Содержание

- 2. Copyright 2006 John Wiley & Sons, Inc. Lecture Outline Basic Layouts Designing Process Layouts Designing Service

- 3. Copyright 2006 John Wiley & Sons, Inc. Facility Layout Minimize material-handling costs Utilize space efficiently Utilize

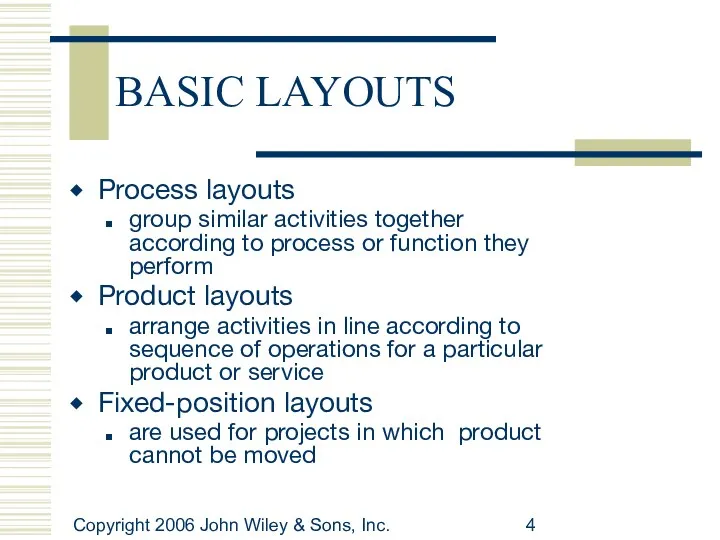

- 4. Copyright 2006 John Wiley & Sons, Inc. BASIC LAYOUTS Process layouts group similar activities together according

