Слайд 2

The Contents of the Program

Introduction & Program Overview

Pretreatment &

Substrates

Powder Coating Materials & Application

Curing, Quality Testing, & Packaging

Materials Handling, Process Control, Tracking & Recording

Safety Issues, OSHA, & Environmental Concerns

Слайд 3

Performance Goals - Understand These Issues:

The Powder Process

The Powder System Components

Powder

Materials

Application Equipment & Controls

Performance Testing & Quality Control

Safety Issues

Слайд 4

How We Got Started In

Powder Coating

The Beginning

Our Progress

Future Plans

Слайд 5

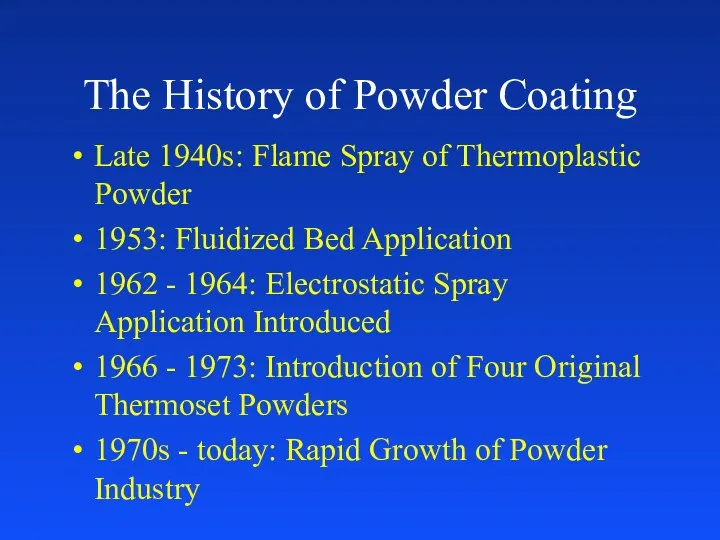

The History of Powder Coating

Late 1940s: Flame Spray of Thermoplastic

Powder

1953: Fluidized Bed Application

1962 - 1964: Electrostatic Spray Application Introduced

1966 - 1973: Introduction of Four Original Thermoset Powders

1970s - today: Rapid Growth of Powder Industry

Слайд 6

