Содержание

- 2. TURBINE CASTING PRESENTATION

- 3. Turbine Parts Manufacturers Alliance (TPMa) is a company with two operating subsidiaries: Turbine Casting (Le Creusot,

- 4. COMPANY PROFILE French Precision Investment Casting . Started in 2004 with a Group of Casting Specialists

- 5. OVERVIEW & HISTORY Highlight Founded July 2004 Swiss based Owners Same building as previous HOWMET facility

- 6. Howmet experience: 1988 >>>> 2008 X Ray inspector (Howmet casting Le Creusot) Product engineer (Howmet Burgundy

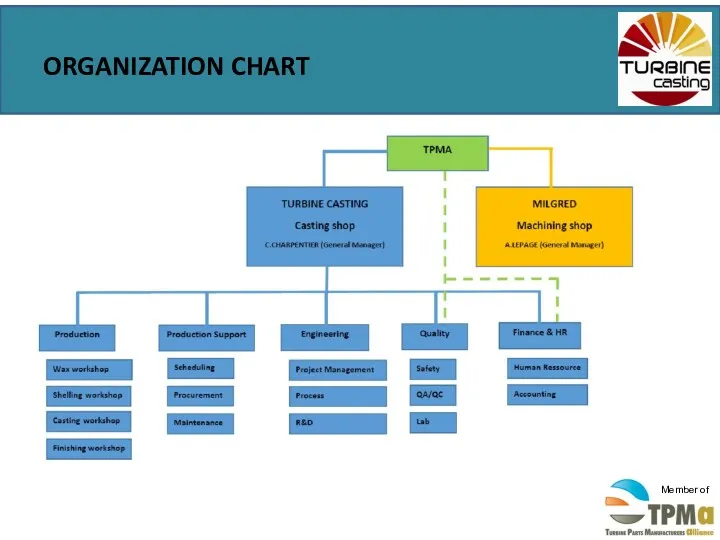

- 7. ORGANIZATION CHART