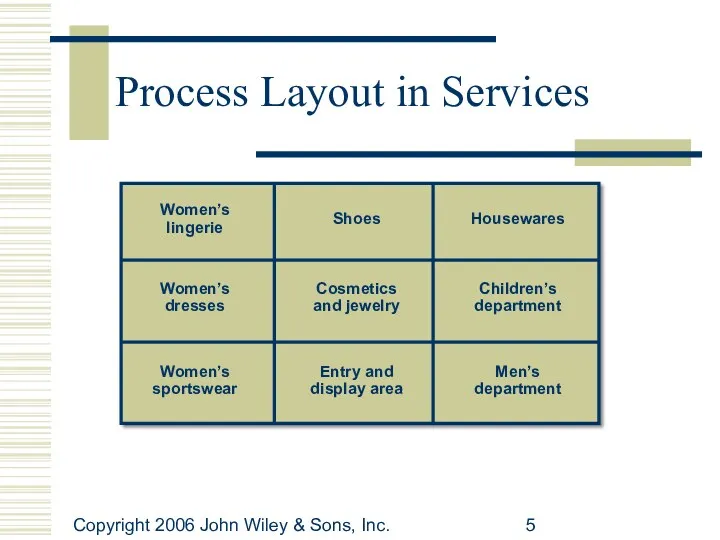

- 5. Copyright 2006 John Wiley & Sons, Inc. Process Layout in Services

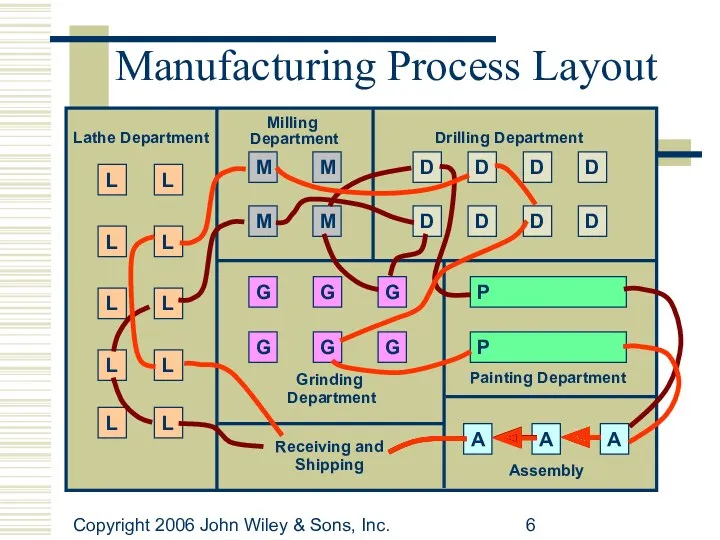

- 6. Copyright 2006 John Wiley & Sons, Inc. Manufacturing Process Layout

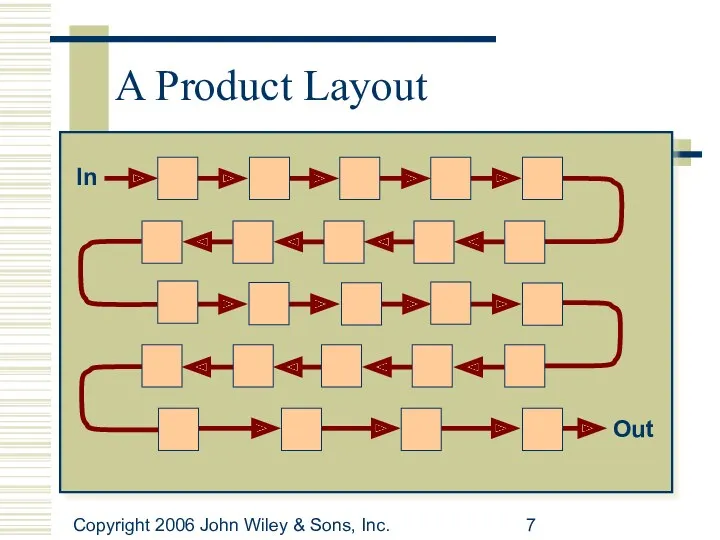

- 7. Copyright 2006 John Wiley & Sons, Inc. A Product Layout

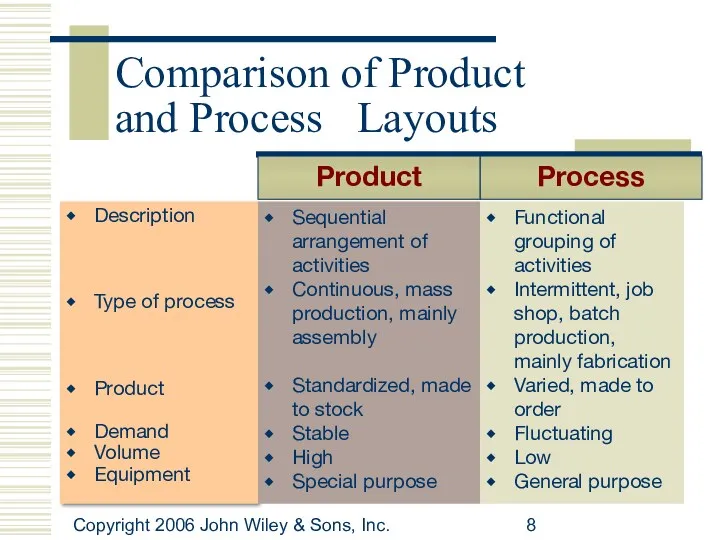

- 8. Copyright 2006 John Wiley & Sons, Inc. Description Type of process Product Demand Volume Equipment Sequential

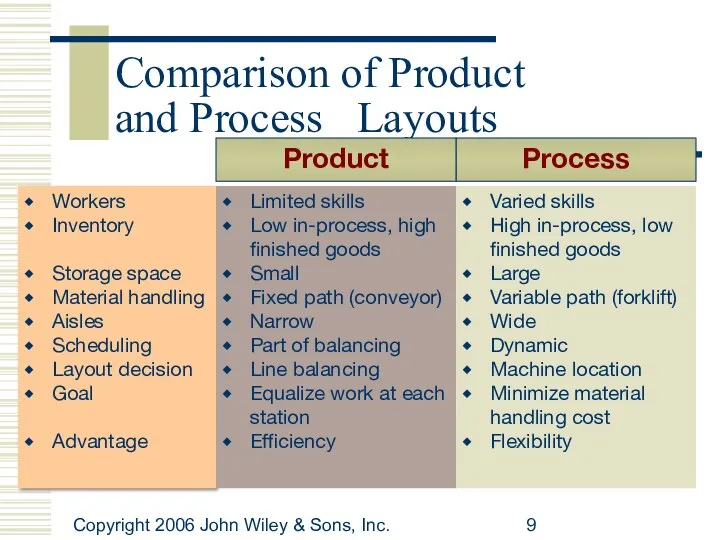

- 9. Copyright 2006 John Wiley & Sons, Inc. Workers Inventory Storage space Material handling Aisles Scheduling Layout

