Содержание

- 2. Introduction Flight Ops Summary Page July 28 2016 This document provides a quick overview of the

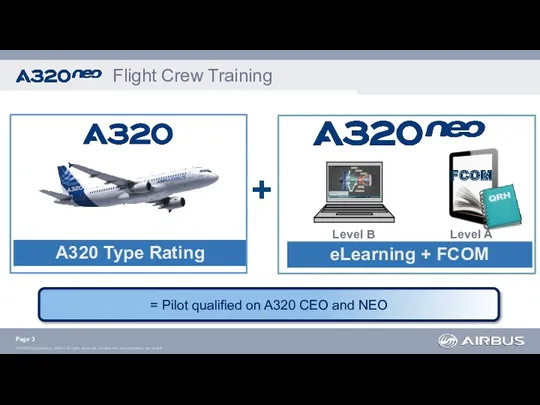

- 3. = Pilot qualified on A320 CEO and NEO Flight Crew Training Level B Level A Page

- 4. Sharklets New engines High Bypass ratio Lower Noise Levels Complete system redesign (pylon, nacelle, bleed) 15%

- 5. Adapted systems ATA22: Autoflight ATA27: Flight Control ATA31: Indicating/Recording System Wing structure, fuselage and cabin adaptations

- 6. Page

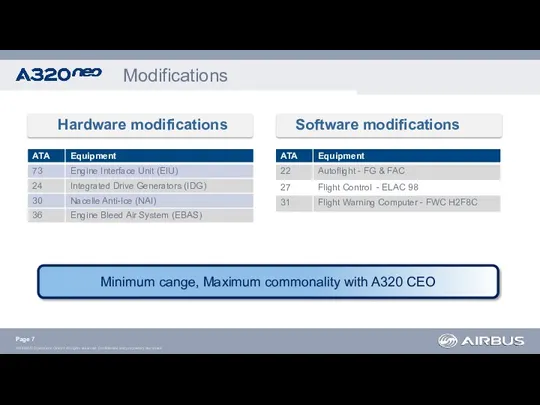

- 7. Hardware modifications Software modifications Page Modifications Minimum cange, Maximum commonality with A320 CEO

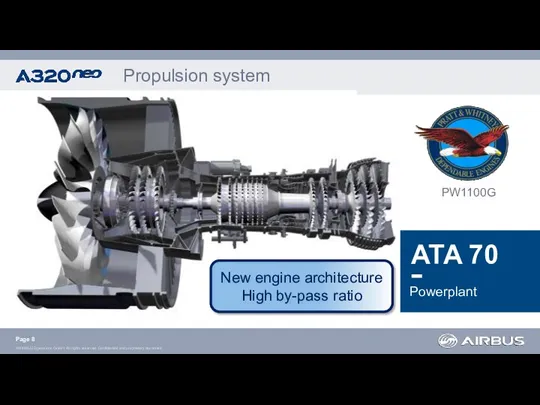

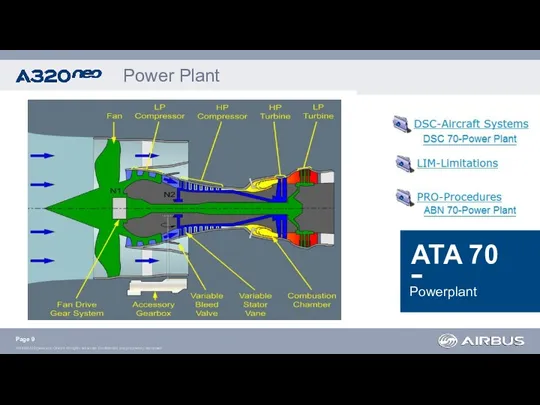

- 8. Propulsion system Powerplant New engine architecture High by-pass ratio Page

