Содержание

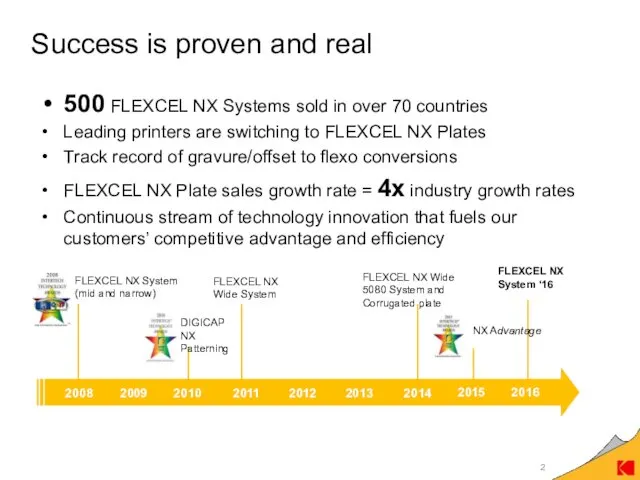

- 2. Success is proven and real 500 FLEXCEL NX Systems sold in over 70 countries Leading printers

- 3. FLEXCEL NX System ‘16 Benefits

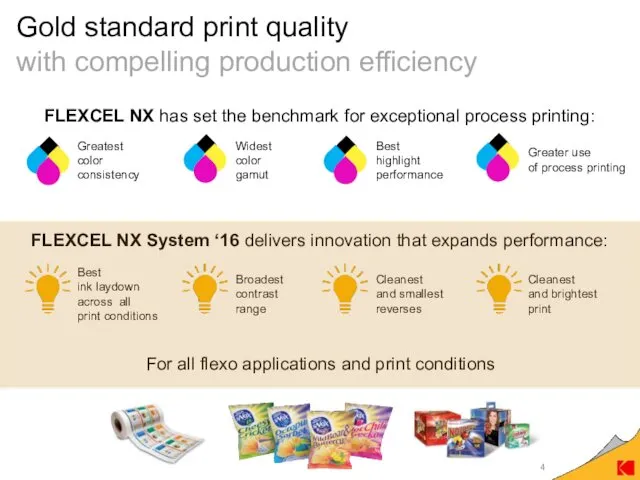

- 4. FLEXCEL NX has set the benchmark for exceptional process printing: Greatest color consistency Widest color gamut

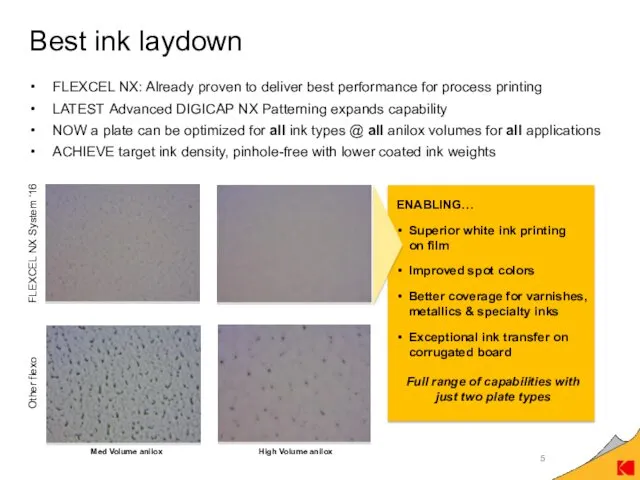

- 5. Best ink laydown FLEXCEL NX: Already proven to deliver best performance for process printing LATEST Advanced

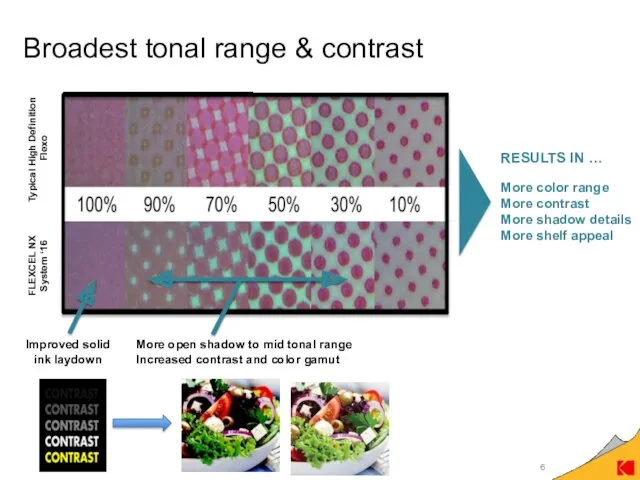

- 6. Broadest tonal range & contrast RESULTS IN … More color range More contrast More shadow details

