Содержание

- 2. Definitions Logistics: the science of the efficient flow of materials. That is; all the activities, which

- 3. Definitions Supply Chain Management: is used as a similar concept, but emphasize the significance of integrating

- 4. Logistics as a system Logistics is an open system that has en exchange with its surroundings

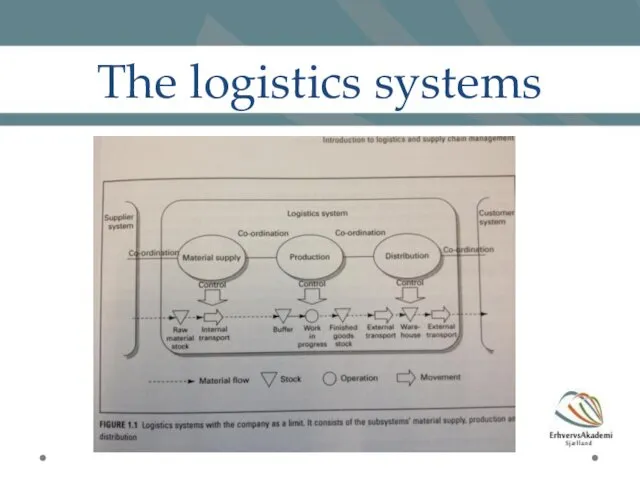

- 5. The logistics systems

- 6. Goals of logistics The goal is to create competitiveness and improve efficiency that positively affect profits

- 7. Goals of logistics The goal is to create competitiveness and improve efficiency that positively affect profits

- 8. Exercise: Conflicting goals Goal conflicts are not uncommon between the marketing and production functions of a

- 9. Distribution structures Chapter 10 Distribution structure design and the role of distribution for supply chain value

- 10. Distribution utility values Activities in a supply chain are aimed at satisfying customers’ needs by supplying

- 11. Division of utilities Division of utility-performing activities divided between functions in a company* But it can

- 12. The distribution gaps The division of activities in the supply chain to create utility is one

- 13. Five gaps Manufacturer vs. customer Pace gap – different intervals Distance gap – few locations vs.

- 14. The intermediary roles Intermediaries are players that carry out distribution functions between producers and consumers. They

