Содержание

- 2. Objectives Explain the basic function of an internal combustion engine. Describe the five events required for

- 3. Internal Combustion Engine Function - Converts potential chemical energy in fuel into heat energy then to

- 4. Requirements for I.C. Engine Operation All Internal combustion engines must carry out five events: Air-fuel mixture

- 5. Historical Development of the I.C. Engine 1862 -- Rochas described the basic principles essential for efficient

- 6. Engine Components and Functions

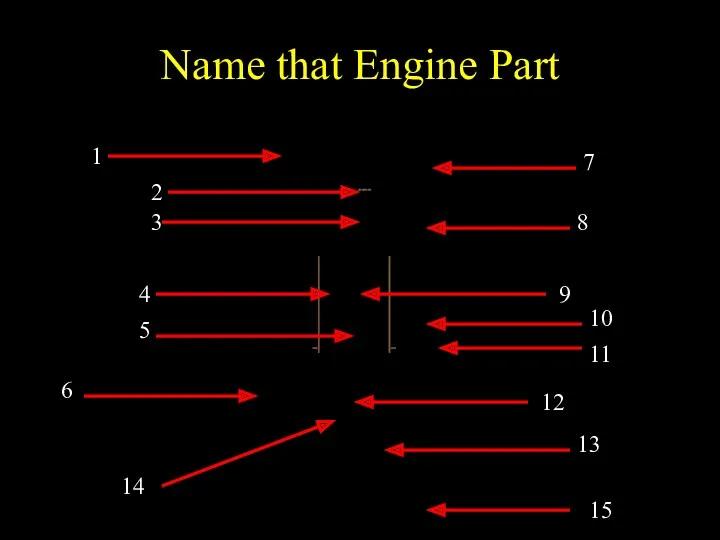

- 7. Name that Engine Part 1 2 3 4 5 6 7 8 9 10 11 12

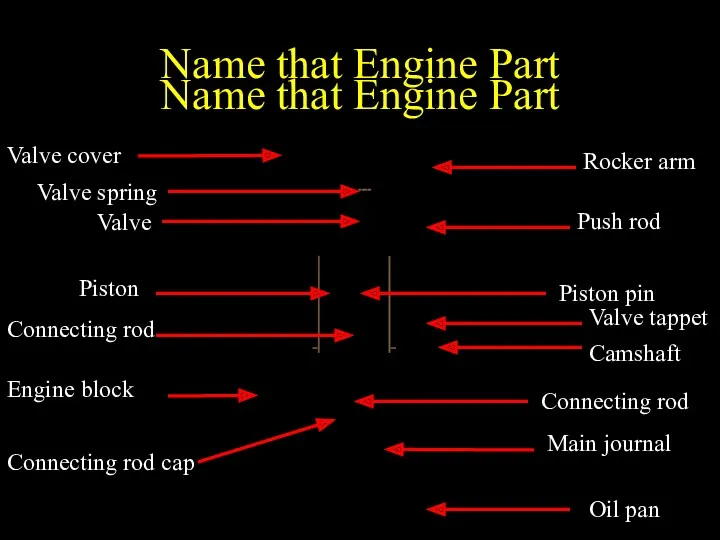

- 8. Name that Engine Part Name that Engine Part

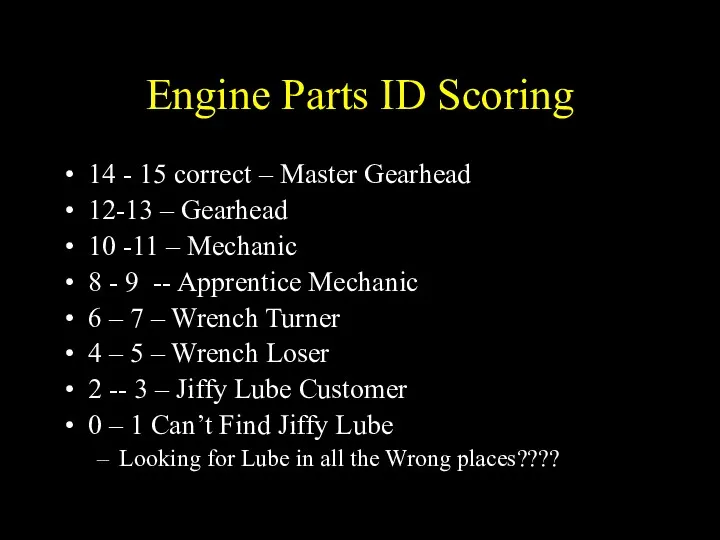

- 9. Engine Parts ID Scoring 14 - 15 correct – Master Gearhead 12-13 – Gearhead 10 -11