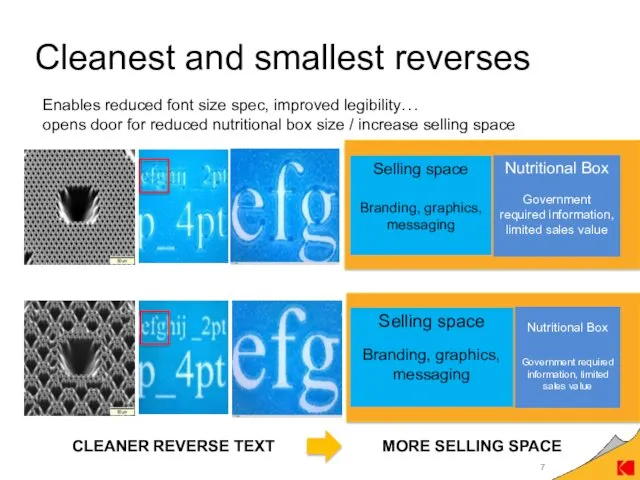

- 7. Cleanest and smallest reverses MORE SELLING SPACE CLEANER REVERSE TEXT Nutritional Box Government required information, limited

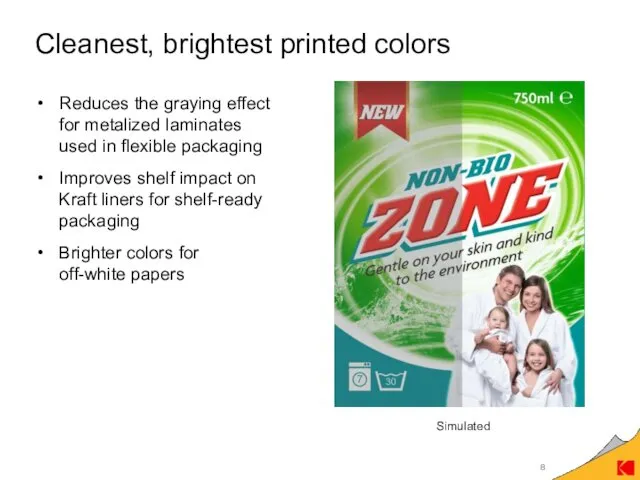

- 8. Cleanest, brightest printed colors Reduces the graying effect for metalized laminates used in flexible packaging Improves

- 9. FLEXCEL NX proven to deliver: Faster startup Reduced ink and substrate Longer plate life Increased press

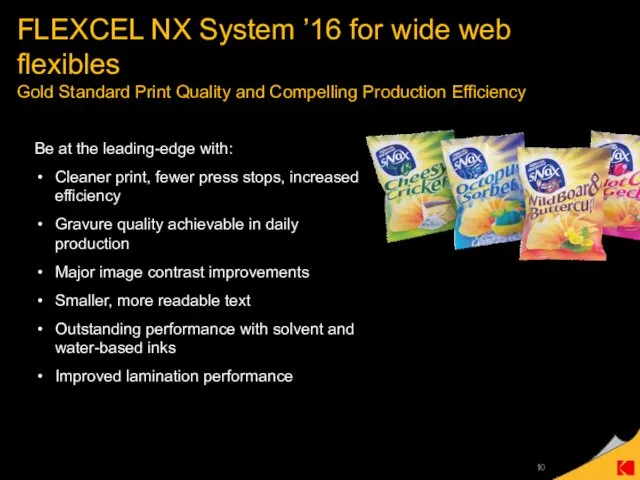

- 10. FLEXCEL NX System ’16 for wide web flexibles Gold Standard Print Quality and Compelling Production Efficiency

- 11. Be at the leading edge with: Improved solid ink laydown – higher densities with lower ink

- 12. Be at the leading edge with Best flexo match to digital printing Offset quality process printing

