Содержание

- 2. Contents D20DT Engine General Removal & Installation Turbo Charger (VGT) Diagnosis

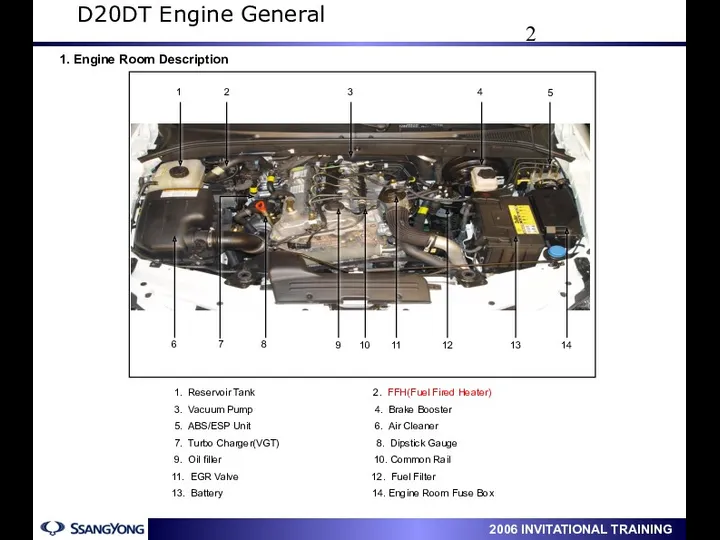

- 3. 1. Engine Room Description 1. Reservoir Tank 2. FFH(Fuel Fired Heater) 3. Vacuum Pump 4. Brake