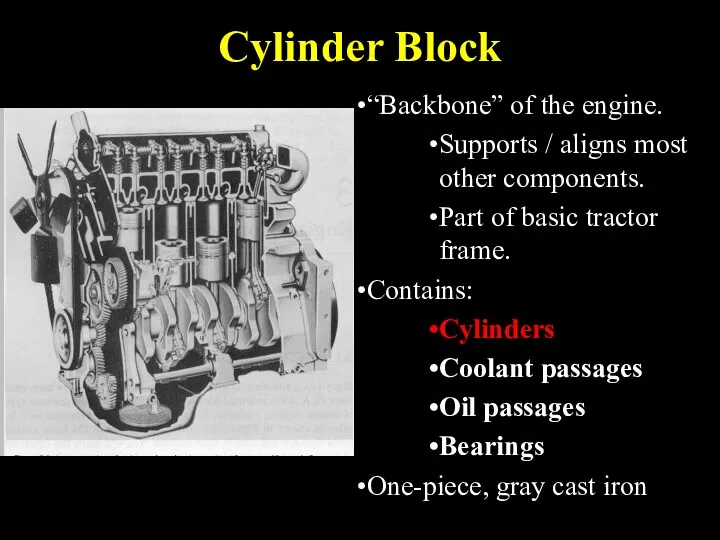

- 10. Cylinder Block “Backbone” of the engine. Supports / aligns most other components. Part of basic tractor

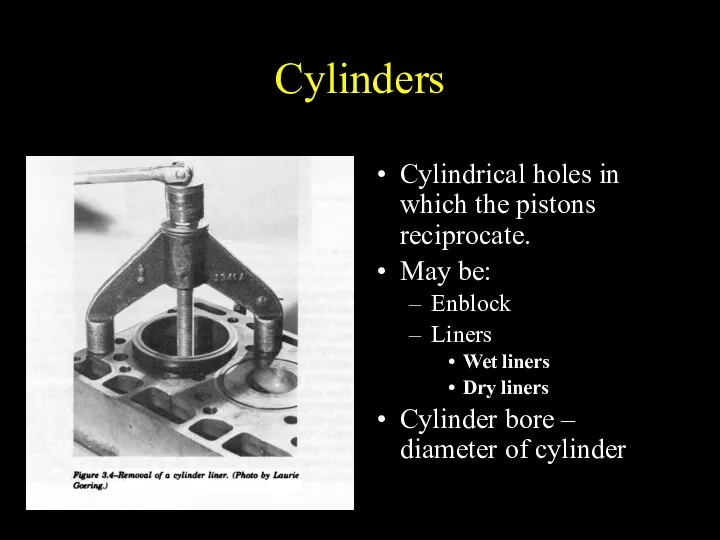

- 11. Cylinders Cylindrical holes in which the pistons reciprocate. May be: Enblock Liners Wet liners Dry liners

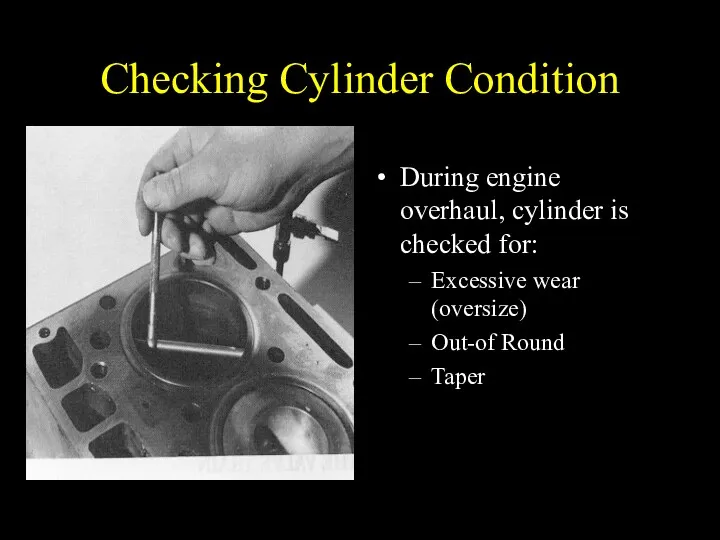

- 12. Checking Cylinder Condition During engine overhaul, cylinder is checked for: Excessive wear (oversize) Out-of Round Taper

- 13. Bearings and Journals Bearing – Stationary (non-rotating) surfaces providing support to moving (rotating) component. Main bearings

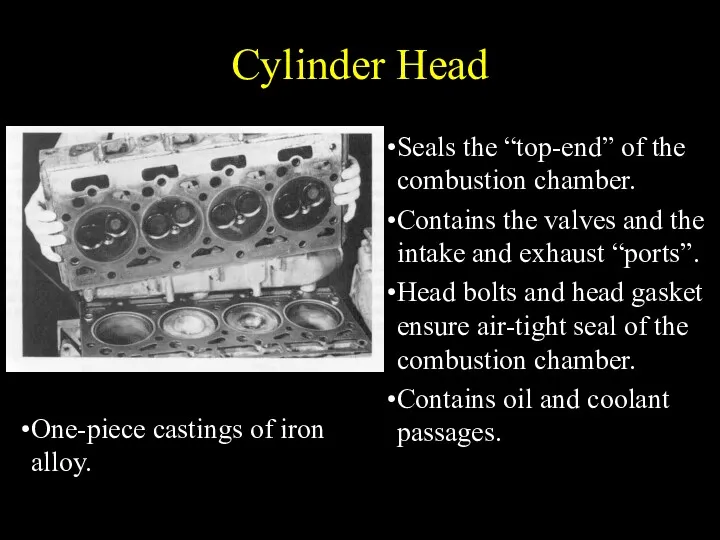

- 14. Cylinder Head Seals the “top-end” of the combustion chamber. Contains the valves and the intake and

