Содержание

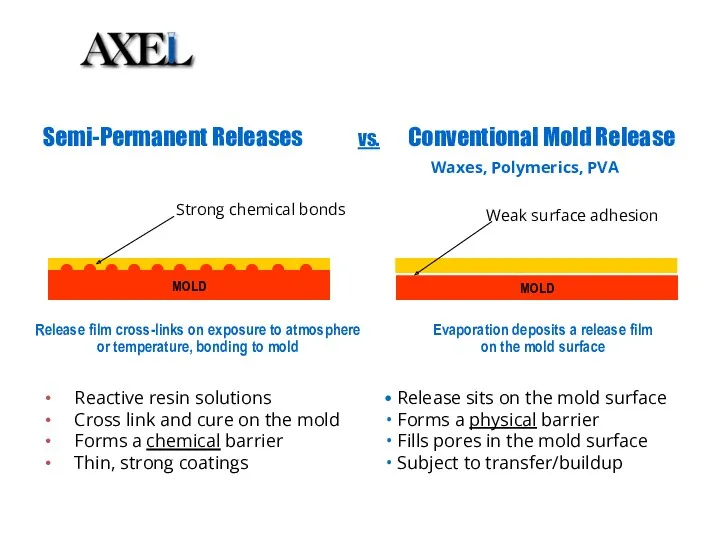

- 2. Semi-Permanent Releases vs. Conventional Mold Release Reactive resin solutions Cross link and cure on the mold

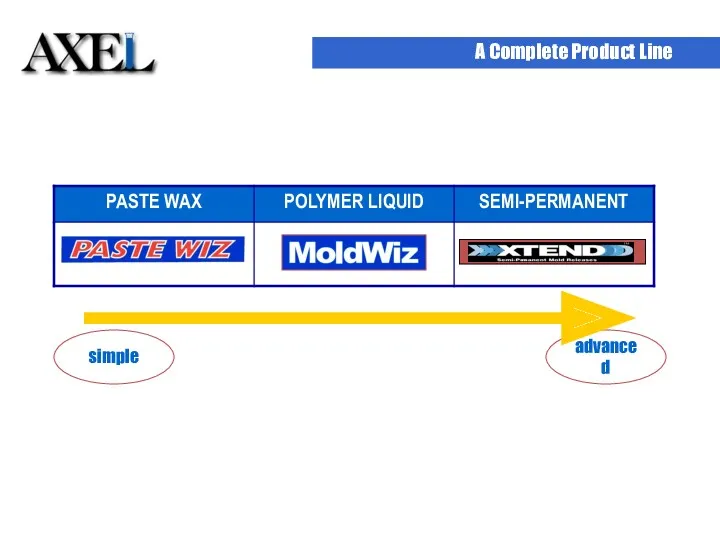

- 3. advanced simple A Complete Product Line A Complete Product Line

- 4. Paste Wax Easy to use to pick up with cloth Easy to apply Easy to buff

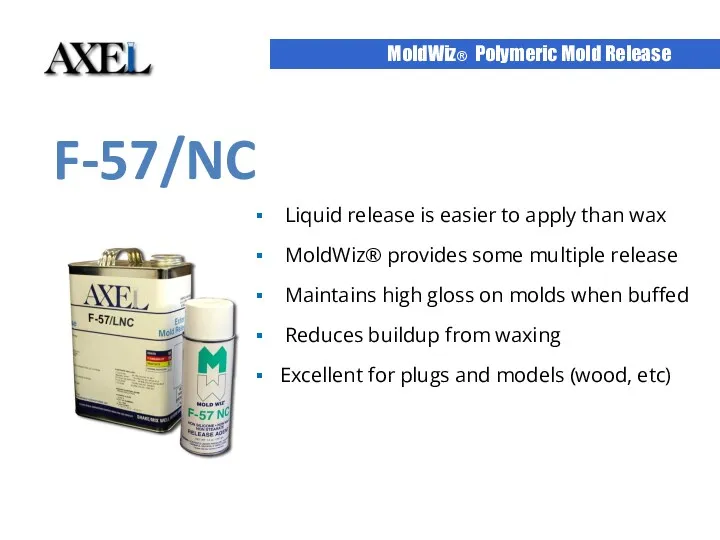

- 5. Liquid release is easier to apply than wax MoldWiz® provides some multiple release Maintains high gloss

