- Главная

- Без категории

- Ayad Mohammad dakil fainal

Содержание

- 2. WORK EXPERIENCE Instrument technical maintenance at "Bonatti" in WQ2 with LUOK OIL (3/4/2019 to now) oil

- 3. Ensures that procedures for the safe execution of tasks are in place and adhered to (including

- 4. Responsible for Carry Out periodic maintenance, calibration, troubleshooting, fault diagnosis, repairs of field instruments. Temperature transmitter

- 6. Скачать презентацию

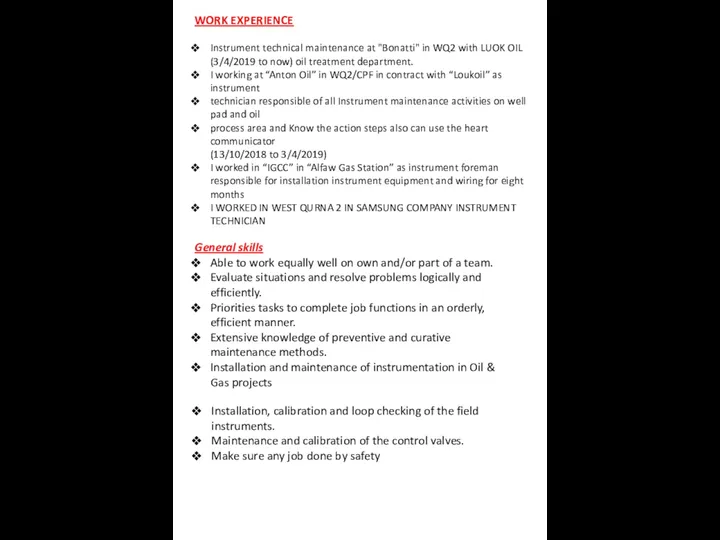

WORK EXPERIENCE

Instrument technical maintenance at "Bonatti" in WQ2 with LUOK

Instrument technical maintenance at "Bonatti" in WQ2 with LUOK

I working at “Anton Oil” in WQ2/CPF in contract with “Loukoil” as instrument

technician responsible of all Instrument maintenance activities on well pad and oil

process area and Know the action steps also can use the heart communicator (13/10/2018 to 3/4/2019)

I worked in “IGCC” in “Alfaw Gas Station” as instrument foreman responsible for installation instrument equipment and wiring for eight months

I WORKED IN WEST QURNA 2 IN SAMSUNG COMPANY INSTRUMENT TECHNICIAN

General skills

Able to work equally well on own and/or part of a team.

Evaluate situations and resolve problems logically and efficiently.

Priorities tasks to complete job functions in an orderly, efficient manner.

Extensive knowledge of preventive and curative maintenance methods.

Installation and maintenance of instrumentation in Oil & Gas projects

Installation, calibration and loop checking of the field instruments.

Maintenance and calibration of the control valves.

Make sure any job done by safety

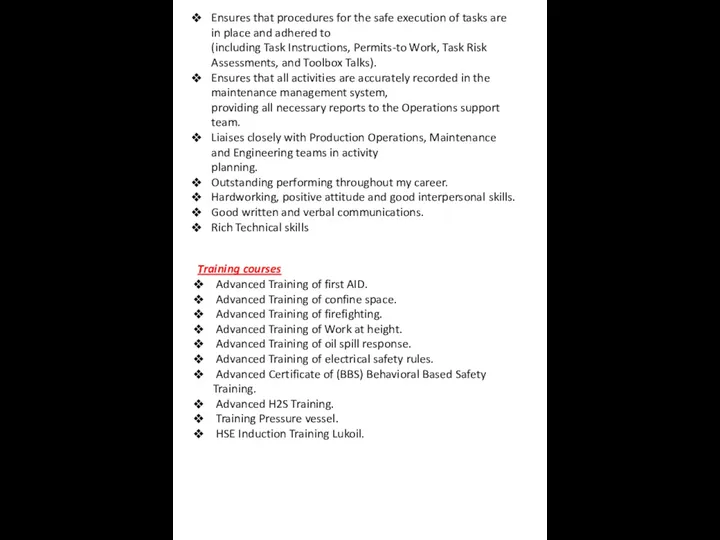

Ensures that procedures for the safe execution of tasks are in

Ensures that all activities are accurately recorded in the maintenance management system, providing all necessary reports to the Operations support team.

Liaises closely with Production Operations, Maintenance and Engineering teams in activity planning.

Outstanding performing throughout my career.

Hardworking, positive attitude and good interpersonal skills.

Good written and verbal communications.

Rich Technical skills

Training courses

Advanced Training of first AID.

Advanced Training of confine space.

Advanced Training of firefighting.

Advanced Training of Work at height.

Advanced Training of oil spill response.

Advanced Training of electrical safety rules.

Advanced Certificate of (BBS) Behavioral Based Safety Training.

Advanced H2S Training.

Training Pressure vessel.

HSE Induction Training Lukoil.

