Содержание

- 2. www.sfcnclaser.com I. Product introduction...........................................02 II.Technical Parameter ...........................................03 III.Configuration.......................................................05 IV.Main Features.......................................................06 V.Cutting Capability and Application....................11 VI.Cost........................................................................16 VII.Bed

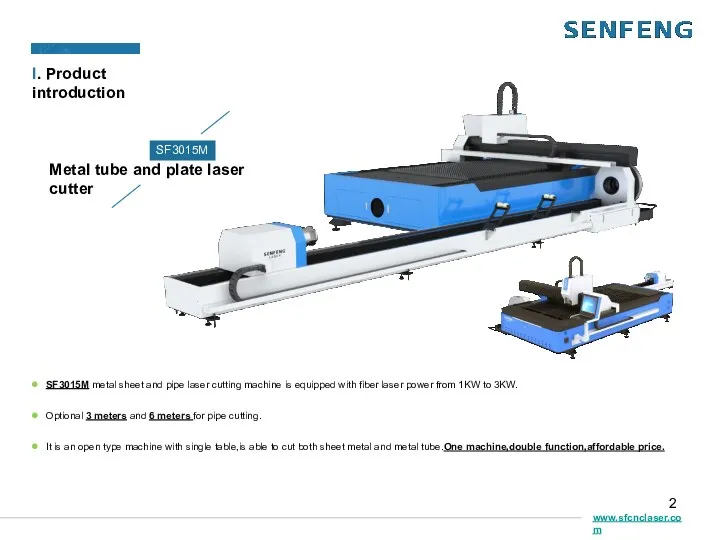

- 3. www.sfcnclaser.com I. Product introduction SF3015M metal sheet and pipe laser cutting machine is equipped with fiber