- 9. Power Plant Powerplant Page

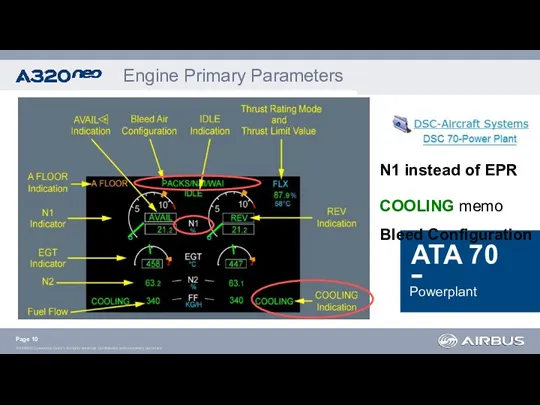

- 10. Engine Primary Parameters Powerplant Page N1 instead of EPR COOLING memo Bleed Configuration

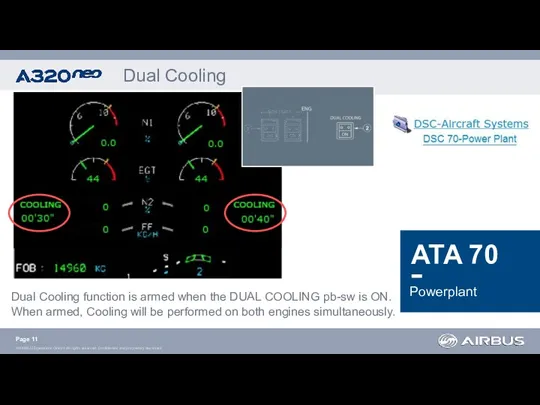

- 11. Dual Cooling Powerplant Page Dual Cooling function is armed when the DUAL COOLING pb-sw is ON.

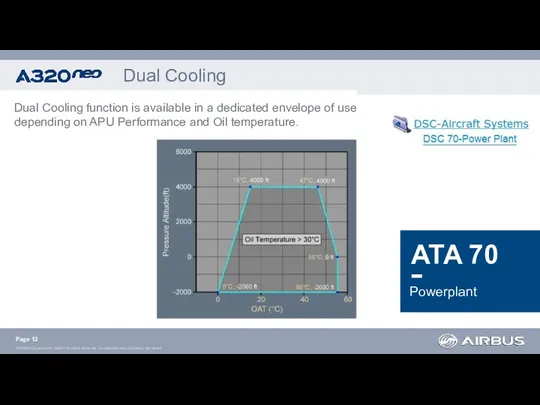

- 12. Dual Cooling Powerplant Page Dual Cooling function is available in a dedicated envelope of use depending

- 13. Electrical Power Integrated Drive Generator (IDG) Derived from A340-500/600 for better reliability Page

- 14. Ice & Rain Protection Nacelle Anti-Ice (NAI) Two Pressure Regulated & Shut off Valves (PRSOV) for

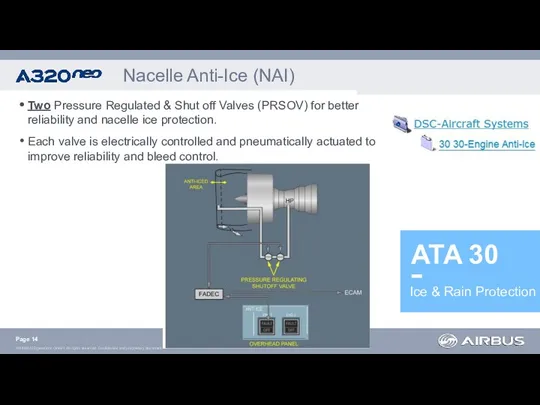

- 15. New Engine Bleed Air System (EBAS) architecture. Electro-pneumatically valves (instead of fully pneumatically). Engine Bleed Air

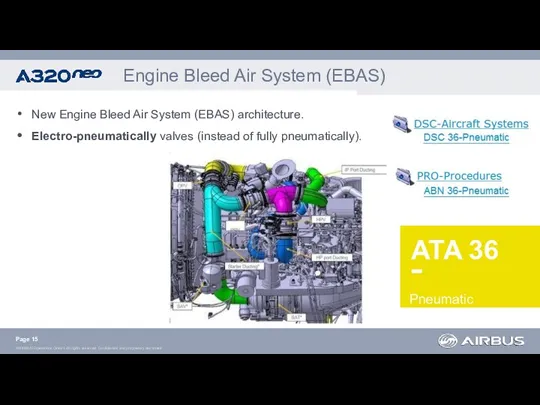

- 16. Standard Operating Procedures (SOP) Limitations (LIM) Supplementary Procedures (SUP) Abnormal Procedures (ABN)