- 8. CUSTOMERS LIST

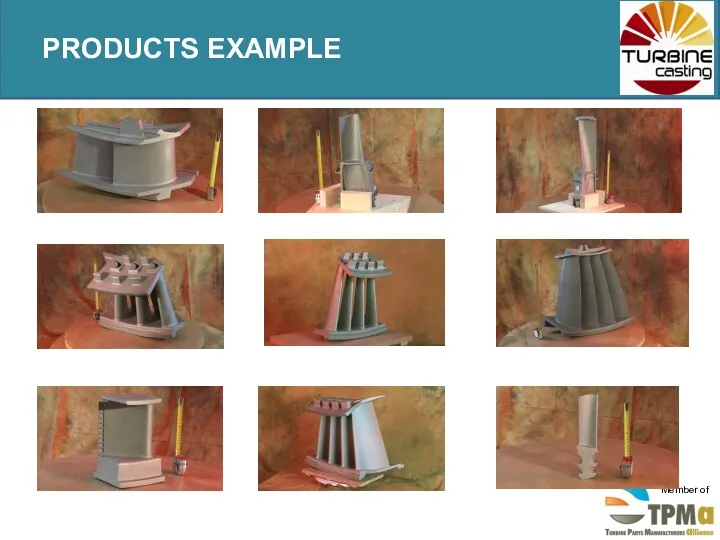

- 9. PRODUCTS EXAMPLE

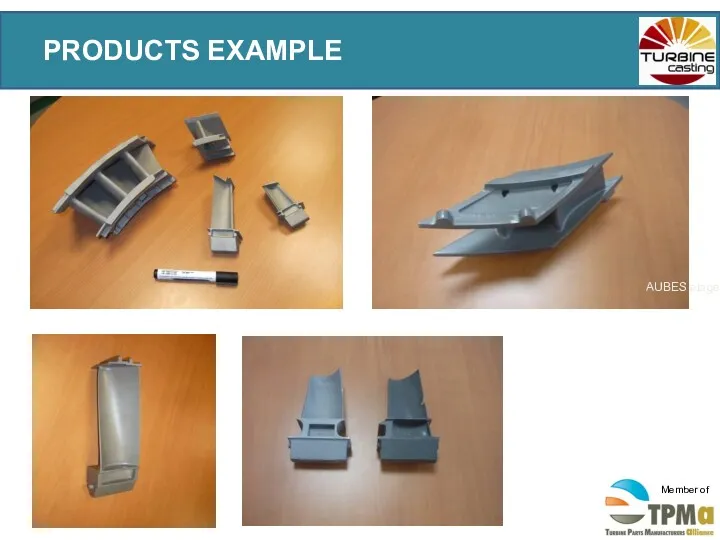

- 10. PRODUCTS EXAMPLE AUBES étage 1 GE 5001

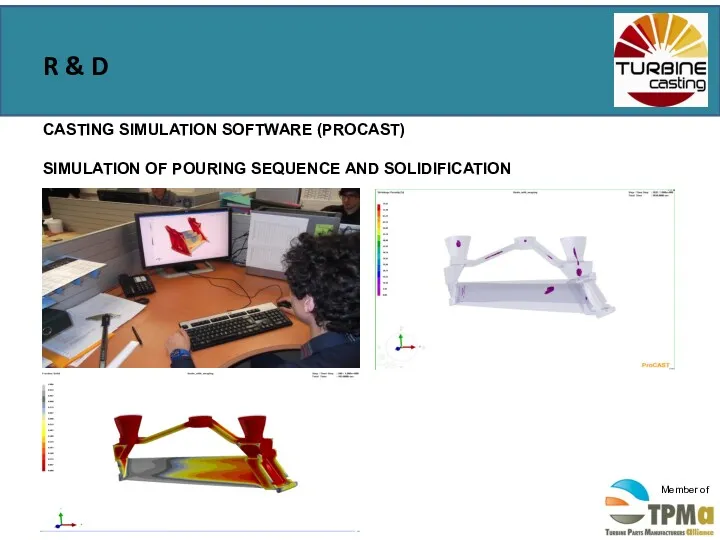

- 11. R & D CASTING SIMULATION SOFTWARE (PROCAST) SIMULATION OF POURING SEQUENCE AND SOLIDIFICATION

- 12. RAPID PROTOTYPING SOFT MATERIAL TOOLING … Additive Manufacturing SLA, Wax 3D printing Epoxy core die, Epoxy

- 13. QUALITY : METALURGICAL ANALYSIS Alloy Chemical Analysis Macrostructure ( Grain Size checking ) Microstucture (Porosity level