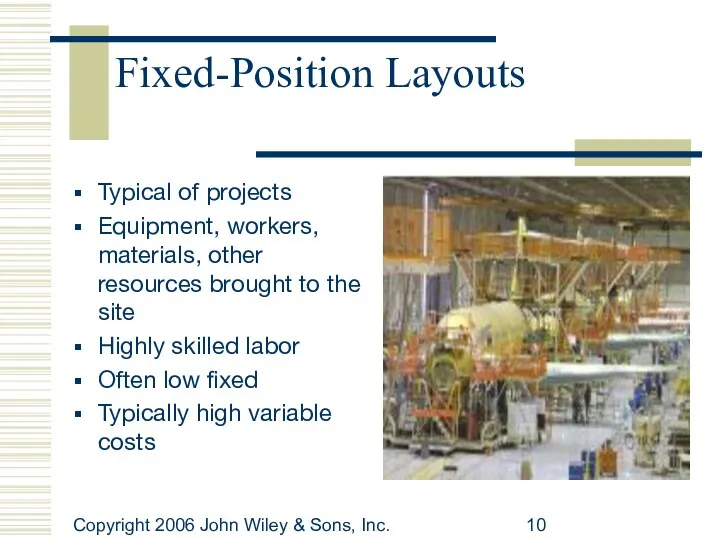

- 10. Copyright 2006 John Wiley & Sons, Inc. Fixed-Position Layouts Typical of projects Equipment, workers, materials, other

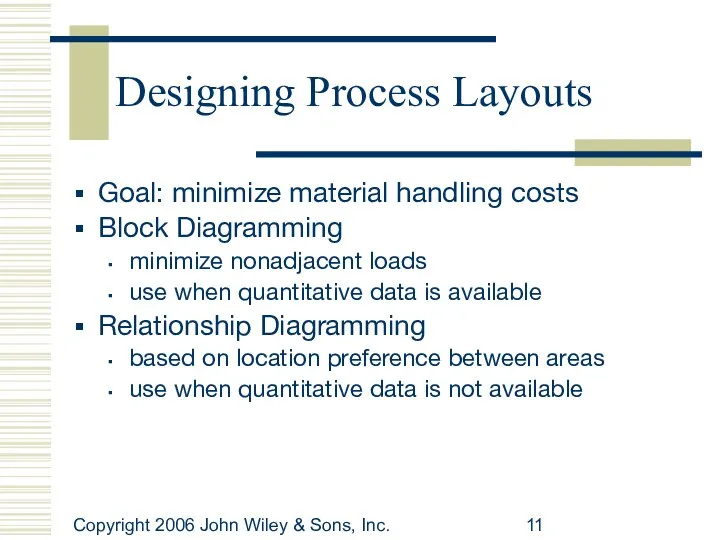

- 11. Copyright 2006 John Wiley & Sons, Inc. Designing Process Layouts Goal: minimize material handling costs Block

- 12. Copyright 2006 John Wiley & Sons, Inc. Block Diagramming Unit load quantity in which material is

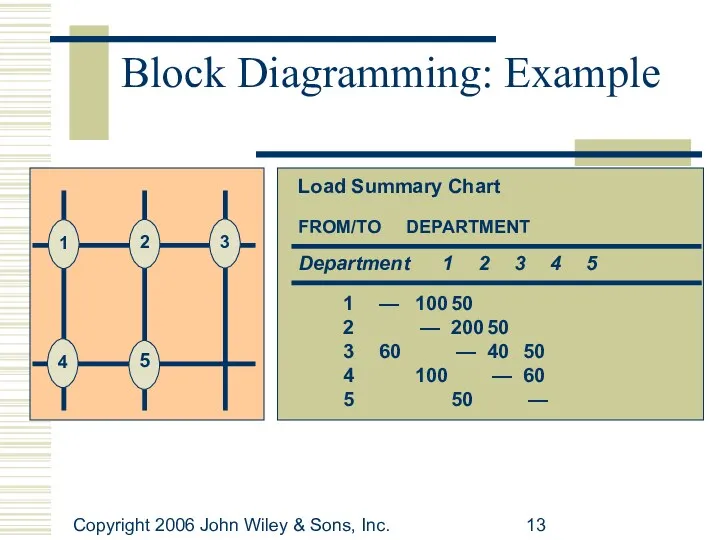

- 13. Copyright 2006 John Wiley & Sons, Inc. Block Diagramming: Example

- 14. Copyright 2006 John Wiley & Sons, Inc. Block Diagramming: Example (cont.)

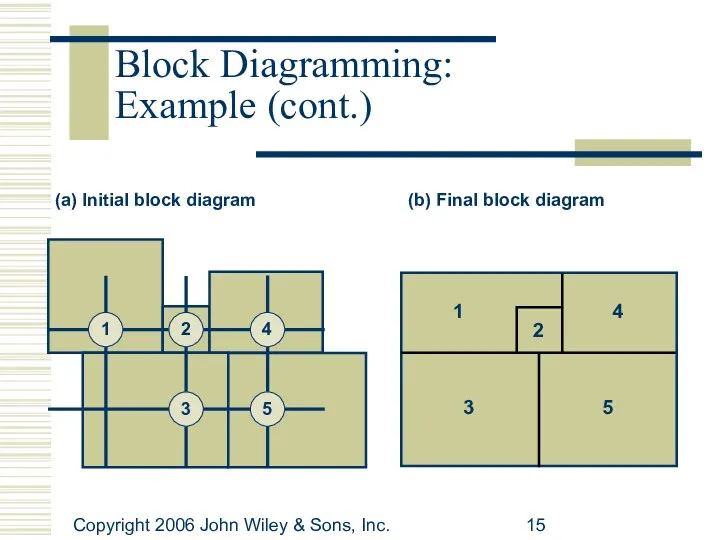

- 15. Copyright 2006 John Wiley & Sons, Inc. Block Diagramming: Example (cont.)