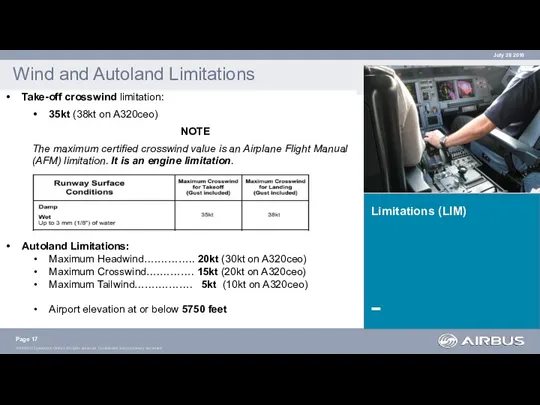

- 17. Limitations (LIM) Wind and Autoland Limitations Page July 28 2016 Take-off crosswind limitation: 35kt (38kt on

- 18. Limitations (LIM) Engine Limitations Page Engine Limitations: Updated to take into account PW1100G specification. RPM: N1

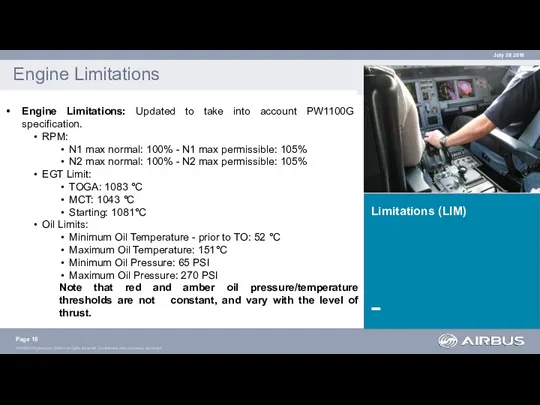

- 19. Limitations (LIM) Engine Limitations Page Starter Limits: 3 consecutive start attempts 35 sec between each cycle

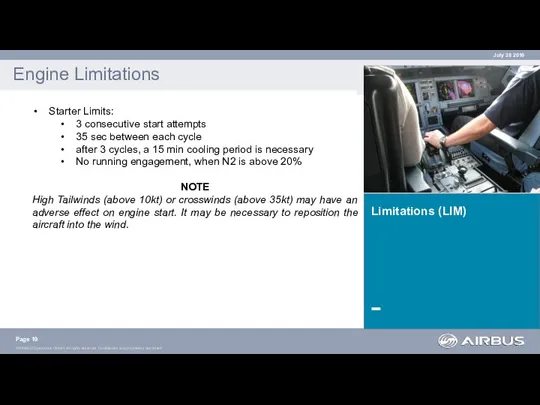

- 20. Standard Operating Procedures (SOP) Preliminary Cockpit Preparation Preliminary Cockpit Preparation - Oil quantity check Minimum Oil

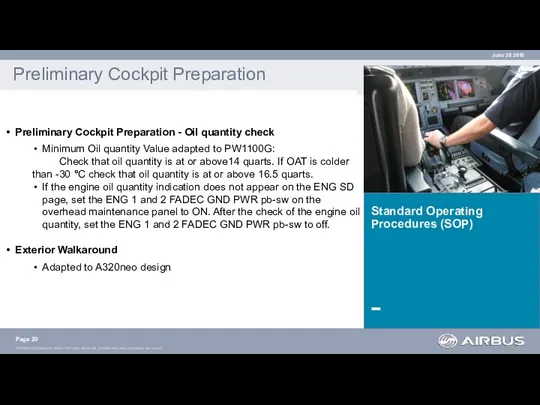

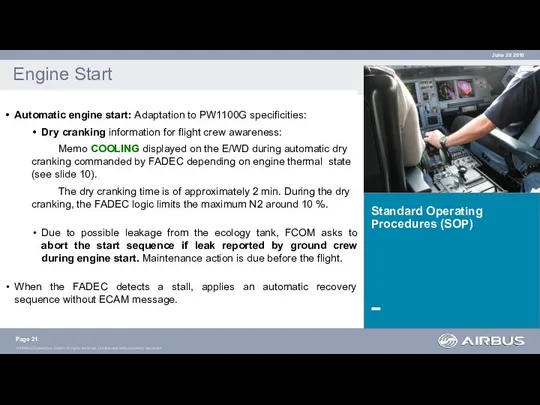

- 21. Standard Operating Procedures (SOP) Engine Start Automatic engine start: Adaptation to PW1100G specificities: Dry cranking information