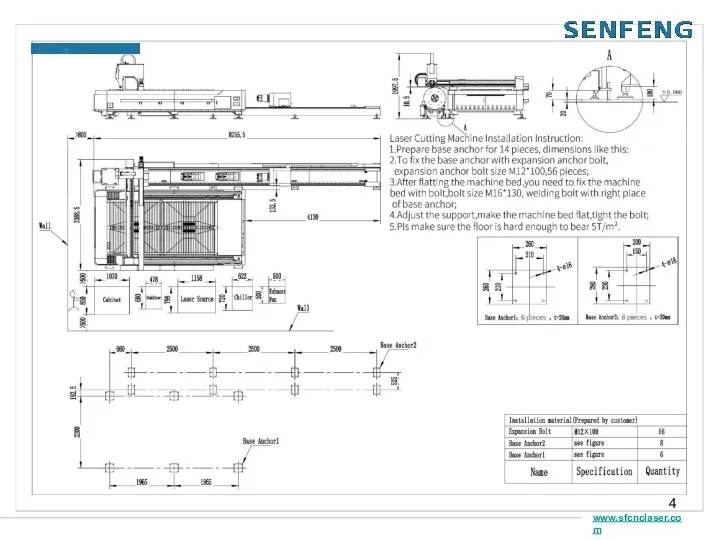

- 4. www.sfcnclaser.com II.Technical Parameter

- 5. www.sfcnclaser.com

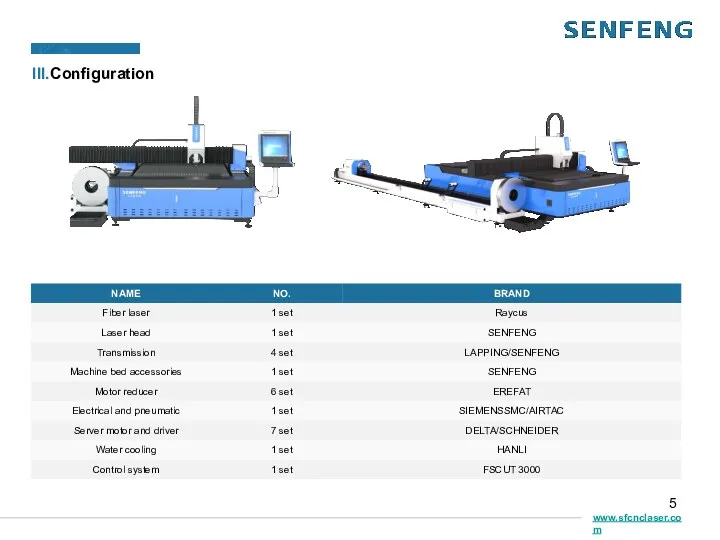

- 6. www.sfcnclaser.com III.Configuration

- 7. www.sfcnclaser.com IV.Main Features High strength machine bed High-strength machine tool, adopting 600℃ high temperature annealing treatment,

- 8. www.sfcnclaser.com SF3015M CNC laser cutting machine is equipped with three different gases, namely air, nitrogen (300psi)

- 9. www.sfcnclaser.com Raycus Laser Device FSCUT3000S medium and low power laser cutting system The FSCUT3000S mid-power laser

- 10. www.sfcnclaser.com Transmission System High precision, long life, can provide rigorous support for quenching helical gears and

- 11. www.sfcnclaser.com Height Controller High precision, long life, can provide rigorous support for quenching helical gears and

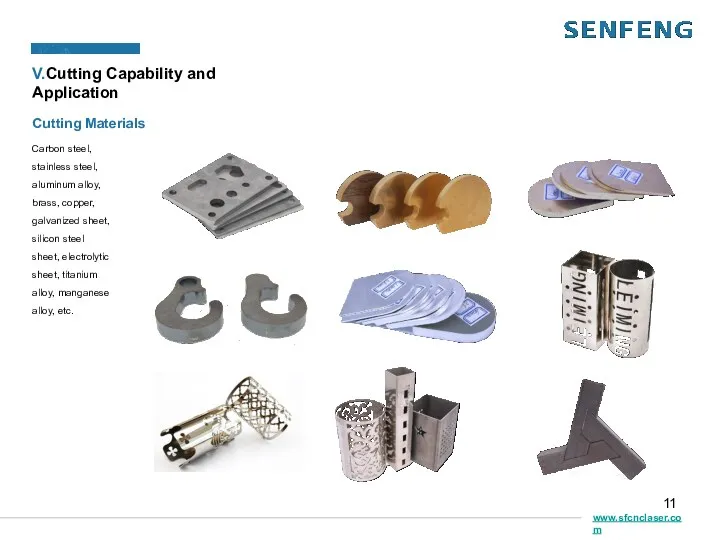

- 12. www.sfcnclaser.com V.Cutting Capability and Application Cutting Materials Carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized

- 13. www.sfcnclaser.com Sheet Metal Fabrication Mechanical processing Advertising industry Refrigeration equipment Manufacturing industry Application Industry Food machinery

