACCESS Анализ данных в табличных процессорах

Анализ данных в табличных процессорах Коммуникационный проект как результат исследования общественного мнения. Тема 14

Коммуникационный проект как результат исследования общественного мнения. Тема 14 Оператор if-else в java. (Лекция 4)

Оператор if-else в java. (Лекция 4) Конспект урока по теме Компьютерные презентации с использованием мультимедиа технологии

Конспект урока по теме Компьютерные презентации с использованием мультимедиа технологии How Slides

How Slides лекция 5

лекция 5 Web-страницы. Язык HTML и др

Web-страницы. Язык HTML и др Тестировщик ПО. Блок 6. Тестирование API

Тестировщик ПО. Блок 6. Тестирование API Как настроить контекст и не слить весь бюджет за один день

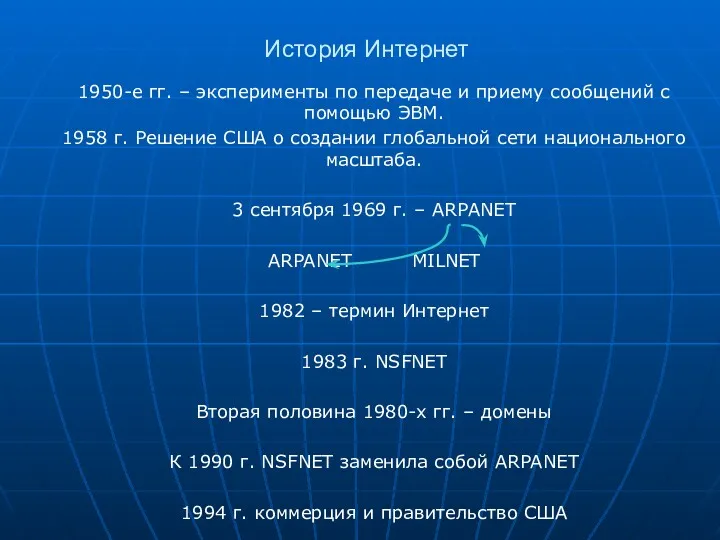

Как настроить контекст и не слить весь бюджет за один день Интернет. Способы поиска в Интернете. Компьютерные телекоммуникации

Интернет. Способы поиска в Интернете. Компьютерные телекоммуникации Победитель конкурса

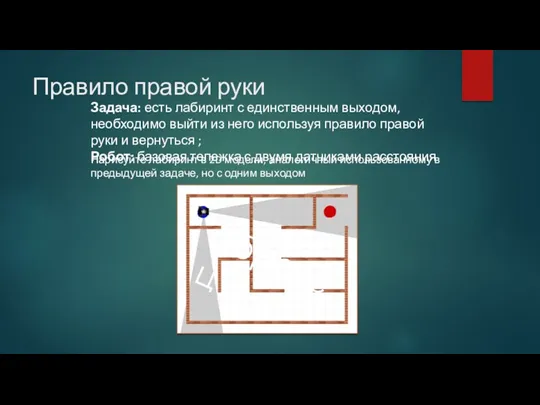

Победитель конкурса Правило правой руки

Правило правой руки Большая игра по информатике. 9-10 класс

Большая игра по информатике. 9-10 класс Исследование информационных моделей

Исследование информационных моделей Информационные процессы. Лекция 4

Информационные процессы. Лекция 4 Как оформить картинку, если ты не дизайнер

Как оформить картинку, если ты не дизайнер Алгоритмы

Алгоритмы Введение в алгоритмизацию. Лекция 1

Введение в алгоритмизацию. Лекция 1 Пользовательский интерфейс. (7 класс)

Пользовательский интерфейс. (7 класс) Графы и сети

Графы и сети Функциональные возможности Microsoft Office

Функциональные возможности Microsoft Office Кестелердің құрылуы

Кестелердің құрылуы Цикл for. Python

Цикл for. Python