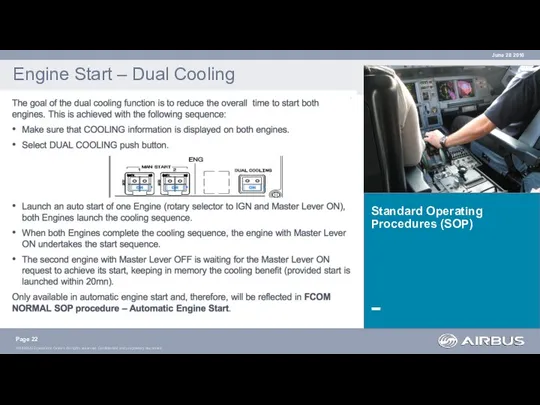

- 22. Standard Operating Procedures (SOP) Engine Start – Dual Cooling Page June 28 2016

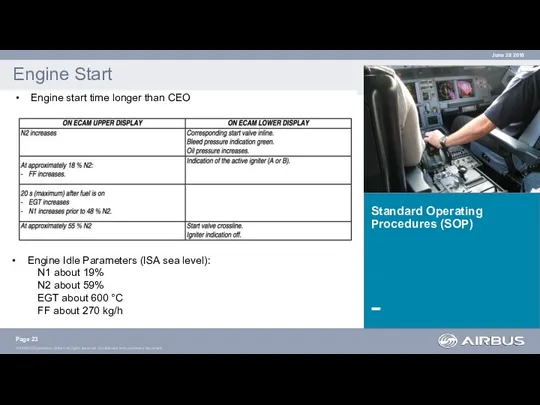

- 23. Standard Operating Procedures (SOP) Engine Start Engine start time longer than CEO Page June 28 2016

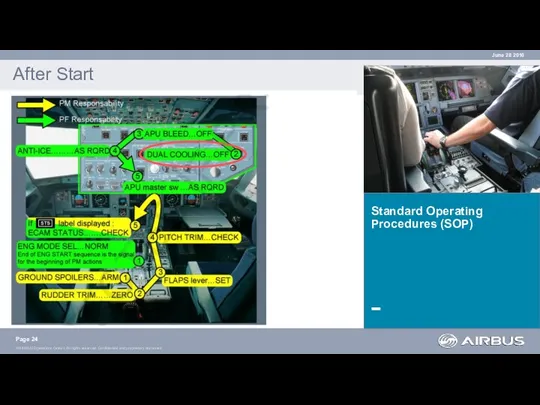

- 24. Standard Operating Procedures (SOP) After Start Page June 28 2016

- 25. Standard Operating Procedures (SOP) Ice Shedding After Start – Ice shedding procedure Engine acceleration at a

- 26. Standard Operating Procedures (SOP) Parking Parking Caution note about brake vibrations The cooling period of 3

- 27. Supplementary Procedures SUP-70 Power Plant SUP-70 Power Plant Effect of the dry cranking function addressed in

- 28. Supplementary Procedures SUP-93 Green Operating Procedures SUP-93 GOP Single Engine Taxi-Out : XBLEED remains closed to

- 29. Abnormal Procedures (ABN) Abnormal Procedures New set of ECAM alerts due to enhanced monitoring of the

- 30. Minimum Equipment List Dispatch Update of A320 MEL Start Valve is a now “NO GO” item

- 31. Performance Page TOW around 3t more than CEO when performance limited. Higher thrust (3% to 7%

- 32. ATA 70. Powerplant ATA 30. Nacelle Anti-Ice (NAI) ATA 36. Engine Bleed Air System (EBAS) FCOM