The Basics of the Powder Coating Process

Fluidized Bed Application Process

Electrostatic Spray

Application Process

Слайд 7

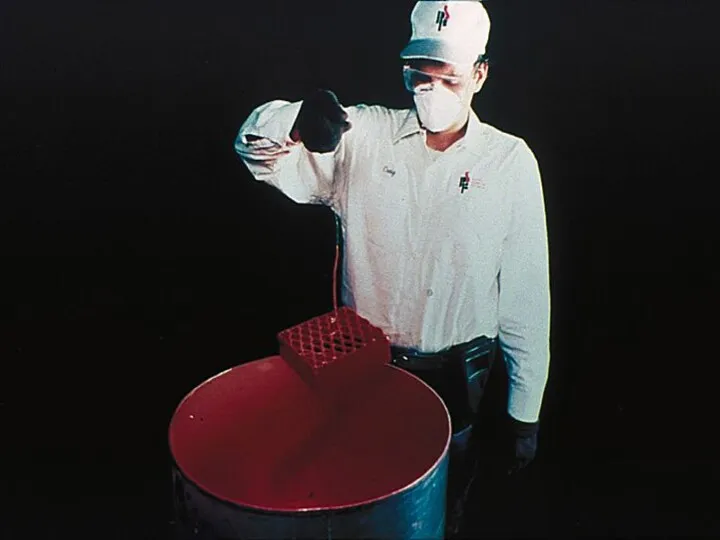

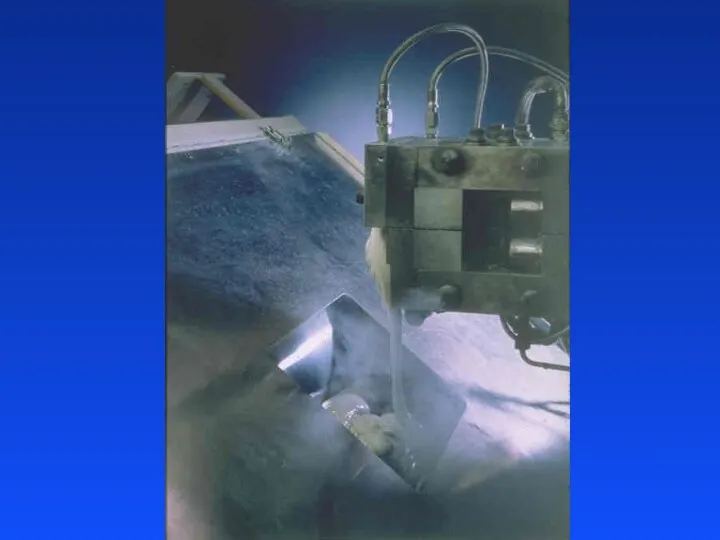

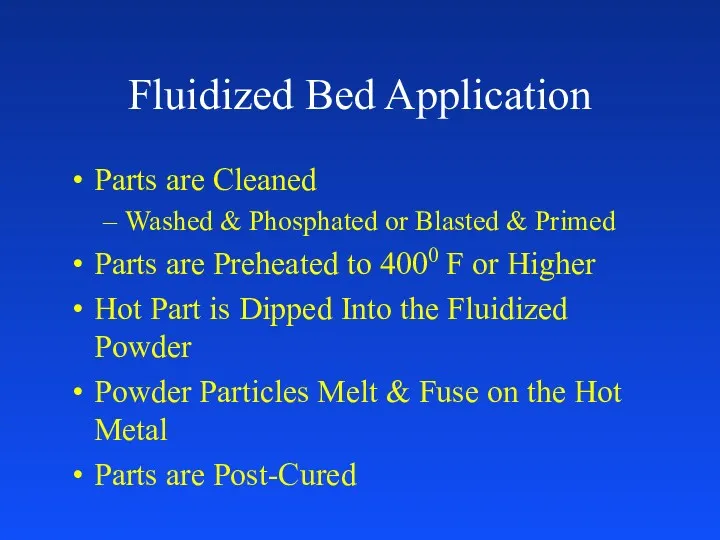

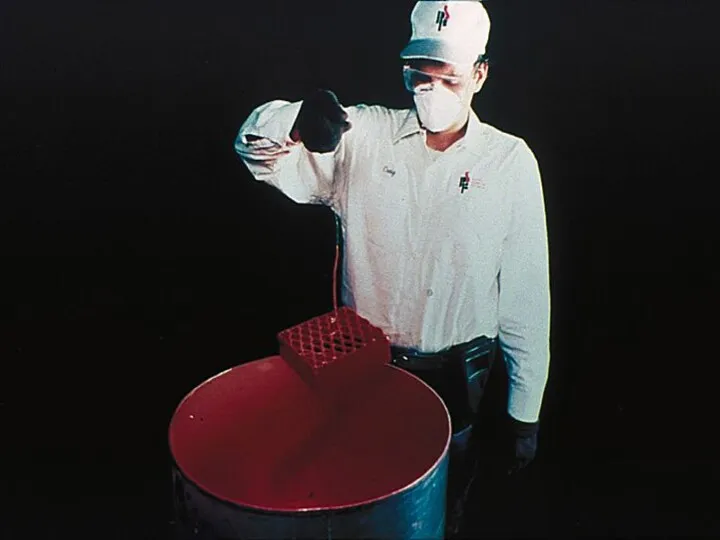

Fluidized Bed Application

Parts are Cleaned

Washed & Phosphated or Blasted &

Primed

Parts are Preheated to 4000 F or Higher

Hot Part is Dipped Into the Fluidized Powder

Powder Particles Melt & Fuse on the Hot Metal

Parts are Post-Cured

Слайд 8

Слайд 9

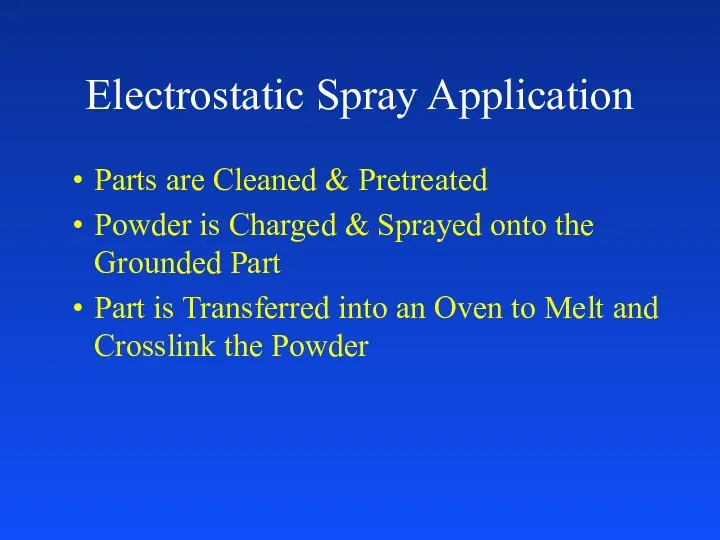

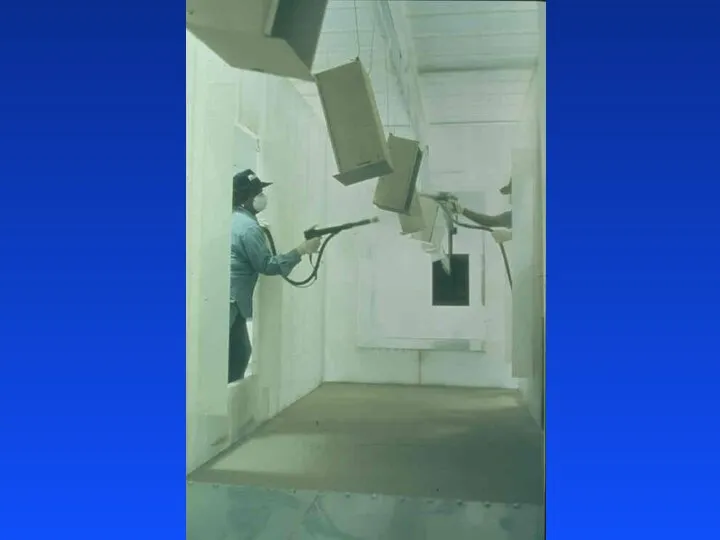

Electrostatic Spray Application

Parts are Cleaned & Pretreated

Powder is Charged & Sprayed

onto the Grounded Part

Part is Transferred into an Oven to Melt and Crosslink the Powder

Слайд 10

Слайд 11

PRETREATMENT & SUBSTRATES

Слайд 12

Pretreatment

Cleaning

Conversion Coating

Rinsing

Слайд 13

Why Clean?