- 13. Be at the leading edge with: High-speed, stable printing Fewer press stops for cleaning Brighter, cleaner

- 14. FLEXCEL NX System ‘16 Technology

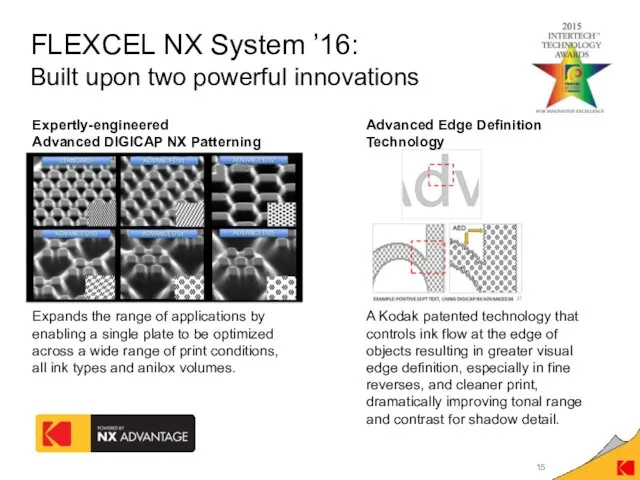

- 15. FLEXCEL NX System ’16: Built upon two powerful innovations A Kodak patented technology that controls ink

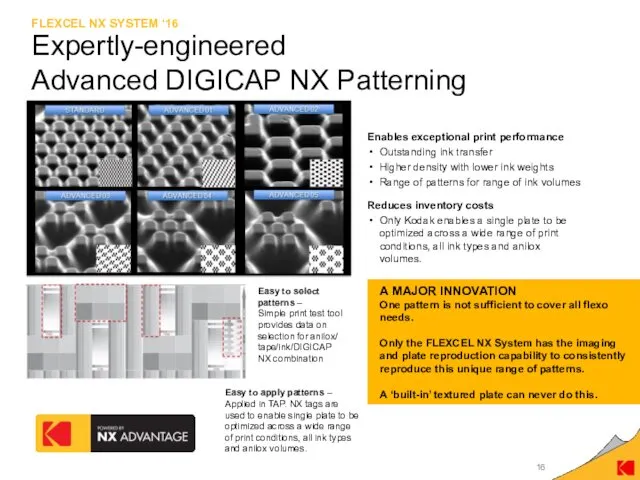

- 16. Expertly-engineered Advanced DIGICAP NX Patterning Enables exceptional print performance Outstanding ink transfer Higher density with lower

- 17. Advanced Edge Definition – Exclusive Patented Technology AED A MAJOR INNOVATION Only the FLEXCEL NX System

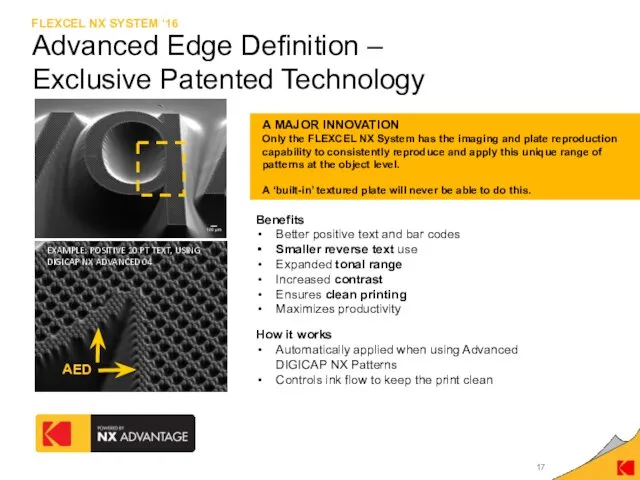

- 18. Additional tools for specific needs Optimizes floor height for best highlight dot print stability, plate making