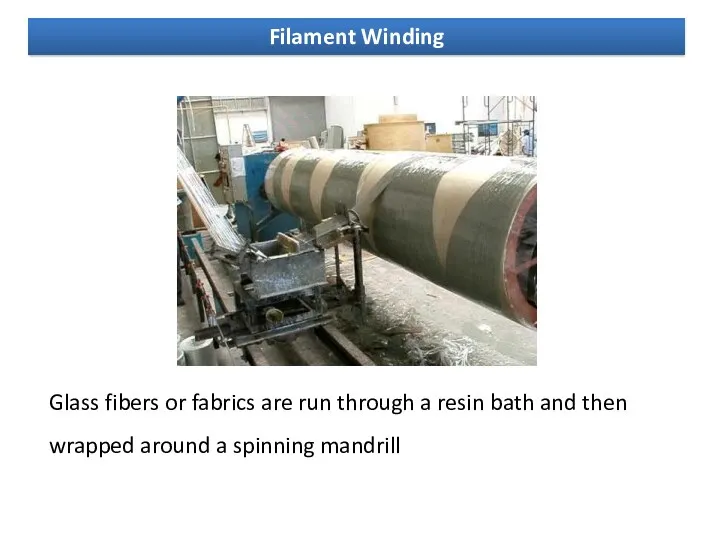

- 6. Glass fibers or fabrics are run through a resin bath and then wrapped around a spinning

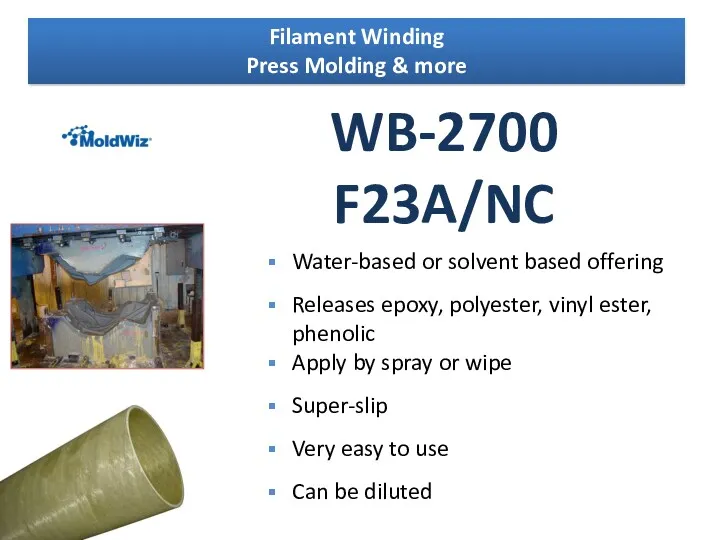

- 7. WB-2700 F23A/NC Water-based or solvent based offering Releases epoxy, polyester, vinyl ester, phenolic Apply by spray

- 8. WB-2700 F23A/NC No Sealers needed No cure time needed – simply allow to dry Filament Winding

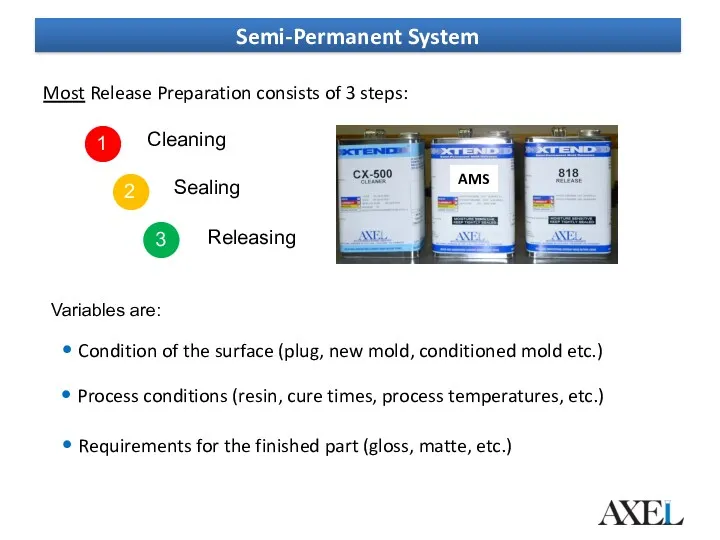

- 9. Condition of the surface (plug, new mold, conditioned mold etc.) Most Release Preparation consists of 3