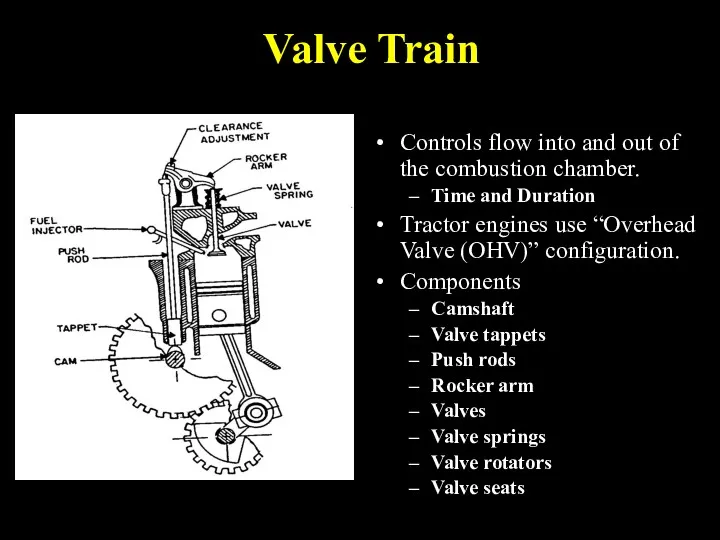

- 15. Valve Train Controls flow into and out of the combustion chamber. Time and Duration Tractor engines

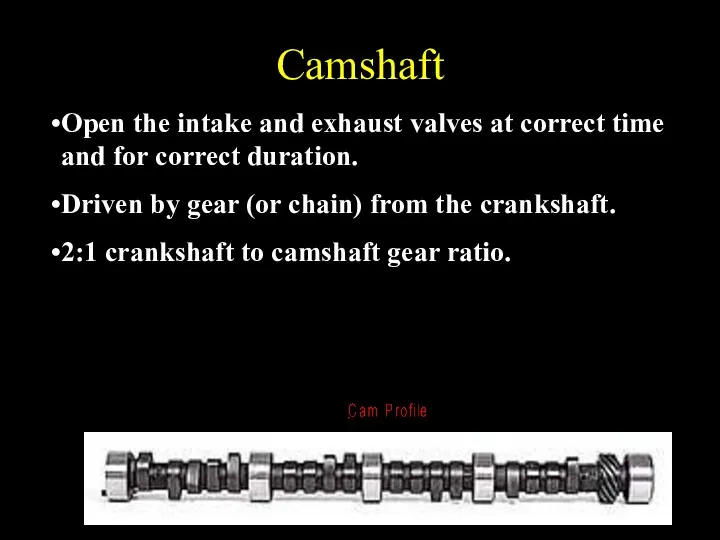

- 16. Camshaft Open the intake and exhaust valves at correct time and for correct duration. Driven by

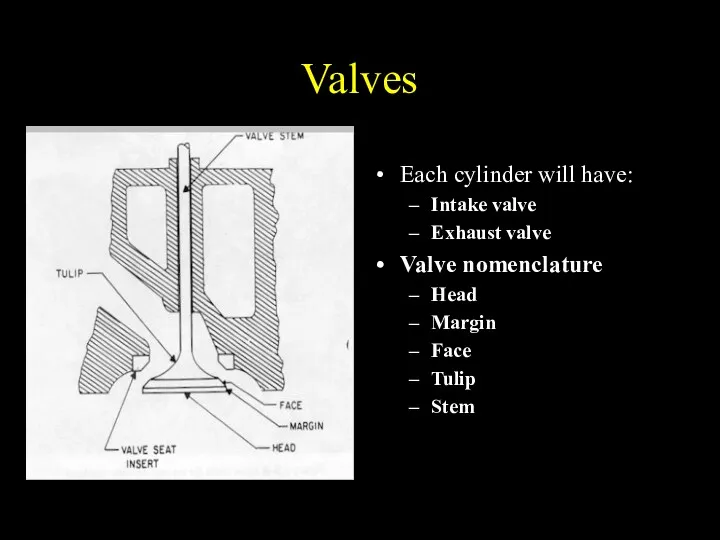

- 17. Valves Each cylinder will have: Intake valve Exhaust valve Valve nomenclature Head Margin Face Tulip Stem