Appearance

Adhesion

Corrosion Resistance

Слайд 14

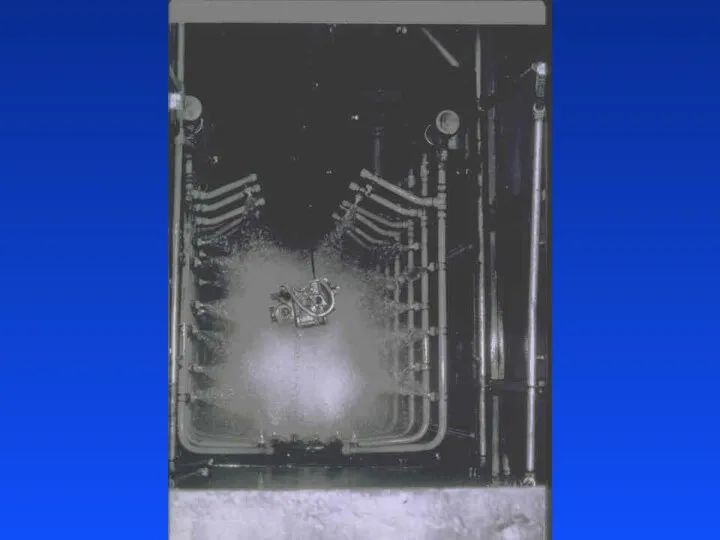

Cleaning Methods

Mechanical

Polishing

Blasting

Chemical

Dip

Spray

Слайд 15

Mechanical Cleaning

Removes

Mill Scale

Rust

Smut

Die Release Contamination

Слайд 16

Chemical Cleaning

Removes

Oil

Shop Dust

Grease

Rust Inhibitors

Слайд 17

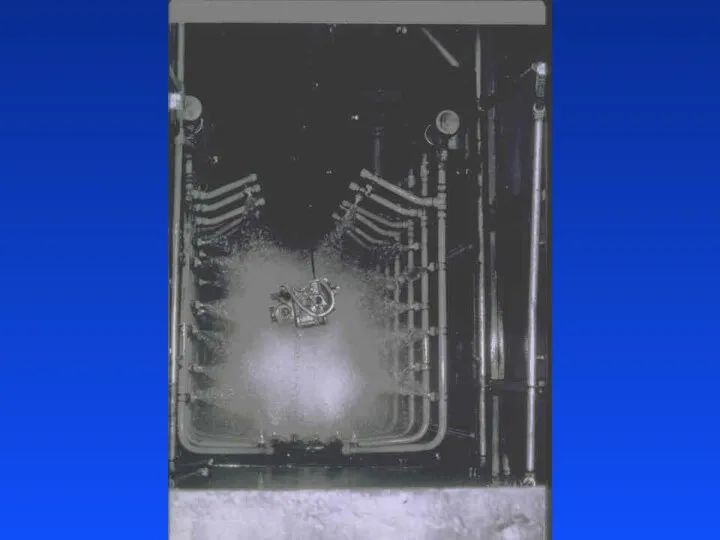

Слайд 18

Cleaner Types

Acidic - pH of 4.0 to 5.5

Alkaline - pH of

9 to 10.5

Слайд 19

Conversion Coating

