Содержание

- 2. Smallest - CD 2 = 2 l/s or 4.24 cfm Largest - CD 280 = 280

- 3. Desiccant Technology Desiccant Technology Desiccant Absortion Absorption process Absorption process Purge Process Purge Process Working principles

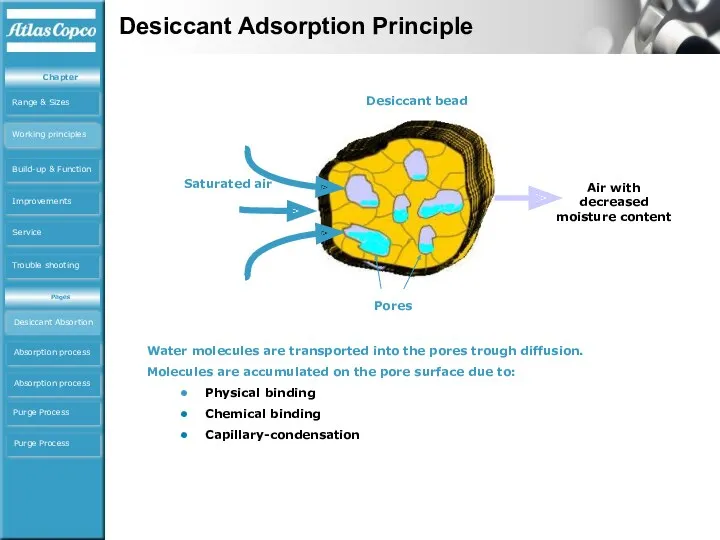

- 4. Desiccant bead Pores Saturated air Air with decreased moisture content Water molecules are transported into the

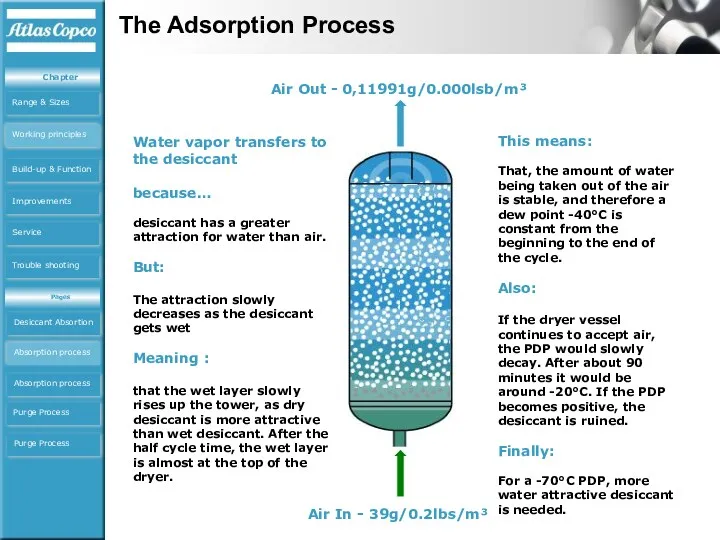

- 5. Air In - 39g/0.2lbs/m³ Air Out - 0,11991g/0.000lsb/m³ Water vapor transfers to the desiccant because… desiccant

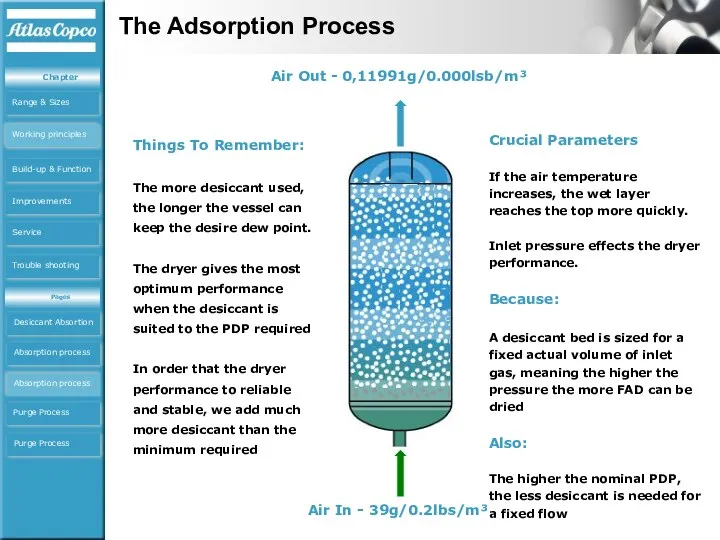

- 6. Things To Remember: The more desiccant used, the longer the vessel can keep the desire dew

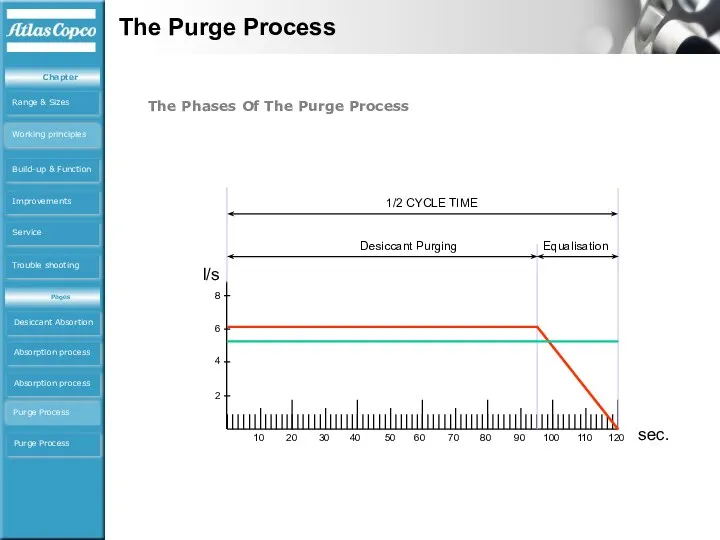

- 7. l/s Desiccant Purging 1/2 CYCLE TIME Equalisation The Phases Of The Purge Process The Purge Process

- 8. Important Things To Know About Purge The actual flow rate (not FAD) of purge air through