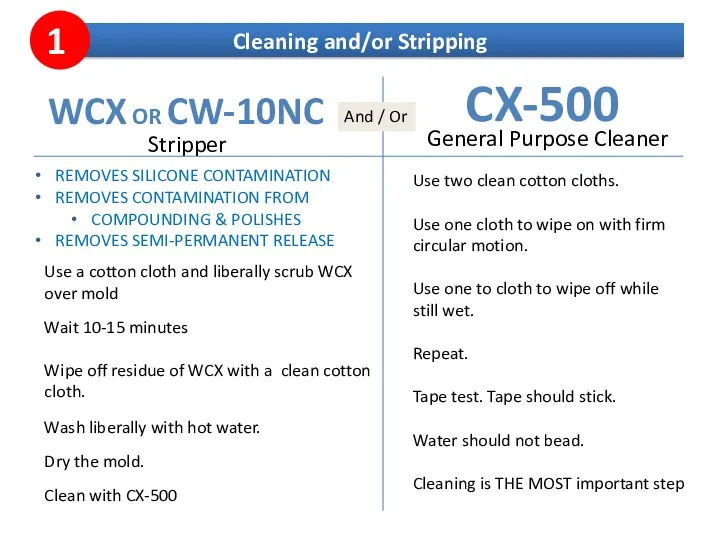

- 10. Cleaning and/or Stripping 1 1 CX-500 WCX OR CW-10NC Stripper General Purpose Cleaner REMOVES SILICONE CONTAMINATION

- 11. Mold Strippers & Cleaners WHY? Because mold cleaners do not remove most compounds & polishes Removes

- 12. Mold Strippers & Cleaners Longest dwell time Allows operator to clean the mold surface before the

- 13. Highest Gloss Sealer in the marketplace Easiest to use Streaks are easily removed Compatible with almost

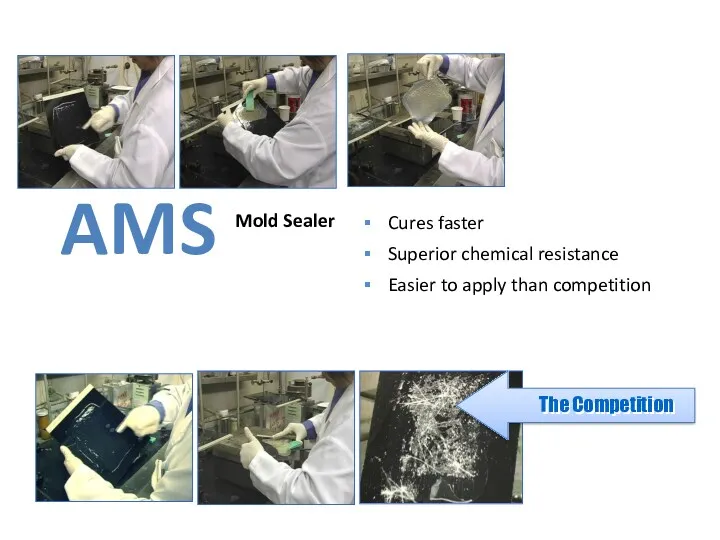

- 14. AMS Mold Sealer Cures faster Superior chemical resistance Easier to apply than competition The Competition

