Содержание

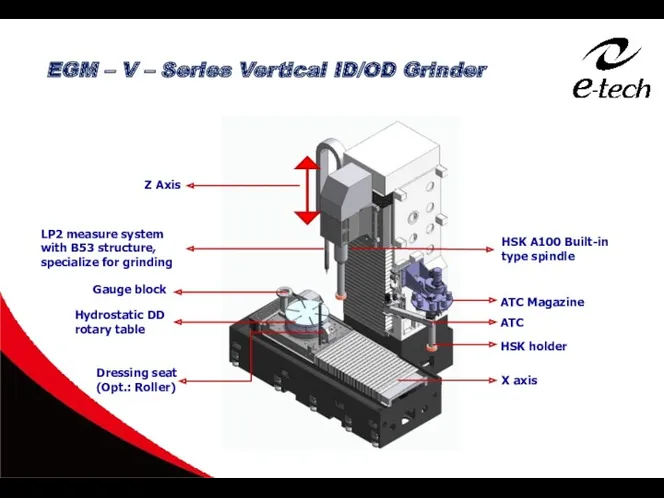

- 2. EGM – V – Series Vertical ID/OD Grinder

- 3. Specification 機台規格 Opertation & Software 軟體及操作 Application 機台應用 INTRODUCTION 機台簡介 簡報大綱 / Outline

- 4. High Accuracy, High Capability, and Cross-boarder EGM-600/800V CNC Vertical Grinder Inner diameter, inner face inner taper,

- 5. Vertical Grinder Machine Model Selection Max. OD grinding: 600 Max. grinding depth: 550 Max. OD grinding:

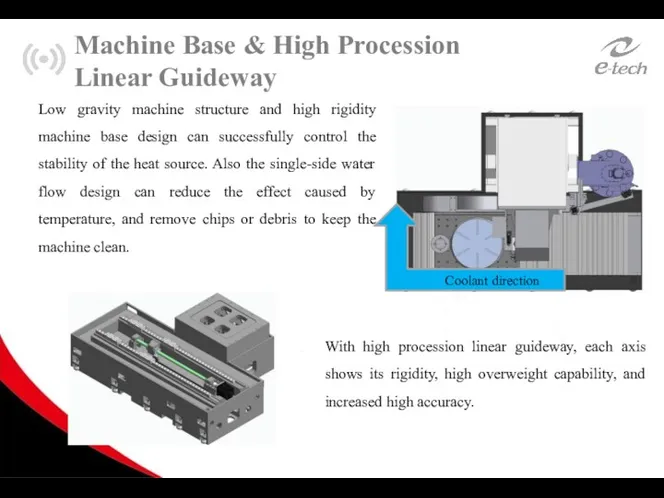

- 6. Low gravity machine structure and high rigidity machine base design can successfully control the stability of

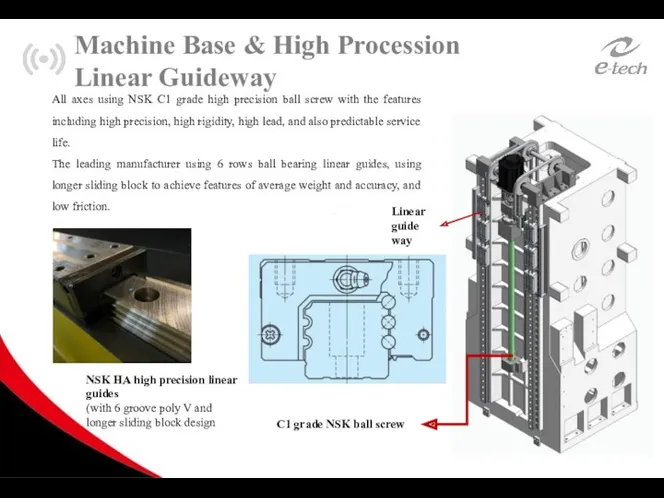

- 7. All axes using NSK C1 grade high precision ball screw with the features including high precision,