Iron Phosphate

Zinc Phosphate

Слайд 20

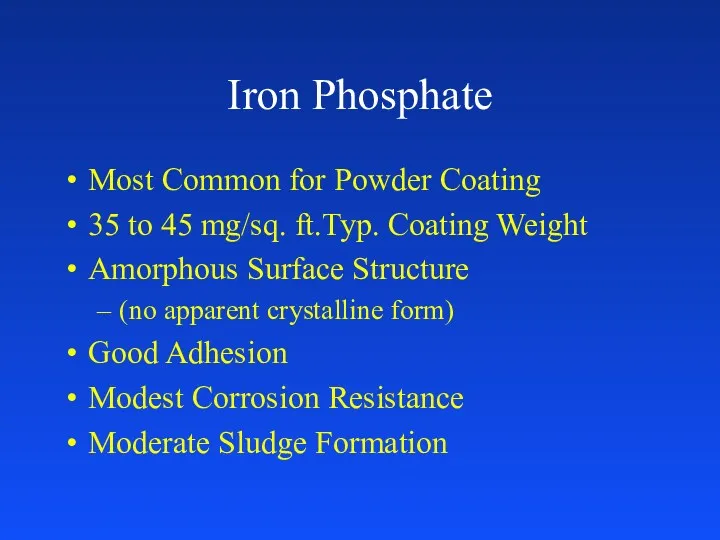

Iron Phosphate

Most Common for Powder Coating

35 to 45 mg/sq. ft.Typ. Coating

Weight

Amorphous Surface Structure

(no apparent crystalline form)

Good Adhesion

Modest Corrosion Resistance

Moderate Sludge Formation

Слайд 21

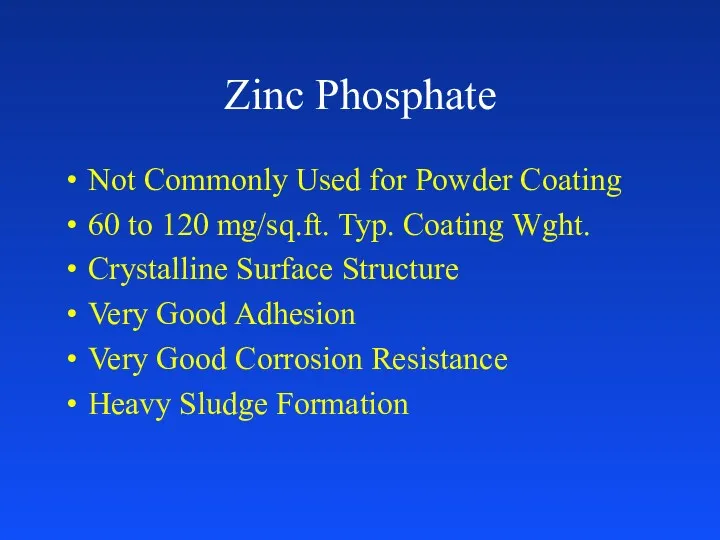

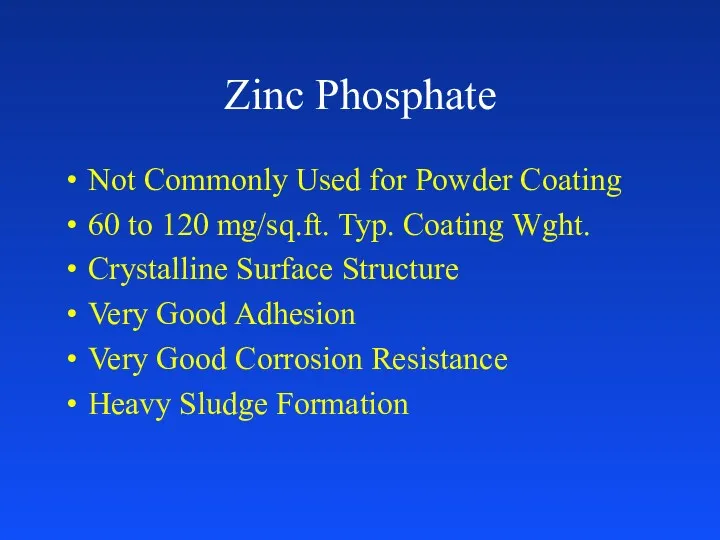

Zinc Phosphate

Not Commonly Used for Powder Coating

60 to 120 mg/sq.ft. Typ.

Coating Wght.