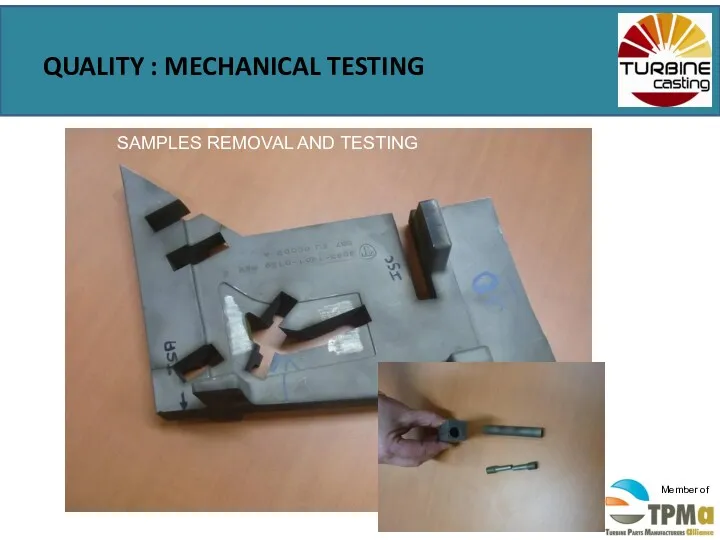

- 14. QUALITY : MECHANICAL TESTING SAMPLES REMOVAL AND TESTING

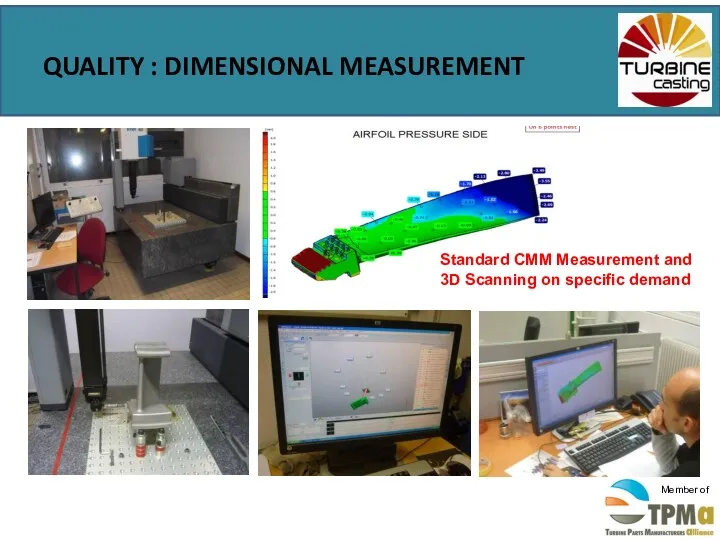

- 15. QUALITY : DIMENSIONAL MEASUREMENT SAMPLES REMOVAL AND TESTING Standard CMM Measurement and 3D Scanning on specific

- 16. QUALITY : NDT CONTROLS SAMPLES REMOVAL AND TESTING Fluorescent Penetrant Inspection (FPI)

- 17. QUALITY : NDT CONTROLS LOCAL SUBCONTRACTINGS Their fields of expertise: - Nuclear industry, production and maintenance,

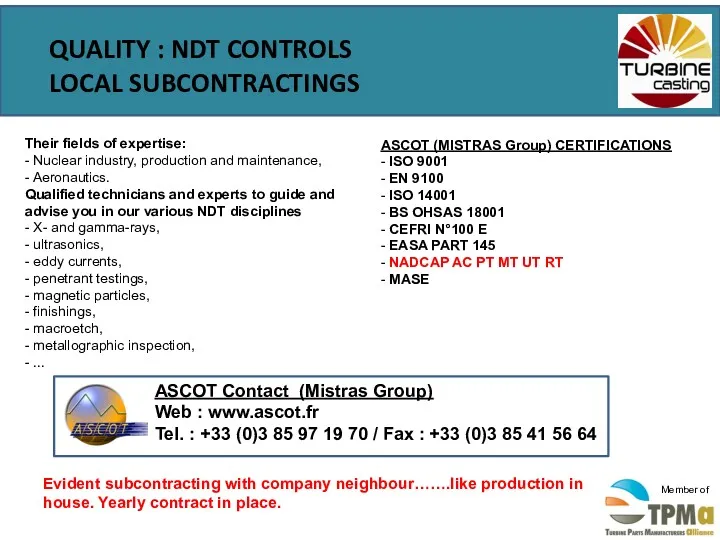

- 18. QUALITY : HIP / HT SUBCONTRACTING Hot isostatic pressure Heat Treatment Facilities of Bodycote France, Belgium

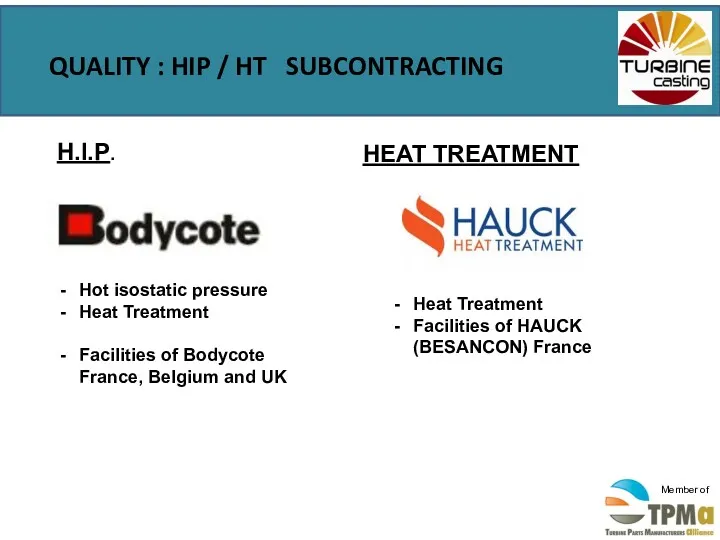

- 19. QUALITY : CERTIFICATION EN ISO 9001 & EN ISO 9100

- 20. PROCESS EQUIPMENTS : WAX INJECTION POSSIBILITIES Single Shot Injection Dies or Wax assembly versions……