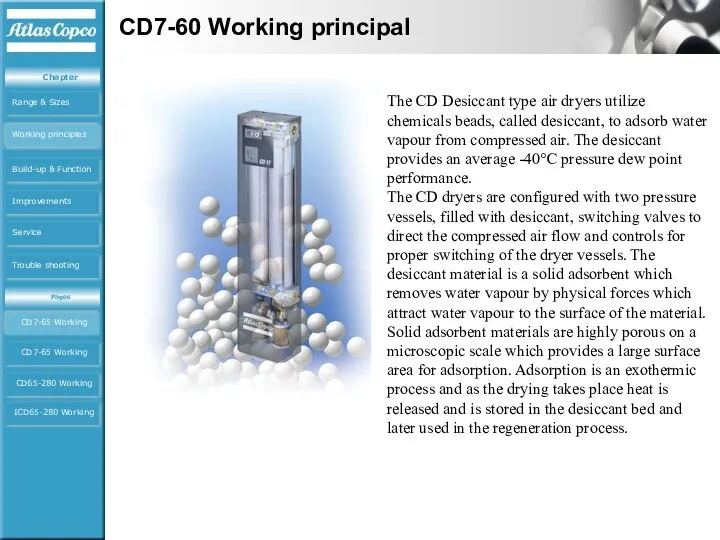

- 9. The CD Desiccant type air dryers utilize chemicals beads, called desiccant, to adsorb water vapour from

- 10. The basic operation of a the CD dryer consists of one drying cycle and one regeneration

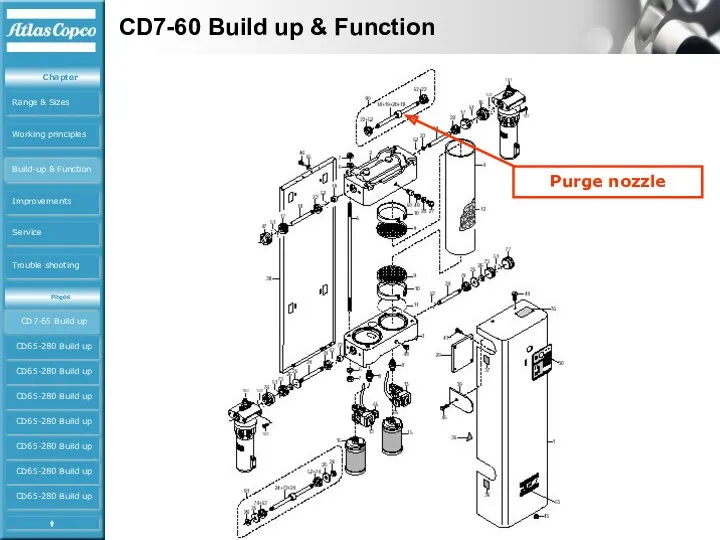

- 11. CD7-60 Build up & Function CD7-65 Build up CD65-280 Build up CD65-280 Build up CD65-280 Build

- 12. CD65-280 Working principal CD7-65 Working CD7-65 Working CD65-280 Working ICD65-280 Working Working principles CD65-280CDAnimation.exe

- 13. CD65-280 Working principal CD65-280ICDAnimation.exe CD7-65 Working CD7-65 Working CD65-280 Working ICD65-280 Working Working principles

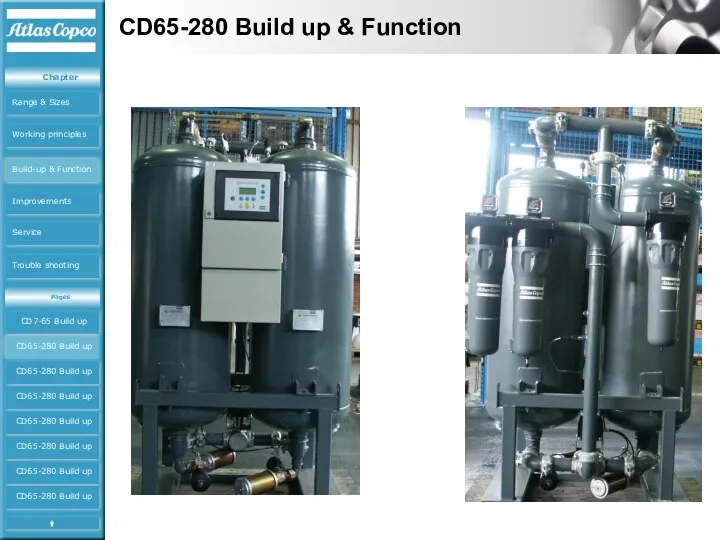

- 14. CD65-280 Build up & Function CD7-65 Build up CD65-280 Build up CD65-280 Build up CD65-280 Build

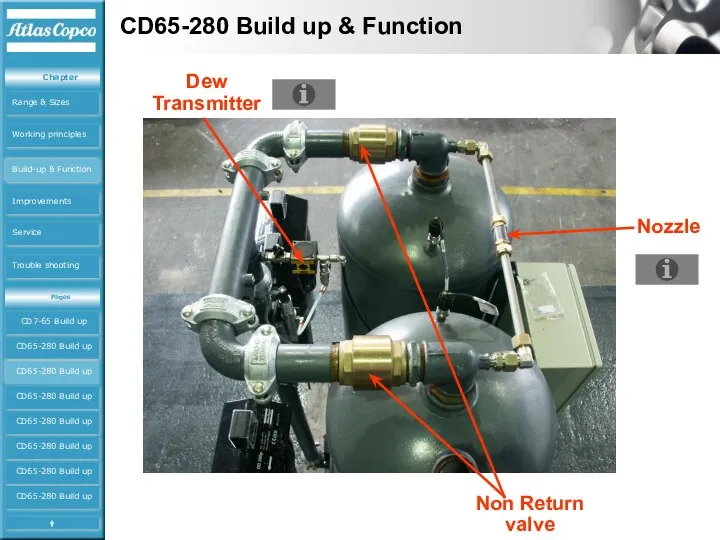

- 15. CD65-280 Build up & Function Nozzle Non Return valve Dew Transmitter CD65-280 Build up CD65-280 Build

