Содержание

- 2. OPERATOR 413

- 3. TECHNICAL SPECIFICATIONS Operator with “OFF-AXIS” thrust Available in versions 230V and 24V Available in versions with

- 4. Release device –key protected and easy to operate Numbered locks 1-36 (optional) OPERATOR 413

- 5. Limit switch 24 Vdc power supplied to guarantee the highest security Possibility for management of “stops”

- 6. Horizontal cable exit for installations close to the ground Predisposition for the use of the “Gatecoder”

- 7. RANGE 413

- 8. OPERATOR 415

- 9. TECHNICAL SPECIFICATIONS Operator with “IN-AXIS” thrust Available in versions 230V and 24V Available in versions with

- 10. Horizontal cable exit for installations close to the ground Predisposition for the use of the “Gatecoder”

- 11. OPERATOR 415 (with carter optional)

- 12. Release device –key protected and easy to operate Numbered locks 1-36 (optional) OPERATOR 415

- 13. Limit switch 24 Vdc power supplied to guarantee the highest security Possibility for management of “stops”

- 14. Horizontal cable exit for installations close to the ground Predisposition for the use of the “Gatecoder”

- 15. RANGE 415

- 16. TECHNICAL REPORT SWING GATE OPERATOR ANALYSIS AMI A180 ATI A3000

- 17. vs 413 CAME BX-A 1) See the test results AMI A180

- 18. AMI A180

- 19. PROTECTION CLASS IP

- 20. Connection terminal board Stator Limit switch power supply 230V PROTECTION IP

- 21. Very few protection of the reduction gearing due to type of cover and lack of joints

- 22. Electric limit switch only in opening, INTERFERES IN THE MOTOR PHASE, PROTECTION CLASS IP20. In the

- 23. The worm screw is made of “normal” steel and protected only by a burnishing treatment (normally

- 24. Functioning test executed on gate LP001 2m leaf weight kg. 360 Start test 23-09-04 End of

- 25. vs 415 CAME BX-A 1) See the test results ATI A3000

- 26. AMI A3000 AMI A5000

- 27. NB.: no models available with mechanical stops ANALYSIS TECHNICAL SPECIFICATIONS

- 28. PROTECTION IP

- 29. Concept and matching of the carter imply low protection of the complete reduction group. H2O IP

- 30. The normative requires expressly that “the apparatus needs to be provided with fixing devices for the

- 31. MOTION TRANSMISSION BETWEEN ROTOR AND EPICYCLOIDAL REDUCTION Motion transmission between rotor e epicycloidal reduction through plastic

- 32. Epicycloidal reduction, locking system through electro brake. The electrobrake keeps the rotor stopped by friction, therefore

- 33. The motor lock is given by the electric brake acting on the rotor, while the release

- 34. ELECTRIC LIMIT SWITCH Electric limit switch in version 230V INTERFERES ON THE MOTOR PHASE, PROTECTION CLASS

- 35. REGULATION OF THE ELECTRIC END TRAVELS In order to regulate the electric limit switches, it is

- 36. WORM SCREW The worm screw is made of “normal” steel and protected only by a burnishing

- 37. The screw covering solution, although it does not guarantee an efficient protection against screw oxidation, can

- 38. Execution test of functioning on gate LP011 with 4m leaf and weight kg. 250 Start 1°

- 39. TECHNICAL REPORT SWING GATE OPERATOR ANALYSIS PLUTO PL4005 MOBY 4006 WINGOKIT

- 40. MOBY

- 41. vs 415 CAME BX-A 1) See the test results MOBY MB4005

- 42. Max. leaf for serie 5000 with max. length m 3,75 For leaf max.m. 5: in order

- 43. H2O entrance H2O entrance H2O entrance H2O entrance PROTECTION IP

- 44. The Moby model range exists only in version with electric limit switches, BY INTERRUPTING THE PHASE,

- 45. The “exclusive” Nice release is certainly easy to operate, but unfortunately it remains in up position

- 46. • Worm screw in normal steel and grease as only protection (Contrary to the FAAC screws

- 47. Execution of functioning test on gate LP011 with leaf m 2,50 and weight kg. 200 Start

- 48. Entrata H2O Entrata H2O Entrata H2O Entrata H2O PROTECTION OF THE INTERNAL MECHANICS

- 49. The worm screw is in normal steel and the protection is guaranteed only by the grease

- 50. The “exclusive” Nice release is certainly easy to operate, but unfortunately it remains in up position

- 51. WINGO

- 52. vs 413 CAME BX-A 1) See the test results WINGOKIT

- 53. Remark : Among the use restrictions with leaf weight and leaf length has been indicated that

- 54. Entrance H2O Protection class IP42, please see the water signs in the motor cable area To