- 21. PROCESS EQUIPMENTS : WAX INJECTION Wax injection : 2x 50 T injection press with shuttle tables

- 22. PROCESS EQUIPMENTS : WAX FRAZING, ASSEMBLY & CONTROLS Equipements: 15 wax working stations, 1 wax CMM

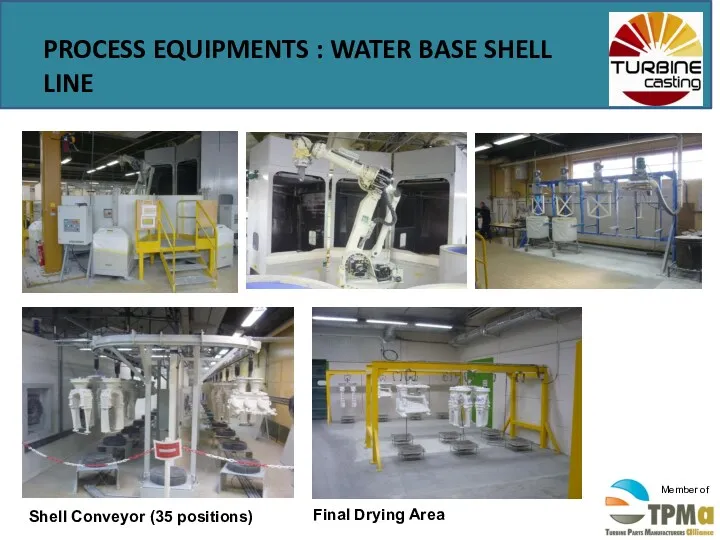

- 23. PROCESS EQUIPMENTS : WATER BASE SHELL LINE Shell Conveyor (35 positions) Final Drying Area

- 24. PROCESS EQUIPMENTS : DEWAXING AND BURN OUT Dewaxing Boilerclave Firing furnace Freezer (dewax prep)

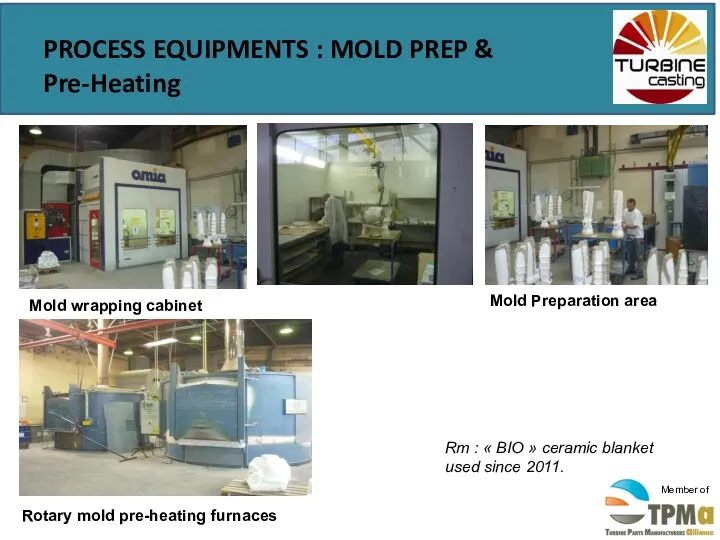

- 25. PROCESS EQUIPMENTS : MOLD PREP & Pre-Heating Rotary mold pre-heating furnaces Mold wrapping cabinet Mold Preparation

- 26. PROCESS EQUIPMENTS : CASTING CAPABILITIES EQ Vacuum Casting Furnace Air Casting Furnace CAPACITY : Pouring Weight

- 27. PROCESS EQUIPMENTS : POST-CAST Cutting Machine Automatic Shot Blasting Machine Manual Sand Blasting Machine Heat Treatment