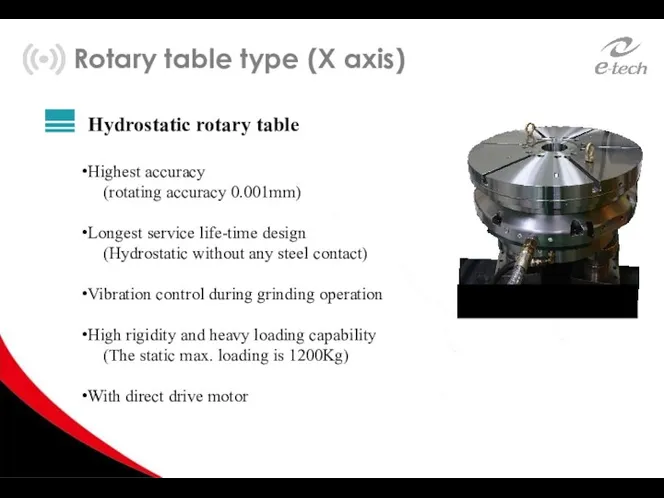

- 8. Hydrostatic rotary table Highest accuracy (rotating accuracy 0.001mm) Longest service life-time design (Hydrostatic without any steel

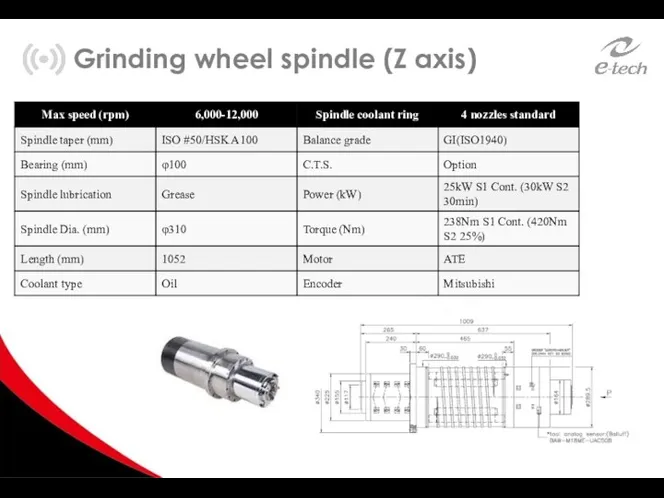

- 9. Grinding wheel spindle (Z axis)

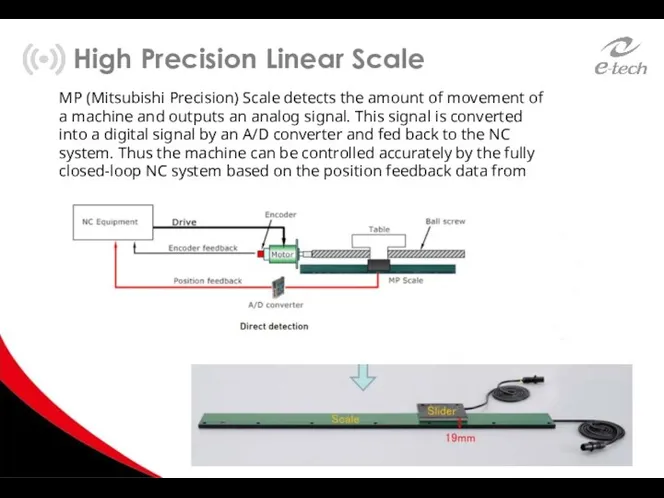

- 10. MP (Mitsubishi Precision) Scale detects the amount of movement of a machine and outputs an analog

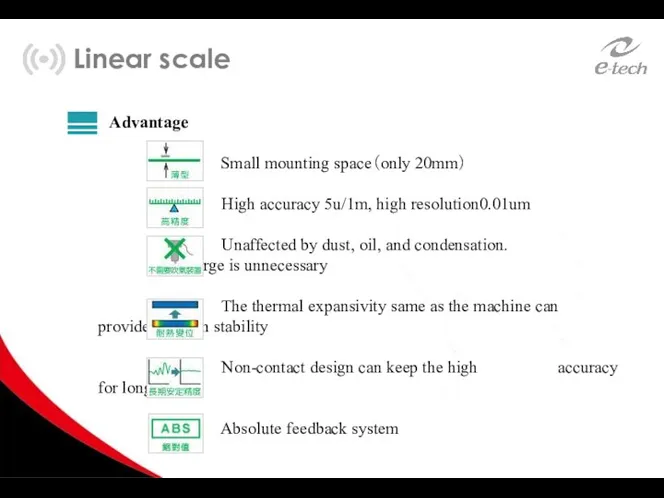

- 11. Advantage Small mounting space(only 20mm) High accuracy 5u/1m, high resolution0.01um Unaffected by dust, oil, and condensation.

