Structural problems with traditional build car parks

The UK car parking industry

was given an important lesson when the Pipers Row car park in Wolverhampton partially collapsed in 1997: that it is important to avoid complacency. Pipers Row could easily have collapsed when fully occupied with parked cars and members of the public.

The warning signs for car park structures had already been recognised by the Standing Committee on Structural Safety (SCOSS) in their tenth report, published in 1994(5).

In addition to chloride ion contamination, structural deterioration can be caused by other mechanisms during service, including:

Impact damage from vehicles, reducing the cover to reinforcement

Carbonation of the concrete over time, resulting in reinforcement corrosion

Alkali-silica reaction, producing expansion and cracking

Freeze-thaw action on unprotected or underspecified concrete

Thermal and shrinkage cracking, providing pathways directly to the reinforcement

Surface abrasion and wear

Failure of protective coatings and waterproof membranes

Poor quality or inadequate cover to steel reinforcement.

Barrier fixings – holding down bolts

Structural problems with traditional build car parks

ОСББ Наша мрія

ОСББ Наша мрія Игра игрушки для детей от 1,5 до 2,5 лет

Игра игрушки для детей от 1,5 до 2,5 лет План в’язального цеху з виготовлення полотна, яке виготовляється на сучасних високопродуктивних машинах

План в’язального цеху з виготовлення полотна, яке виготовляється на сучасних високопродуктивних машинах Родительское собрание Подготовка к проведению в 2014 году государственной итоговой аттестации выпускников 11-х классов

Родительское собрание Подготовка к проведению в 2014 году государственной итоговой аттестации выпускников 11-х классов Климат Южной Америки

Климат Южной Америки Открытый урок Сложные эфиры. Жиры.

Открытый урок Сложные эфиры. Жиры. Дисплазия костей

Дисплазия костей Урок-презентация по СБО Овощи и фрукты и их польза

Урок-презентация по СБО Овощи и фрукты и их польза Технология успешного трудоустройства

Технология успешного трудоустройства Гордость Богородского края

Гордость Богородского края Презентация к уроку географии

Презентация к уроку географии Спасо-Казанский женский монастырь. Епитрахиль И.Кронштадтского

Спасо-Казанский женский монастырь. Епитрахиль И.Кронштадтского Мороженое пломбир ГОСТ 31457-2012

Мороженое пломбир ГОСТ 31457-2012 Внеклассное мероприятие Путешествие по городу Светофорск.

Внеклассное мероприятие Путешествие по городу Светофорск. В концертном зале. Московская консерватория им. П.И. Чайковского

В концертном зале. Московская консерватория им. П.И. Чайковского Стратегия ведения бренда в социальных сетях

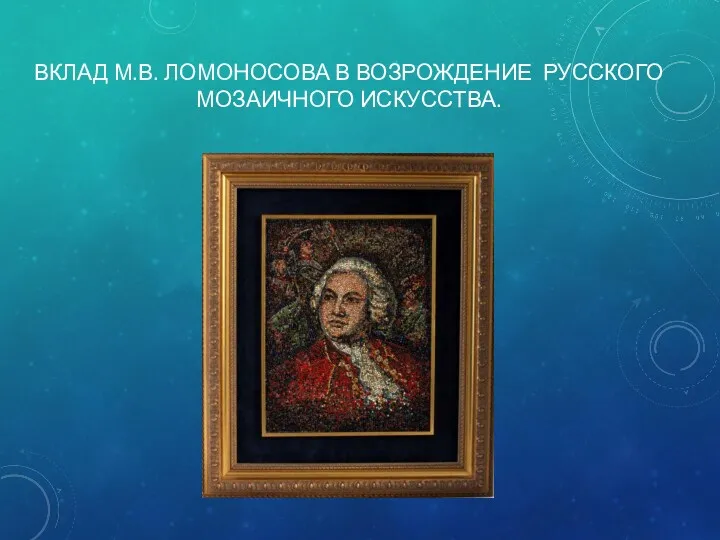

Стратегия ведения бренда в социальных сетях Вклад М.В. Ломоносова в возрождение русского мозаичного искусства

Вклад М.В. Ломоносова в возрождение русского мозаичного искусства Часові форми дієслів

Часові форми дієслів Русские народные ремёсла

Русские народные ремёсла на тему: Развитие творческих способностей воспитанников посредства использования нетрадиционных техник изобразительного искусства

на тему: Развитие творческих способностей воспитанников посредства использования нетрадиционных техник изобразительного искусства Они ковали победу. Труженики тыла

Они ковали победу. Труженики тыла Образование первых государств

Образование первых государств История становления специальной педагогики в России

История становления специальной педагогики в России Презентация для родителей Учебные способности ребёнка

Презентация для родителей Учебные способности ребёнка Правила дорожного движениядля средней группы

Правила дорожного движениядля средней группы Дискретные системы

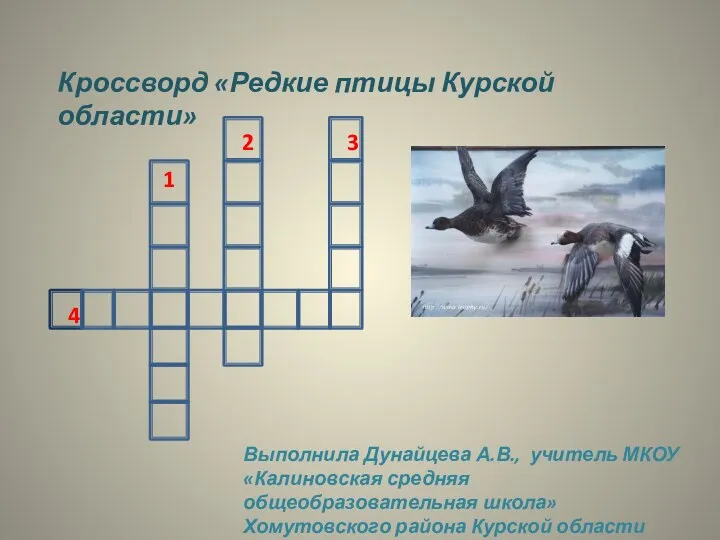

Дискретные системы Кроссворд Редкие птицы Курской области

Кроссворд Редкие птицы Курской области Методическое портфолио победителя школьного этапа конкурса Учитель года -2015 Сибгатуллиной Р.И.

Методическое портфолио победителя школьного этапа конкурса Учитель года -2015 Сибгатуллиной Р.И.