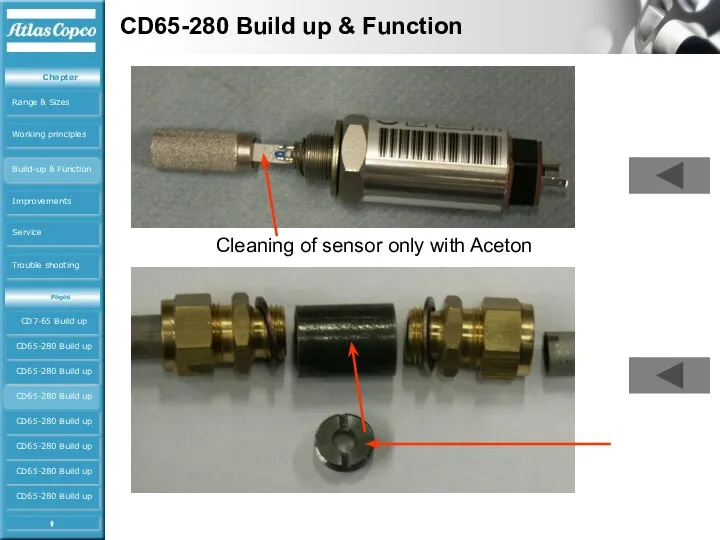

- 16. CD65-280 Build up & Function Cleaning of sensor only with Aceton CD65-280 Build up CD65-280 Build

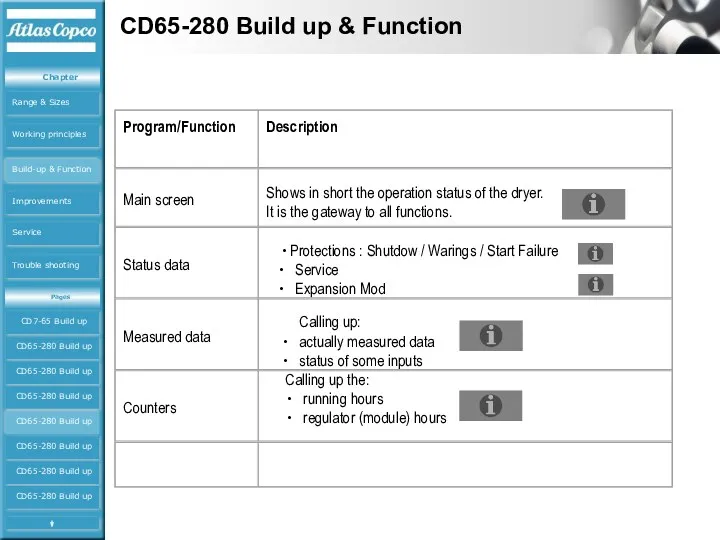

- 17. CD65-280 Build up & Function CD65-280 Build up CD65-280 Build up CD65-280 Build up CD65-280 Build

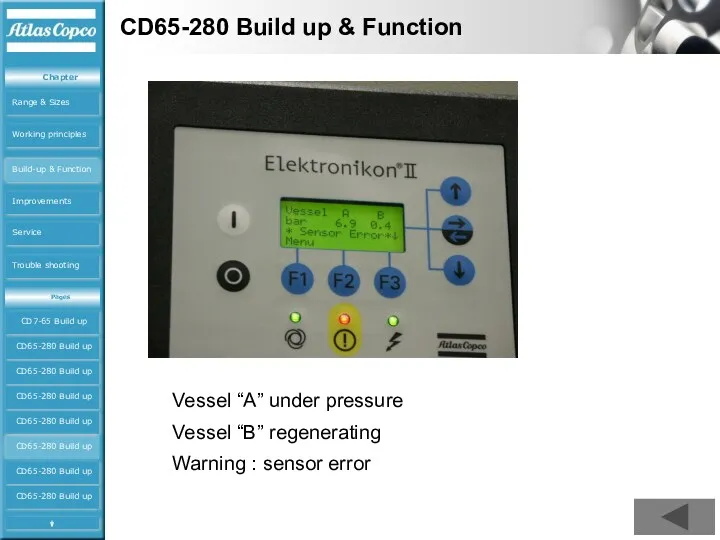

- 18. CD65-280 Build up & Function Vessel “A” under pressure Vessel “B” regenerating Warning : sensor error

- 19. CD65-280 Build up & Function Warnings Dewpoint Failure No dewpoint CD65-280 Build up CD65-280 Build up

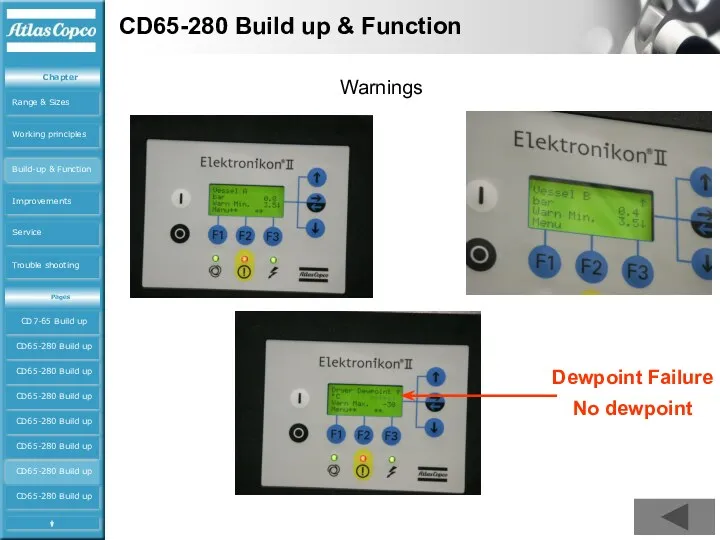

- 20. CD65-280 Build up & Function Service CD65-280 Build up CD65-280 Build up CD65-280 Build up CD65-280

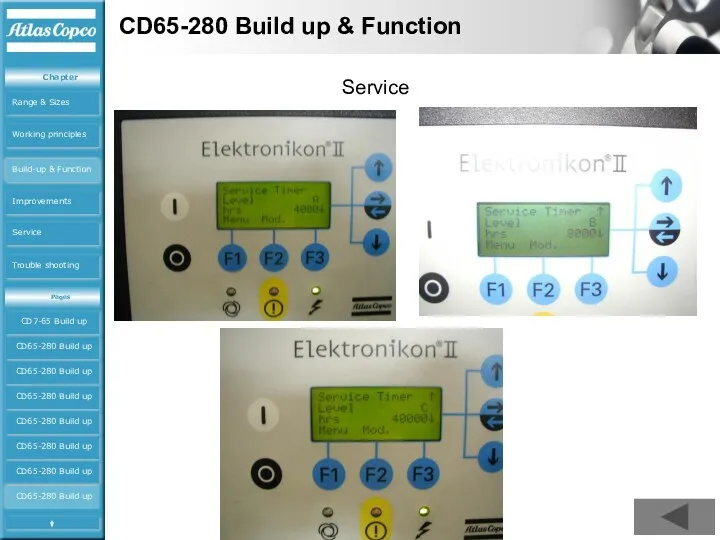

- 21. CD65-280 Build up & Function CD7-65 Build up CD65-280 Build up CD65-280 Build up CD65-280 Build