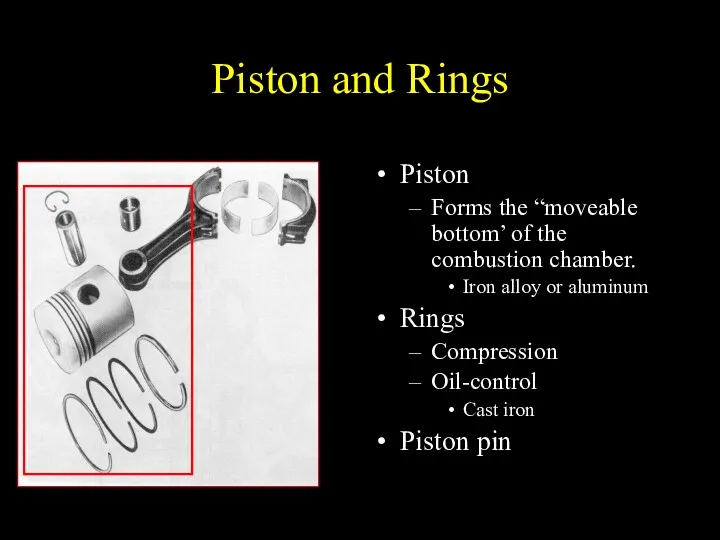

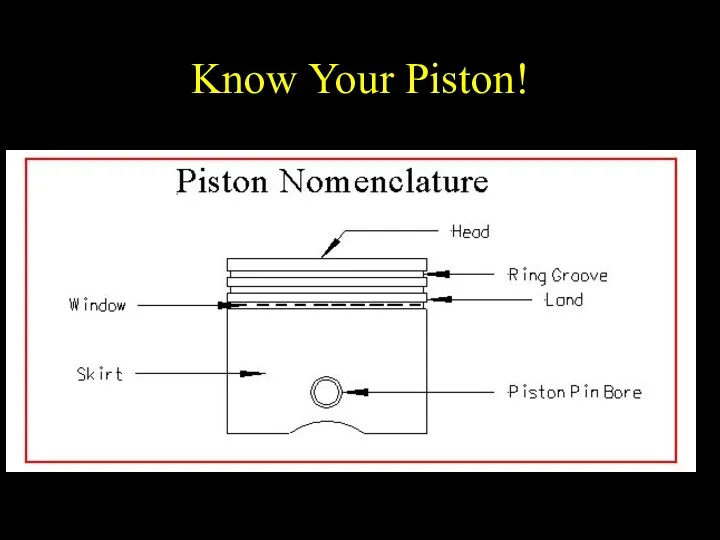

- 18. Piston and Rings Piston Forms the “moveable bottom’ of the combustion chamber. Iron alloy or aluminum

- 19. Know Your Piston!

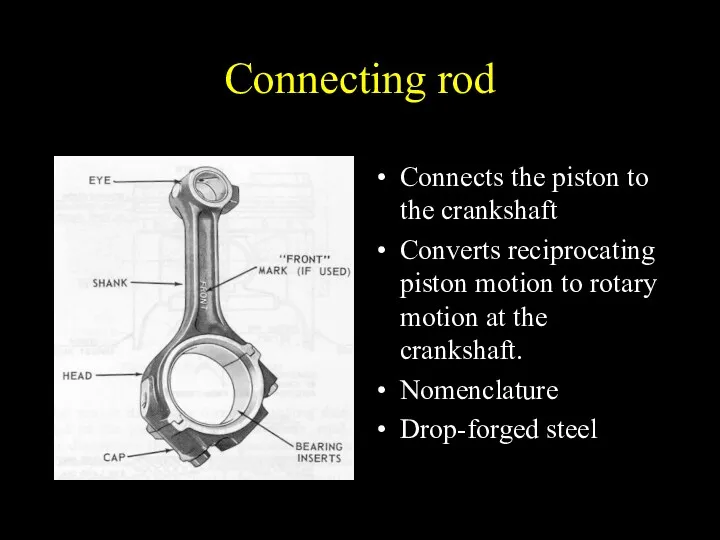

- 20. Connecting rod Connects the piston to the crankshaft Converts reciprocating piston motion to rotary motion at

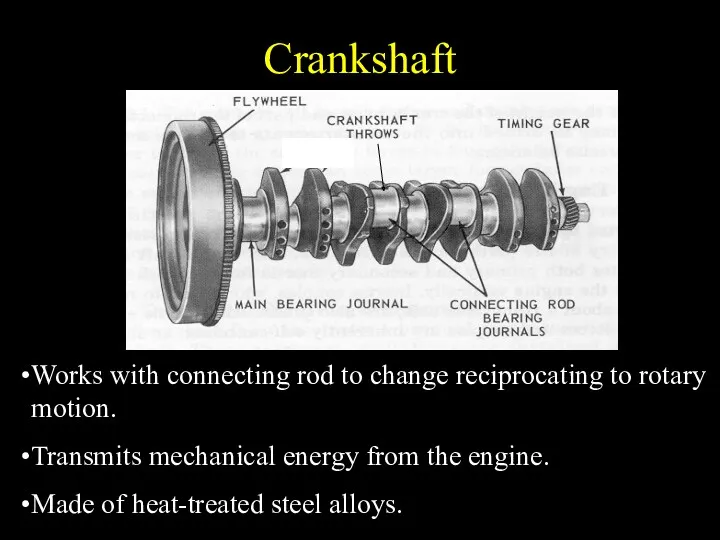

- 21. Crankshaft Works with connecting rod to change reciprocating to rotary motion. Transmits mechanical energy from the