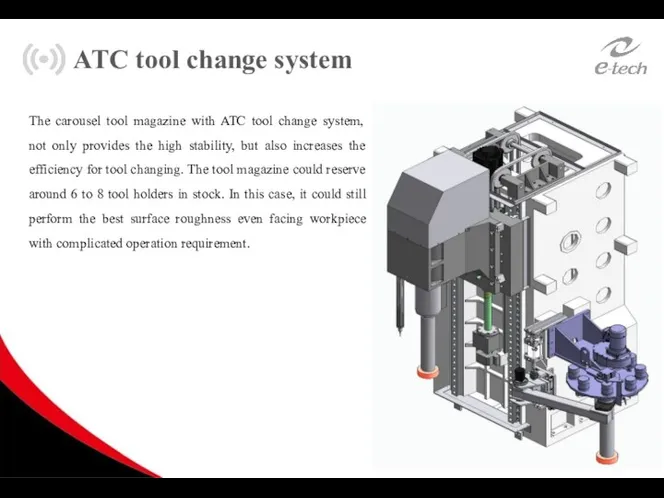

- 12. The carousel tool magazine with ATC tool change system, not only provides the high stability, but

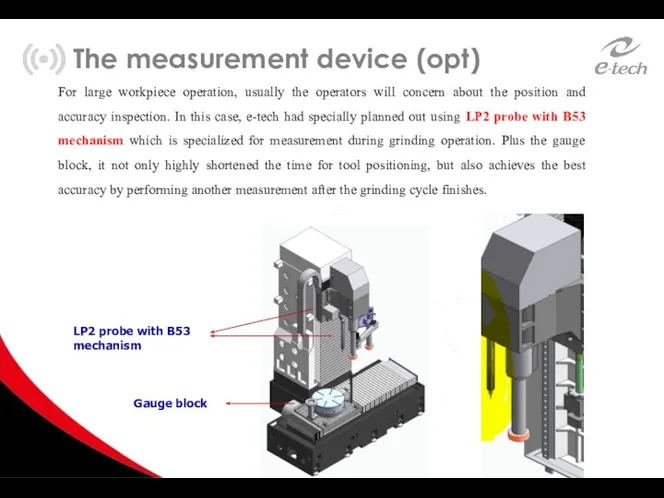

- 13. LP2 probe with B53 mechanism Gauge block For large workpiece operation, usually the operators will concern

- 14. Specification 機台規格 Opertation & Software 軟體及操作 Application 機台應用 INTRODUCTION 機台簡介 簡報大綱 / Outline

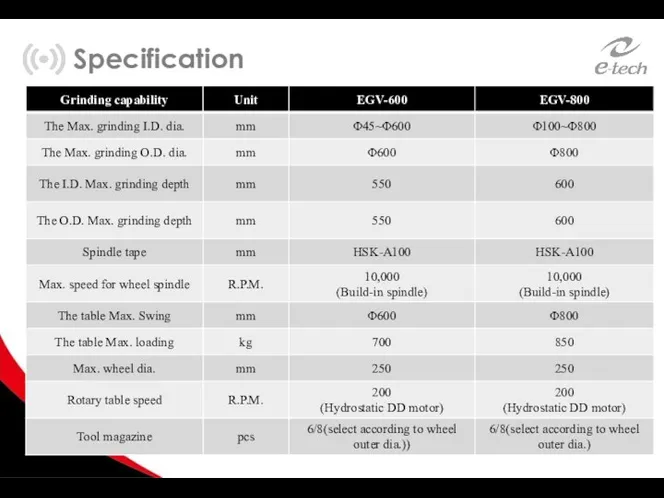

- 15. Specification

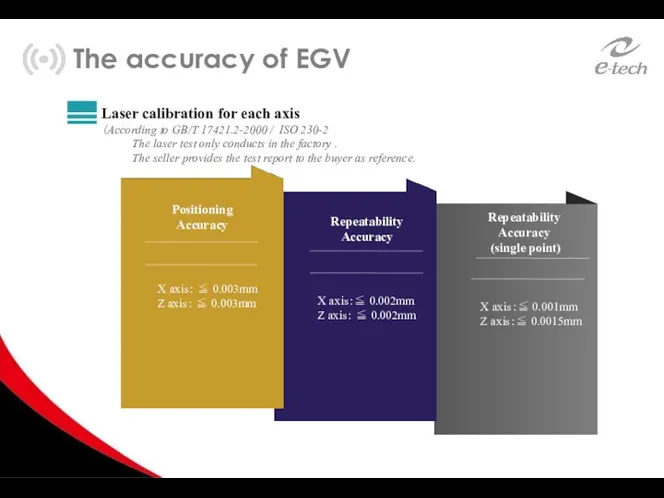

- 16. The accuracy of EGV Laser calibration for each axis (According to GB/T 17421.2-2000 / ISO 230-2