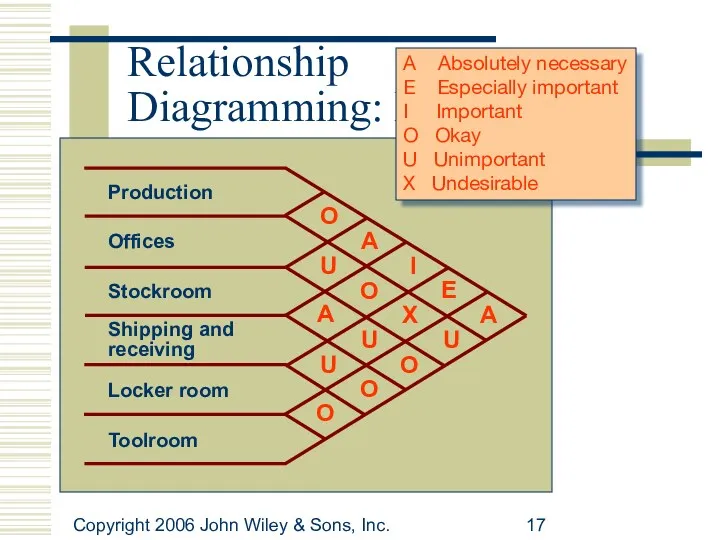

- 16. Copyright 2006 John Wiley & Sons, Inc. Relationship Diagramming Schematic diagram that uses weighted lines to

- 17. Copyright 2006 John Wiley & Sons, Inc. Relationship Diagramming: Example

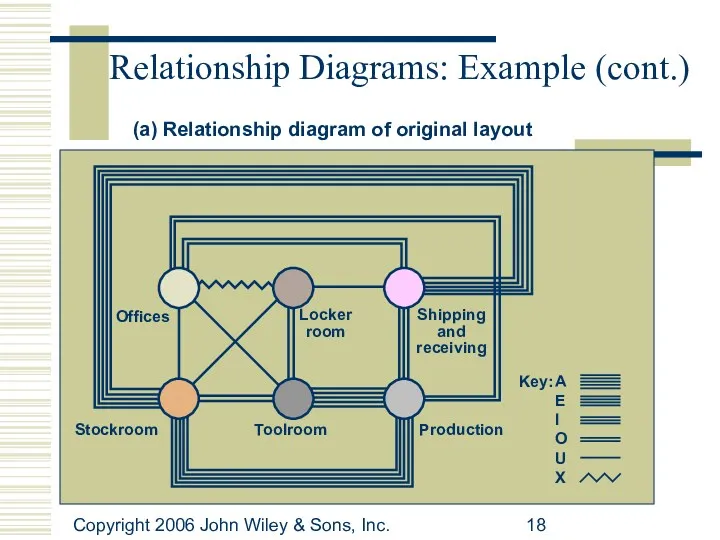

- 18. Copyright 2006 John Wiley & Sons, Inc. Relationship Diagrams: Example (cont.)

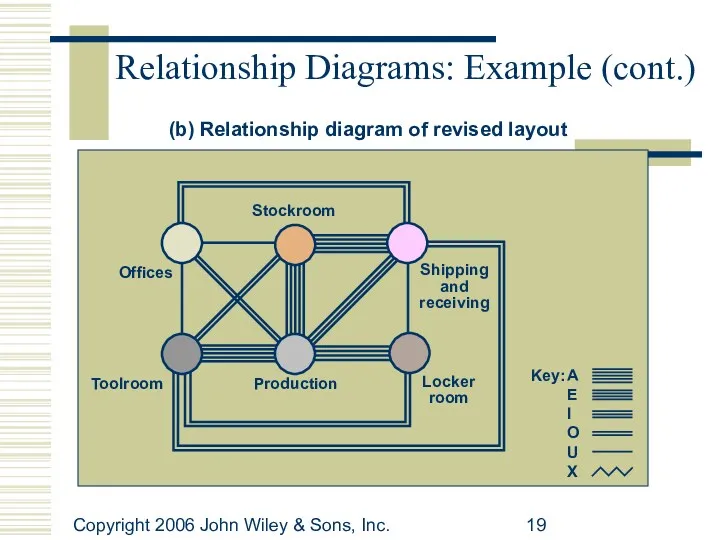

- 19. Copyright 2006 John Wiley & Sons, Inc. Relationship Diagrams: Example (cont.)