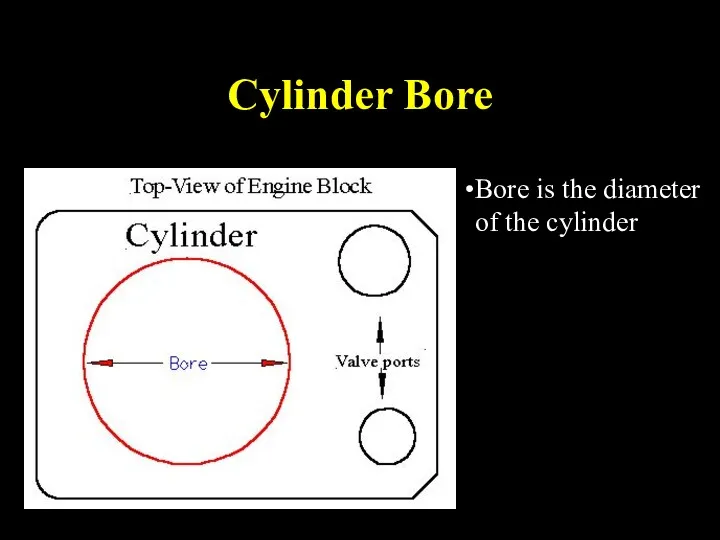

- 22. Cylinder Bore Bore is the diameter of the cylinder

- 23. Stroke Linear distance piston travels from Top Dead Center (TDC) to Bottom Dead Center (BDC).

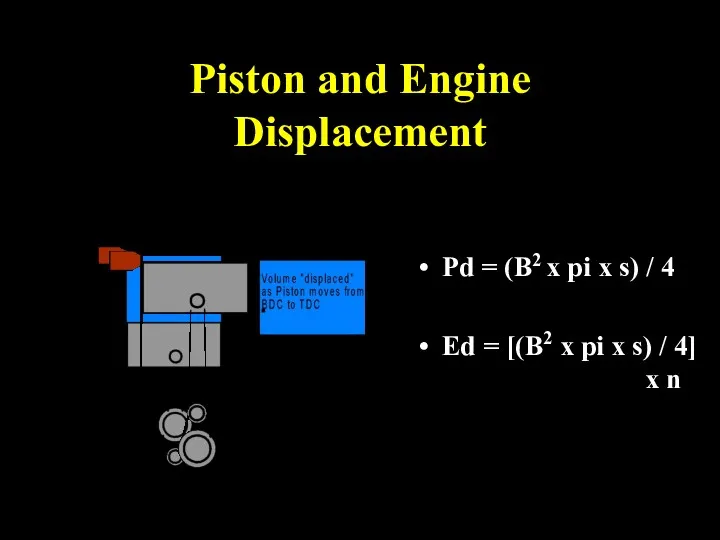

- 24. Piston and Engine Displacement Pd = (B2 x pi x s) / 4 Ed = [(B2

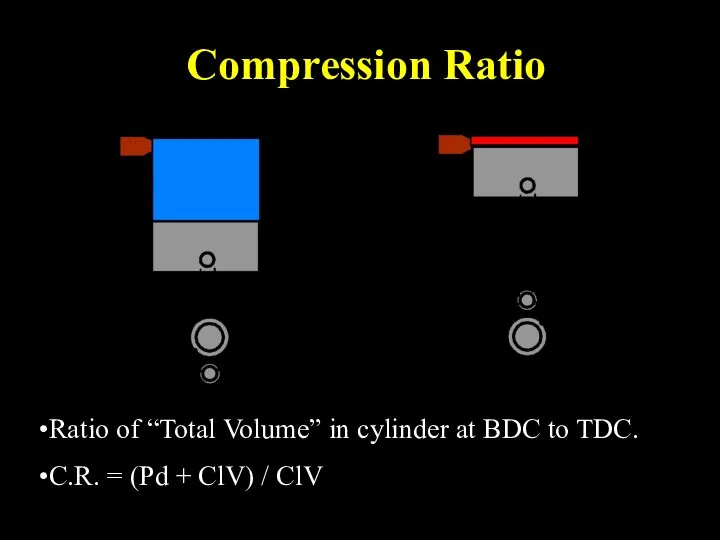

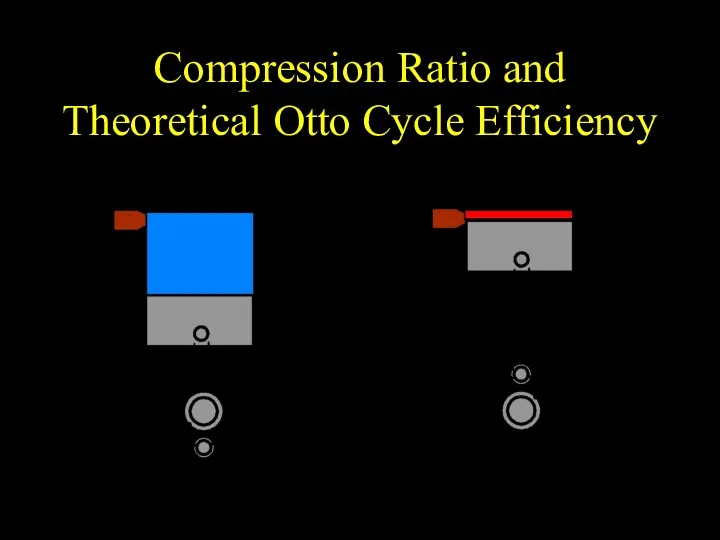

- 25. Compression Ratio Ratio of “Total Volume” in cylinder at BDC to TDC. C.R. = (Pd +