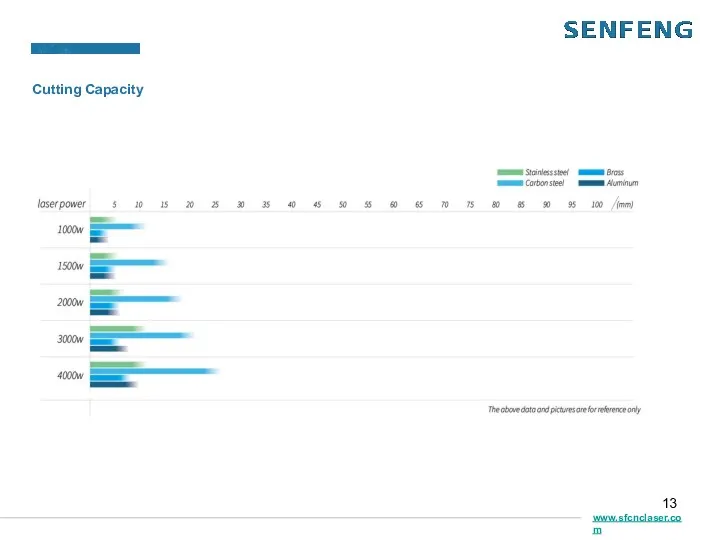

- 14. www.sfcnclaser.com Cutting Capacity

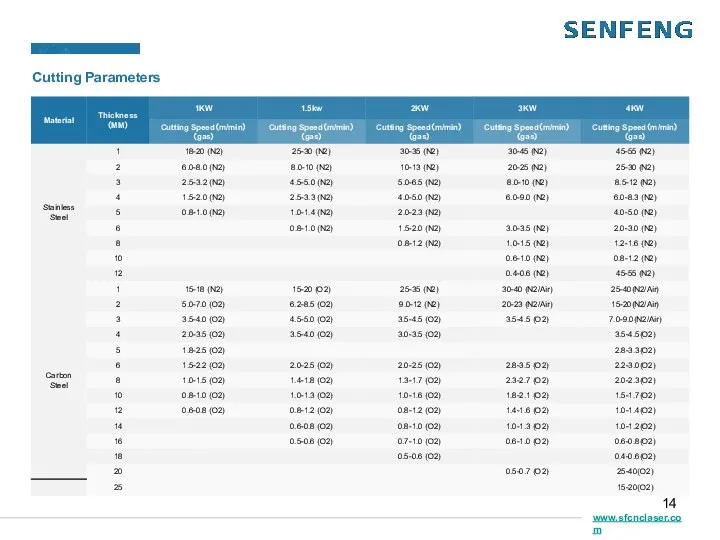

- 15. www.sfcnclaser.com Cutting Parameters

- 16. www.sfcnclaser.com Cutting Parameters

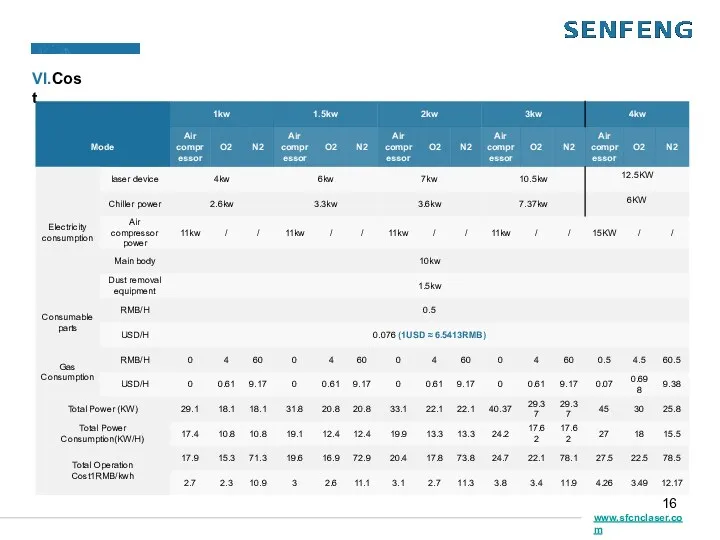

- 17. www.sfcnclaser.com VI.Cost

- 18. www.sfcnclaser.com VII.Bed body processing process Metal Cutting The raw materials for machine bed welding are all

- 19. www.sfcnclaser.com Shot Blasting It can clear the excess rust layer, oxide skin and oil stains on

- 20. www.sfcnclaser.com VIII.Product Certification Senfeng fiber laser machines have passed CE from TÜV,ROHS,FDA,ETL certificates, which is in

- 21. www.sfcnclaser.com IX .5 Star Service High efficiency 24 hours a day (mainly for international), 7 days

- 22. www.sfcnclaser.com Worry-free Pre-sale service: theoretical + practical operation training, self-diagnosis training for common faults, guidance for

- 23. www.sfcnclaser.com X.Customer Testimonials SENFENG LASER

- 24. www.sfcnclaser.com XI.Trade show SENFENG LASER

- 25. www.sfcnclaser.com XII.Company Strength Senfeng Laser is a leading manufacturer engaged in the research, development, Production, sale