Crystalline Surface Structure

Very Good Adhesion

Very Good Corrosion Resistance

Heavy Sludge Formation

Слайд 22

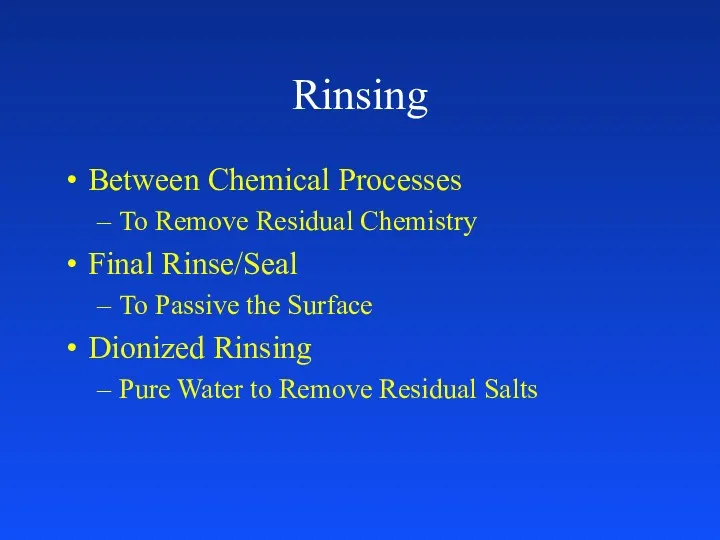

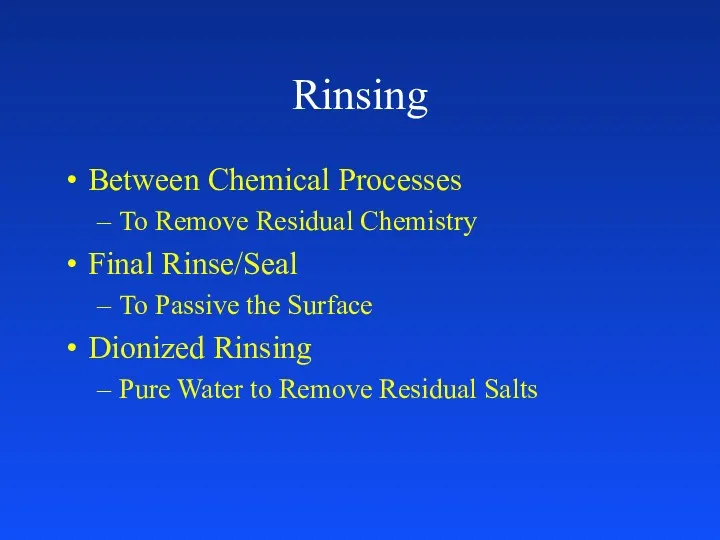

Rinsing

Between Chemical Processes

To Remove Residual Chemistry

Final Rinse/Seal

To Passive the Surface

Dionized

Rinsing

Pure Water to Remove Residual Salts

Слайд 23

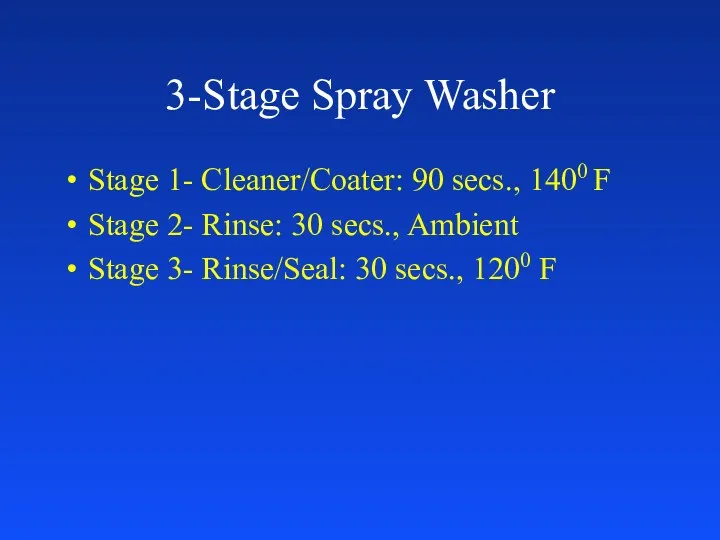

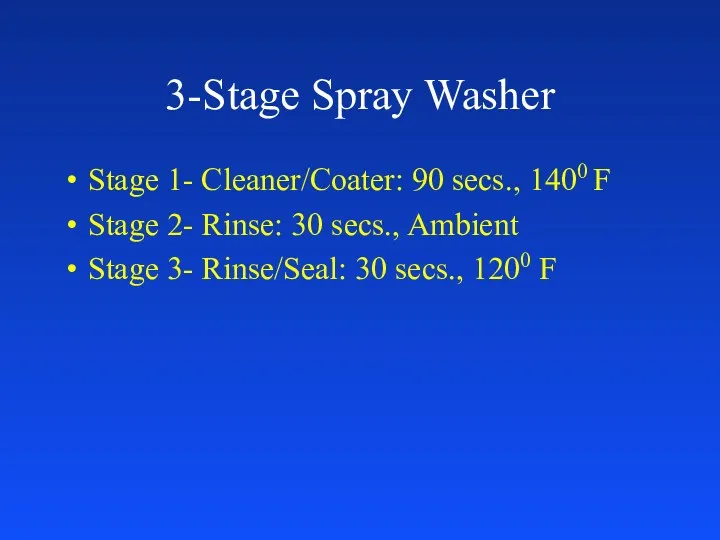

3-Stage Spray Washer

Stage 1- Cleaner/Coater: 90 secs., 1400 F

Stage 2- Rinse:

30 secs., Ambient

Stage 3- Rinse/Seal: 30 secs., 1200 F

Слайд 24

Слайд 25

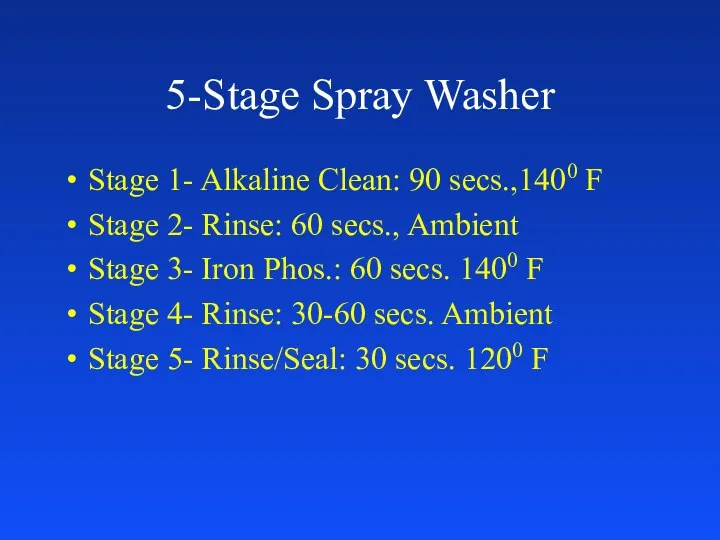

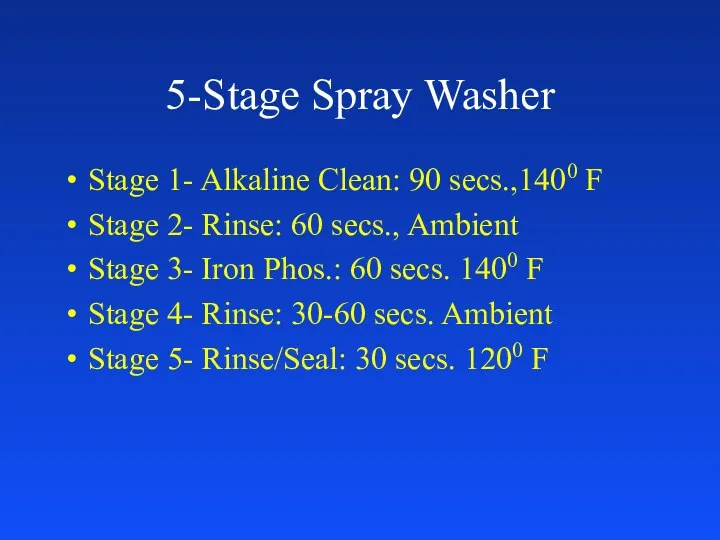

5-Stage Spray Washer

Stage 1- Alkaline Clean: 90 secs.,1400 F

Stage 2- Rinse:

60 secs., Ambient

Stage 3- Iron Phos.: 60 secs. 1400 F

Stage 4- Rinse: 30-60 secs. Ambient

Stage 5- Rinse/Seal: 30 secs. 1200 F

Слайд 26

Слайд 27

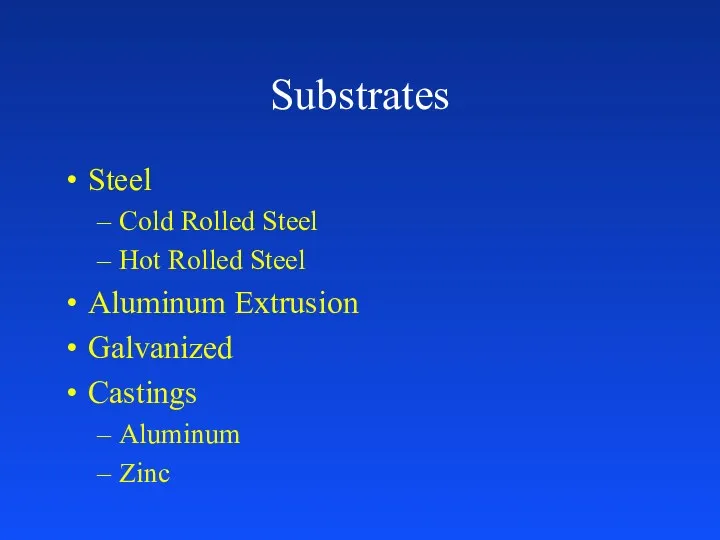

Substrates

Steel

Cold Rolled Steel

Hot Rolled Steel

Aluminum Extrusion

Galvanized

Castings

Aluminum

Zinc

Слайд 28

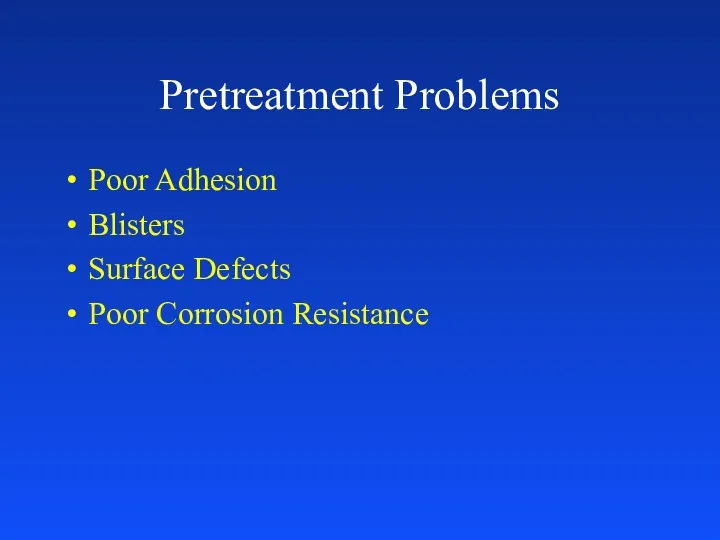

Pretreatment Problems

Poor Adhesion

Blisters

Surface Defects