- 20. Copyright 2006 John Wiley & Sons, Inc. Computerized layout Solutions CRAFT Computerized Relative Allocation of Facilities

- 21. Copyright 2006 John Wiley & Sons, Inc. Designing Service Layouts Must be both attractive and functional

- 22. Copyright 2006 John Wiley & Sons, Inc. Types of Store Layouts

- 23. Copyright 2006 John Wiley & Sons, Inc. Designing Product Layouts Objective Balance the assembly line Line

- 24. Copyright 2006 John Wiley & Sons, Inc. Cycle Time Example

- 25. Copyright 2006 John Wiley & Sons, Inc. Flow Time vs Cycle Time Cycle time = max

- 26. Copyright 2006 John Wiley & Sons, Inc. Efficiency of Line

- 27. Copyright 2006 John Wiley & Sons, Inc. Line Balancing Procedure Draw and label a precedence diagram

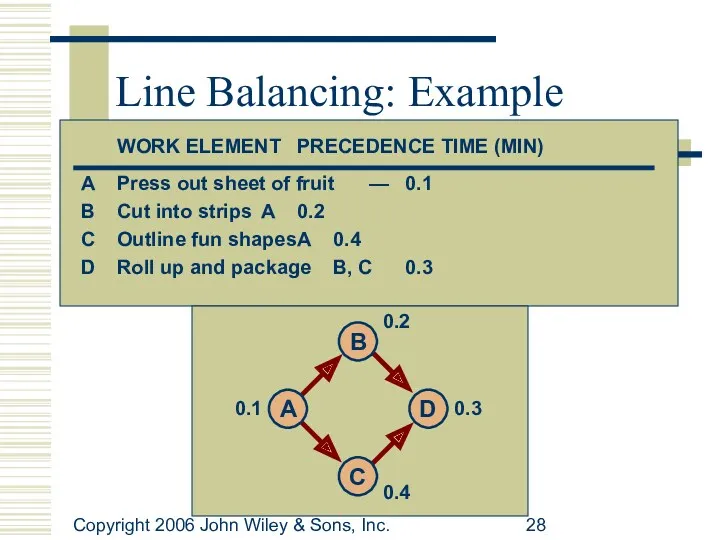

- 28. Copyright 2006 John Wiley & Sons, Inc. Line Balancing: Example

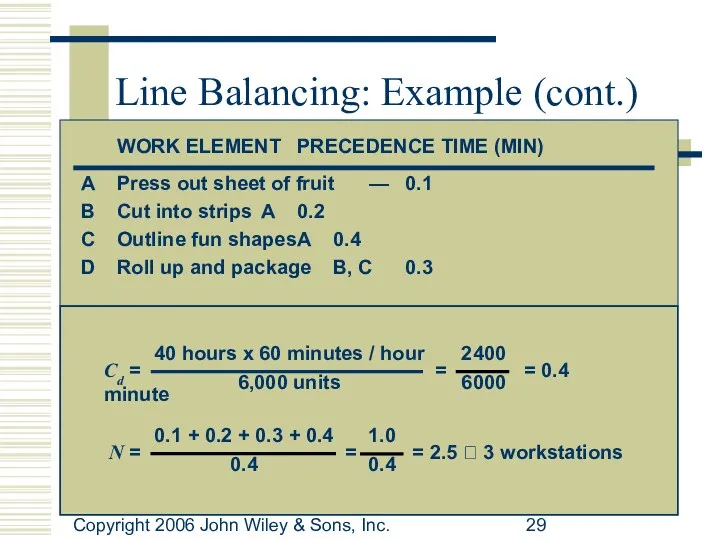

- 29. Copyright 2006 John Wiley & Sons, Inc. Line Balancing: Example (cont.)

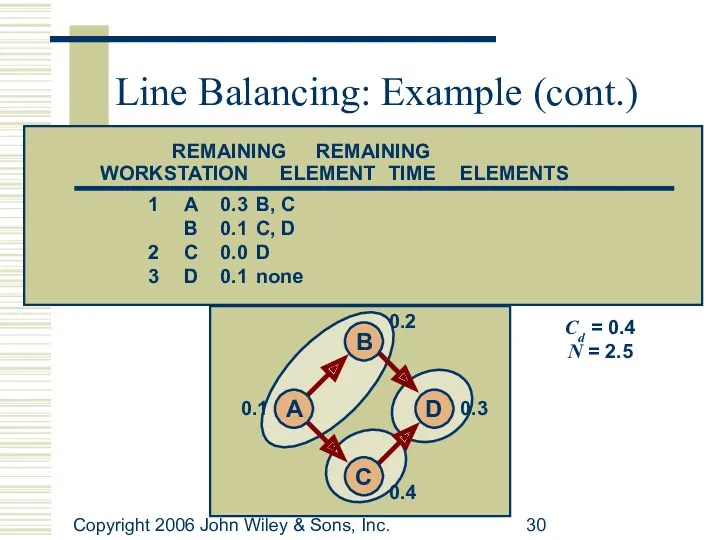

- 30. Copyright 2006 John Wiley & Sons, Inc. Line Balancing: Example (cont.) Cd = 0.4 N =