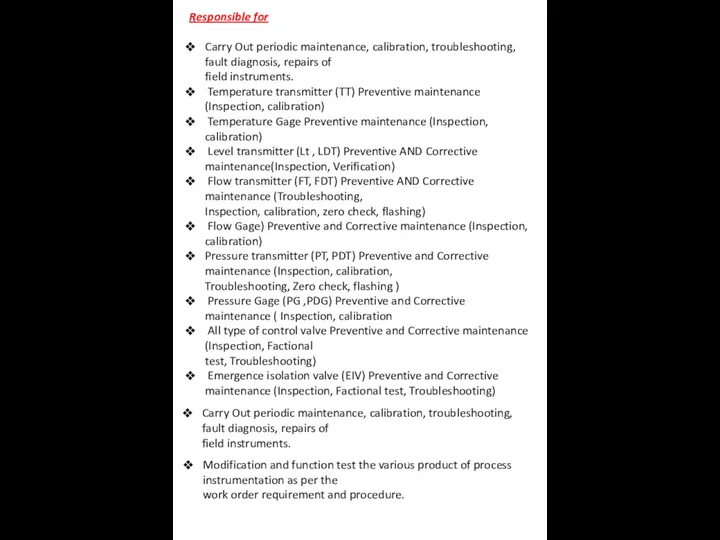

Responsible for

Carry Out periodic maintenance, calibration, troubleshooting, fault diagnosis, repairs of

field

Responsible for

Carry Out periodic maintenance, calibration, troubleshooting, fault diagnosis, repairs of

field

Temperature transmitter (TT) Preventive maintenance (Inspection, calibration)

Temperature Gage Preventive maintenance (Inspection, calibration)

Level transmitter (Lt , LDT) Preventive AND Corrective maintenance(Inspection, Verification)

Flow transmitter (FT, FDT) Preventive AND Corrective maintenance (Troubleshooting, Inspection, calibration, zero check, flashing)

Flow Gage) Preventive and Corrective maintenance (Inspection, calibration)

Pressure transmitter (PT, PDT) Preventive and Corrective maintenance (Inspection, calibration, Troubleshooting, Zero check, flashing )

Pressure Gage (PG ,PDG) Preventive and Corrective maintenance ( Inspection, calibration

All type of control valve Preventive and Corrective maintenance (Inspection, Factional test, Troubleshooting)

Emergence isolation valve (EIV) Preventive and Corrective maintenance (Inspection, Factional test, Troubleshooting)

Carry Out periodic maintenance, calibration, troubleshooting, fault diagnosis, repairs of

field instruments.

Modification and function test the various product of process instrumentation as per the

work order requirement and procedure.

Запрошення

Запрошення Наука иммунология

Наука иммунология Викторина для 11 класса

Викторина для 11 класса ВИЧ - инфекция

ВИЧ - инфекция Презентация Игра как ведущий вид деятельности дошкольника

Презентация Игра как ведущий вид деятельности дошкольника Публичный доклад по итогам работы. Отдел культуры, спорта и молодежи Администрации Песчанокопского района

Публичный доклад по итогам работы. Отдел культуры, спорта и молодежи Администрации Песчанокопского района Презентация к уроку химии: Оксиды. Номенклатура. Классификация

Презентация к уроку химии: Оксиды. Номенклатура. Классификация Портрет пожилого человека

Портрет пожилого человека Гитары Gibson

Гитары Gibson ЕГЭ по биологии. Задания части С

ЕГЭ по биологии. Задания части С Викинги. Культура, быт

Викинги. Культура, быт Синупрет. Дозы и способы применения

Синупрет. Дозы и способы применения Введение в предмет “Религиоведение”

Введение в предмет “Религиоведение” История хип-хопа и современной электронной музыки

История хип-хопа и современной электронной музыки Советско-китайские отношения времен застоя. Тема 25

Советско-китайские отношения времен застоя. Тема 25 Треугольник. Первый признак равенства треугольников

Треугольник. Первый признак равенства треугольников Дефекты сварных соединений. Фотоальбом

Дефекты сварных соединений. Фотоальбом БТС-Биоуправляемые протезы

БТС-Биоуправляемые протезы Презентация по тем Белки

Презентация по тем Белки Ледяные композиции (круглые скульптуры, сказочные замки)

Ледяные композиции (круглые скульптуры, сказочные замки) Паллиативная медицинская помощь в России и за рубежом

Паллиативная медицинская помощь в России и за рубежом Проект озеленення приватного будинку

Проект озеленення приватного будинку Красная книга растений. 5 класс. Диск

Красная книга растений. 5 класс. Диск Презентация Маленькая планета

Презентация Маленькая планета Духовно - нравственное воспитание

Духовно - нравственное воспитание презентация об алкоголизме

презентация об алкоголизме Географическая игра Антарктида

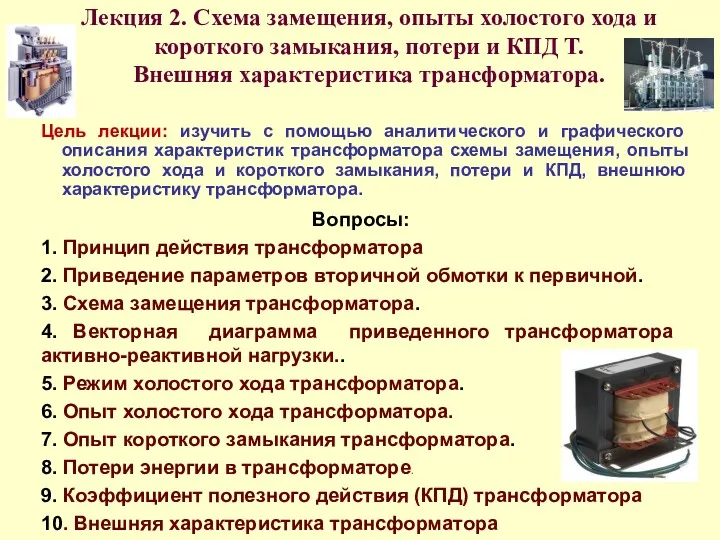

Географическая игра Антарктида Схема замещения, опыты холостого хода и короткого замыкания, потери и КПД Т. Внешняя характеристика трансформатора

Схема замещения, опыты холостого хода и короткого замыкания, потери и КПД Т. Внешняя характеристика трансформатора