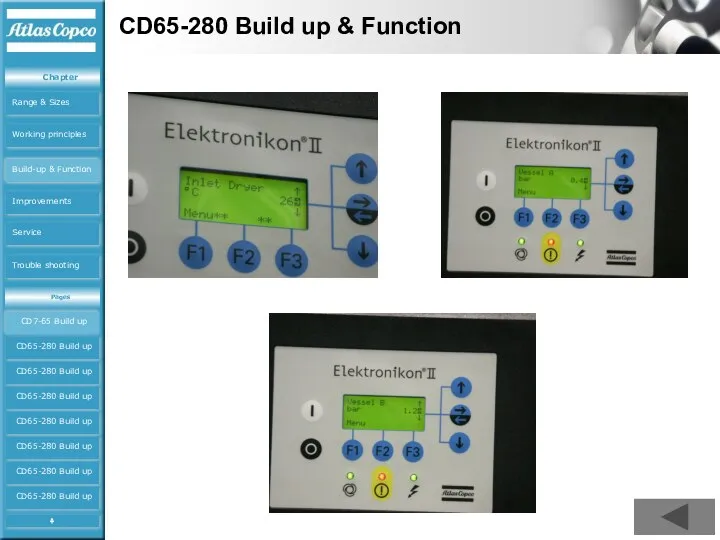

- 22. CD65-280 Build up & Function CD7-65 Build up CD65-280 Build up CD65-280 Build up CD65-280 Build

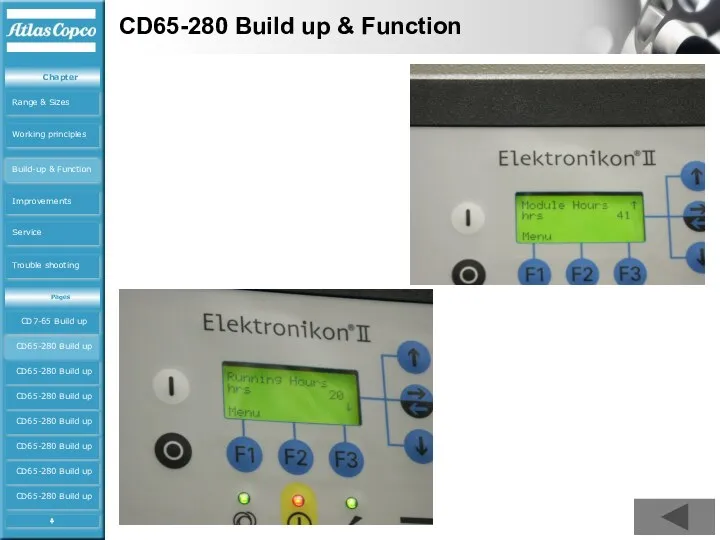

- 23. CD65-280 Build up & Function CD7-65 Build up CD65-280 Build up CD65-280 Build up CD65-280 Build

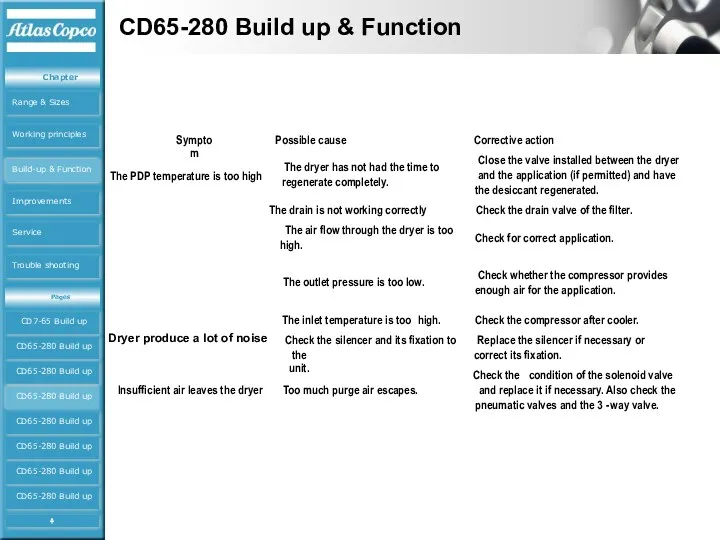

- 24. CD65-280 Build up & Function Symptom Possible cause Corrective action The dryer has not had the

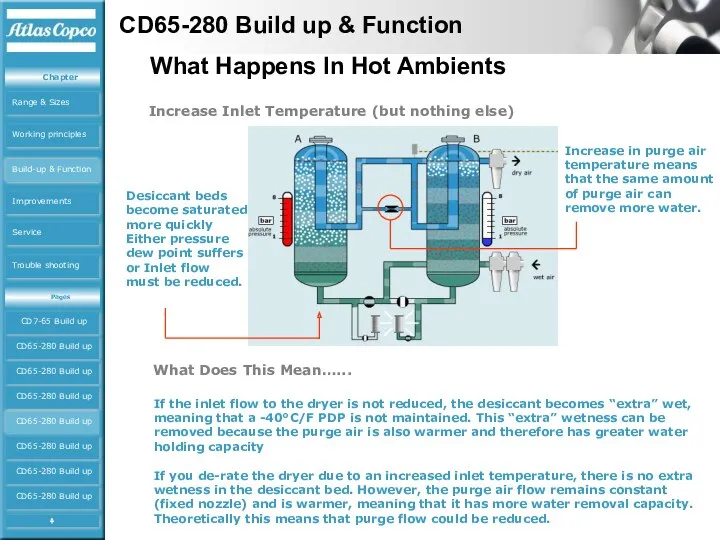

- 25. Increase Inlet Temperature (but nothing else) Desiccant beds become saturated more quickly Either pressure dew point