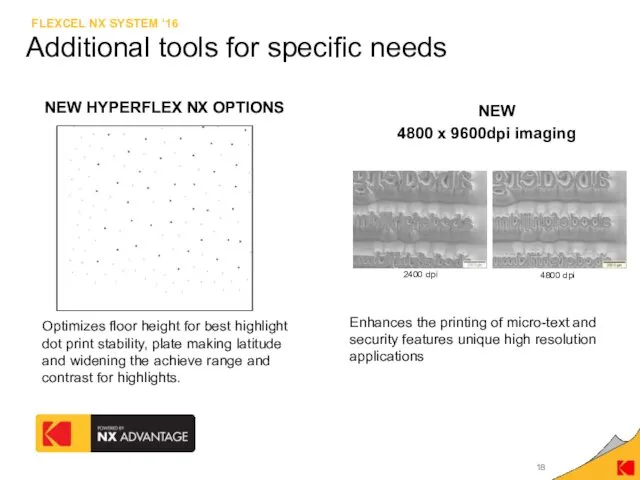

- 19. New HYPERFLEX NX Options Benefits Improved highlight dot stability, consistency and holding of isolated highlight dots

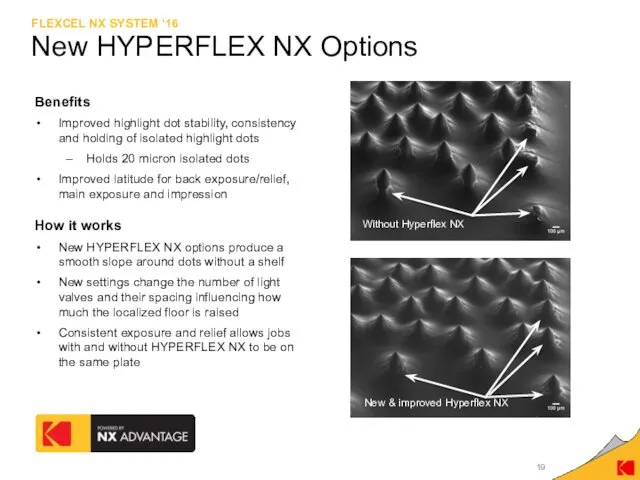

- 20. High Resolution 9600x4800 dpi (license sold separately) Benefits Enhances performance for micro text ( Supports 4800x4800

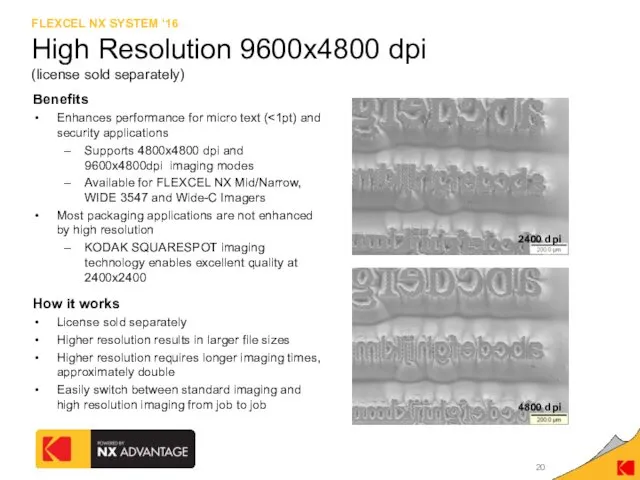

- 21. Powerful plate-making productivity tools Solvent Saving Invert Waste Feature – software features that help drive efficiencies

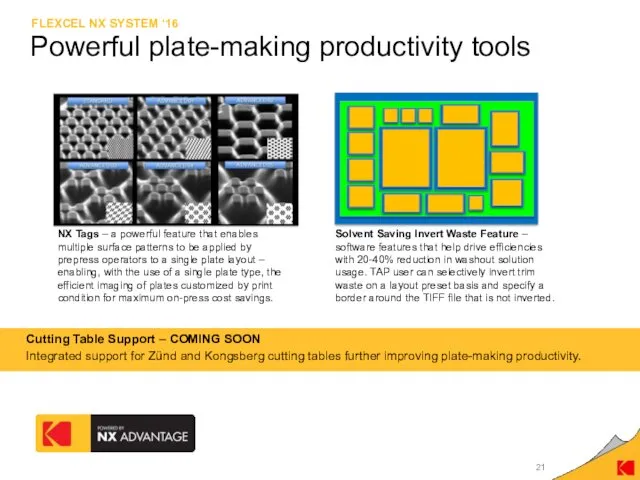

- 22. Easy Controls – TAP Software includes easy controls for defining and using NX tags Benefits Pre-press