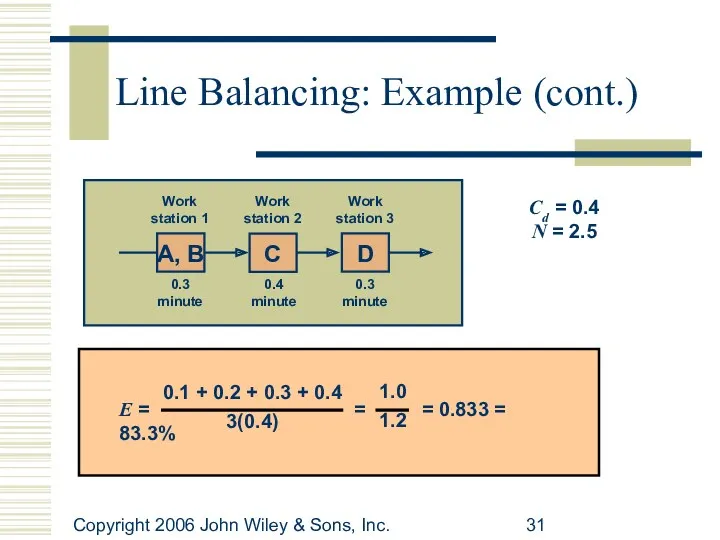

- 31. Copyright 2006 John Wiley & Sons, Inc. Cd = 0.4 N = 2.5 Line Balancing: Example

- 32. Copyright 2006 John Wiley & Sons, Inc. Computerized Line Balancing Use heuristics to assign tasks to

- 33. Copyright 2006 John Wiley & Sons, Inc. Hybrids Layouts Cellular layouts group dissimilar machines into work

- 34. Copyright 2006 John Wiley & Sons, Inc. Cellular Layouts Identify families of parts with similar flow