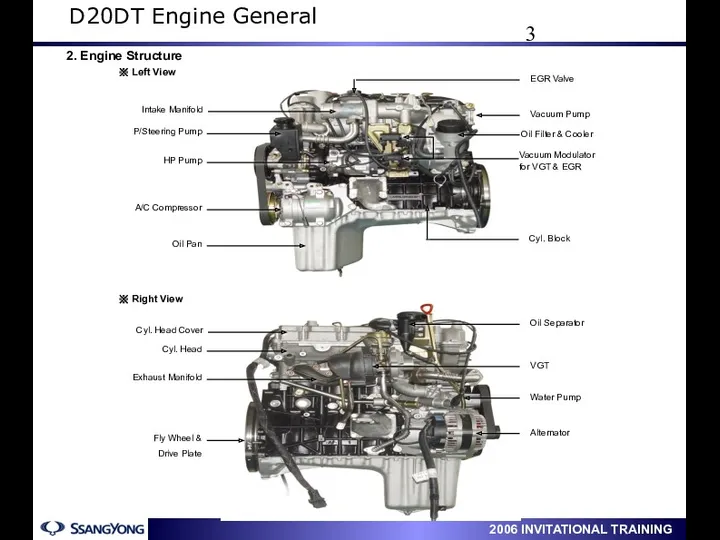

- 4. 2. Engine Structure D20DT Engine General

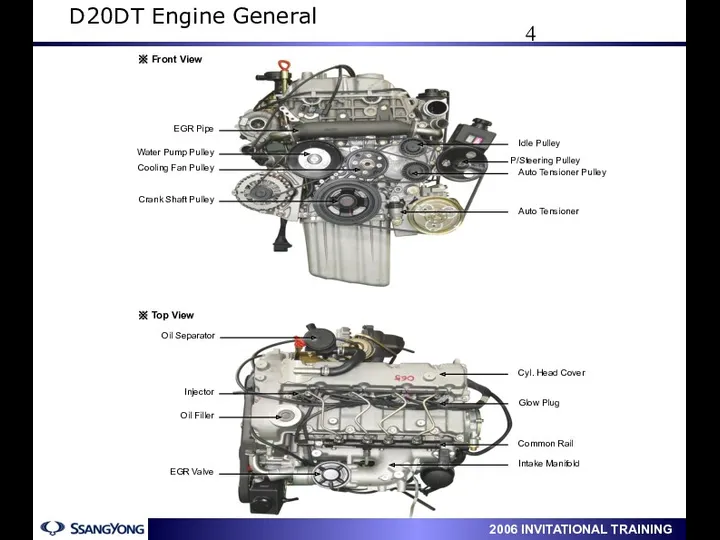

- 5. D20DT Engine General

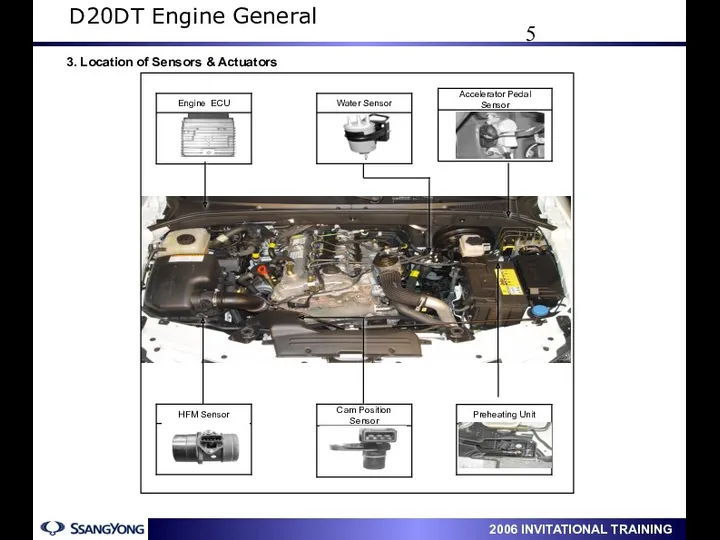

- 6. 3. Location of Sensors & Actuators D20DT Engine General

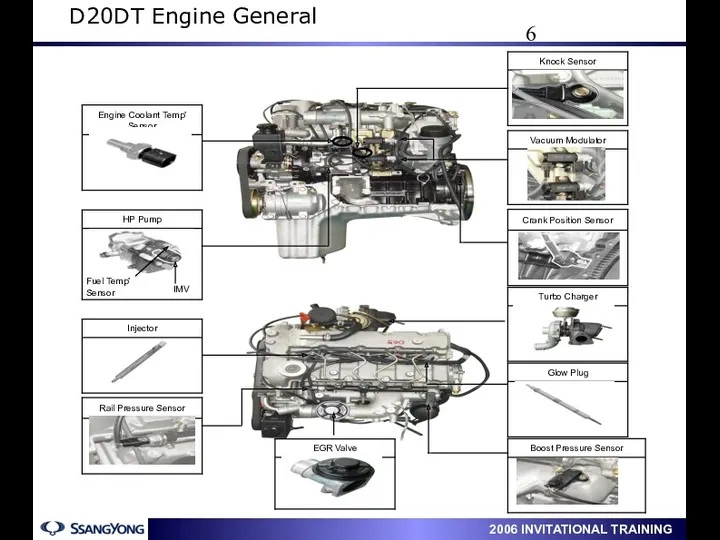

- 7. D20DT Engine General

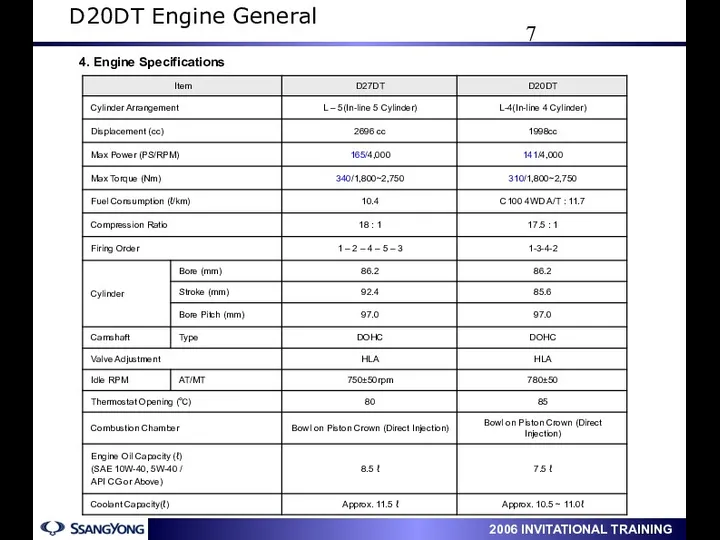

- 8. 4. Engine Specifications D20DT Engine General

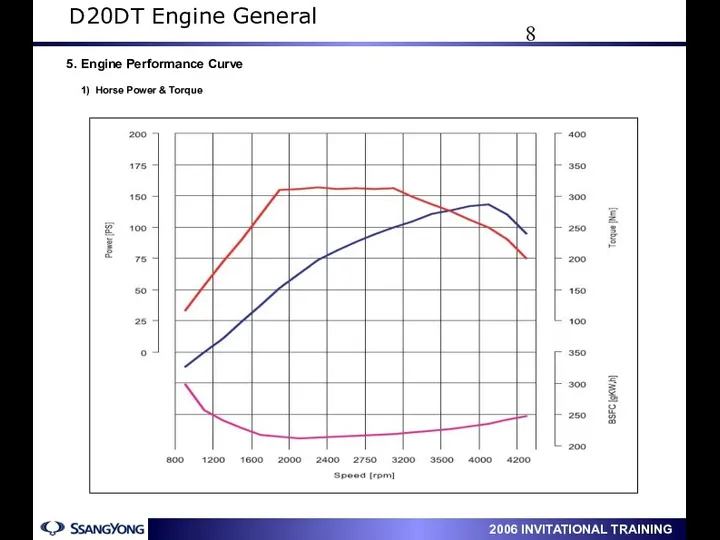

- 9. 5. Engine Performance Curve 1) Horse Power & Torque D20DT Engine General

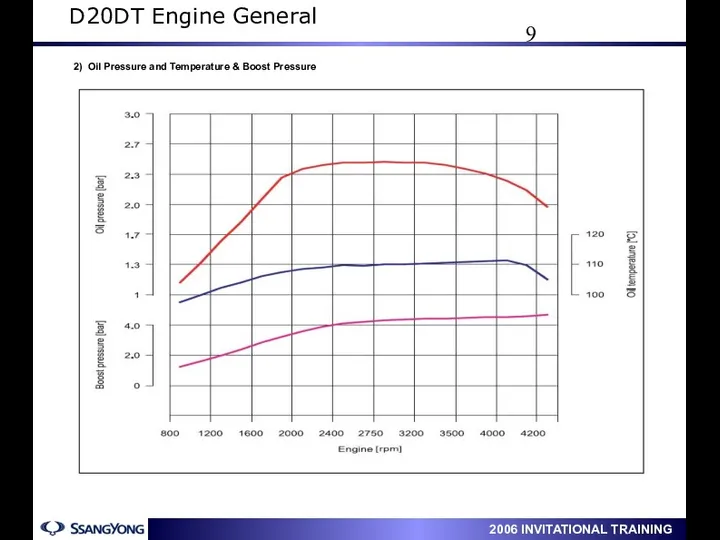

- 10. 2) Oil Pressure and Temperature & Boost Pressure D20DT Engine General

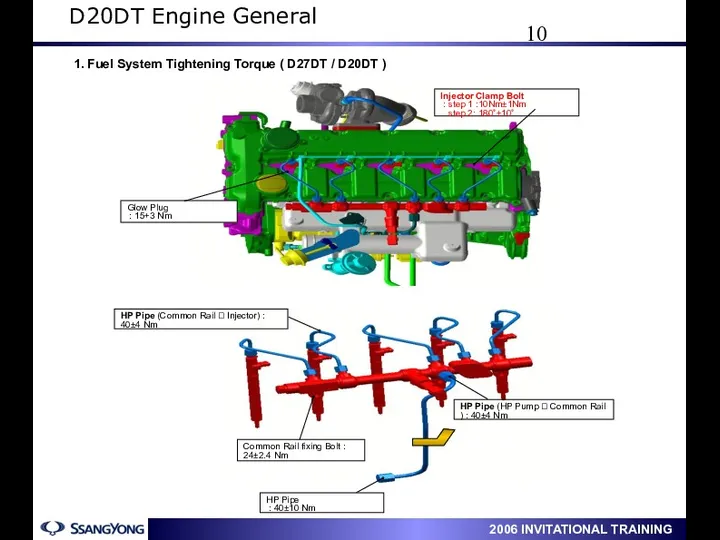

- 11. 1. Fuel System Tightening Torque ( D27DT / D20DT ) D20DT Engine General

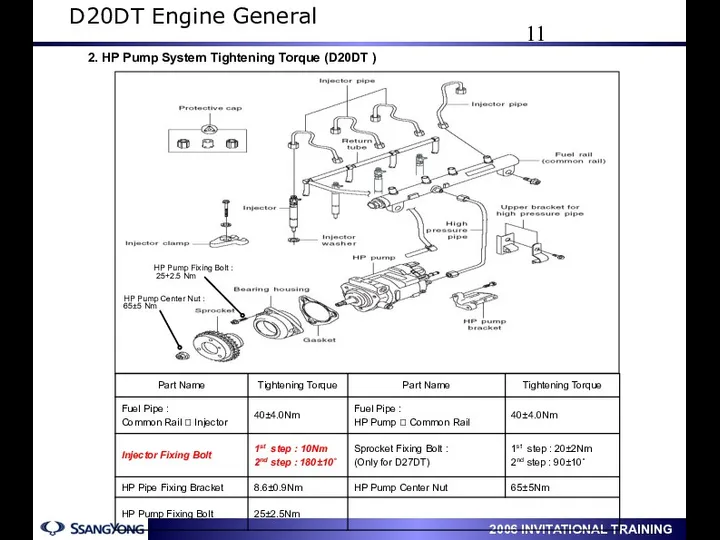

- 12. 2. HP Pump System Tightening Torque (D20DT ) D20DT Engine General

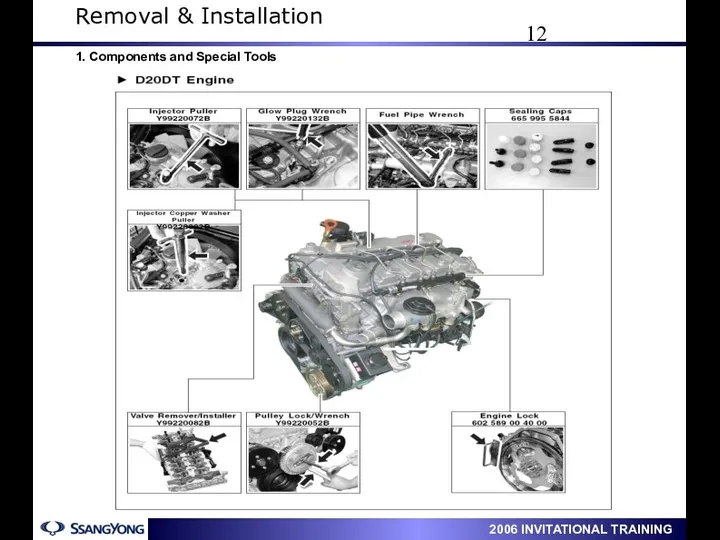

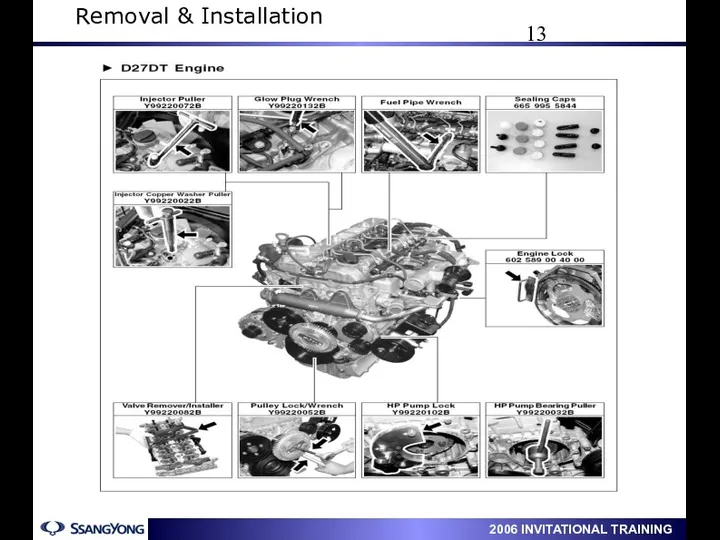

- 13. 1. Components and Special Tools Removal & Installation

- 14. Removal & Installation

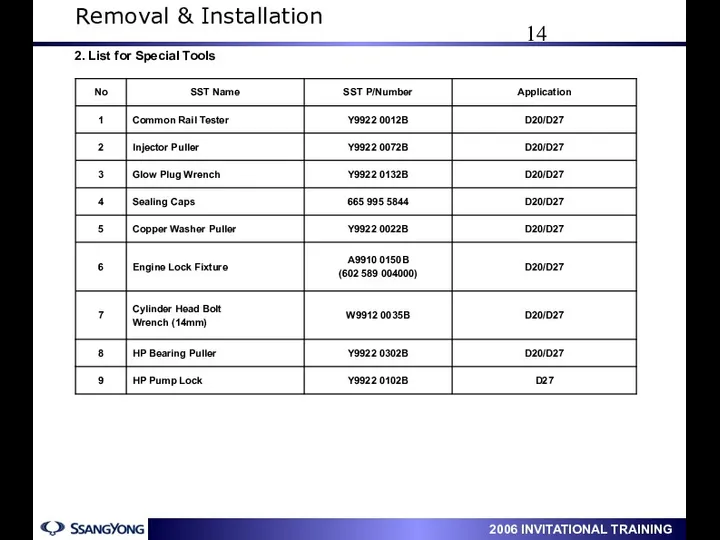

- 15. 2. List for Special Tools Removal & Installation

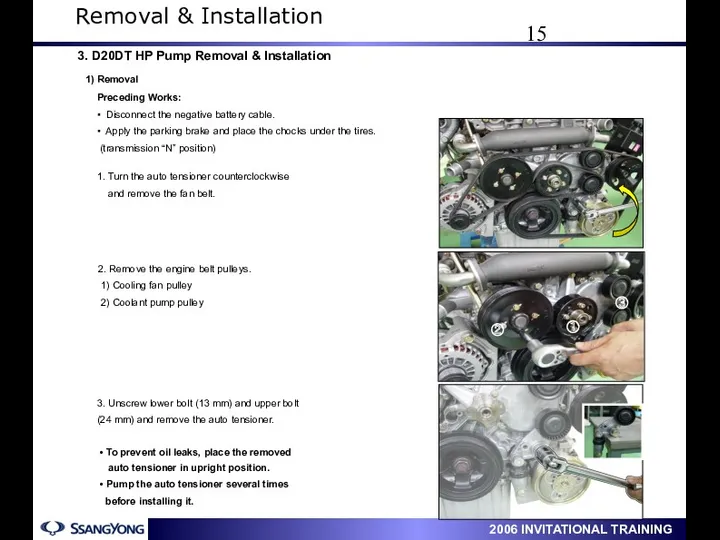

- 16. 1. Turn the auto tensioner counterclockwise and remove the fan belt. 2. Remove the engine belt