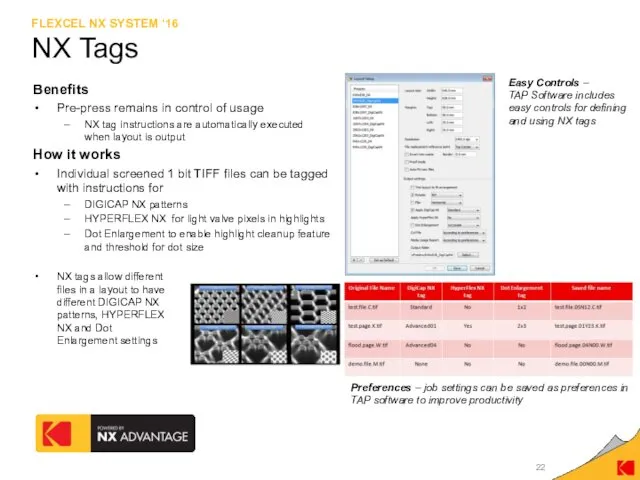

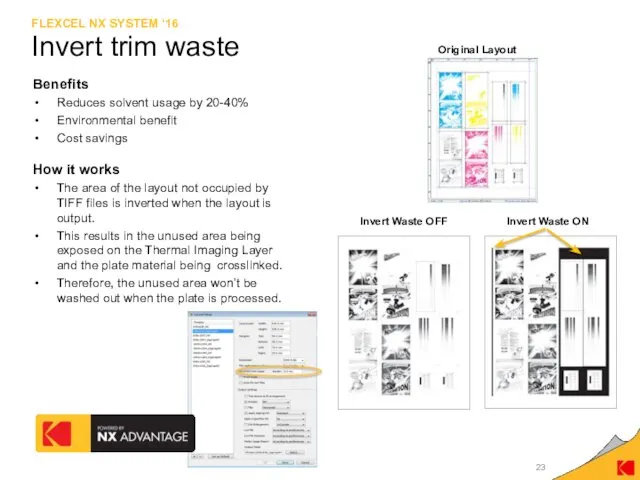

- 23. Original Layout Benefits Reduces solvent usage by 20-40% Environmental benefit Cost savings How it works The

- 24. FLEXCEL NX System ‘16 Support

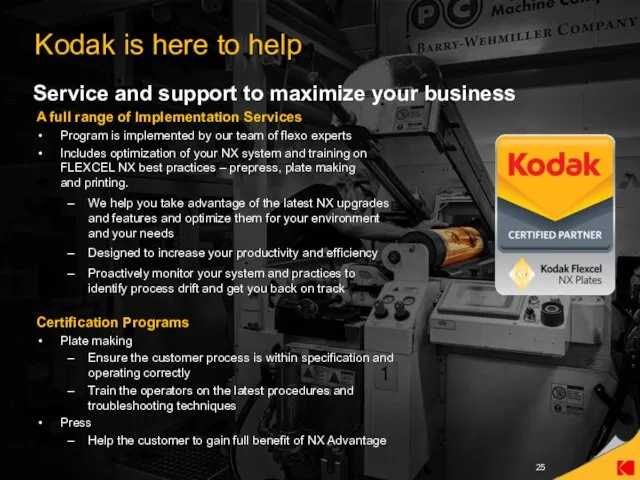

- 25. Kodak is here to help A full range of Implementation Services Program is implemented by our

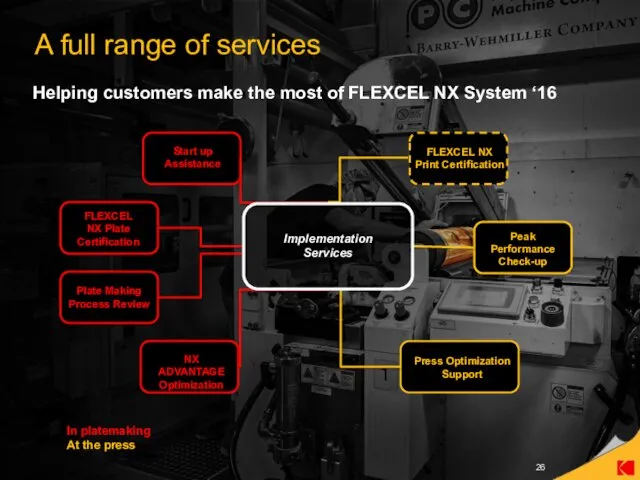

- 26. A full range of services In platemaking At the press Helping customers make the most of