- 35. Copyright 2006 John Wiley & Sons, Inc. Parts Families

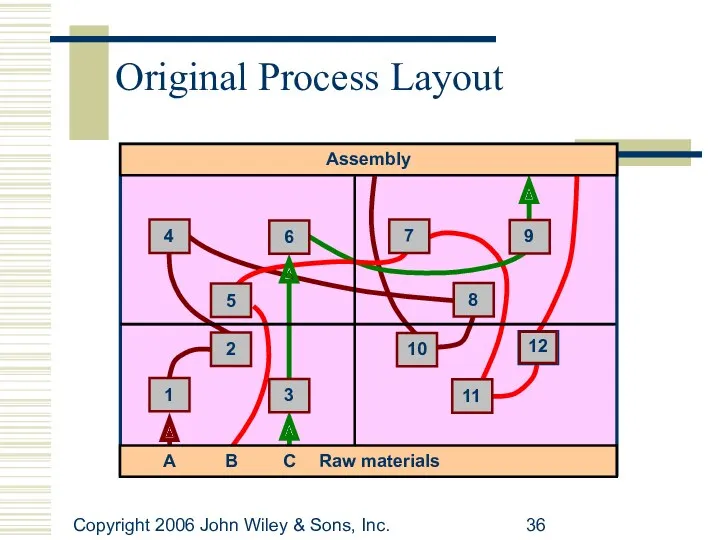

- 36. Copyright 2006 John Wiley & Sons, Inc. Original Process Layout

- 37. Copyright 2006 John Wiley & Sons, Inc. Part Routing Matrix Figure 5.8

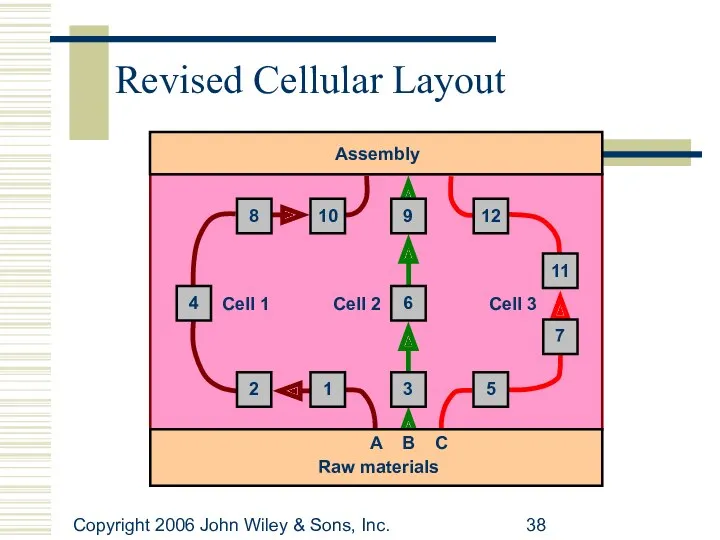

- 38. Copyright 2006 John Wiley & Sons, Inc. Revised Cellular Layout

- 39. Copyright 2006 John Wiley & Sons, Inc. Reordered Routing Matrix

- 40. Copyright 2006 John Wiley & Sons, Inc.

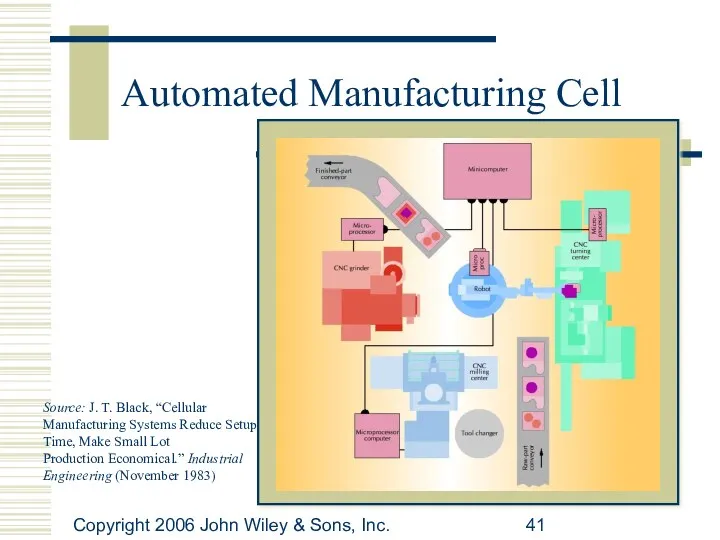

- 41. Copyright 2006 John Wiley & Sons, Inc. Automated Manufacturing Cell

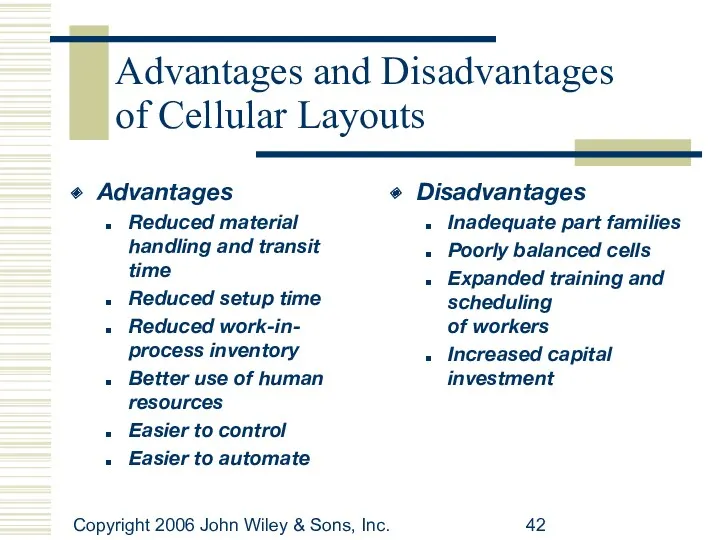

- 42. Copyright 2006 John Wiley & Sons, Inc. Advantages and Disadvantages of Cellular Layouts Advantages Reduced material

- 43. Copyright 2006 John Wiley & Sons, Inc. Flexible Manufacturing Systems (FMS) FMS consists of numerous programmable