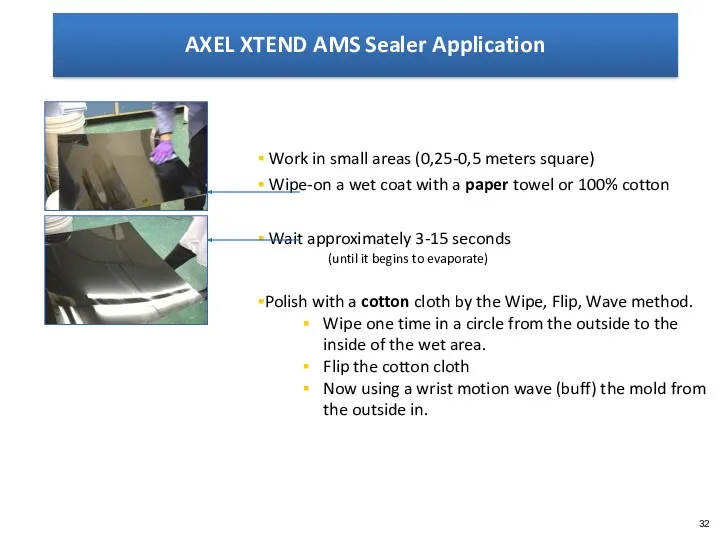

- 15. XTR Sealer Application 32 Work in small areas (0,25-0,5 meters square) Wipe-on a wet coat with

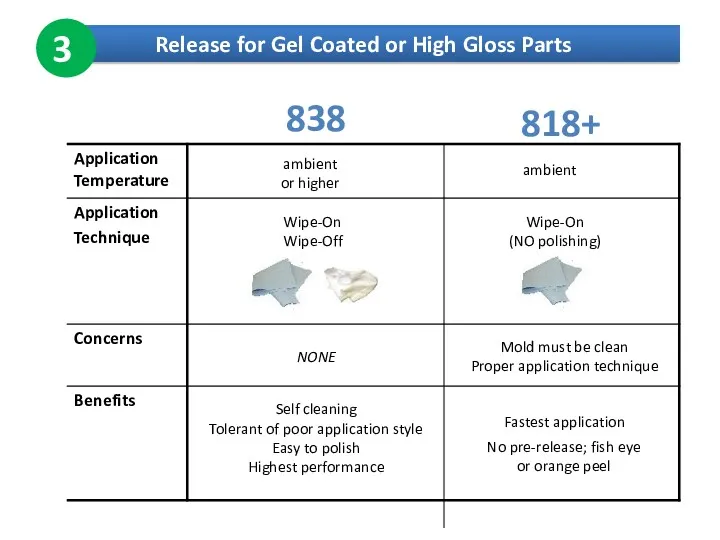

- 16. ambient or higher Wipe-On (NO polishing) ambient Wipe-On Wipe-Off For Gel-Coated or High Gloss Parts Release

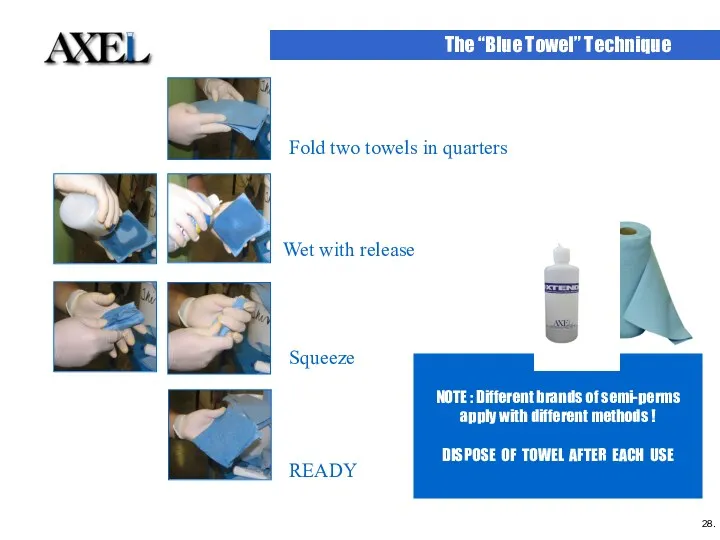

- 17. The “Blue Towel” Technique NOTE : Different brands of semi-perms apply with different methods ! DISPOSE