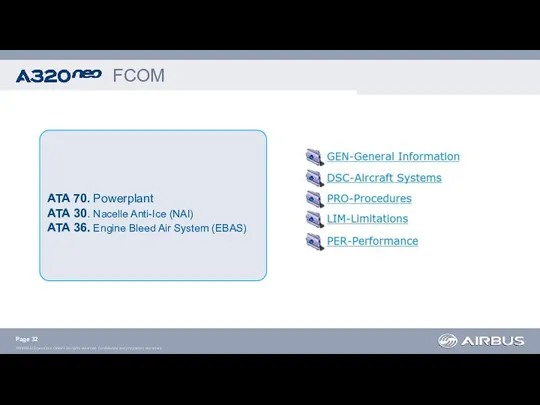

- 33. SOP & SUP ? No major changes ABN ? New alerts New FWC standard ATA70, ATA24,

- 34. LIM 11. Weight & Center of Gravity limits LIM 12. Environment Envelope – Wind Limitation LIM

- 35. Updated Performance tables FCOM Page

- 36. MEL ATA 7x, 24, 30, 36 Update of Performance data MEL Entries MEL Items MEL Operational

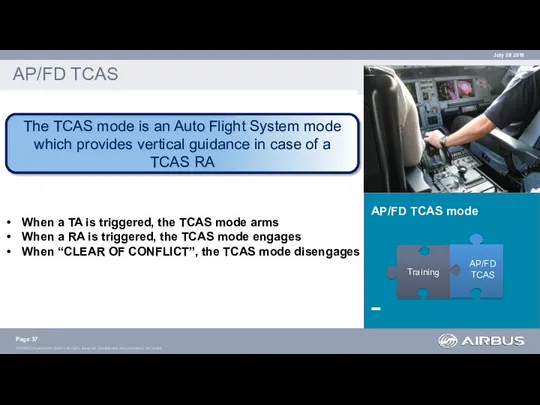

- 37. AP/FD TCAS mode AP/FD TCAS Page July 28 2016 The TCAS mode is an Auto Flight

- 38. AP/FD TCAS mode mode AP/FD TCAS When the TCAS mode arms, the FMA displays TCAS in

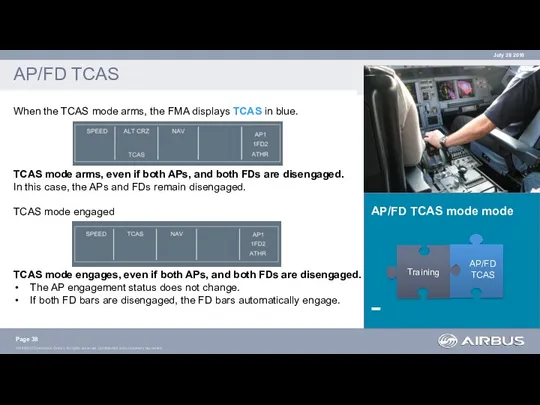

- 39. AP/FD TCAS mode AP/FD TCAS Page July 28 2016 Training AP/FD TCAS Lateral mode If the

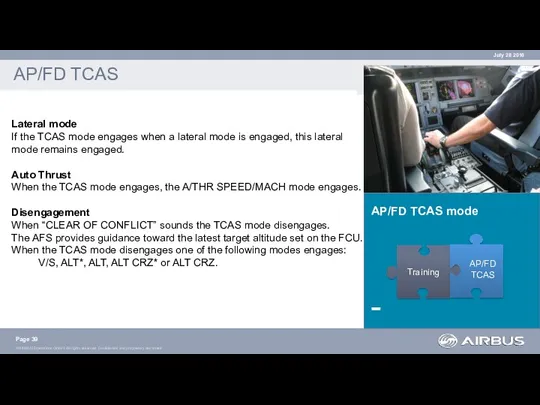

- 40. AP/FD TCAS mode AP/FD TCAS Page July 28 2016 Training AP/FD TCAS The TCAS mode is