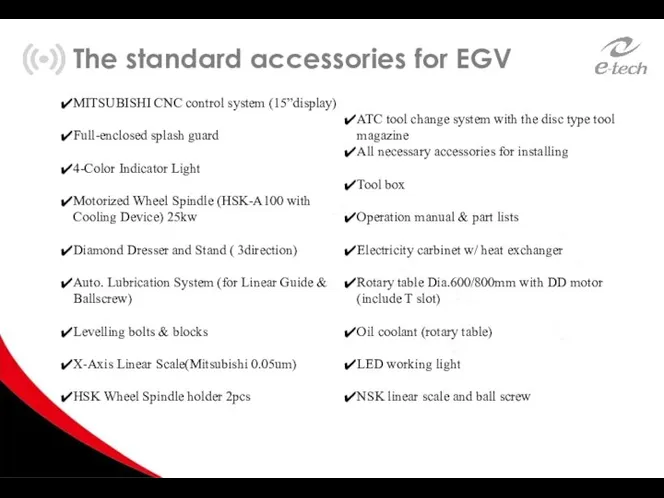

- 17. The standard accessories for EGV

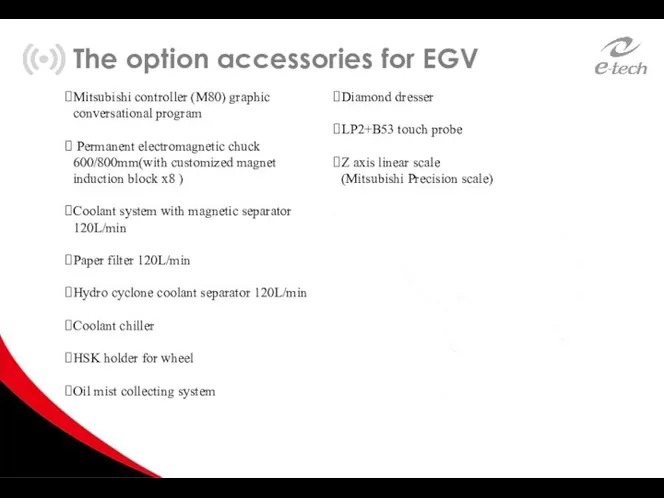

- 18. The option accessories for EGV

- 19. Specification 機台規格 Opertation & Software 軟體及操作 Application 機台應用 INTRODUCTION 機台簡介 簡報大綱 / Outline

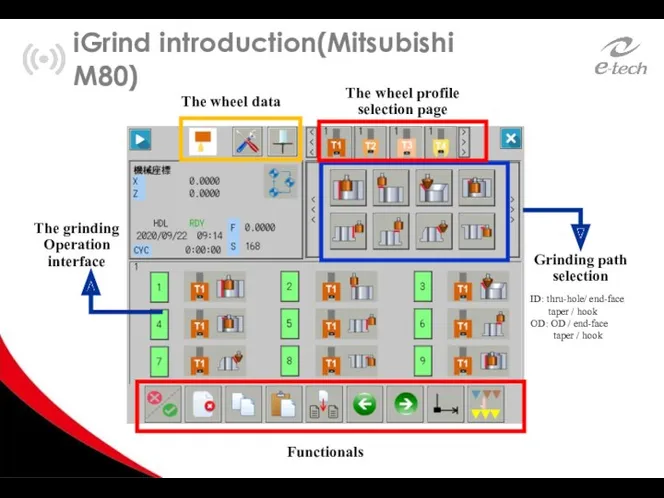

- 20. Functionals Grinding path selection The grinding Operation interface The wheel profile selection page The wheel data

- 21. The wheel shape selection Zero point setting of the workpiece iGrind introduction (Mitsubishi M80)

