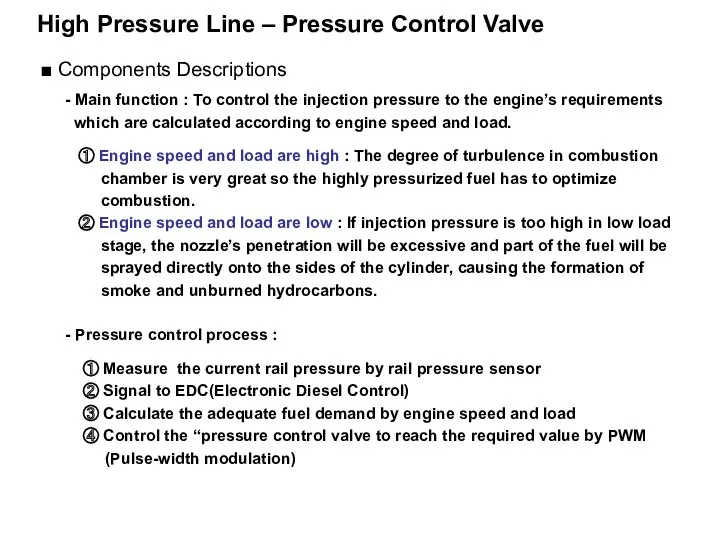

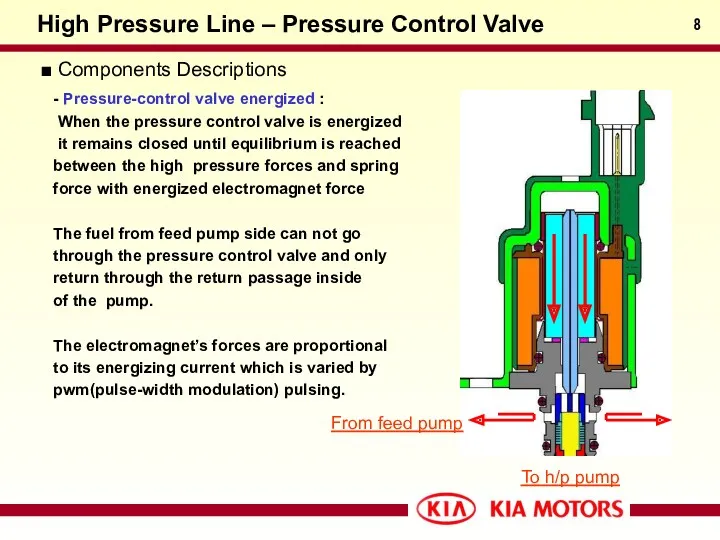

- Pressure-control valve energized :

When the pressure control

valve is energized

it remains closed until equilibrium is reached

between the high pressure forces and spring

force with energized electromagnet force

The fuel from feed pump side can not go

through the pressure control valve and only

return through the return passage inside

of the pump.

The electromagnet’s forces are proportional

to its energizing current which is varied by

pwm(pulse-width modulation) pulsing.