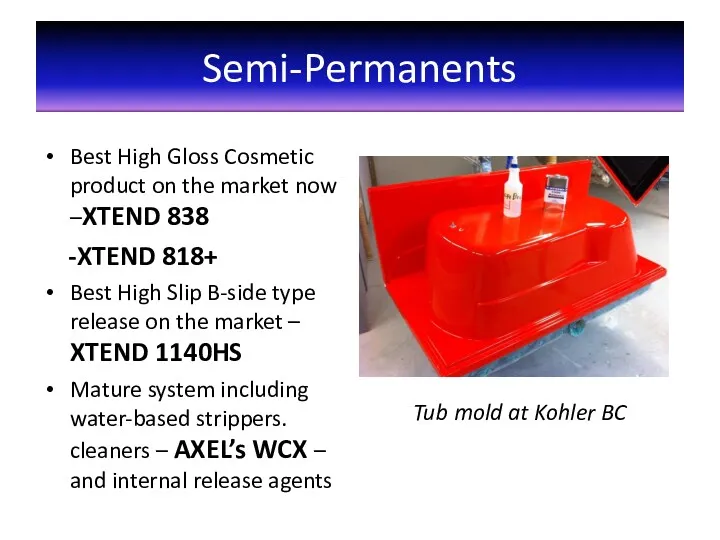

- 18. Semi-Permanents Best High Gloss Cosmetic product on the market now –XTEND 838 -XTEND 818+ Best High

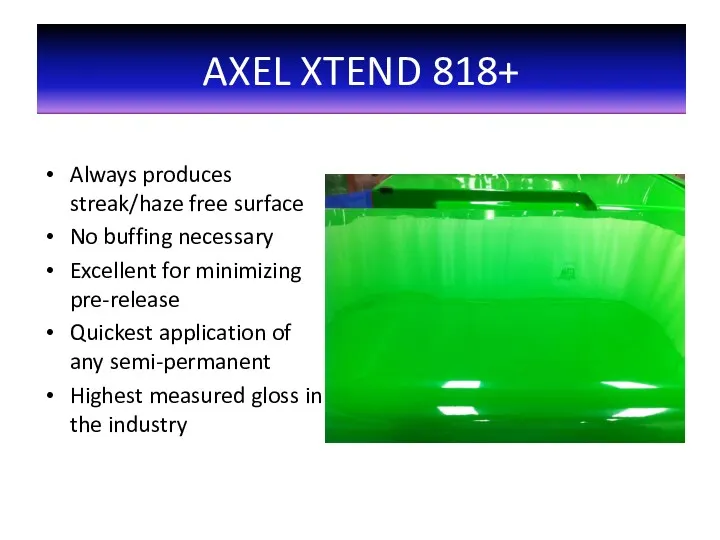

- 19. Always produces streak/haze free surface No buffing necessary Excellent for minimizing pre-release Quickest application of any

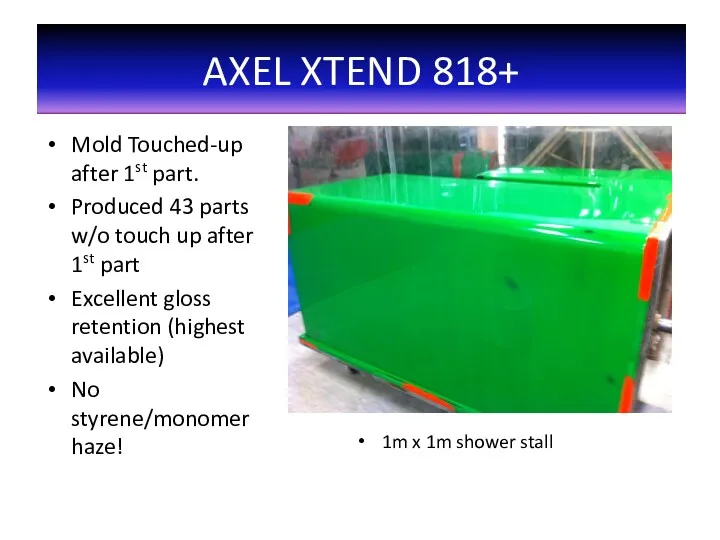

- 20. Mold Touched-up after 1st part. Produced 43 parts w/o touch up after 1st part Excellent gloss

- 21. Excellent ease of release Excellent in can stability Compatible with other release systems AXEL XTEND 818+

- 22. Suitable for everything! Urethane, epoxy, polyester, vinyl-ester, gel-coats. Works well at ambient and on heated molds

