Слайд 2

IMPROVEMENTS ON CURRENT EB76CNC6 V5

LONG OPERATING LIFE AND MORE RELIABILITY

INCREASED MACHINE CAPACITY

IMPROVED REPEATABILITY

Thanks to…..

Слайд 3

IMPROVEMENTS ON CURRENT EB76CNC6 V5

Redesigned bend axis supported by oversized heavy

duty tapered roller bearings.

Слайд 4

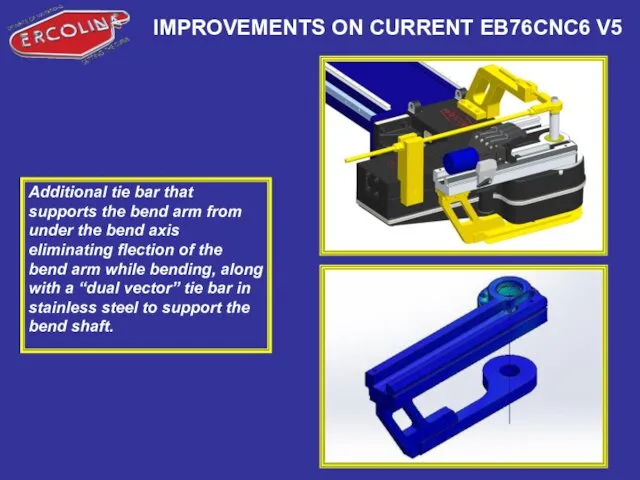

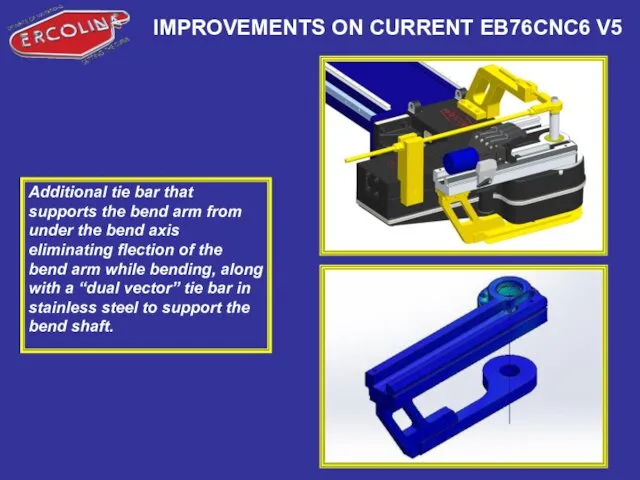

IMPROVEMENTS ON CURRENT EB76CNC6 V5

Additional tie bar that supports the bend

arm from under the bend axis eliminating flection of the bend arm while bending, along with a “dual vector” tie bar in stainless steel to support the bend shaft.

Слайд 5

Слайд 6

INTRODUCING NEW EB76CNC3S

Designed and developed to bend serpentine profiles, 180-degree bends,

for refrigerator's condensers or evaporators and other applications, with minimum radii 2 x ø.

New EB76CNC3S basically allows to produce serpentines thanks to a new kit of tools specifically developed.

In addition the Ercobender S-Line, with Y and B electrically controlled by brushless motors and C Bending Axis hydraulically driven, has been further improved with respect to the already high performance V5 currently in production.

Договор франчайзинга

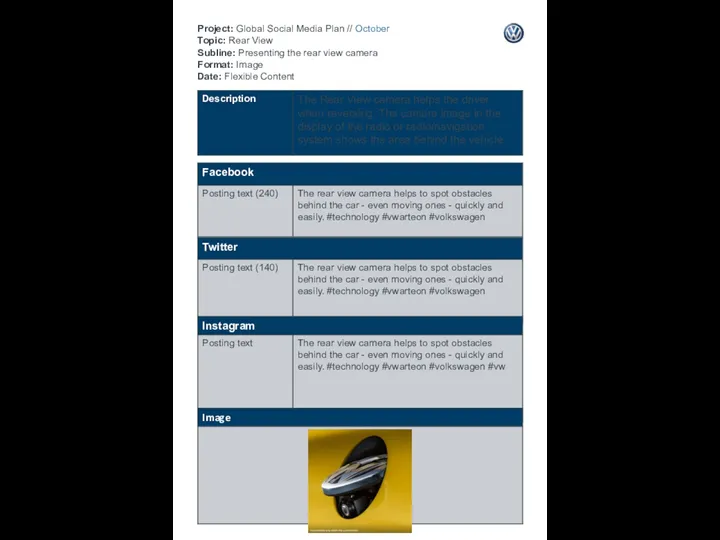

Договор франчайзинга Project: Global Social Media Plan // October Topic: Rear View Subline: Presenting the rear view camera Format: Image

Project: Global Social Media Plan // October Topic: Rear View Subline: Presenting the rear view camera Format: Image Технология продаж услуг и дополнительной гарантии. Рабочая тетрадь

Технология продаж услуг и дополнительной гарантии. Рабочая тетрадь Fudgenta, новинка от Рошен

Fudgenta, новинка от Рошен Секреты успешного резюме

Секреты успешного резюме Tassimo. Тренинг по продажам

Tassimo. Тренинг по продажам План работы ПТ на 2023 г

План работы ПТ на 2023 г Бриф и аудит. Анкета клиента

Бриф и аудит. Анкета клиента Vibro mattress quotation

Vibro mattress quotation Комплексный уход за кожей лица от Орифлэйм

Комплексный уход за кожей лица от Орифлэйм Площадь прямоугольника

Площадь прямоугольника Ростовые куклы

Ростовые куклы Компания Biocad

Компания Biocad Маркетинг-план

Маркетинг-план Парфюмерия

Парфюмерия Презентация объекта ЖК Павшинская пойма город Красногорск

Презентация объекта ЖК Павшинская пойма город Красногорск Кредобанк - кращий партнер

Кредобанк - кращий партнер Календарь событий. Кыргызстан

Календарь событий. Кыргызстан Sport-X – Polska firma produkująca obuwie i odzież sportową

Sport-X – Polska firma produkująca obuwie i odzież sportową Разработка рекламной кампании для Европлан

Разработка рекламной кампании для Европлан Реклама. Функції реклами

Реклама. Функції реклами Маркетинг. Введение

Маркетинг. Введение Продажа автотранспортной техники. Ямало-Ненецкий автономный округ г. Новый Уренгой ООО Газпром добыча Уренгой

Продажа автотранспортной техники. Ямало-Ненецкий автономный округ г. Новый Уренгой ООО Газпром добыча Уренгой Город Мурманск. ТЦ Северное Нагорное. Сводный отчет

Город Мурманск. ТЦ Северное Нагорное. Сводный отчет Спутниковое ТВ для Агентского канала РФ

Спутниковое ТВ для Агентского канала РФ Преимущества комплексного интернет-маркетинга

Преимущества комплексного интернет-маркетинга Бизнес-идея. Продажа винтажных вещей на online-аукционах

Бизнес-идея. Продажа винтажных вещей на online-аукционах Компания Global Exterior. Благоустройство городской среды

Компания Global Exterior. Благоустройство городской среды