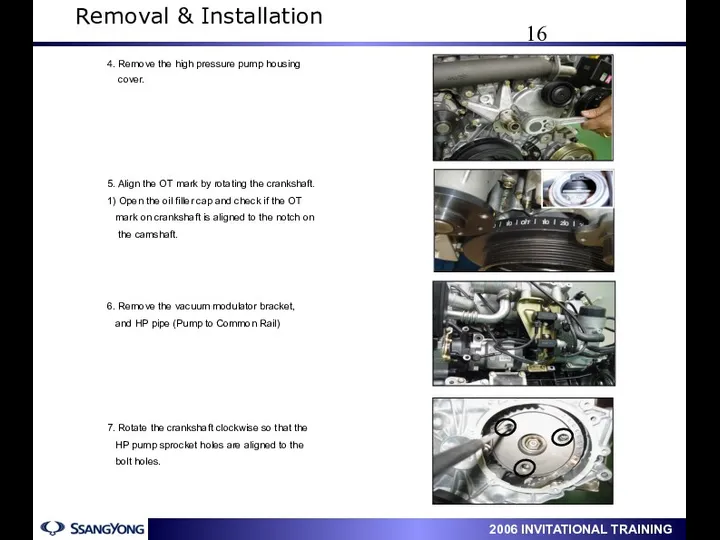

- 17. 5. Align the OT mark by rotating the crankshaft. 1) Open the oil filler cap and

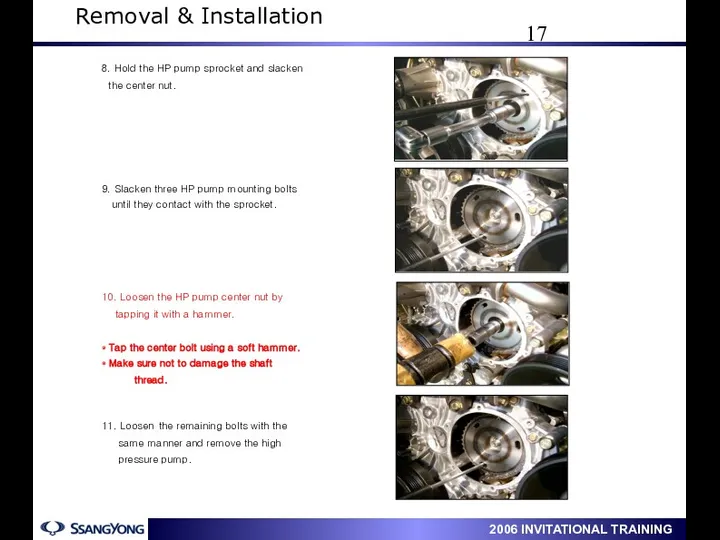

- 18. 9. Slacken three HP pump mounting bolts until they contact with the sprocket. 10. Loosen the

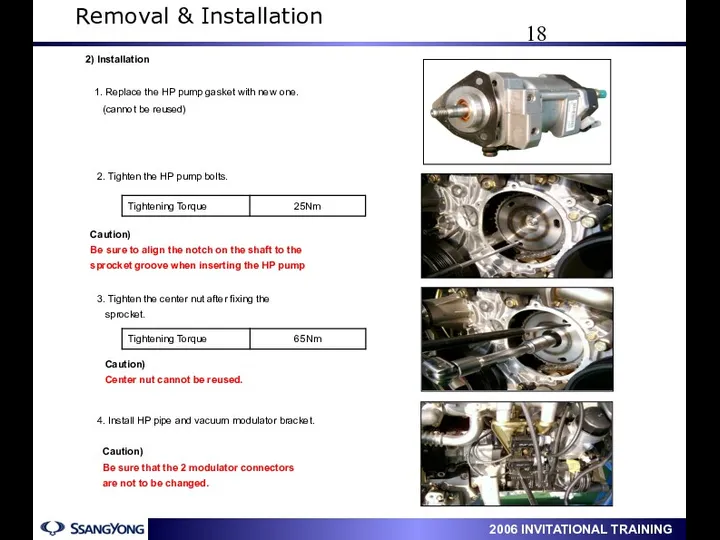

- 19. 2. Tighten the HP pump bolts. 3. Tighten the center nut after fixing the sprocket. 1.

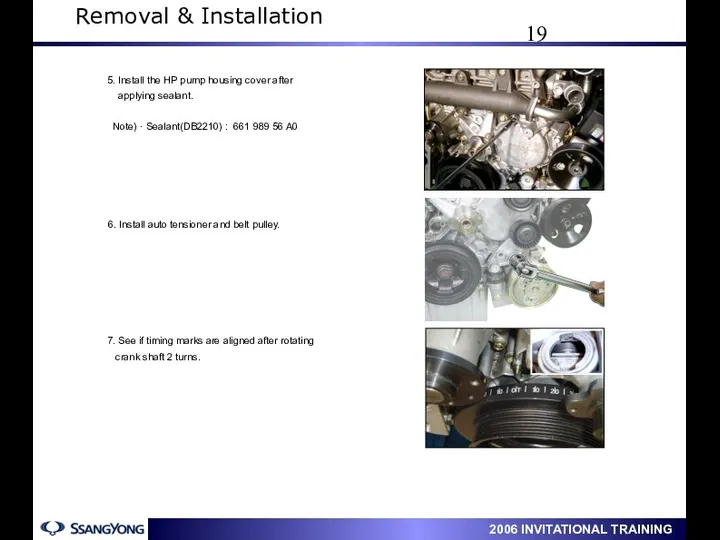

- 20. 6. Install auto tensioner and belt pulley. 7. See if timing marks are aligned after rotating

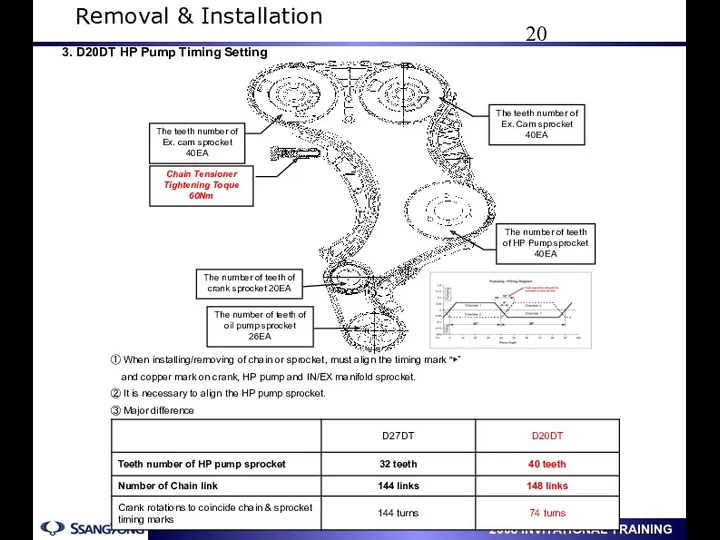

- 21. ① When installing/removing of chain or sprocket, must align the timing mark “▶” and copper mark

- 22. 4. Glow plug distinction When replacing one or more plugs, must use the same type by