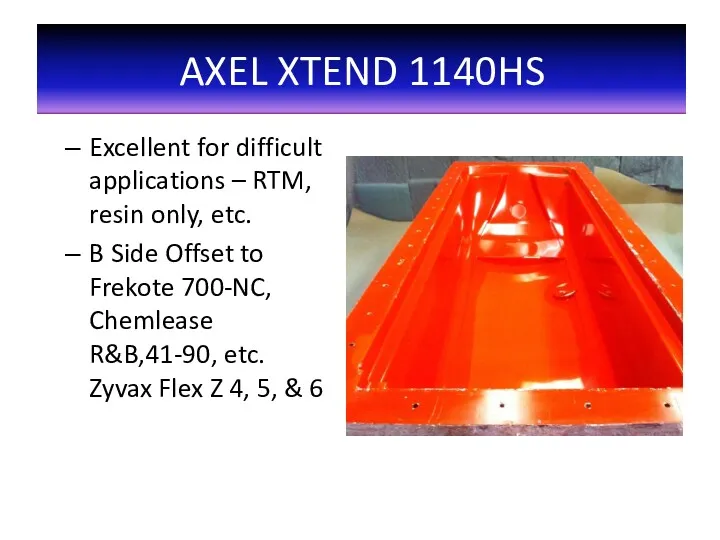

- 23. Excellent for difficult applications – RTM, resin only, etc. B Side Offset to Frekote 700-NC, Chemlease

- 24. Excellent cosmetics when needed No build-up Ease of release is best of all AXEL High Slip

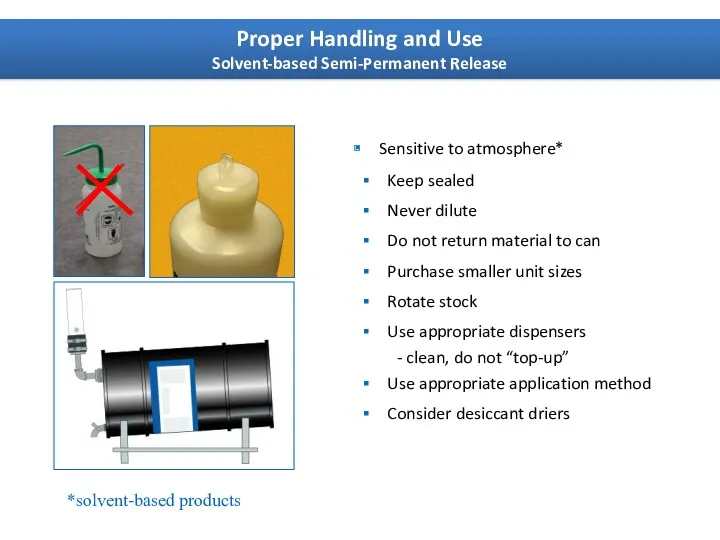

- 25. Sensitive to atmosphere* Keep sealed Never dilute Do not return material to can Purchase smaller unit

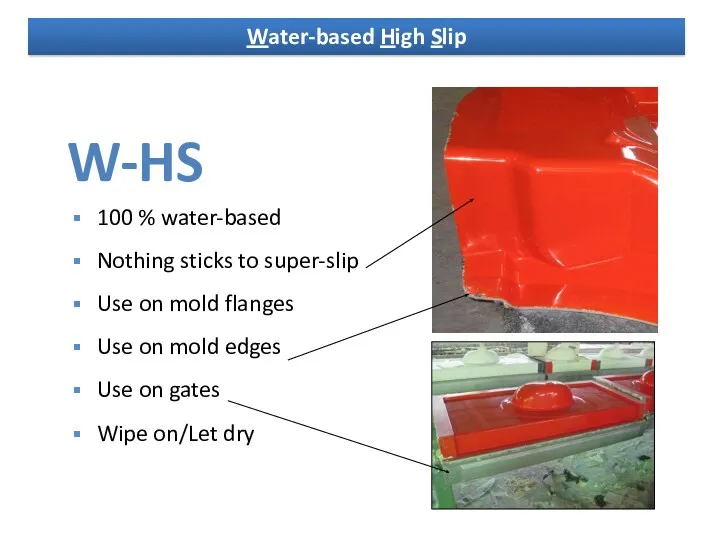

- 26. W-HS 100 % water-based Nothing sticks to super-slip Use on mold flanges Use on mold edges