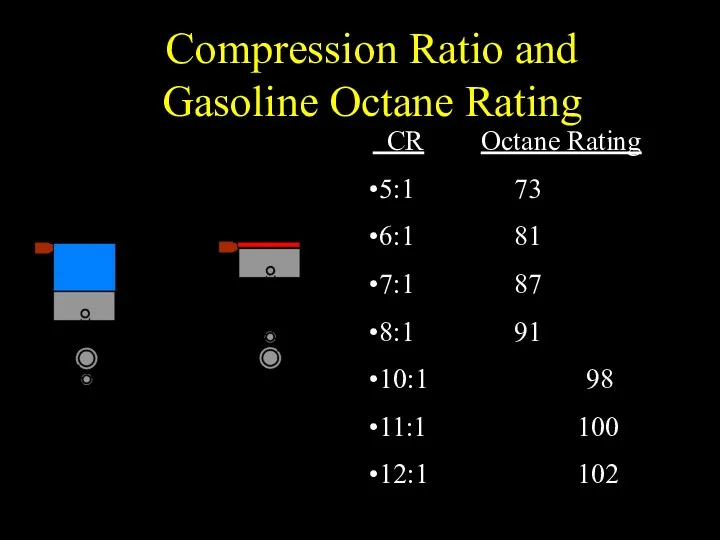

- 26. Compression Ratio and Gasoline Octane Rating CR Octane Rating 5:1 73 6:1 81 7:1 87 8:1

- 27. Compression Ratio and Theoretical Otto Cycle Efficiency

- 28. 4-Stroke Cycle Engine Operation 4-stroke cycle engines require four strokes of the piston to complete the

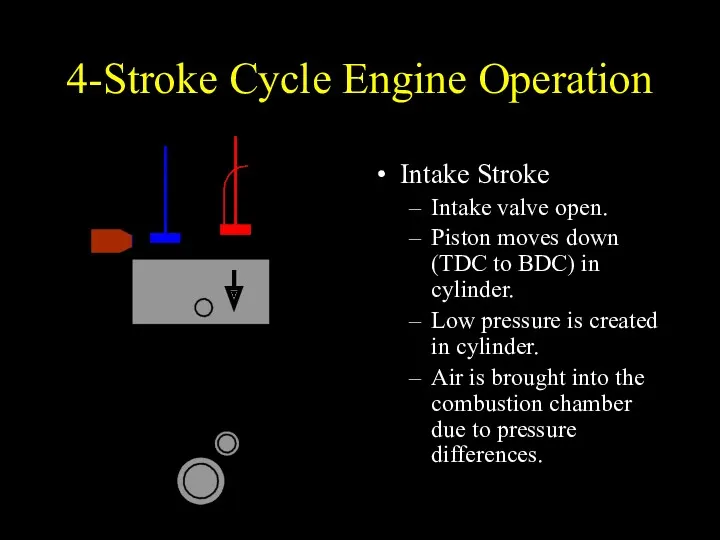

- 29. 4-Stroke Cycle Engine Operation Intake Stroke Intake valve open. Piston moves down (TDC to BDC) in

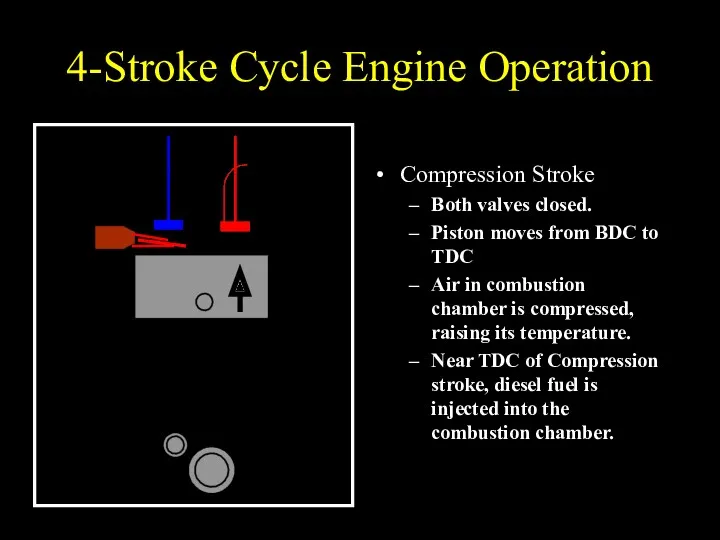

- 30. 4-Stroke Cycle Engine Operation Compression Stroke Both valves closed. Piston moves from BDC to TDC Air