- 27. The competition

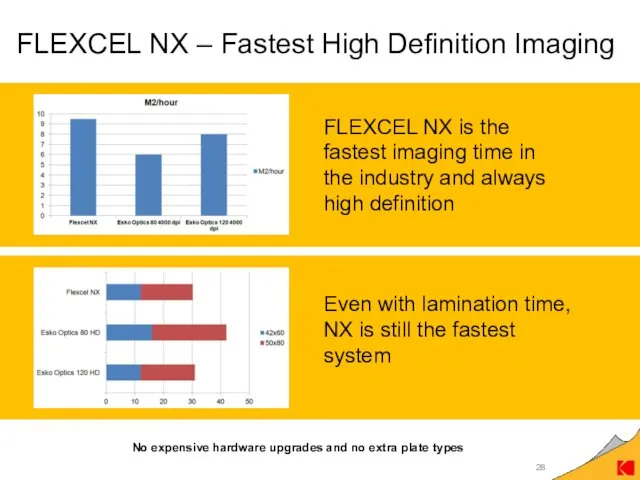

- 28. FLEXCEL NX – Fastest High Definition Imaging FLEXCEL NX is the fastest imaging time in the

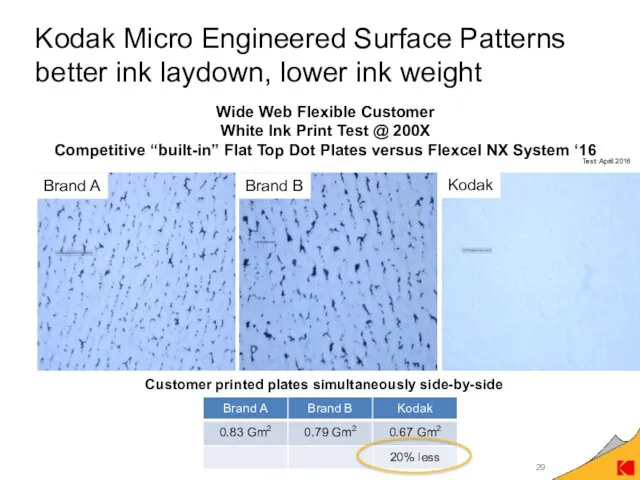

- 29. Kodak Micro Engineered Surface Patterns better ink laydown, lower ink weight Test: April 2016 Wide Web

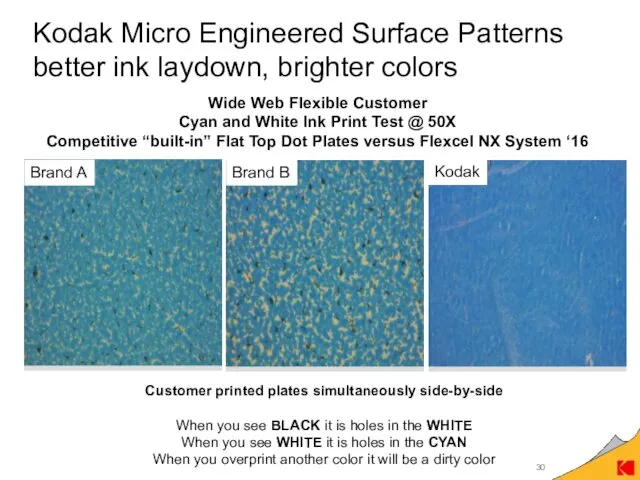

- 30. Brand A Kodak Brand B Customer printed plates simultaneously side-by-side When you see BLACK it is

- 31. Questions?