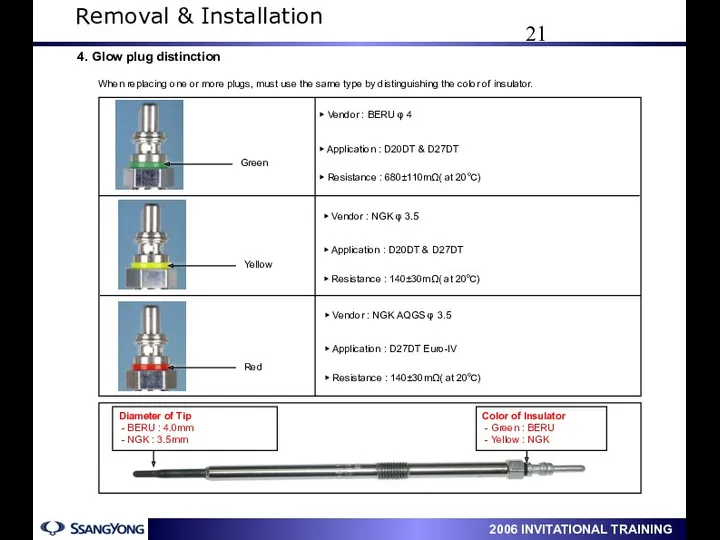

- 23. 5. D20DT/D27DT Parts major difference Removal & Installation

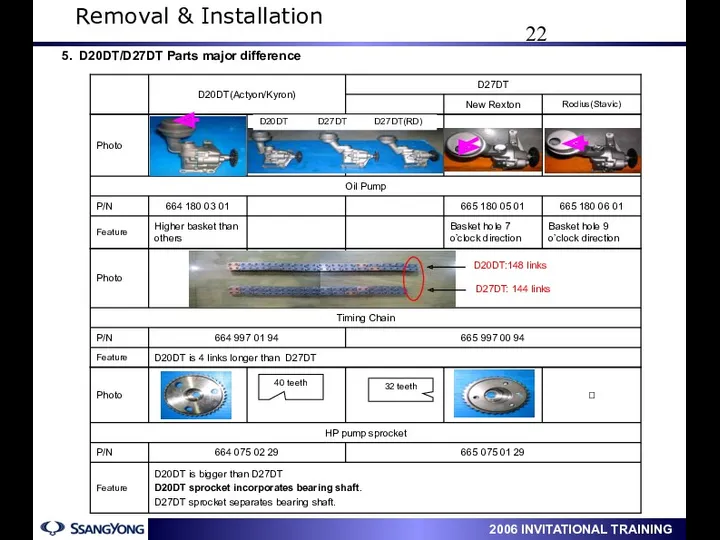

- 24. D20DT D27DT D20DT D27DT #1 #2 #3 #4 #1 #2 #3 #4 #5 Removal & Installation

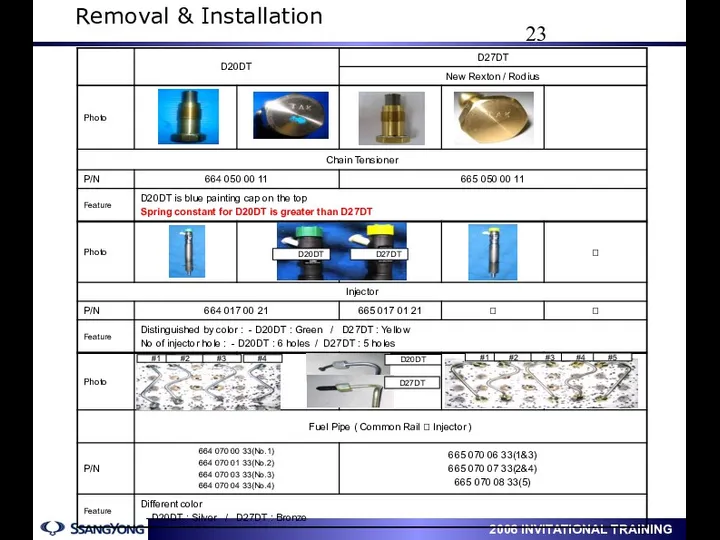

- 25. Max 7.5L Min 5.0L Max 8.5L Min 6.0L Max 8.0L Min 6.0L 7 Removal & Installation

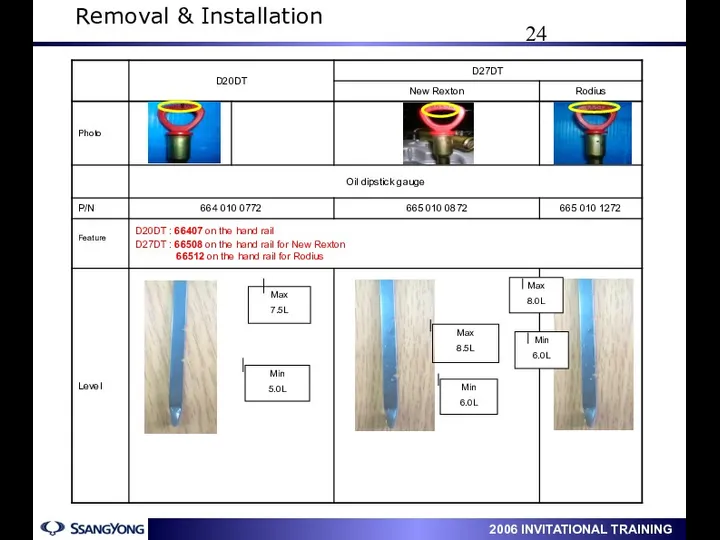

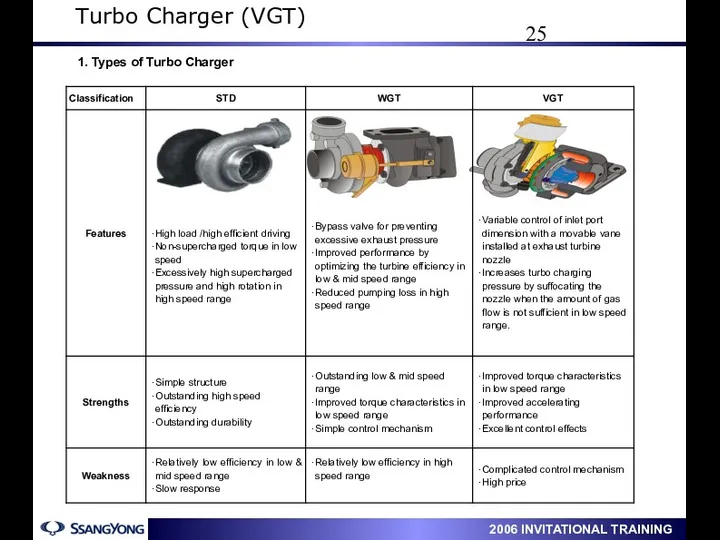

- 26. 1. Types of Turbo Charger Turbo Charger (VGT)

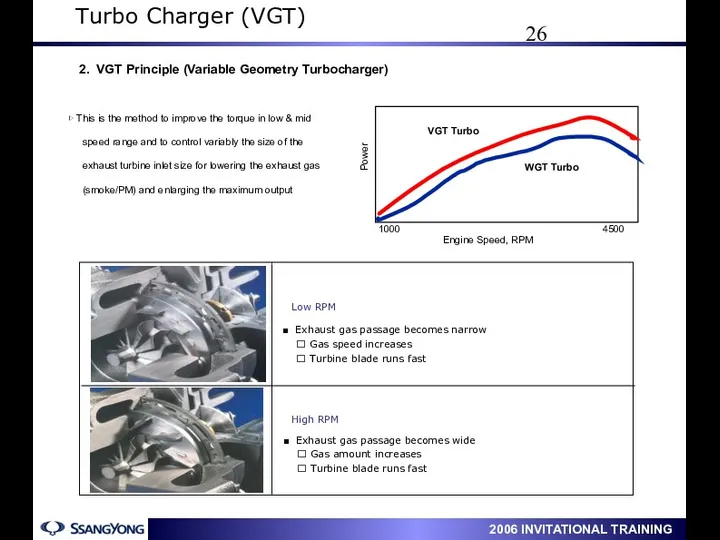

- 27. 2. VGT Principle (Variable Geometry Turbocharger) Engine Speed, RPM 1000 4500 VGT Turbo WGT Turbo Power

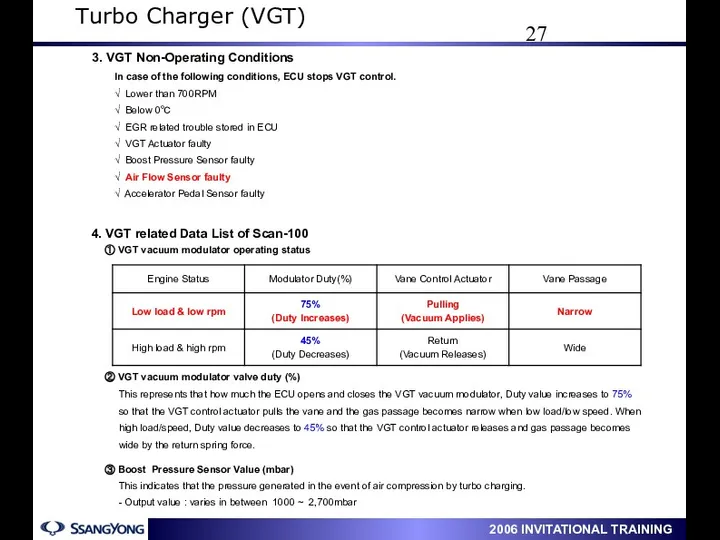

- 28. This represents that how much the ECU opens and closes the VGT vacuum modulator, Duty value

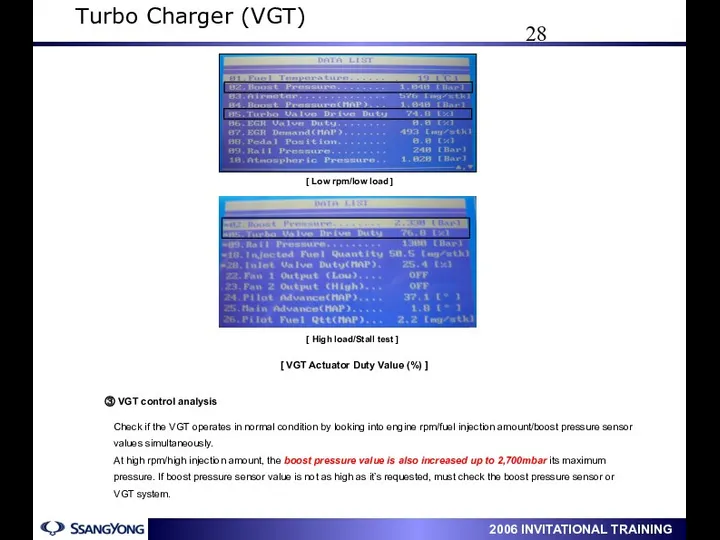

- 29. Check if the VGT operates in normal condition by looking into engine rpm/fuel injection amount/boost pressure

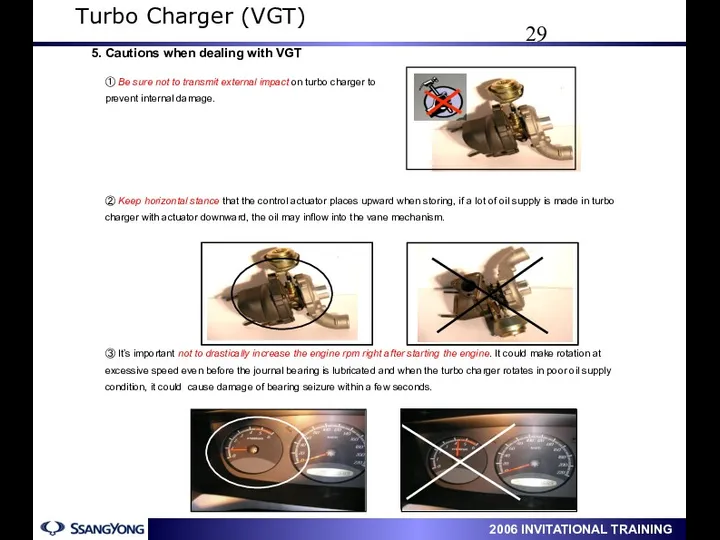

- 30. ① Be sure not to transmit external impact on turbo charger to prevent internal damage. 5.