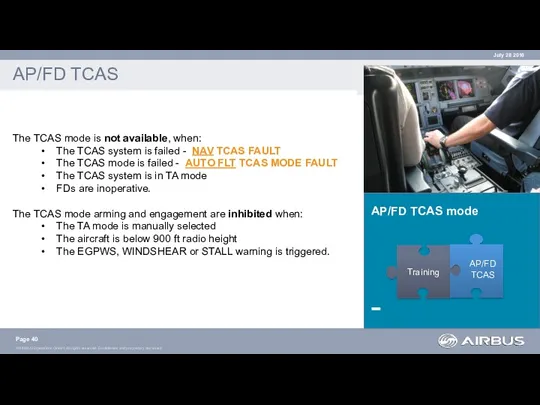

- 41. AP/FD TCAS proc AP/FD TCAS Page July 28 2016 Training AP/FD TCAS (AP/FD) TCAS WARNINGS QRH

- 42. AP/FD TCAS proc (TA) AP/FD TCAS Page July 28 2016 Training AP/FD TCAS

- 43. AP/FD TCAS proc (RA) AP/FD TCAS Page July 28 2016 Training AP/FD TCAS

- 44. AP/FD TCAS proc (RA) AP/FD TCAS Page July 28 2016 Training AP/FD TCAS

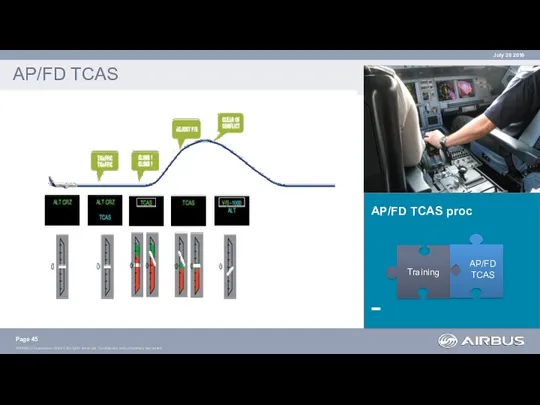

- 45. AP/FD TCAS proc AP/FD TCAS Page July 28 2016 Training AP/FD TCAS

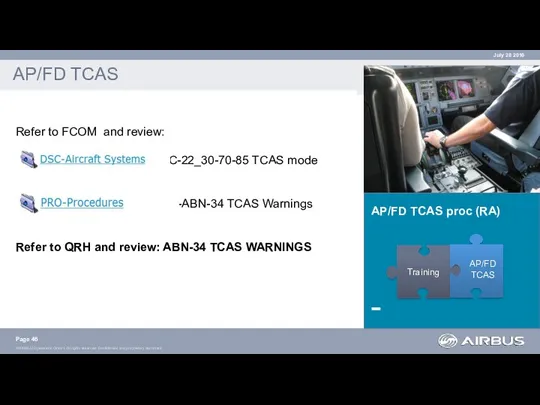

- 46. AP/FD TCAS proc (RA) AP/FD TCAS Page July 28 2016 Training AP/FD TCAS Refer to FCOM

- 48. Скачать презентацию

День народного единства

День народного единства Силы в механике. Виды сил в природе

Силы в механике. Виды сил в природе Вызовы 21-го века. Терроризм

Вызовы 21-го века. Терроризм Творческий проект Семейный калейдоскоп

Творческий проект Семейный калейдоскоп Развитие велопешеходной инфраструктры Петрозаводского городского округа

Развитие велопешеходной инфраструктры Петрозаводского городского округа Особенности проведения лечебно-эвакуационных мероприятий при применении противником отравляющих веществ

Особенности проведения лечебно-эвакуационных мероприятий при применении противником отравляющих веществ Топологические модели электронных схем. Схемы замещения электронных цепей по постоянному и переменному току

Топологические модели электронных схем. Схемы замещения электронных цепей по постоянному и переменному току 4.Презентация к проекту

4.Презентация к проекту Влияние режимов термообработки на свойства сталей

Влияние режимов термообработки на свойства сталей Путешествие по стране Здоровье.