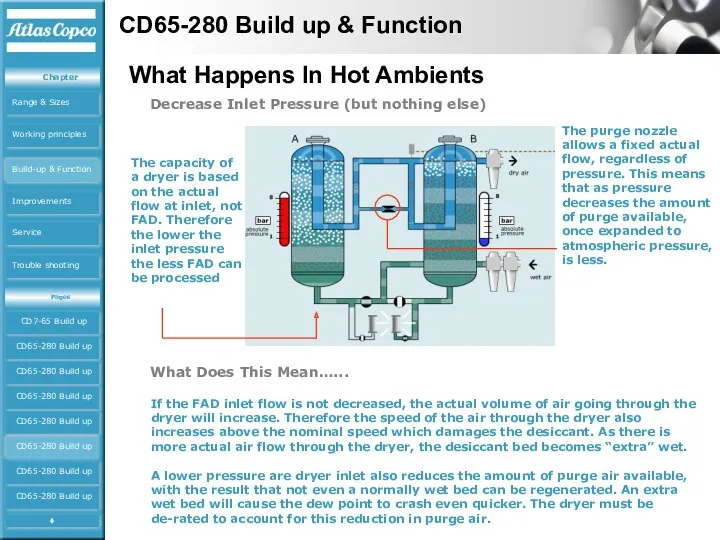

- 26. Decrease Inlet Pressure (but nothing else) The capacity of a dryer is based on the actual

- 27. Increase Required PDP (but nothing else) When air passes through a regenerated desiccant bed, the PDP

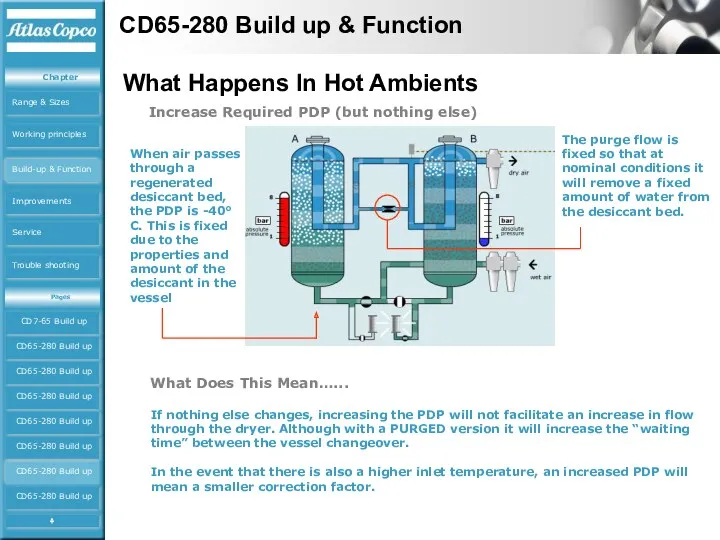

- 28. Using Correction Factors - Do’s and Don’ts DO Remember that for inlet temperatures greater than 50°C,

- 29. CD7-60 Improvements O-ring rolled in piston inlet-outlet valve Starting from serial number AIQ 556 570 And

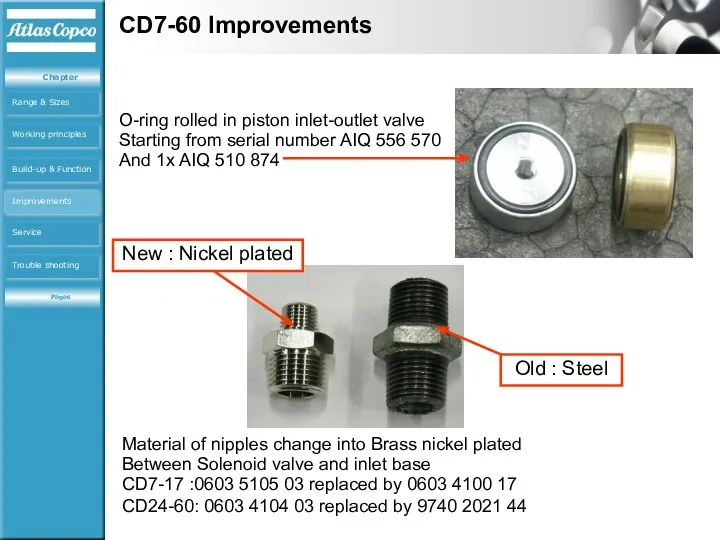

- 30. CD7-60 Service tools CD24-60 for plug 1617 6181 00 (old) and 1617 6225 00 (new) CD7-17

- 31. CD7-60 Service tools Valve seat CD7-60 2903 0014 01 is for CD7-17 2903 0014 02 is

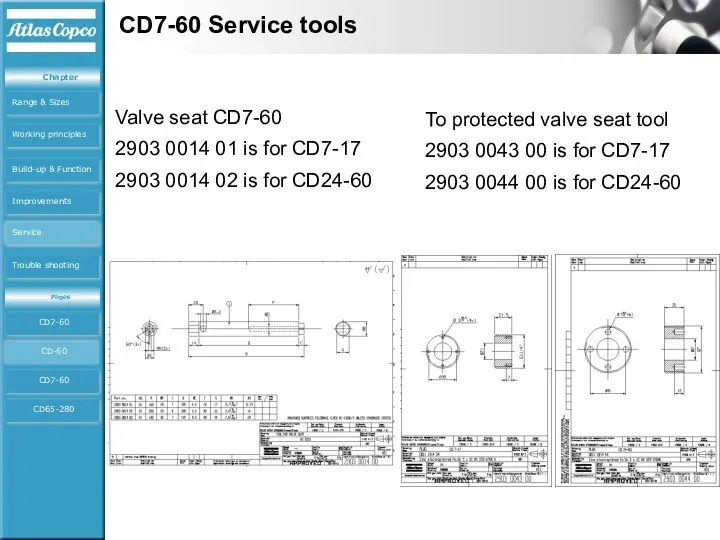

- 32. CD7-60 Service Kits Service kits CD7-60 Tools CD-60 Tools CD7-60 Kits CD65-280 Kits Service

- 33. CD65-280 Service Kits CD65-80-100 4000Hrs 2901 1000 00 CD65-80-100 40000Hrs 2901 1001 00 CD140 4000Hrs 2901