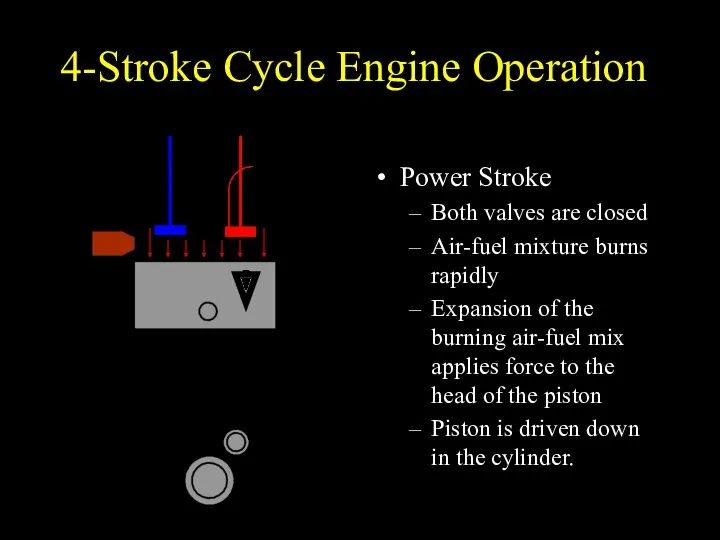

- 31. 4-Stroke Cycle Engine Operation Power Stroke Both valves are closed Air-fuel mixture burns rapidly Expansion of

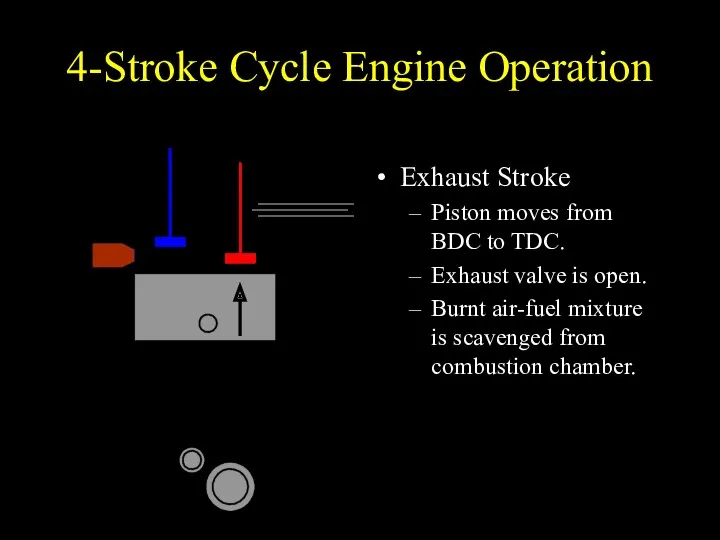

- 32. 4-Stroke Cycle Engine Operation Exhaust Stroke Piston moves from BDC to TDC. Exhaust valve is open.