- 27. SMC/BMC EM-1212SF2 for all surfaces including steel JB-5 for chrome – lowest cost, least build-up Polymeric

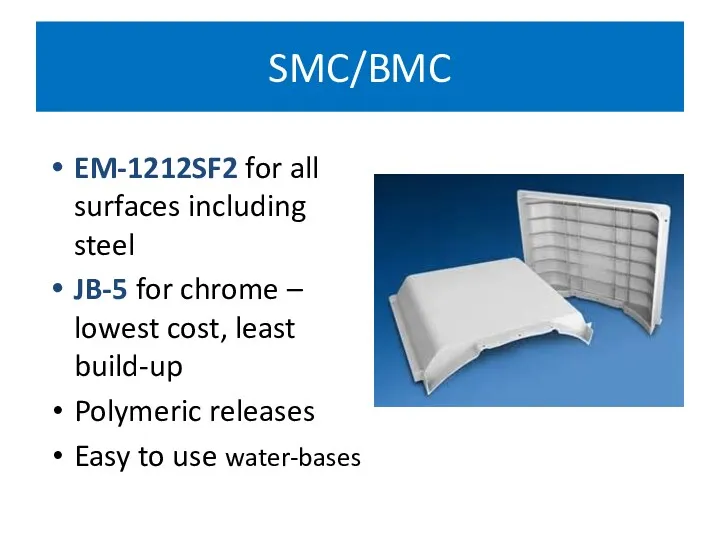

- 28. INTERNAL MOLD RELEASE ADDITIVES DCPD’s, Ortho, Iso, V.E., resin blends Excellent for reducing scumming Improved ease

- 29. For Polyester or DCPD Molding INT-DLP22E DCPD resin - no gel coat Excellent release from core/mandrel

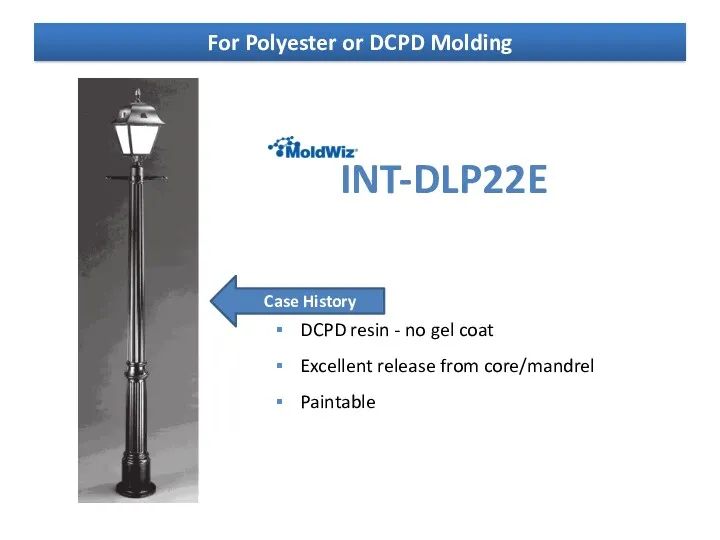

- 30. INTERNAL MOLD RELEASE ADDITIVES – See our brochure Also have a full line of internals for