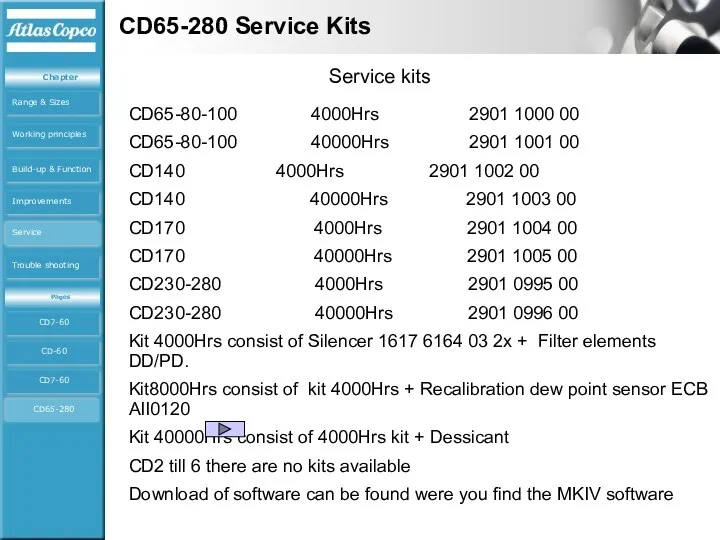

- 34. Trouble shooting 1/ Dew point too high : Electrical Problem 2/ Dew point too high :

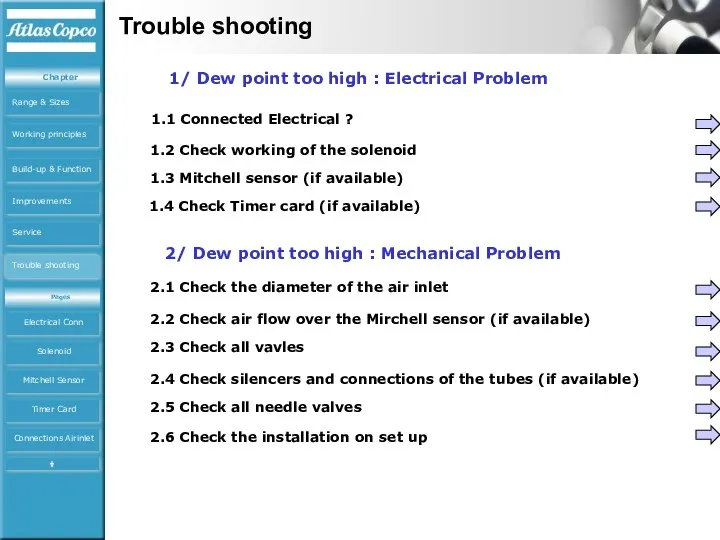

- 35. Trouble shooting CD7-280 Check if the power supply is connected This is for the CD65-280 purge

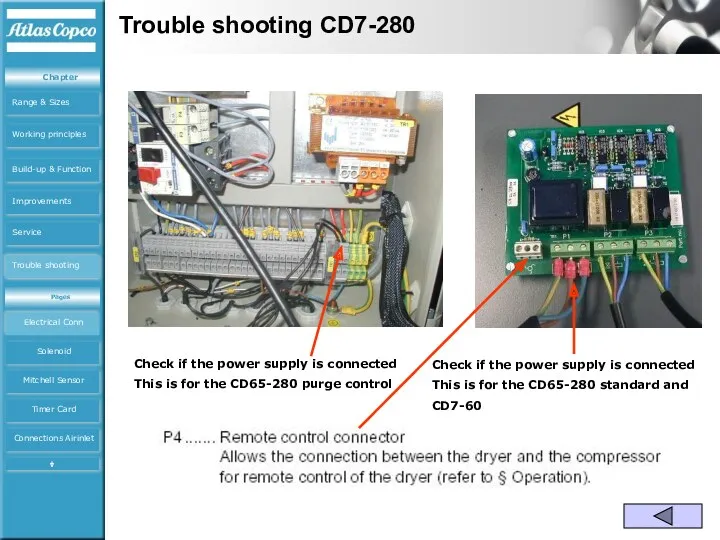

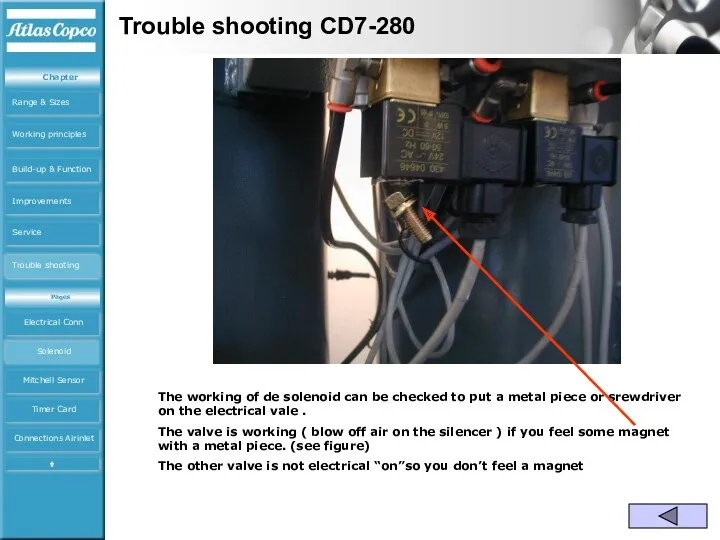

- 36. Trouble shooting CD7-280 The working of de solenoid can be checked to put a metal piece

- 37. Trouble shooting CD65-280 Check also the electrical connection , if one of the wires is grounded

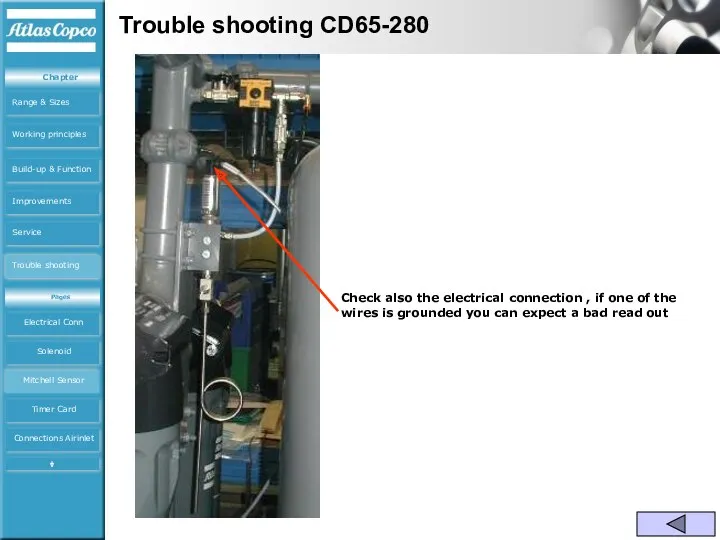

- 38. Trouble shooting CD7-280 How to check te working of the time card : Connect with the