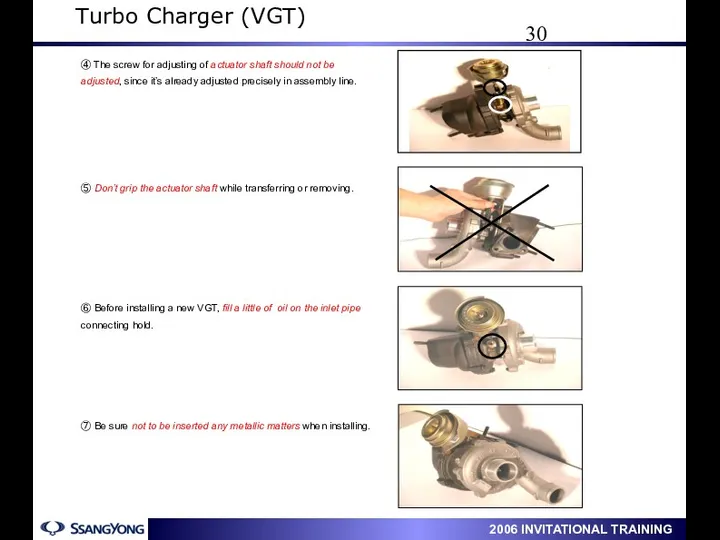

- 31. ④ The screw for adjusting of actuator shaft should not be adjusted, since it’s already adjusted