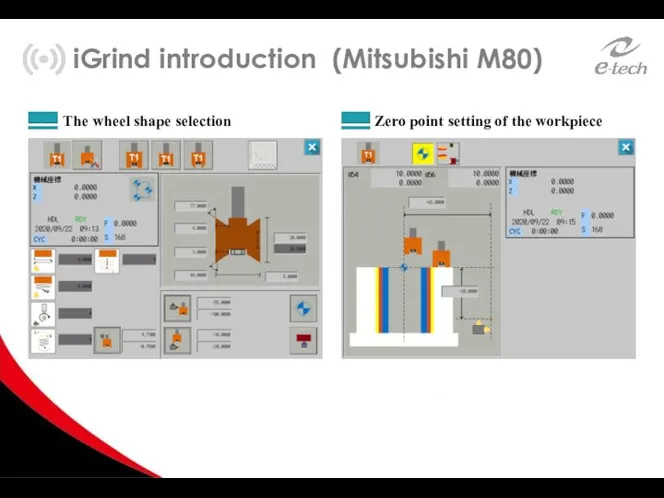

- 22. Grinding Path Dressing Path The grinding application

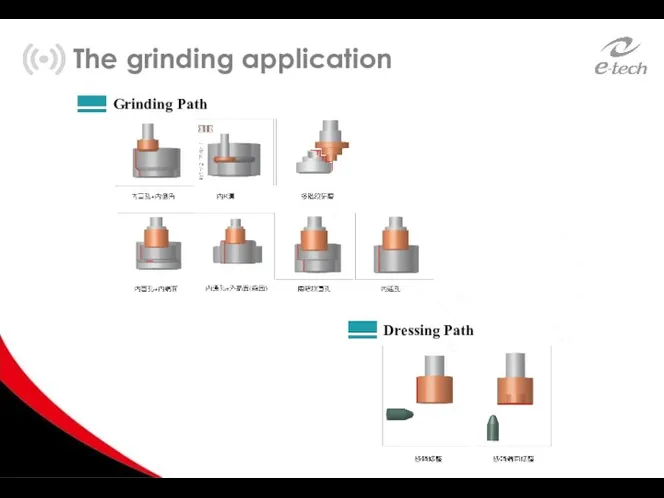

- 23. Quality 1/2 - Provide the test report We know well about all details about our machine.

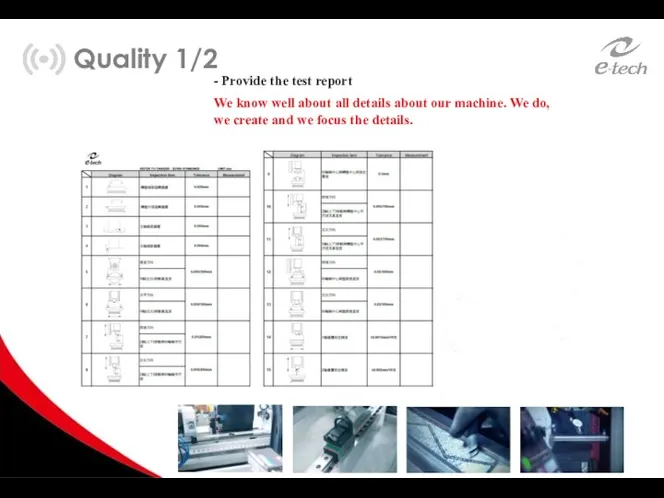

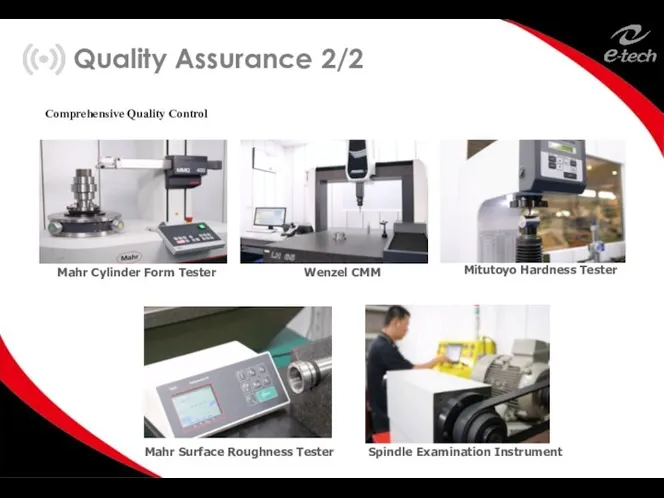

- 24. Quality Assurance 2/2 Comprehensive Quality Control Mahr Cylinder Form Tester Mitutoyo Hardness Tester Wenzel CMM Mahr

- 26. Скачать презентацию

Сущность и современное понимание менеджмента, ориентированного на рынок

Сущность и современное понимание менеджмента, ориентированного на рынок Корейская косметика