- 32. Appendix

- 33. Packaging growth: opportunity for flexo Source: PIRA, PRIMIR, EK internal analysis

- 34. Industry needs

- 35. FLEXCEL Direct System FLEXCEL NX System Media Digital and Analog Flexo plates, films and sleeves APPROVAL

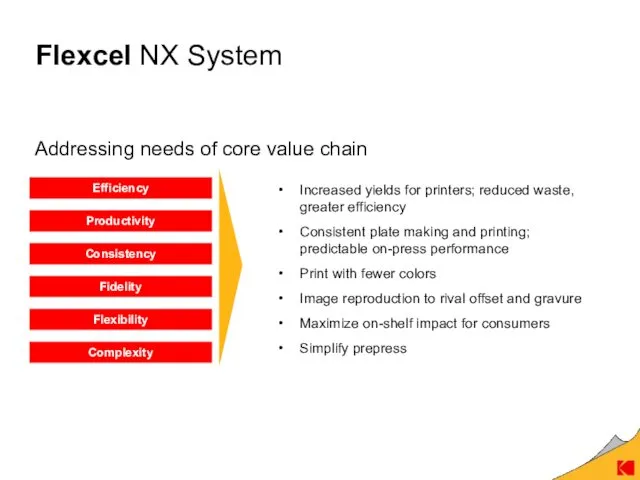

- 36. Flexcel NX System Increased yields for printers; reduced waste, greater efficiency Consistent plate making and printing;

- 37. Value in the pressroom FLEXCEL NX SYSTEM Average cost model for a $10M flexo printer 70%

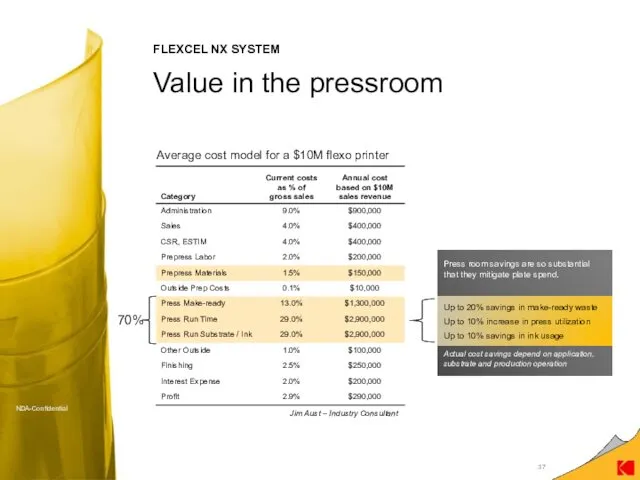

- 38. Flexcel NX System: Simple integrated solution Flexcel NX Mid System Flexcel NX Wide System (4260) Choice