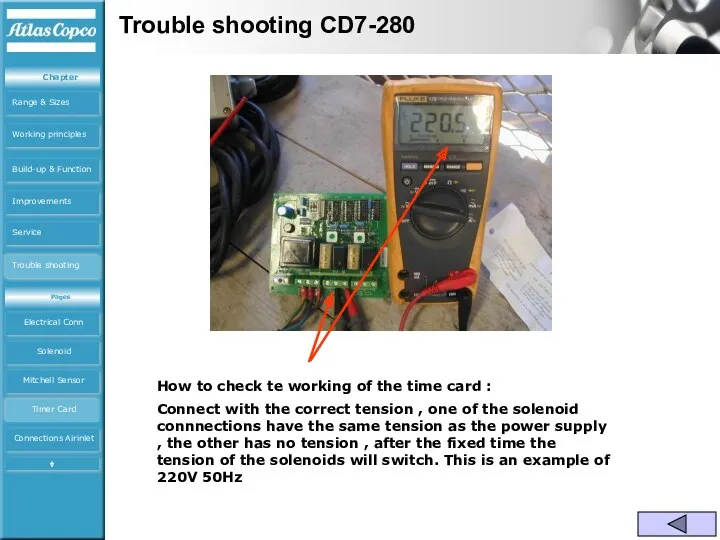

- 39. Trouble shooting CD7-280 Check if the the right in-outlet connetion is foreseen ( for the correct

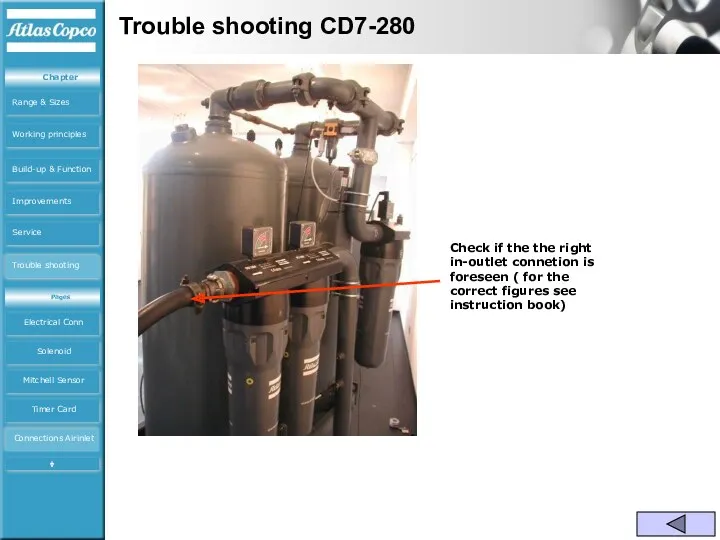

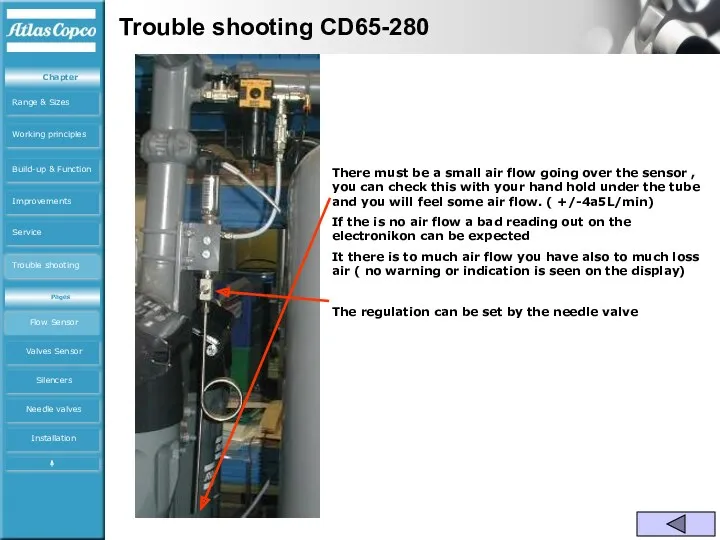

- 40. Trouble shooting CD65-280 There must be a small air flow going over the sensor , you

- 41. Trouble shooting CD65-280 Valves must be open , in case on of them is closed a

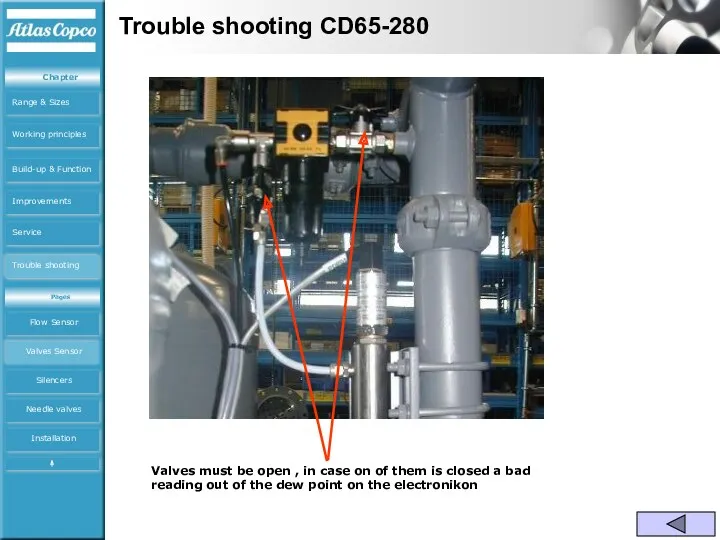

- 42. Trouble shooting CD7-65 Check the right connections of the tubes ( see intrustion munual) Ckeck the