- 55. H2O entrance H2O entrance H2O entrance PROTECTION IP

- 56. The worm screw is in normal steel and the protection is guaranteed only by the grease

- 57. The cable connection is situated in the area of the fixation pin on the bracket without

- 58. The “exclusive” Nice release is certainly easy to operate, but unfortunately it remains in up position

- 59. NB. The water you see inside entered with closed release. The plastic carter protection is useless

- 61. Скачать презентацию

Виды излучений

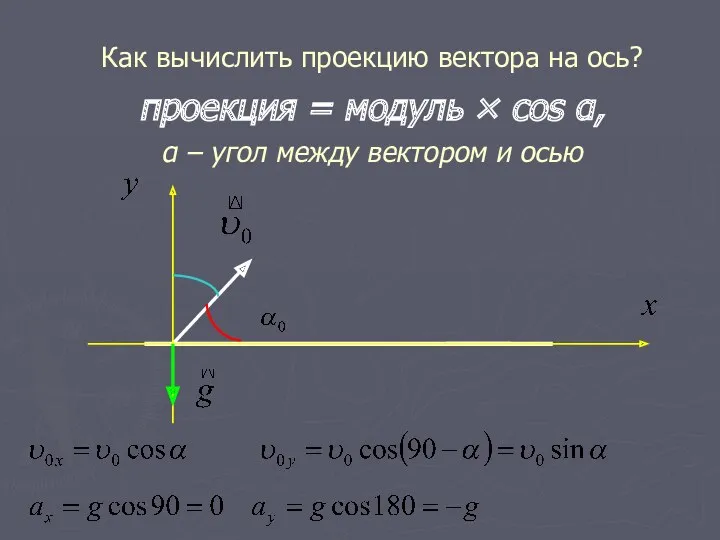

Виды излучений Как вычислить проекцию?

Как вычислить проекцию? Спутниковые системы связи

Спутниковые системы связи Випарники і повітроохолоджувачі

Випарники і повітроохолоджувачі Gas laser

Gas laser Расчет количества теплоты необходимого для нагревания тела или выделяемого им при охлаждении. Решение задач. Физика. 8 класс

Расчет количества теплоты необходимого для нагревания тела или выделяемого им при охлаждении. Решение задач. Физика. 8 класс Рентгеновское излучение

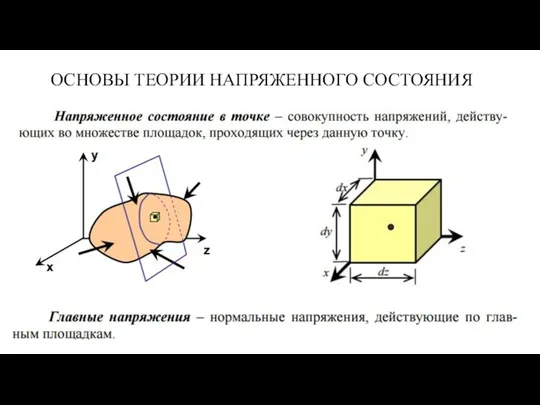

Рентгеновское излучение Основы теории напряженного состояния

Основы теории напряженного состояния Физические величины. 10 класс

Физические величины. 10 класс Закон всемирного тяготения

Закон всемирного тяготения Закон Ома. Тест

Закон Ома. Тест Э.М. Спиридонов. Эволюция минералов серебра в зоне гипергенеза

Э.М. Спиридонов. Эволюция минералов серебра в зоне гипергенеза Контроль параметрів радіовипромінювання. Радіоперешкоди

Контроль параметрів радіовипромінювання. Радіоперешкоди Передача и использование электрической энергии

Передача и использование электрической энергии Сцепление. Требования к сцеплению

Сцепление. Требования к сцеплению Закон всесвітнього тяжіння. Розв’язання задач

Закон всесвітнього тяжіння. Розв’язання задач Презентация Силы в природе

Презентация Силы в природе Электрический ток в различных средах

Электрический ток в различных средах Лекция №3 (3 ). Волновые уравнения электродинамики

Лекция №3 (3 ). Волновые уравнения электродинамики Элементарные частицы

Элементарные частицы Жарықтандыру және дабылдау

Жарықтандыру және дабылдау Урок физики 7 класс Применение простых механизмов

Урок физики 7 класс Применение простых механизмов Электростатика

Электростатика Методическая разработка Проблемное обучение в преподавании физики

Методическая разработка Проблемное обучение в преподавании физики В мире звуков

В мире звуков Простые механизмы. Рычаг

Простые механизмы. Рычаг Токарно-винторезный станок мод. 16К20

Токарно-винторезный станок мод. 16К20 Урок-путешествие. Электричество 8 класс

Урок-путешествие. Электричество 8 класс