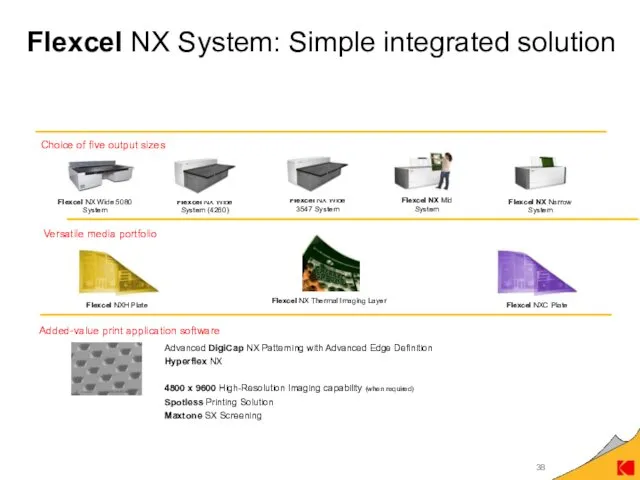

- 39. Flexcel NX System Differentiated technology delivers customer value

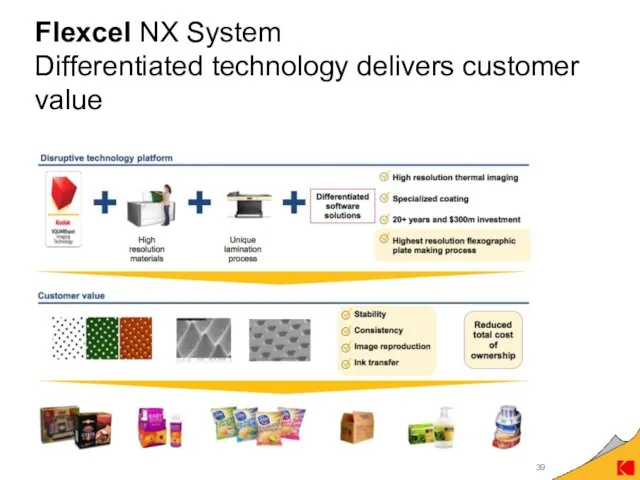

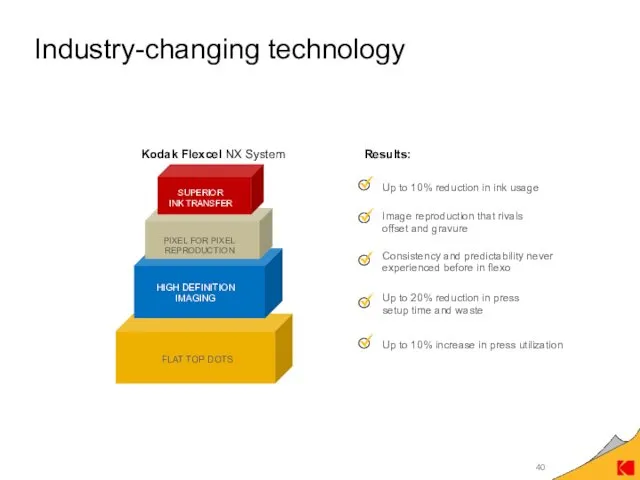

- 40. Industry-changing technology FLAT TOP DOTS Kodak Flexcel NX System Results:

- 42. Скачать презентацию

Декорхейм - этнические элементы декора

Декорхейм - этнические элементы декора Здоровый образ жизни и продукты Вэлнэс

Здоровый образ жизни и продукты Вэлнэс Проект сотрудничества от почты России

Проект сотрудничества от почты России Автомобильный комплекс Ангар авто. Приглашаем на вакансию

Автомобильный комплекс Ангар авто. Приглашаем на вакансию Effective and Creative Advertising Messages

Effective and Creative Advertising Messages Знакомство с мобильной системой ПО Агент 2.0, для работы мерчендайзеров

Знакомство с мобильной системой ПО Агент 2.0, для работы мерчендайзеров Разработка Digital стратегии

Разработка Digital стратегии Экспозиторы

Экспозиторы Управление Услугами Campaign

Управление Услугами Campaign Основные виды реструктуризации предприятий. Особенности реструктуризации в РФ

Основные виды реструктуризации предприятий. Особенности реструктуризации в РФ Миссия группы компаний Пионер

Миссия группы компаний Пионер Пакет базовый. Все платформы 2ГИС

Пакет базовый. Все платформы 2ГИС Товарознавчі аспекти дослідження вітчизняного ринку керамічної плитки. ТзОВ ЕПІЦЕНТР К, м. Стрий

Товарознавчі аспекти дослідження вітчизняного ринку керамічної плитки. ТзОВ ЕПІЦЕНТР К, м. Стрий Отдел продаж

Отдел продаж Marketing Dissertations

Marketing Dissertations Koton Jeans. Тренинг

Koton Jeans. Тренинг Маркетинговый мониторинг раздражающих лекарственных средств

Маркетинговый мониторинг раздражающих лекарственных средств Успешная команда Орифлэйм

Успешная команда Орифлэйм Презентация бренда MORIZO. Процедуры с использованием продукции линии

Презентация бренда MORIZO. Процедуры с использованием продукции линии Коммерческое предложение oneRa

Коммерческое предложение oneRa Android STB Wink. О продукте

Android STB Wink. О продукте Особенности управления товарными запасами на розничных торговых предприятиях на примере магазина GeNAs

Особенности управления товарными запасами на розничных торговых предприятиях на примере магазина GeNAs Осень-зима 2020/2021

Осень-зима 2020/2021 ООО Саратовская макаронная фабрика

ООО Саратовская макаронная фабрика Мастер по шугарингу. Базовое обучение

Мастер по шугарингу. Базовое обучение Research of existing business centers and under construction ones St. Petersburg

Research of existing business centers and under construction ones St. Petersburg Рекламация и актуальность. Сегментация рынка. Предприятия, занимающиеся опреснением воды

Рекламация и актуальность. Сегментация рынка. Предприятия, занимающиеся опреснением воды Компания KRASS

Компания KRASS