Корейская косметика Медициналық (фармацевтикалық) өкіл жұмысын зерттеу

Медициналық (фармацевтикалық) өкіл жұмысын зерттеу Сводный анализ деятельности в ЭК

Сводный анализ деятельности в ЭК Маркетинг персонала: понятие, задачи, функции

Маркетинг персонала: понятие, задачи, функции Бытовая химия Fedora. Японская серия

Бытовая химия Fedora. Японская серия Стиральные машины LG Titan 2 0

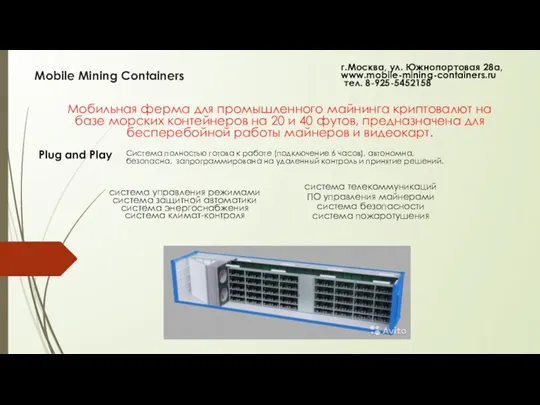

Стиральные машины LG Titan 2 0 Мобильная ферма для промышленного майнинга криптовалют на базе морских контейнеров

Мобильная ферма для промышленного майнинга криптовалют на базе морских контейнеров Разработка сайта интернет-магазина компьютерной техники

Разработка сайта интернет-магазина компьютерной техники Rainpark. Ассортимент продукции

Rainpark. Ассортимент продукции Яндекс Маркет для вашего бизнеса

Яндекс Маркет для вашего бизнеса Маркетинговый план и стратегия продаж

Маркетинговый план и стратегия продаж Гарантия на автомобили с пробегом

Гарантия на автомобили с пробегом Косметические и парфюмерные новинки Faberlic

Косметические и парфюмерные новинки Faberlic Коммерческое предложение от группы компаний МТС

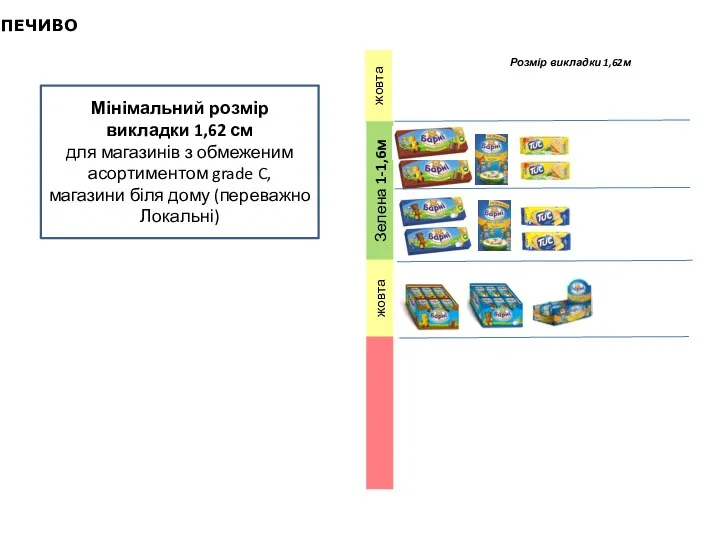

Коммерческое предложение от группы компаний МТС Планограми викладки печива

Планограми викладки печива OEM & BoatBuilders Meeting

OEM & BoatBuilders Meeting Маркетинговый анализ товара

Маркетинговый анализ товара Новый поток клиентов в ваш бизнес: до 80% больше продаж с помощью чат-бота

Новый поток клиентов в ваш бизнес: до 80% больше продаж с помощью чат-бота Мотивация сотрудников Розничной Сети. AW21

Мотивация сотрудников Розничной Сети. AW21 Маркетплейсы. Как и с чем входить

Маркетплейсы. Как и с чем входить Вчера. Сегодня. Завтра

Вчера. Сегодня. Завтра 9. Техническое задание

9. Техническое задание Бриф на брошюру Бунге Про

Бриф на брошюру Бунге Про Анализ конкурентов

Анализ конкурентов Магазин натуральной косметики и мыла ручной работы

Магазин натуральной косметики и мыла ручной работы Заработок на Ютуб

Заработок на Ютуб