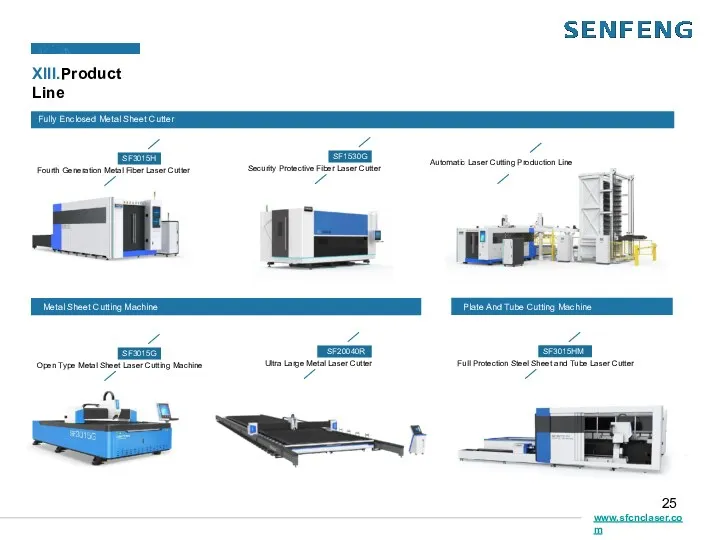

- 26. www.sfcnclaser.com XIII.Product Line Fully Enclosed Metal Sheet Cutter Metal Sheet Cutting Machine Plate And Tube Cutting

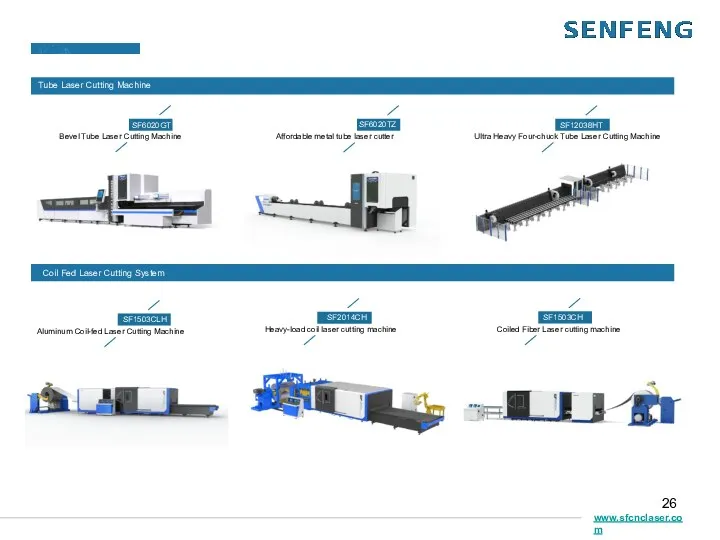

- 27. www.sfcnclaser.com Tube Laser Cutting Machine Coil Fed Laser Cutting System

- 28. www.sfcnclaser.com Fiber Laser Welding Machine / Fiber Laser Cleaning Machine 3D Robot

- 29. www.sfcnclaser.com Laser Cladding Equipment Metal sheet bending machine Wide Belt Sheet Metal Sander