- 28. PROCESS EQUIPMENTS : WELDING REPAIR OR INSTALLATION GTAW for repair & accessories installation

- 29. PROCESS EQUIPMENTS :INVESTMENT IN PROGRESS – Ramp-up in 2019 New VIM Furnace – Pouring weight capacity

- 31. Board Members Gordon Walsh: US citizen with many years of management experience at GE. Executive of

- 32. Sales & marketing Support team Alex Silin , Ex GE for Europe For Russia. Jean Claude

- 33. The Start. TPMa started as Casting supplier of IGT blades and vanes.. To secure growth and

- 34. TPMa Differentiators: High quality superalloy castings & advanced machining company Cost leadership in complex & Large

- 35. New markets/ Customers GE Europe/ America for Cross Fleet Ansaldo Energia for Mature Fleet. Siemens Mature

- 37. Скачать презентацию

EDU 6005-cours 7. . Introduction à la profession enseignante au primaire

EDU 6005-cours 7. . Introduction à la profession enseignante au primaire Дополнительное образование

Дополнительное образование Програма Європейського Союзу Erasmus+

Програма Європейського Союзу Erasmus+ Центр карьеры

Центр карьеры Федеральный государственный образовательный стандарт.дошкольного образования.

Федеральный государственный образовательный стандарт.дошкольного образования. Проектна діяльність учнів

Проектна діяльність учнів Структура и содержание адаптированной образовательной программы для детей с ограниченными возможностями здоровья

Структура и содержание адаптированной образовательной программы для детей с ограниченными возможностями здоровья Конкурс на лучшие комплексные междисциплинарные проекты исследований по естественно-научным и социо-гуманитарным направлениям

Конкурс на лучшие комплексные междисциплинарные проекты исследований по естественно-научным и социо-гуманитарным направлениям Минобрнауки России

Минобрнауки России Муниципальное общеобразовательное учреждение Гимназия №46 города Кирова. Школа развития 5 лет. 2018-2019 учебный год

Муниципальное общеобразовательное учреждение Гимназия №46 города Кирова. Школа развития 5 лет. 2018-2019 учебный год Требования к содержанию и порядок защиты выпускной квалификационной работы бакалавра направления подготовки 38.03.01Экономика

Требования к содержанию и порядок защиты выпускной квалификационной работы бакалавра направления подготовки 38.03.01Экономика Звіт директора про діяльність ліцею

Звіт директора про діяльність ліцею Методология научных исследований

Методология научных исследований Презентация Предметно-пространственная развивающая среда ДОУ, в соответствии с ФГОС

Презентация Предметно-пространственная развивающая среда ДОУ, в соответствии с ФГОС Технологии образования. Сущность основных понятий

Технологии образования. Сущность основных понятий Система образования Дании

Система образования Дании Комплексное сопровождение обучающихся с ОВЗ в рамках реализации АООП (адаптированной основной общеобразовательной программы)

Комплексное сопровождение обучающихся с ОВЗ в рамках реализации АООП (адаптированной основной общеобразовательной программы) деловая игра по менеджменту

деловая игра по менеджменту Школа нового поколения СОлНЦе

Школа нового поколения СОлНЦе Школьное образование в США

Школьное образование в США Новая образовательная программа Иностранные языки и межкультурная коммуникация

Новая образовательная программа Иностранные языки и межкультурная коммуникация Локальные нормативные акты финансового университета

Локальные нормативные акты финансового университета Формы организации работы по духовно - нравственному воспитанию.

Формы организации работы по духовно - нравственному воспитанию. Методологія наукового дослідження

Методологія наукового дослідження Презентация к статье Система домашних заданий

Презентация к статье Система домашних заданий Национальный исследовательский Томский государственный университет. Регионоведение России

Национальный исследовательский Томский государственный университет. Регионоведение России Развитие творческой самостоятельности на уроках русского языка и литературы в условиях введения ФГОС

Развитие творческой самостоятельности на уроках русского языка и литературы в условиях введения ФГОС Использование приемов технологии критического мышления на уроках

Использование приемов технологии критического мышления на уроках