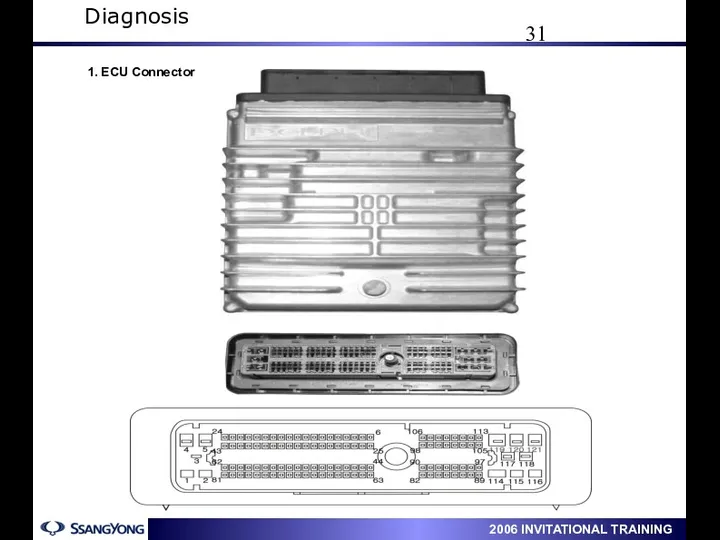

- 32. 1. ECU Connector Diagnosis

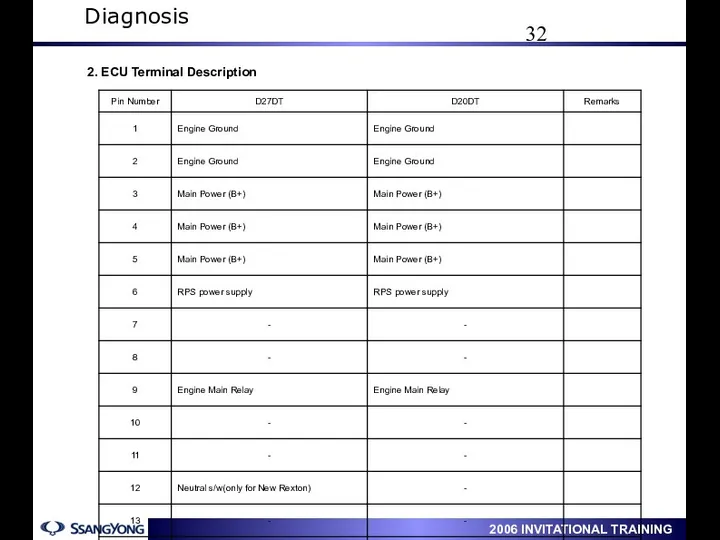

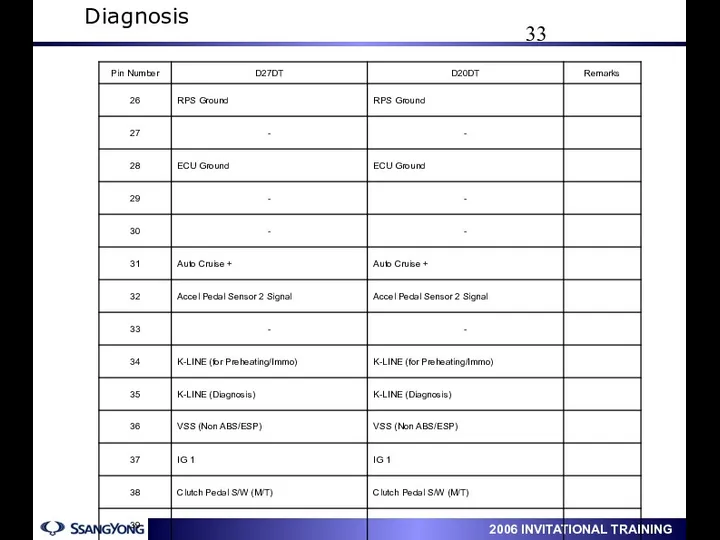

- 33. Diagnosis 2. ECU Terminal Description

- 34. Diagnosis

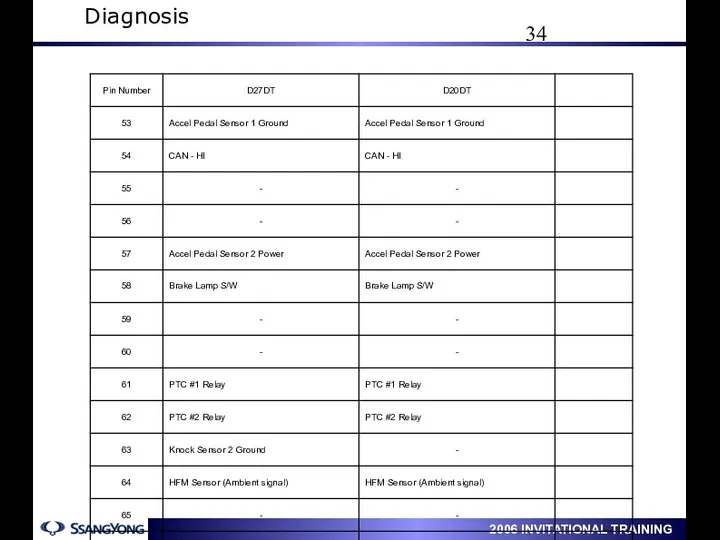

- 35. Diagnosis

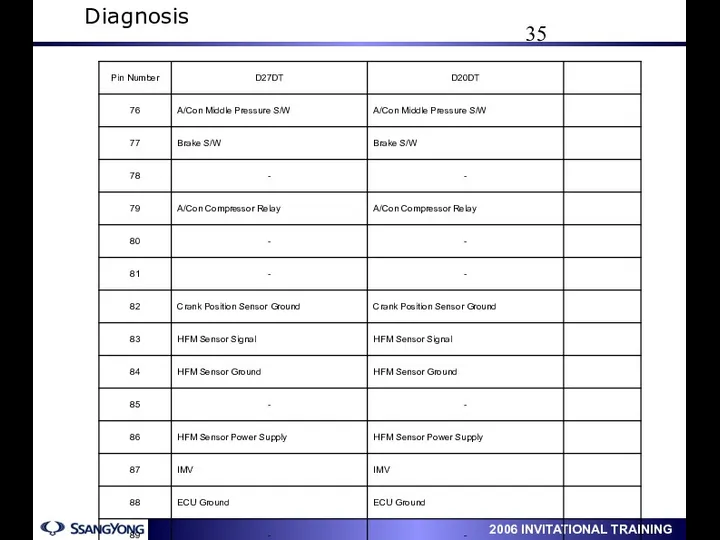

- 36. Diagnosis

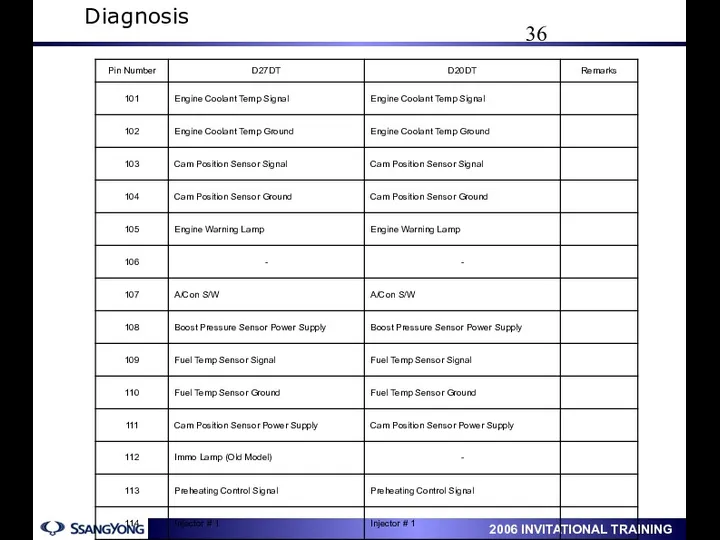

- 37. Diagnosis

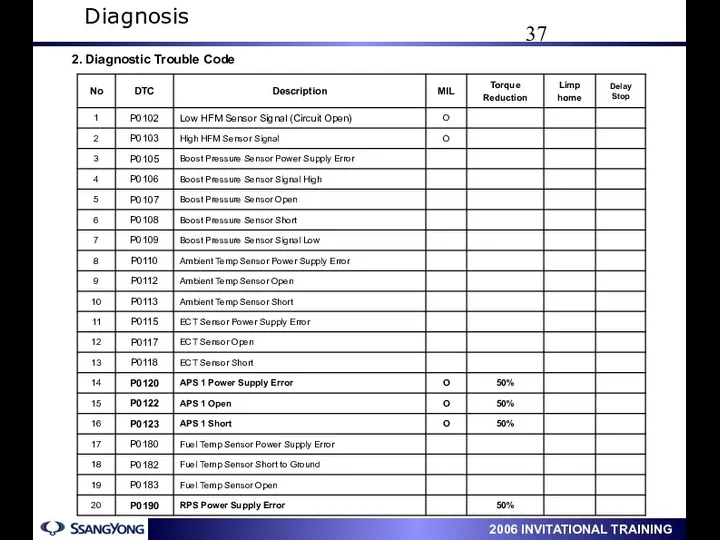

- 38. 2. Diagnostic Trouble Code Diagnosis

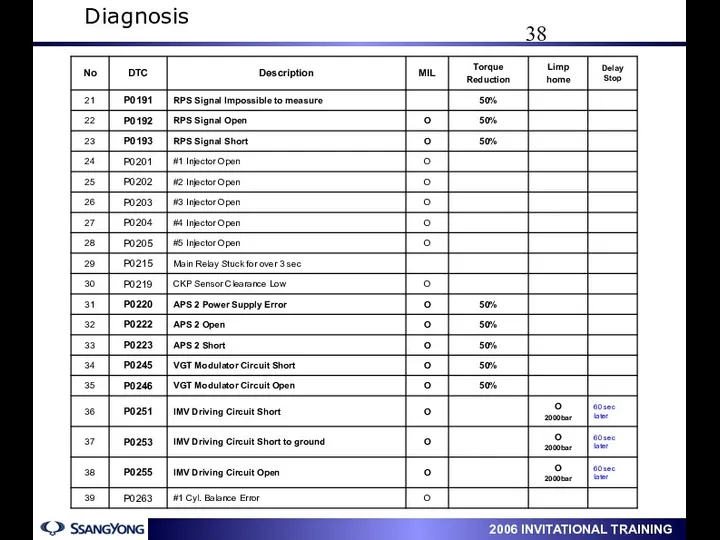

- 39. Diagnosis

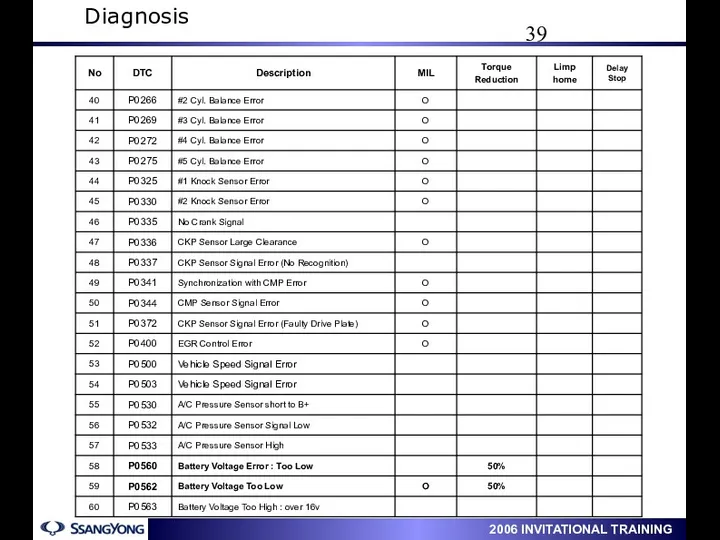

- 40. Diagnosis

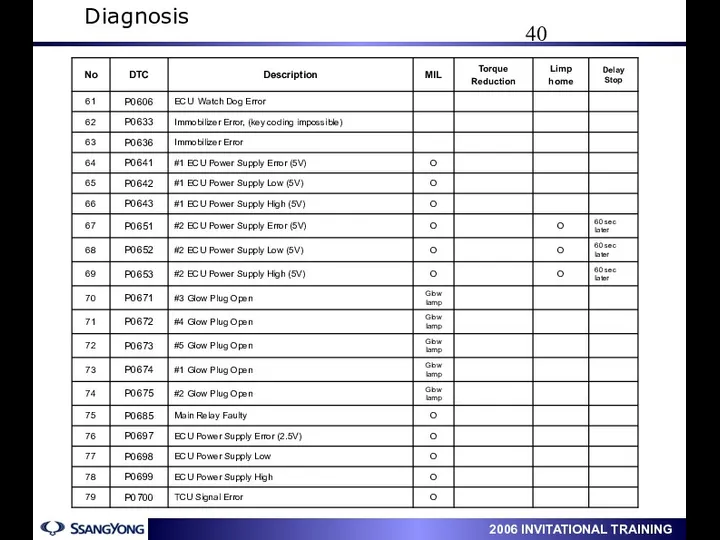

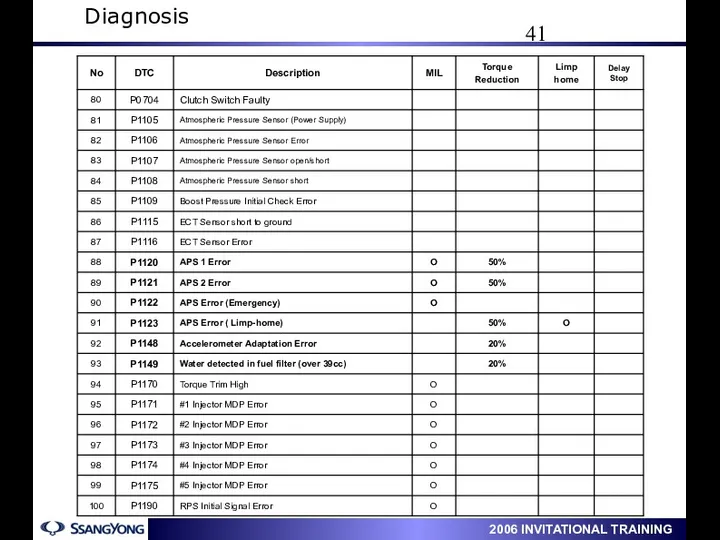

- 41. Diagnosis

- 42. Diagnosis

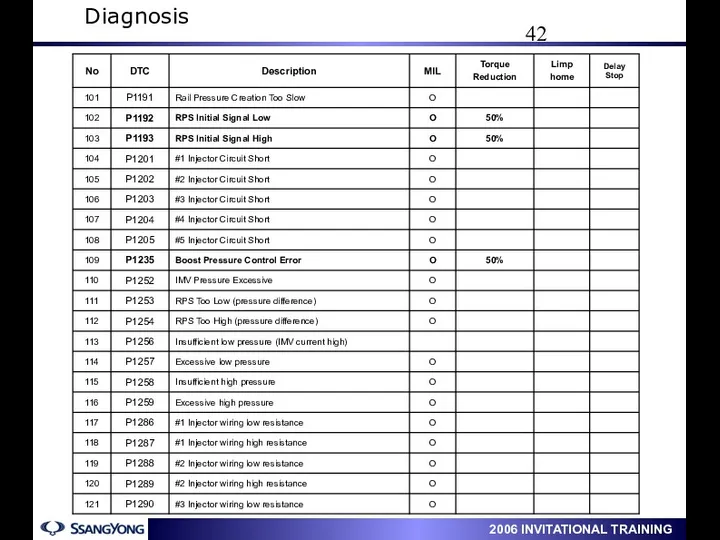

- 43. Diagnosis

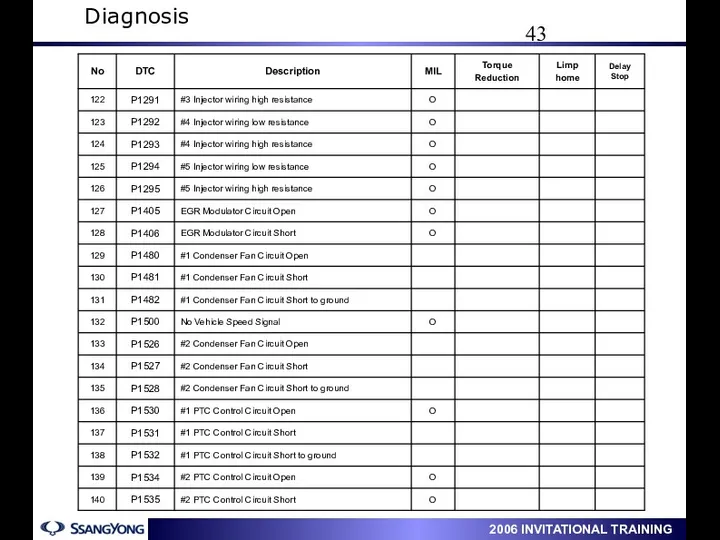

- 44. Diagnosis

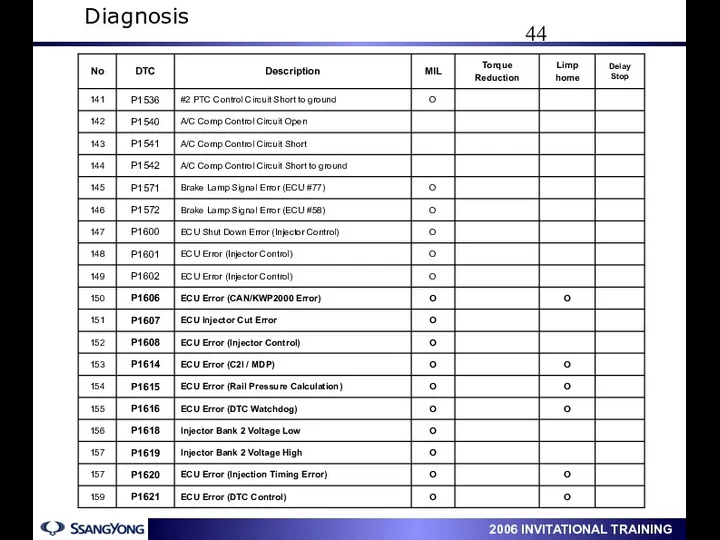