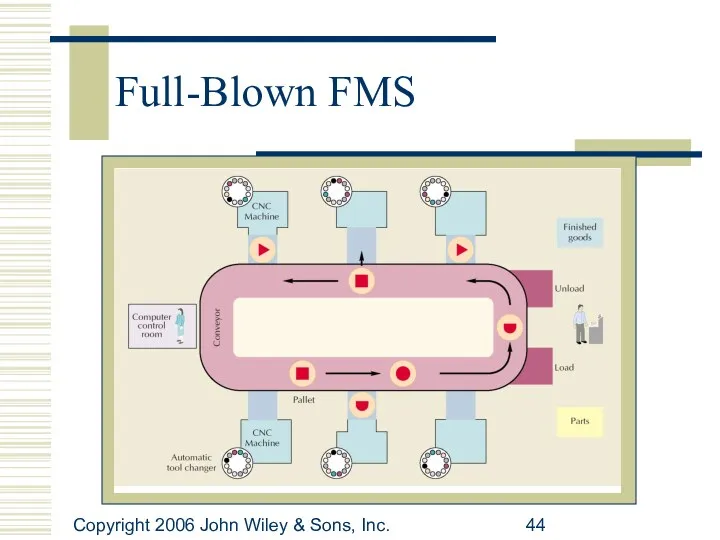

- 44. Copyright 2006 John Wiley & Sons, Inc. Full-Blown FMS

- 45. Copyright 2006 John Wiley & Sons, Inc. Mixed Model Assembly Lines Produce multiple models in any

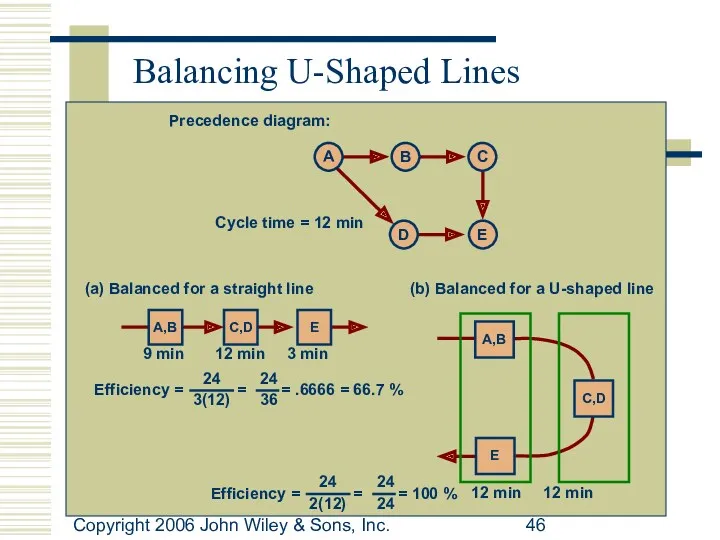

- 46. Copyright 2006 John Wiley & Sons, Inc. Balancing U-Shaped Lines

- 48. Скачать презентацию

Формулирование стратегии

Формулирование стратегии Планирование и развитие деловой карьеры. Высвобождение работников

Планирование и развитие деловой карьеры. Высвобождение работников How can you become a better recruiter and get even paid for it?

How can you become a better recruiter and get even paid for it? Компания ООО ИК СИБИНТЕК. Вакансии и карьера в компании

Компания ООО ИК СИБИНТЕК. Вакансии и карьера в компании Работа с возражениями и с сомнениями

Работа с возражениями и с сомнениями Методики анализа состояния внешней среды компании

Методики анализа состояния внешней среды компании Как получить работу мечты в ВТБ

Как получить работу мечты в ВТБ Організація обслуговування споживачів за місцем навчання та відпочинку

Організація обслуговування споживачів за місцем навчання та відпочинку Инвентаризация. Что такое инвентаризация

Инвентаризация. Что такое инвентаризация Составление номенклатуры дел

Составление номенклатуры дел Подготовка и проведение собраний, совещаний и конференций

Подготовка и проведение собраний, совещаний и конференций The Role of Financial Management

The Role of Financial Management Стратегическое управление персоналом в организации

Стратегическое управление персоналом в организации Современные технологии подбора персонала

Современные технологии подбора персонала Эффективные коммуникации по телефону для внутреннего пользования. eCall

Эффективные коммуникации по телефону для внутреннего пользования. eCall Понятие и виды деловой карьеры

Понятие и виды деловой карьеры Методологічні основи планування діяльності підприємства

Методологічні основи планування діяльності підприємства Контрольный листок качества

Контрольный листок качества Что такое команда. Роли в команде. (Тема 7)

Что такое команда. Роли в команде. (Тема 7) SWOT-анализ

SWOT-анализ Архитектура предприятия

Архитектура предприятия Логистика складирования

Логистика складирования Теории мотивации. Содержательная и процессуальная теории мотивации

Теории мотивации. Содержательная и процессуальная теории мотивации Практическое задание: командообразование

Практическое задание: командообразование 1С Управление автотранспортом (1С УАТ)

1С Управление автотранспортом (1С УАТ) Процеси управління стратегічними ресурсами будівельної компанії ТОВ БК Пролетар

Процеси управління стратегічними ресурсами будівельної компанії ТОВ БК Пролетар Концепции управления персоналом

Концепции управления персоналом Сапалы медициналық қызмет көрсетуде сапс менеджмент жүйесінiң орны

Сапалы медициналық қызмет көрсетуде сапс менеджмент жүйесінiң орны