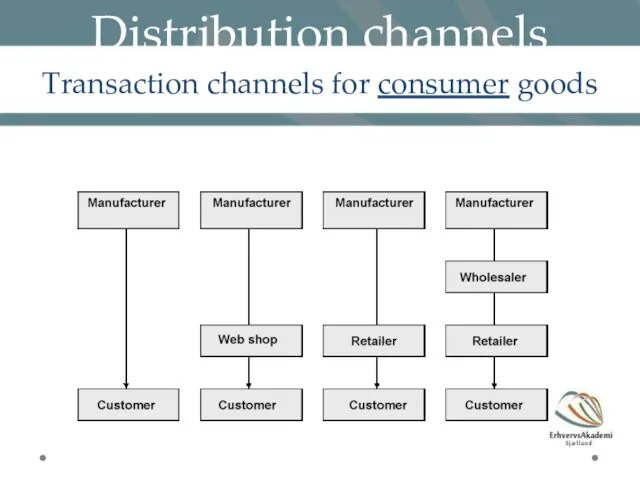

- 15. Distribution channels Transaction channels for consumer goods

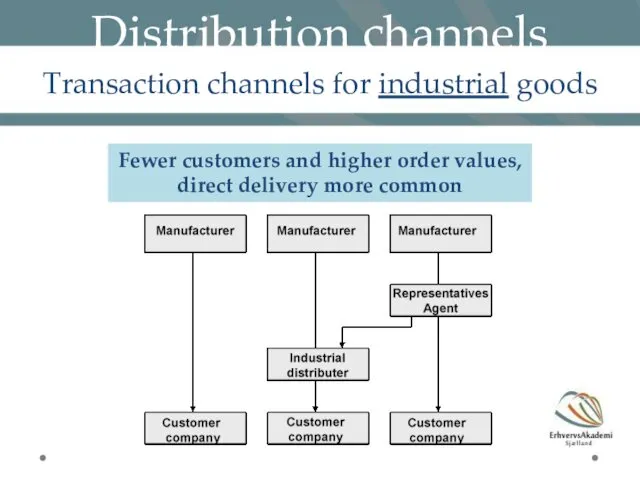

- 16. Distribution channels Transaction channels for industrial goods Fewer customers and higher order values, direct delivery more

- 17. Customer Order Decoupling Point (CODP) The point in the supply chain from which a product is

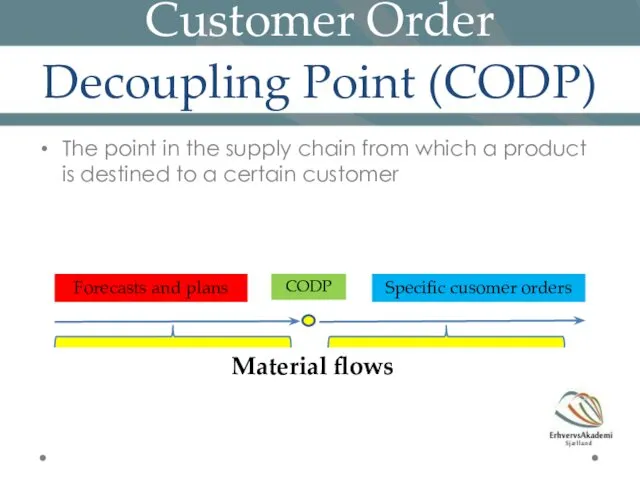

- 18. Material flows in distribution channels When the transaction channel and the material flow channel are separated,