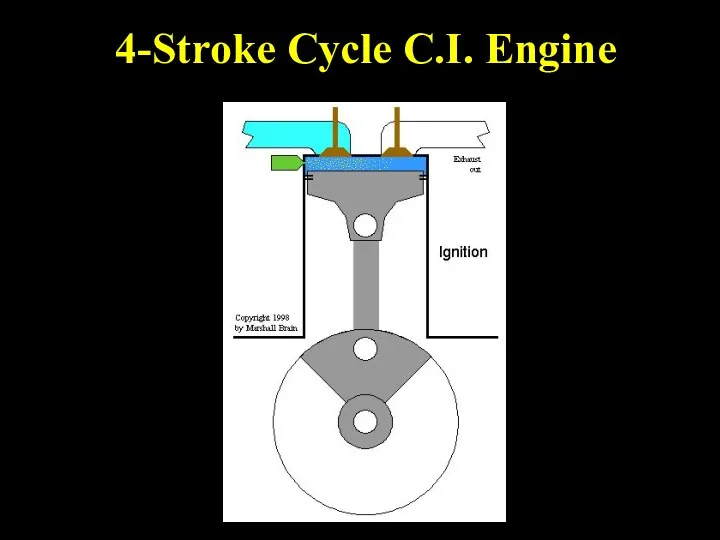

- 33. 4-Stroke Cycle C.I. Engine

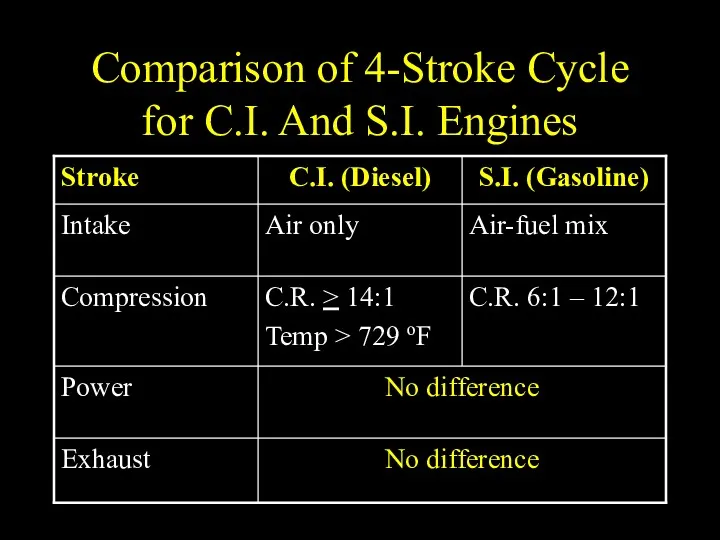

- 34. Comparison of 4-Stroke Cycle for C.I. And S.I. Engines

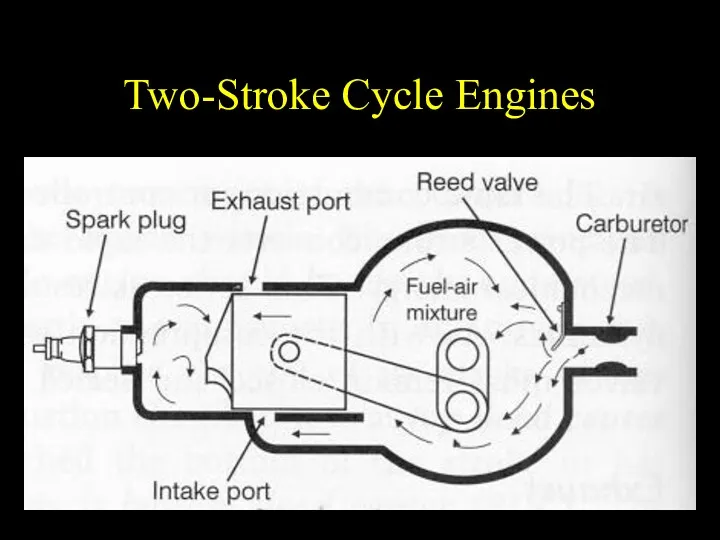

- 35. Two-Stroke Cycle Engines

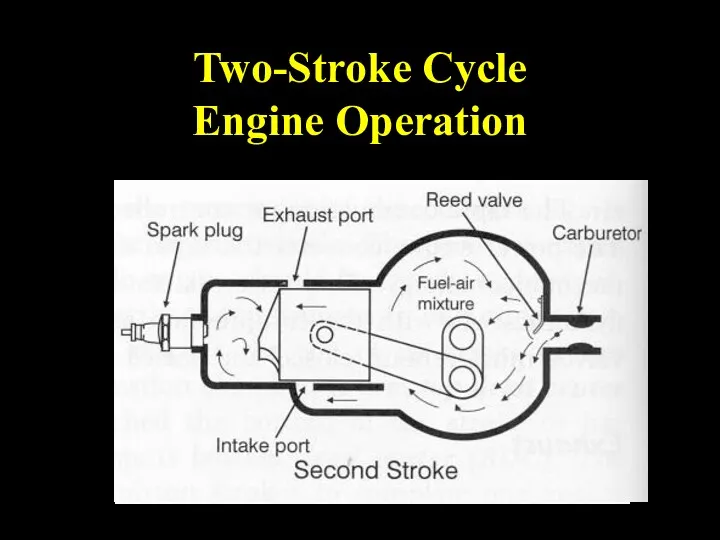

- 36. Two-Stroke Cycle Engine Operation

- 38. Скачать презентацию

Биологические науки. Интерактивный кроссворд

Биологические науки. Интерактивный кроссворд ТБ на летних каникулах

ТБ на летних каникулах Кремнийорганикалық қосылыстар

Кремнийорганикалық қосылыстар Арифметические и логические основы работы компьютера

Арифметические и логические основы работы компьютера Верховино 1917-1920

Верховино 1917-1920 Дополнительная общеобразовательная программа Малая тимирязевка

Дополнительная общеобразовательная программа Малая тимирязевка Элементы IА-группы и их соединения

Элементы IА-группы и их соединения География 6 класс Изображение на плане неровностей земной поверхности

География 6 класс Изображение на плане неровностей земной поверхности Мышечная ткань. Мышцы частей тела

Мышечная ткань. Мышцы частей тела 200 лет Царскосельскому лицею

200 лет Царскосельскому лицею Избирательная система

Избирательная система Избирательное право. Избирательные системы их виды

Избирательное право. Избирательные системы их виды Ко Дню Защитника Отечества.

Ко Дню Защитника Отечества. История медиа. Наскальные рисунки индейцев

История медиа. Наскальные рисунки индейцев Презентация Рефлексия

Презентация Рефлексия Цветная металлургия

Цветная металлургия Осложнения в процессе бурения скважин

Осложнения в процессе бурения скважин Человекообразные обезьяны

Человекообразные обезьяны Managementul integrat al pacienților cu diaree

Managementul integrat al pacienților cu diaree презентация на тему Метод проектов в ДОУ

презентация на тему Метод проектов в ДОУ Презентация конкурса Мамочка милая, мама моя!

Презентация конкурса Мамочка милая, мама моя! Презентация Пасхальная викторина

Презентация Пасхальная викторина Проект Аты-баты, шли солдаты в подготовительной к школе группе

Проект Аты-баты, шли солдаты в подготовительной к школе группе Конструкции элементов полупроводниковых ИС на МДП-транзисторах

Конструкции элементов полупроводниковых ИС на МДП-транзисторах X областной кинофестиваль для детей, юношества и семьи

X областной кинофестиваль для детей, юношества и семьи презентация по химии Техника безопасности

презентация по химии Техника безопасности Производство конструкционных материалов

Производство конструкционных материалов Меры безопасности при переходе железной дороги и автомобильных дорог

Меры безопасности при переходе железной дороги и автомобильных дорог