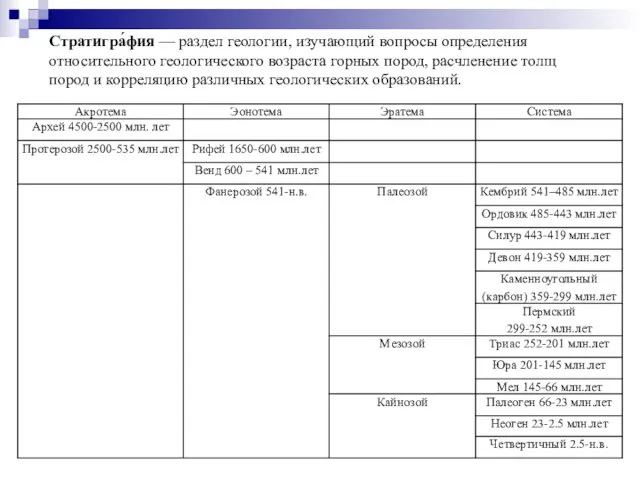

Путешествие по стране Здоровье. Стратигра́фия

Стратигра́фия портфолио

портфолио Гемофилия А, В, С. Классификация по степени тяжести

Гемофилия А, В, С. Классификация по степени тяжести Полупроводниковые диоды. Область применения

Полупроводниковые диоды. Область применения Структура кредитной системы и рынок ссудных капиталов

Структура кредитной системы и рынок ссудных капиталов Итоговый тест по физике

Итоговый тест по физике Теории управления персоналом

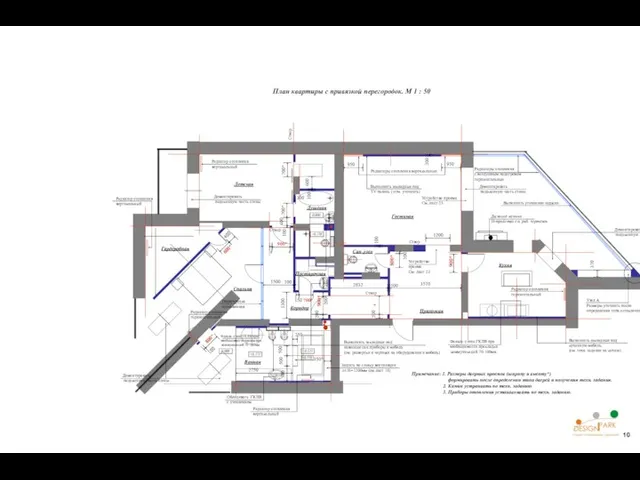

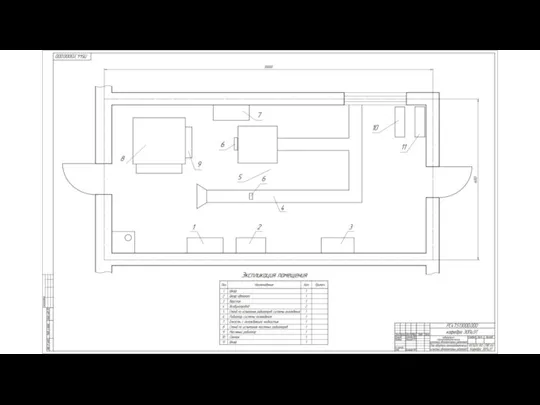

Теории управления персоналом План квартиры с привязкой перегородок

План квартиры с привязкой перегородок Франція. Економіко-географічна характеристика. Історико-культурні особливості

Франція. Економіко-географічна характеристика. Історико-культурні особливості Презентация Загадки от Деда Мороза

Презентация Загадки от Деда Мороза Успешный руководитель

Успешный руководитель Индия - страна чудес. (10 класс)

Индия - страна чудес. (10 класс) Call center operator

Call center operator Экспериментальные исследования в лаборатории теплоаэродинамических испытаний автотракторных радиаторов

Экспериментальные исследования в лаборатории теплоаэродинамических испытаний автотракторных радиаторов Кто в море живет

Кто в море живет Предпринимательская тайна и способы ее защиты. Лекция 8

Предпринимательская тайна и способы ее защиты. Лекция 8 Презентация Синяя лента апреля в МБО УСОШ № 3

Презентация Синяя лента апреля в МБО УСОШ № 3 Физико-химические свойства нефтей и нефтепродуктов

Физико-химические свойства нефтей и нефтепродуктов