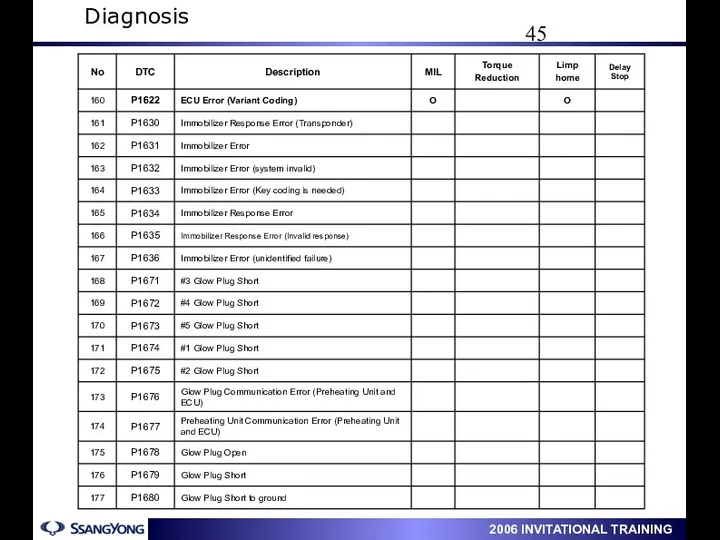

- 45. Diagnosis

- 46. Diagnosis

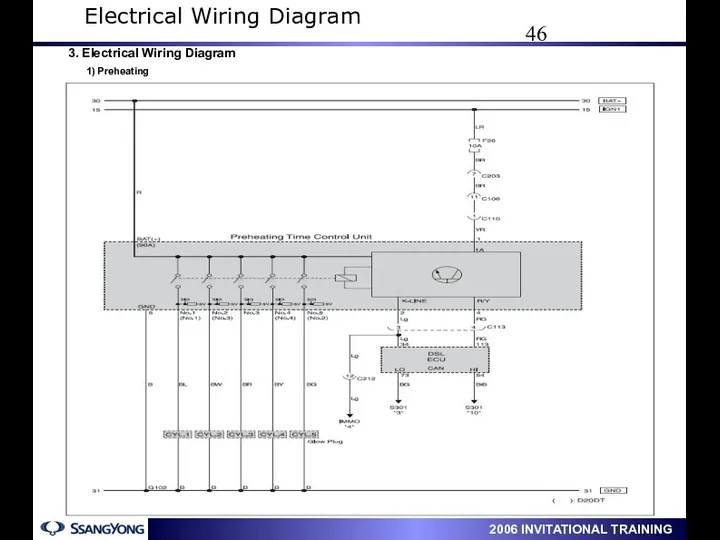

- 47. 3. Electrical Wiring Diagram 1) Preheating Electrical Wiring Diagram

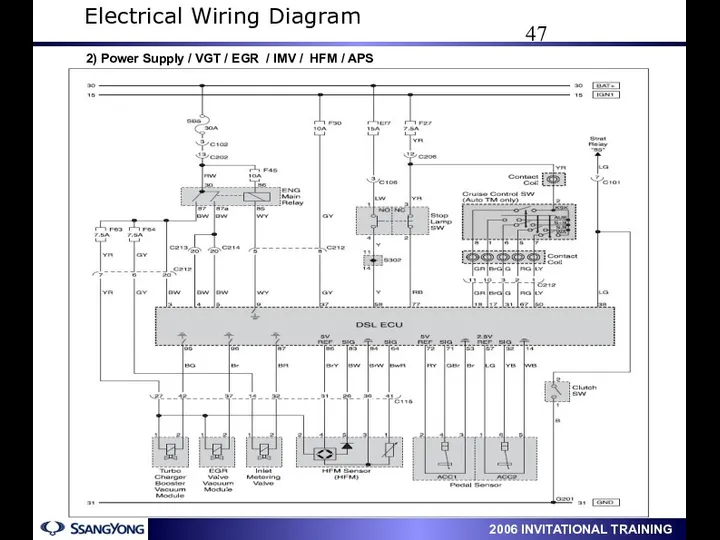

- 48. 2) Power Supply / VGT / EGR / IMV / HFM / APS Electrical Wiring Diagram

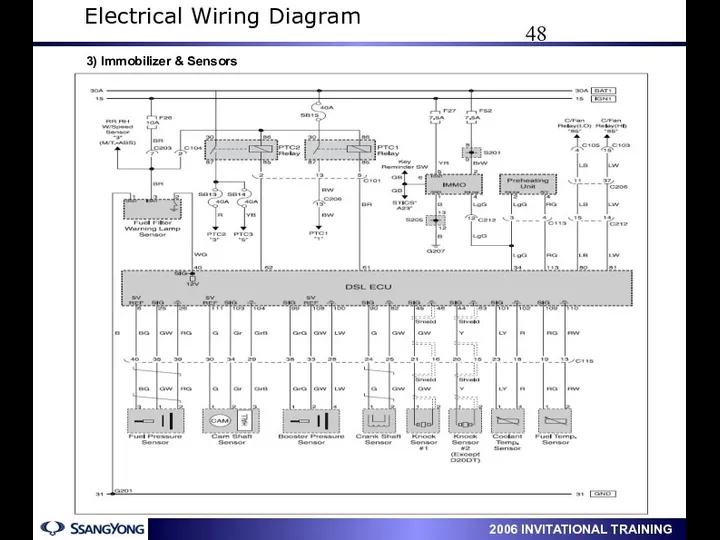

- 49. 3) Immobilizer & Sensors Electrical Wiring Diagram

- 50. 4) Injector / Air-con / Triple Pressure Switch Electrical Wiring Diagram

- 51. Data List Analysis Boost Pressure at Stall Test Boost Pressure at Idle 레일 압력 현재값과 목표값(MAP)을

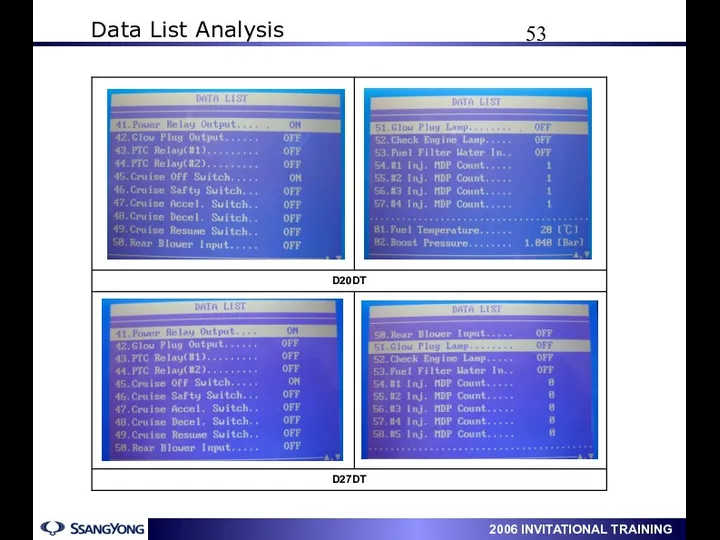

- 52. Data List Analysis

- 53. Data List Analysis

- 54. Data List Analysis

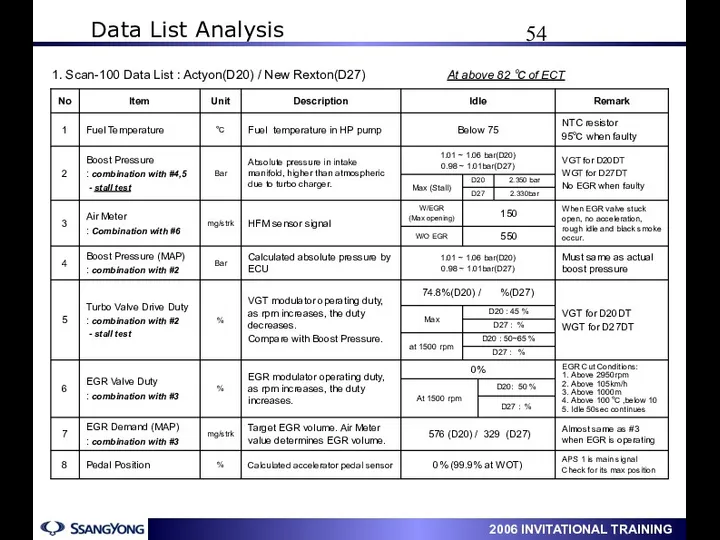

- 55. 1. Scan-100 Data List : Actyon(D20) / New Rexton(D27) At above 82 ℃ of ECT Data