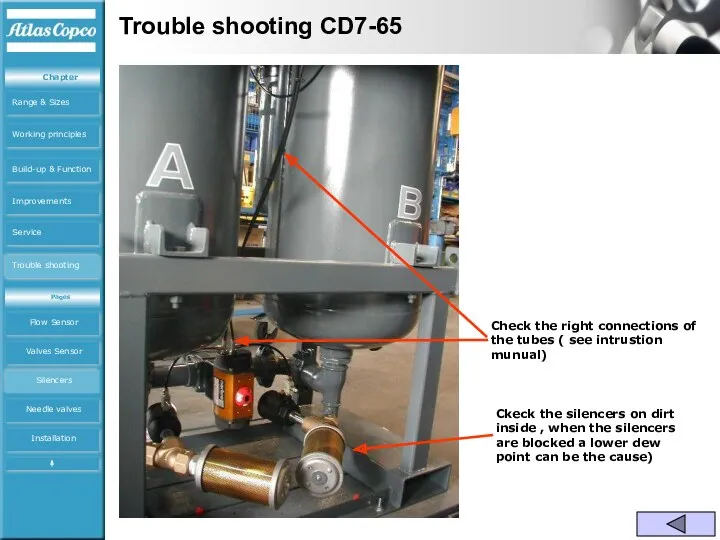

- 43. Trouble shooting CD65-280 Check the needle valves , a closed needle valve means no switching of

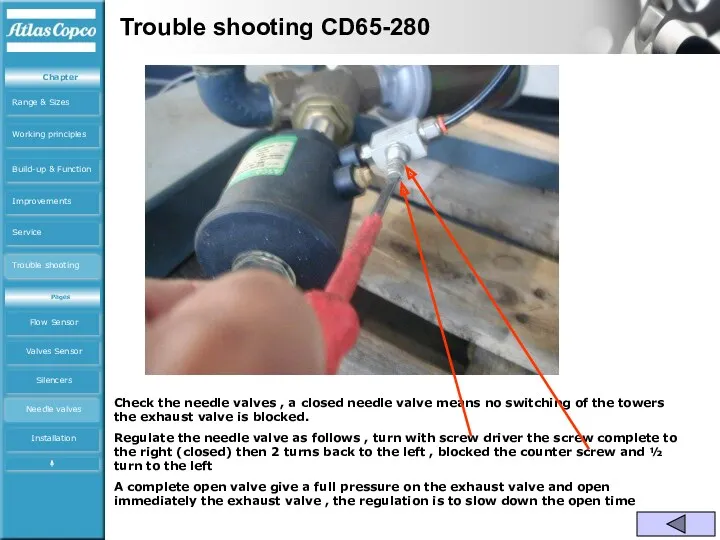

- 45. Скачать презентацию

Русский язык. Лексика и грамматика

Русский язык. Лексика и грамматика Игра За сутки до.... Проект

Игра За сутки до.... Проект Поставка по контракту. Заключение и исполнение. Ответственность

Поставка по контракту. Заключение и исполнение. Ответственность Оңтүстік Қазақстан және Батыс Қазақстанда таралған пайдалы өсімдіктер

Оңтүстік Қазақстан және Батыс Қазақстанда таралған пайдалы өсімдіктер Фәнис Яруллин

Фәнис Яруллин Теория коллектива

Теория коллектива Воспитательное пространство: основные характеристики

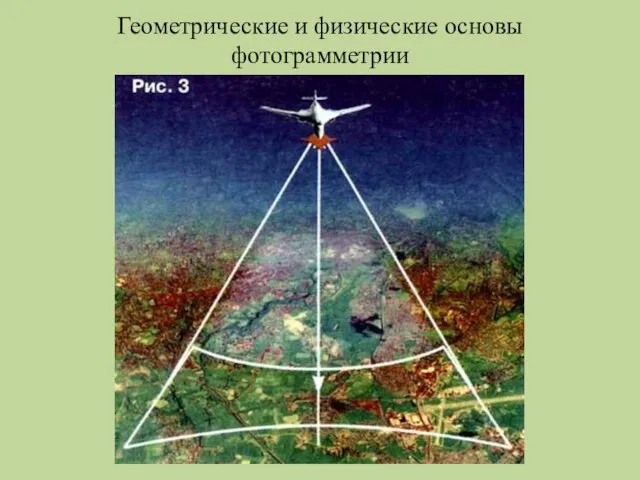

Воспитательное пространство: основные характеристики Фотограмметрия. Геометрические и физические основы фотограмметрии. (Лекция 2)

Фотограмметрия. Геометрические и физические основы фотограмметрии. (Лекция 2) Новогодняя ночь

Новогодняя ночь Сын полка. 16.04

Сын полка. 16.04 Электронные деловые коммуникации

Электронные деловые коммуникации Здоровое питание школьника презентация

Здоровое питание школьника презентация Игра́ (удм. Эгра) — посёлок в Удмуртии

Игра́ (удм. Эгра) — посёлок в Удмуртии Окончание и основа. 2 класс

Окончание и основа. 2 класс Творческий отчет

Творческий отчет Притча Светланы Копыловой Окно

Притча Светланы Копыловой Окно Полимерные материалы и изделия

Полимерные материалы и изделия Триггеры. (Лекция 6)

Триггеры. (Лекция 6) Обнинская АЭС

Обнинская АЭС Инструкция: Как стать хорошим человеком

Инструкция: Как стать хорошим человеком Dry cleaning. Профессиональный персонал и передовые химические технологии бережно почистят Ваши вещи

Dry cleaning. Профессиональный персонал и передовые химические технологии бережно почистят Ваши вещи С Благовещеньем!

С Благовещеньем! Источники финансирования предпринимательства

Источники финансирования предпринимательства Потенциал. Разность потенциалов. Связь напряжённости поля с разностью потенциалов

Потенциал. Разность потенциалов. Связь напряжённости поля с разностью потенциалов Халықаралық жария құқық субъектілері

Халықаралық жария құқық субъектілері внеурочное мероприятие в 1 классе Турнир Смекалочка

внеурочное мероприятие в 1 классе Турнир Смекалочка Детский воспитательный коллектив

Детский воспитательный коллектив Алльфа страхование. Выявление ключевых проблем филиала и их решение

Алльфа страхование. Выявление ключевых проблем филиала и их решение