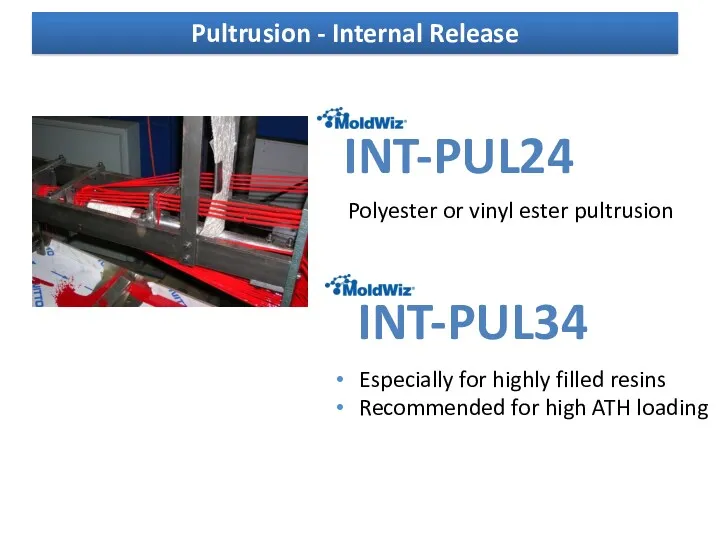

- 31. Pultrusion - Internal Release INT-PUL24 INT-PUL34 Polyester or vinyl ester pultrusion Especially for highly filled resins

- 32. Pultrusion - Internal Release INT-1888LE INT-1857DC FOR EPOXY INT-1948MCH FOR POLYURETHANE NEW NEW

- 33. XTEND® Semi-Permanent Mold Release Research & Development at AXEL New lubricants for pultrusion – lower cost,

- 35. Скачать презентацию

Историческая обусловленность формирования родоплеменной структуры казахов

Историческая обусловленность формирования родоплеменной структуры казахов Фильтрация информационных сигналов. Современные модели помехоподавляющих фильтров, их основные характеристики и возможности

Фильтрация информационных сигналов. Современные модели помехоподавляющих фильтров, их основные характеристики и возможности Суицид как форма девиантного поведения подростков

Суицид как форма девиантного поведения подростков Гематологические анализаторы

Гематологические анализаторы ОГОНЬ – ДРУГ ИЛИ ВРАГ?

ОГОНЬ – ДРУГ ИЛИ ВРАГ? профессиональное выгорание педагогов: причины, способы избавления

профессиональное выгорание педагогов: причины, способы избавления Развитие доходов на отходах производства грибов

Развитие доходов на отходах производства грибов Неделя игры и игрушки в подготовительной группе №8

Неделя игры и игрушки в подготовительной группе №8 Элементы комплексного благоустройства объекта: лесопарк Сосновка

Элементы комплексного благоустройства объекта: лесопарк Сосновка Наука, техника, религия и искусство в системе культуры

Наука, техника, религия и искусство в системе культуры Образование СССР

Образование СССР Буровые технологические жидкости. Фильтрационно-коркообразующие свойства. (Лекция 4)

Буровые технологические жидкости. Фильтрационно-коркообразующие свойства. (Лекция 4) Национальные интересы РФ, стратегия в направлениях: сфера деятельности, социальная, военная, информационная и политическая

Национальные интересы РФ, стратегия в направлениях: сфера деятельности, социальная, военная, информационная и политическая Принятие христианство на Руси

Принятие христианство на Руси Инструментальные методы исследования мочевыделительной системы у детей

Инструментальные методы исследования мочевыделительной системы у детей Патогенетические механизмы при гипоксии

Патогенетические механизмы при гипоксии Олимпийские игры в Древней Греции

Олимпийские игры в Древней Греции Немецкий эволюционизм

Немецкий эволюционизм Проектная деятельность Книги

Проектная деятельность Книги к уроку Политическая карта мира

к уроку Политическая карта мира Возможности получения поддержки для СОНКО на муниципальном, краевом, региональном и федеральном уровнях

Возможности получения поддержки для СОНКО на муниципальном, краевом, региональном и федеральном уровнях Презентация работы Школьного методического объединения

Презентация работы Школьного методического объединения Колмогоров Андрей Николаевич. Гений, живший среди нас

Колмогоров Андрей Николаевич. Гений, живший среди нас Игра-презентация Дифференциация в-ф

Игра-презентация Дифференциация в-ф Онтология. Предметная область философии и онтологии

Онтология. Предметная область философии и онтологии 20231102_prezentatsiya_finansovaya_i_matematicheskaya_gramotnost_dlya_obuchayushchihsya_s_ovz_

20231102_prezentatsiya_finansovaya_i_matematicheskaya_gramotnost_dlya_obuchayushchihsya_s_ovz_ Организация работы в реабилитационных и оздоровительных центрах для детей

Организация работы в реабилитационных и оздоровительных центрах для детей Логопедический проект: Поможем язычку заговорить.

Логопедический проект: Поможем язычку заговорить.