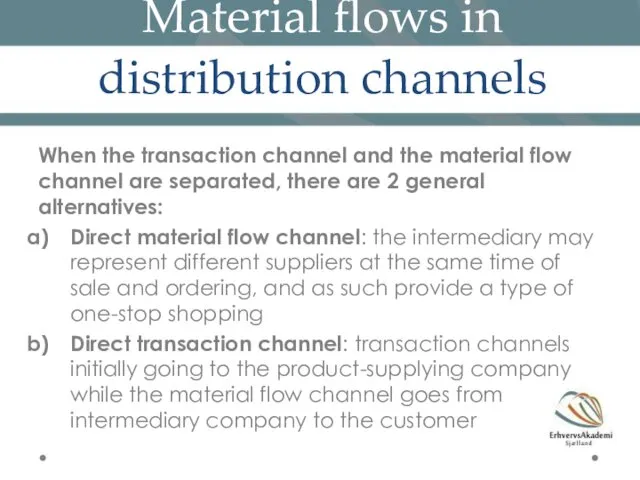

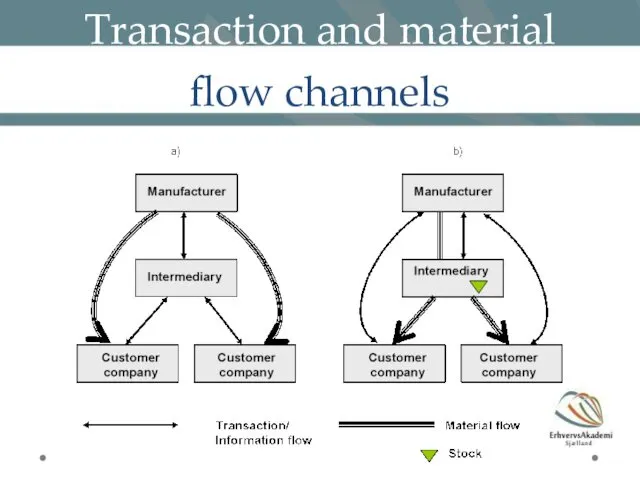

- 19. Transaction and material flow channels

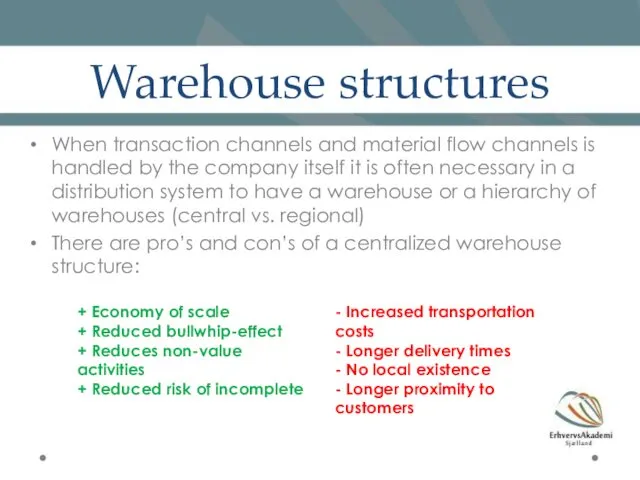

- 20. Warehouse structures When transaction channels and material flow channels is handled by the company itself it

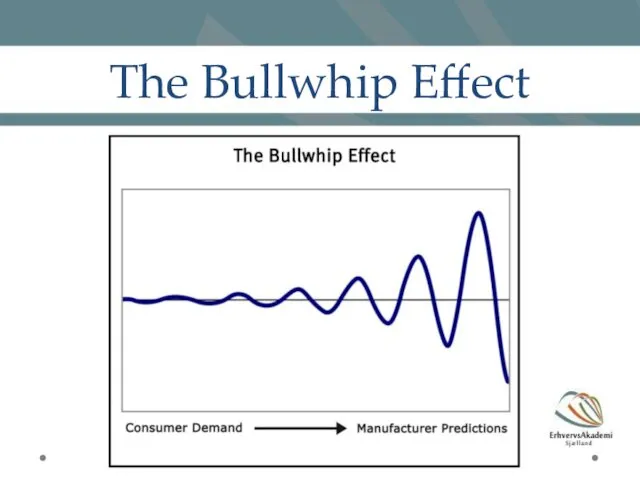

- 21. eThe Bullwhip Effect Demand variability increases as one moves up the supply chain away from the

- 22. The Bullwhip Effect

- 23. The Bullwhip Effect http://www.youtube.com/watch?v=wLNdDSYqhNw

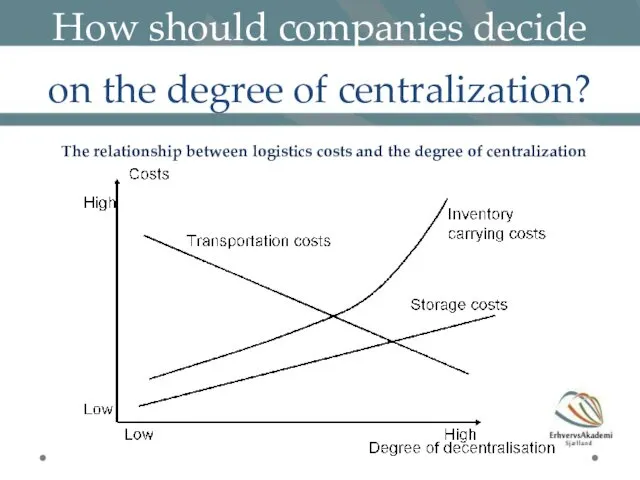

- 24. How should companies decide on the degree of centralization? The relationship between logistics costs and the