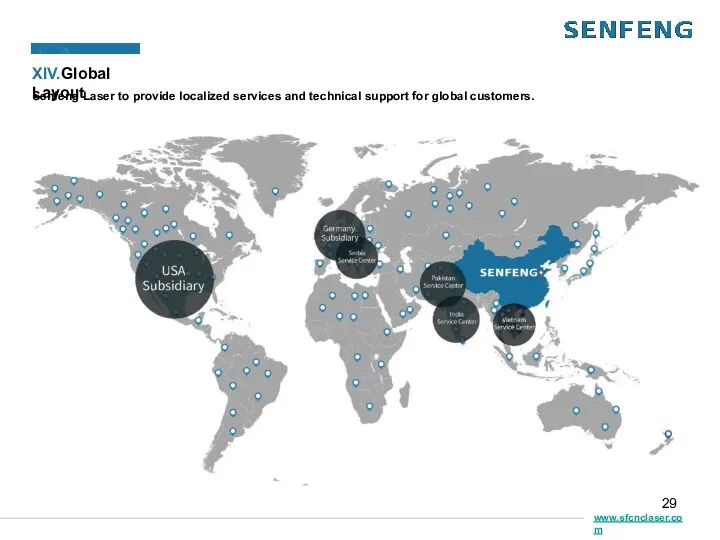

- 30. www.sfcnclaser.com XIV.Global Layout Senfeng Laser to provide localized services and technical support for global customers.

- 32. Скачать презентацию

St-Feuillien вrewery

St-Feuillien вrewery Царское вино Грузии. Традиции веков

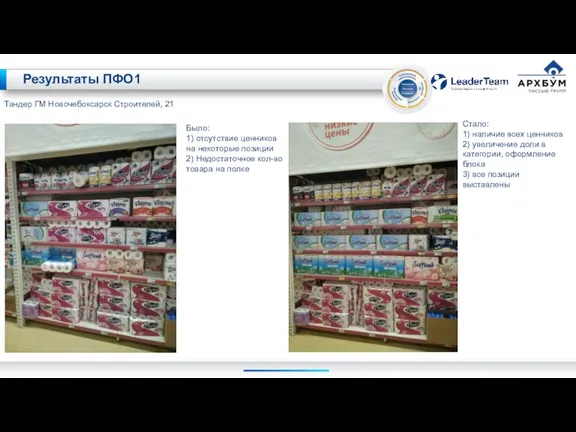

Царское вино Грузии. Традиции веков Лидер Тим. Итоги работы

Лидер Тим. Итоги работы Интернет-маркетинг

Интернет-маркетинг Школа молодого політолога

Школа молодого політолога Производственно-коммерческая фирма Интехсервис

Производственно-коммерческая фирма Интехсервис Моя профессия рекламодатель

Моя профессия рекламодатель Банкет с полным обслуживанием официантами на 40 человек, по случаю Золотой свадьбы на базе ресторана Бочонок

Банкет с полным обслуживанием официантами на 40 человек, по случаю Золотой свадьбы на базе ресторана Бочонок Для пользователей IQOS или курильщиков

Для пользователей IQOS или курильщиков Какой смартфон выбрать в 2019 году

Какой смартфон выбрать в 2019 году Здоровый сон

Здоровый сон Коммерческое предложение Синема парк в г. Красноярске

Коммерческое предложение Синема парк в г. Красноярске Dspm. Фундаментальные основы продаж

Dspm. Фундаментальные основы продаж Стратегии маркетинга территорий на примере разных стран и регионов

Стратегии маркетинга территорий на примере разных стран и регионов История Командор

История Командор Конструктор роботов ДИОЛА

Конструктор роботов ДИОЛА Логотипи та реклама фітнес-клубів

Логотипи та реклама фітнес-клубів Центр Британской книги

Центр Британской книги Презентация каталога. Такой разный Новый год: традиции празднования в разных странах мира. Зимний фестиваль красоты

Презентация каталога. Такой разный Новый год: традиции празднования в разных странах мира. Зимний фестиваль красоты Комплексное оформление праздников и различных мероприятий в Ялте

Комплексное оформление праздников и различных мероприятий в Ялте 15 главных вопросов об обоях

15 главных вопросов об обоях Реклама на автомобилях

Реклама на автомобилях Основы маркетинга

Основы маркетинга Tiens.Продукт, как качество жизни!

Tiens.Продукт, как качество жизни! Bacardi B-Black & Cuba Libre 2+1

Bacardi B-Black & Cuba Libre 2+1 Управление подписками. Новый дизайн

Управление подписками. Новый дизайн Праздник окончания учебного года

Праздник окончания учебного года Электронный рекламный буклет Творческой студии ILA

Электронный рекламный буклет Творческой студии ILA