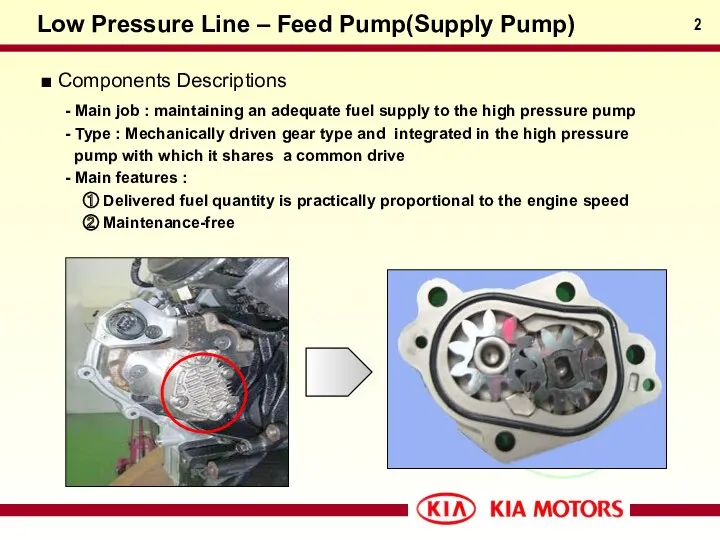

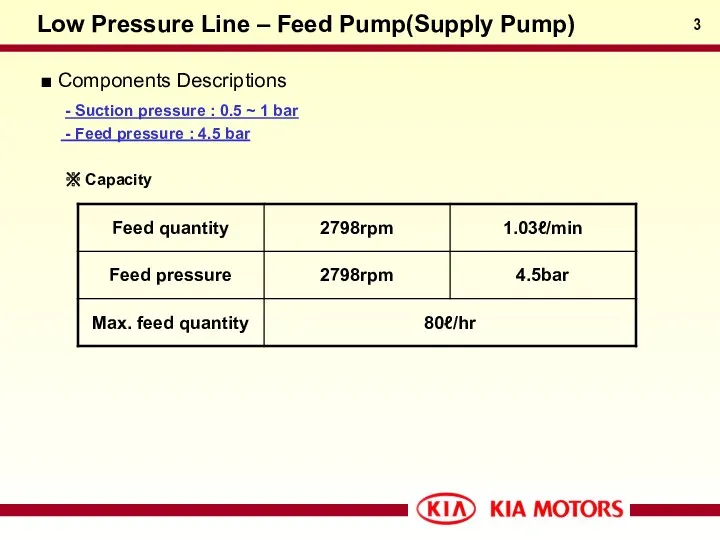

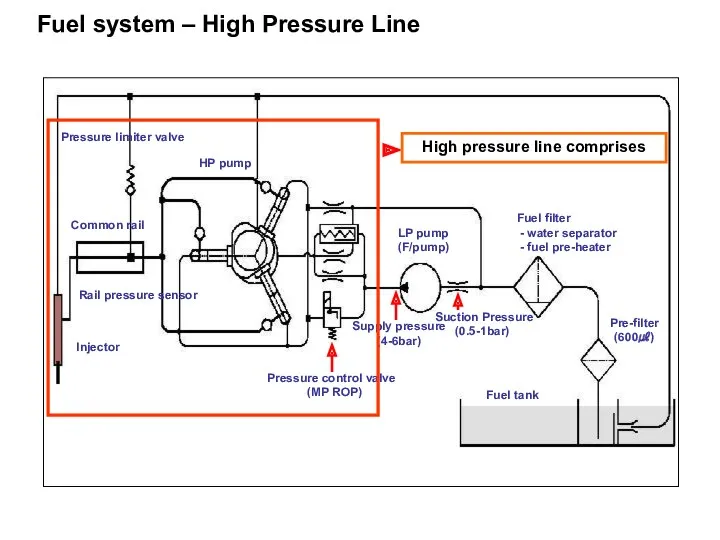

■ Components Descriptions

From feed pump

To h/p pump

High Pressure Line – Pressure Control Valve

Исчисление сроков в гражданском праве. Исковая давность

Исчисление сроков в гражданском праве. Исковая давность Стресс у младших школьников

Стресс у младших школьников Задание 3. Город Киров

Задание 3. Город Киров Средства и методы оказания первой помощи. (Тема 2)

Средства и методы оказания первой помощи. (Тема 2) Крестовые походы и инквизиция

Крестовые походы и инквизиция Ветра. Что такое ветер

Ветра. Что такое ветер Биосфера, биогеосфера, фитогеосфера, витасфера туралы түсініктер

Биосфера, биогеосфера, фитогеосфера, витасфера туралы түсініктер Федот Никитич Орлов

Федот Никитич Орлов Ваш ребёнок идёт в школу

Ваш ребёнок идёт в школу Занятие по предшкольной подготовке Дикие животные

Занятие по предшкольной подготовке Дикие животные Охрана растений

Охрана растений Михаил Иванович Глинка (1804-1857), опера Иван Сусанин

Михаил Иванович Глинка (1804-1857), опера Иван Сусанин Презентация Сенсорное воспитание детей раннего возраста

Презентация Сенсорное воспитание детей раннего возраста Страна после И.В. Сталина

Страна после И.В. Сталина Творческая работа ученика 5 класса Динозавры

Творческая работа ученика 5 класса Динозавры Технологическое и комплектующее оборудование автомобильных средств заправки и транспортирования горючего. (Тема 4.3)

Технологическое и комплектующее оборудование автомобильных средств заправки и транспортирования горючего. (Тема 4.3) Газовые турбины в энергетике – задачи и возможности

Газовые турбины в энергетике – задачи и возможности Винсент Ван Гог - краткая биография и картины художника

Винсент Ван Гог - краткая биография и картины художника Поздравляем с юбилеем

Поздравляем с юбилеем Вводное занятие на тему: кружевоплетение на коклюшках По программе Вологодское кружево

Вводное занятие на тему: кружевоплетение на коклюшках По программе Вологодское кружево Высотные конструкции

Высотные конструкции Республика Башкортостан

Республика Башкортостан Формирование карманов КМОП (комплементарная структура металл-оксид-полупроводник) интегральных схем. (Лекция 5)

Формирование карманов КМОП (комплементарная структура металл-оксид-полупроводник) интегральных схем. (Лекция 5) Нетрадиционное рисование с детьми дошкольного возраста Диск Диск

Нетрадиционное рисование с детьми дошкольного возраста Диск Диск Возможности использования учебного пособия Моя будущая профессия. Тесты по профессиональной ориентации школьников

Возможности использования учебного пособия Моя будущая профессия. Тесты по профессиональной ориентации школьников Мұнай-газ саласындағы терминдер

Мұнай-газ саласындағы терминдер Сучасне теплове обладнання (Експрес-кавоварки)

Сучасне теплове обладнання (Експрес-кавоварки) Профессиональная пригодность

Профессиональная пригодность