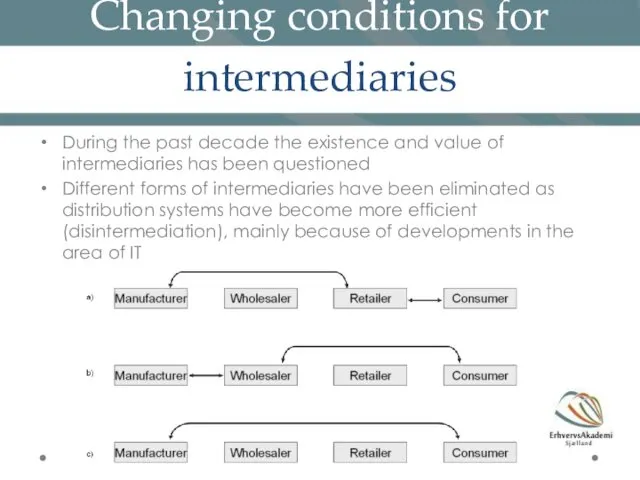

- 25. Changing conditions for intermediaries During the past decade the existence and value of intermediaries has been

- 27. Скачать презентацию

Протек. Папка нового сотрудника

Протек. Папка нового сотрудника Связующие процессы в управлении. Коммуникационный процесс. Процесс принятия решений

Связующие процессы в управлении. Коммуникационный процесс. Процесс принятия решений Понятие профессиональной компетентности, подходы к определению компонентов профессиональной компетенции

Понятие профессиональной компетентности, подходы к определению компонентов профессиональной компетенции Эффективные методы тайм-менеджмента

Эффективные методы тайм-менеджмента Особенности этики делового общения в Японии

Особенности этики делового общения в Японии Регулирование оплаты труда. Грейдинг в системе управления персоналом. Тема 13

Регулирование оплаты труда. Грейдинг в системе управления персоналом. Тема 13 История становления менеджмента качества

История становления менеджмента качества Підхід “Кейс-менеджмент” при здійсненні соціальної роботи безпосередньо у місцевій громаді

Підхід “Кейс-менеджмент” при здійсненні соціальної роботи безпосередньо у місцевій громаді Samsung. История развития. Схема управления. Система ценностей

Samsung. История развития. Схема управления. Система ценностей Управление персоналом. Лидерство

Управление персоналом. Лидерство Анализ и совершенствование кадрового планирования в организации

Анализ и совершенствование кадрового планирования в организации Overbooking або подвійне бронювання

Overbooking або подвійне бронювання Стратегия управления персоналом. Кадровая политика организации

Стратегия управления персоналом. Кадровая политика организации Удосконалення мотиваційного механізму управління персоналом

Удосконалення мотиваційного механізму управління персоналом Управление инвестиционными проектами в строительстве в Республике Беларусь

Управление инвестиционными проектами в строительстве в Республике Беларусь Программы серии Monitor CRM

Программы серии Monitor CRM Анализ конкурентных позиций предприятия

Анализ конкурентных позиций предприятия Сущность и содержание мотивации и стимулирования трудовой деятельности

Сущность и содержание мотивации и стимулирования трудовой деятельности Тема 4.2. Коммуникативное поведение в организации. Раздел 4. Управление поведением организации

Тема 4.2. Коммуникативное поведение в организации. Раздел 4. Управление поведением организации Методика непрерывного совершенствования КАЙДЗЕН и ее применение в самоменеджменте

Методика непрерывного совершенствования КАЙДЗЕН и ее применение в самоменеджменте Теории содержания мотивации

Теории содержания мотивации Менеджмент и менеджеры

Менеджмент и менеджеры Роль технопарков в инновационном развитии страны

Роль технопарков в инновационном развитии страны Мотивация персонала. Иерархия потребностей

Мотивация персонала. Иерархия потребностей Портрет менеджера. Основные качества менеджера

Портрет менеджера. Основные качества менеджера Управление проектными рисками. Лекция 6

Управление проектными рисками. Лекция 6 Управление конфликтами в проекте

Управление конфликтами в проекте Учебник специалиста ОВЗ. День 1

Учебник специалиста ОВЗ. День 1