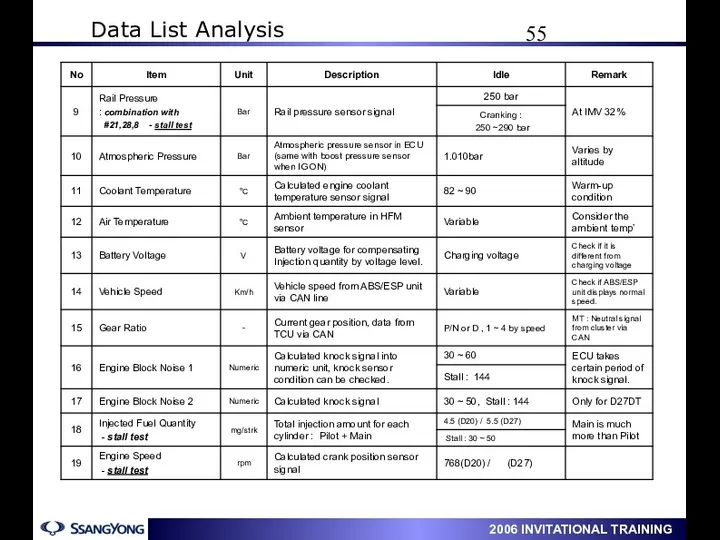

- 56. Data List Analysis

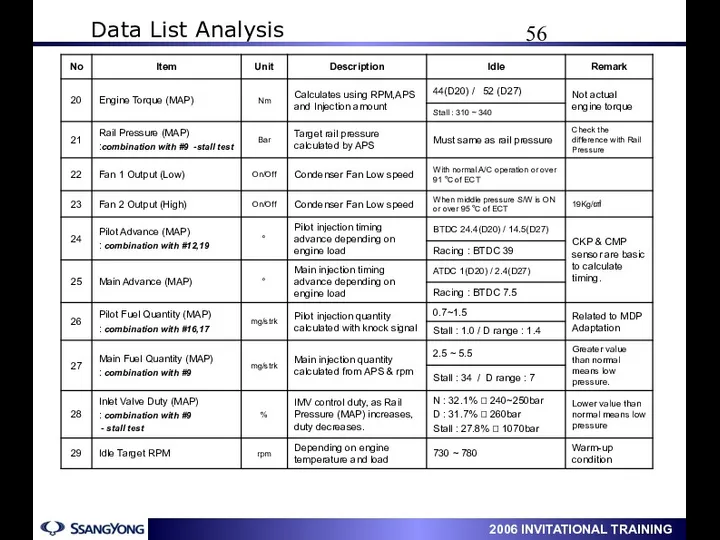

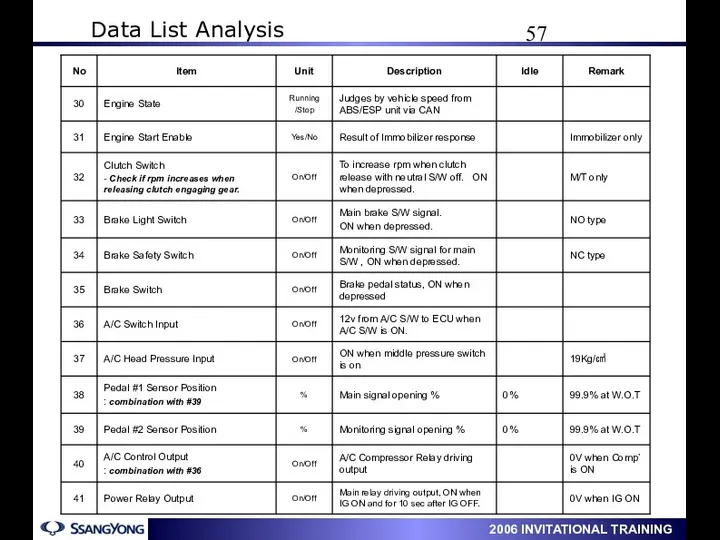

- 57. Data List Analysis

- 58. Data List Analysis

- 60. Скачать презентацию

Снаряжение первоклассника (презентация)

Снаряжение первоклассника (презентация) координатная прямая

координатная прямая Экологические болезни

Экологические болезни Литература 1950-1980 гг

Литература 1950-1980 гг Полуфабрикаты из мяса говядины

Полуфабрикаты из мяса говядины Спряжение глаголов (урок русского языка в 4 классе)

Спряжение глаголов (урок русского языка в 4 классе) Установка гнб. Применение современных технологий в ланшафтном строительстве

Установка гнб. Применение современных технологий в ланшафтном строительстве Болезнь Такаясу (неспецифический аортоартериит)

Болезнь Такаясу (неспецифический аортоартериит) Цифровая схемотехника. Счетчики. (Лекция 11)

Цифровая схемотехника. Счетчики. (Лекция 11) Глобальная сеть Интернет

Глобальная сеть Интернет Портфолио учащегося

Портфолио учащегося Чудо - дерево. Сказки и оформление детей подготовительной группы № 9

Чудо - дерево. Сказки и оформление детей подготовительной группы № 9 Особенности устройства рельсовой колеи на кривом участке двухпутной линии

Особенности устройства рельсовой колеи на кривом участке двухпутной линии День Победы (2). Фото

День Победы (2). Фото Что изучает история

Что изучает история Технология коллективного творческого воспитания

Технология коллективного творческого воспитания Кафе-пиццерия Coffecup

Кафе-пиццерия Coffecup Основные технико-экономические показатели ТЭС; методы разделения производимой энергии

Основные технико-экономические показатели ТЭС; методы разделения производимой энергии Основные понятия о грузах

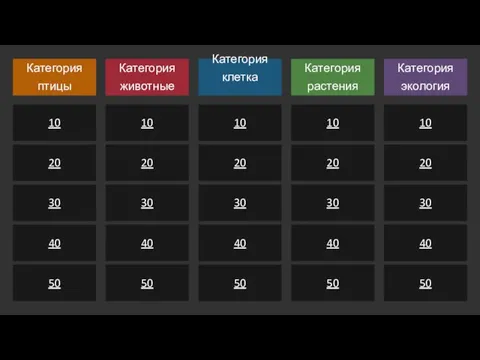

Основные понятия о грузах Категория птицы. Категория животные

Категория птицы. Категория животные Контрольная работа по теме Четырехугольники

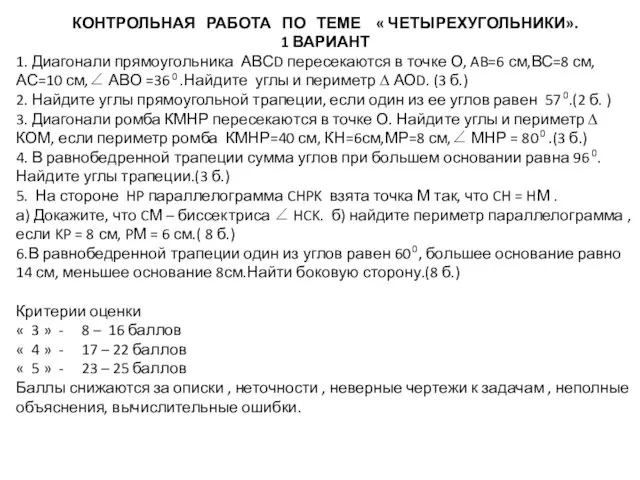

Контрольная работа по теме Четырехугольники Английские надписи на одежде и их влияние на культуру современных подростков

Английские надписи на одежде и их влияние на культуру современных подростков Способы ориентирования. 6 класс

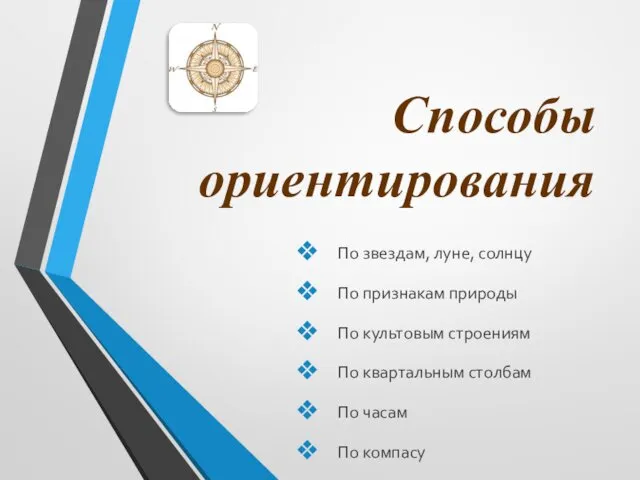

Способы ориентирования. 6 класс Презентация Использование метода наглядного моделирования в работе логопеда

Презентация Использование метода наглядного моделирования в работе логопеда Технические средства наноэлектроники. Методы получения тонких пленок. (Тема 3.2)

Технические средства наноэлектроники. Методы получения тонких пленок. (Тема 3.2) Крылатые слова

Крылатые слова Логистическая оптимизация материального потока в сфере обращения

Логистическая оптимизация материального потока в сфере обращения Программа расчета на прочность и устойчивость сосудов и аппаратов для оценки несущей способности при рабочих условиях

Программа расчета на прочность и устойчивость сосудов и аппаратов для оценки несущей способности при рабочих условиях