Poor Corrosion Resistance

Слайд 29

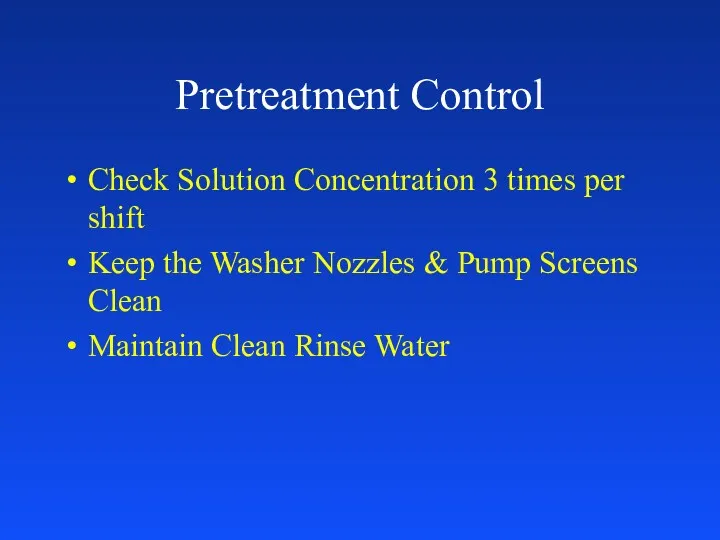

Pretreatment Control

Check Solution Concentration 3 times per shift

Keep the Washer Nozzles

& Pump Screens Clean

Maintain Clean Rinse Water

Слайд 30

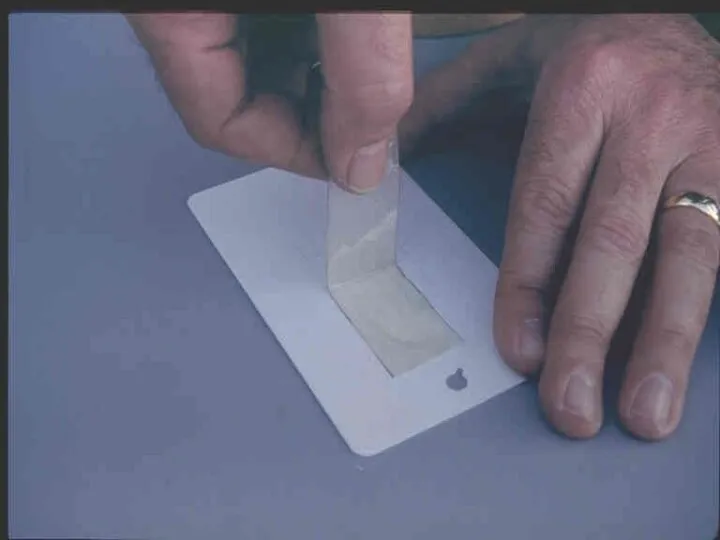

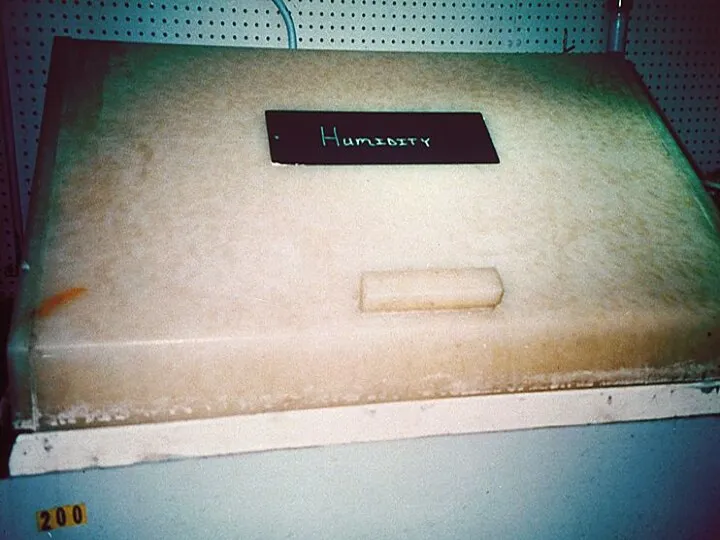

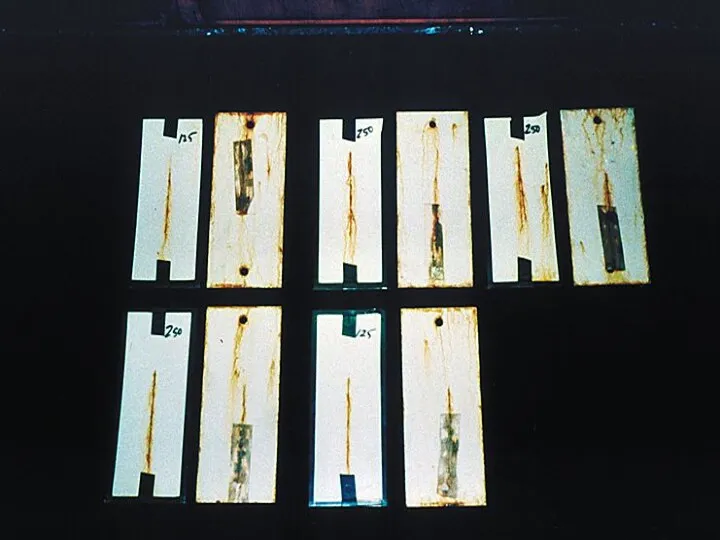

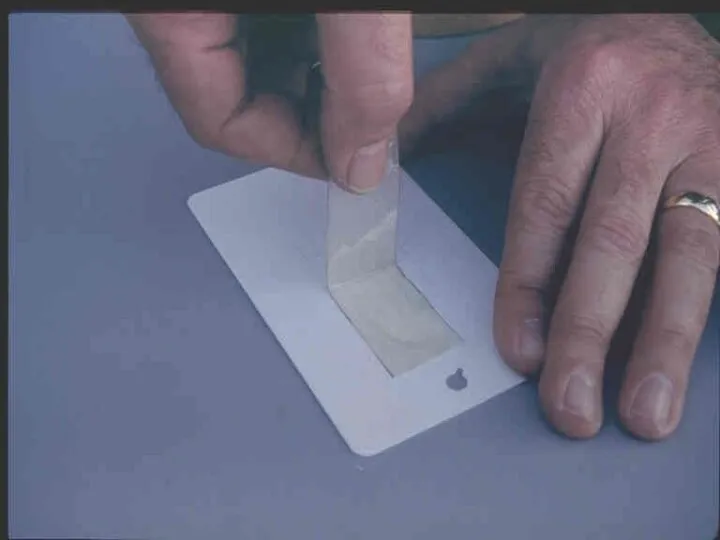

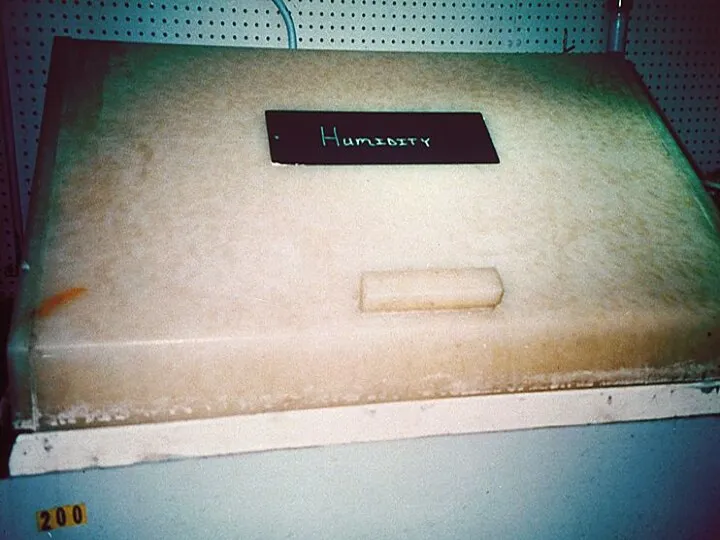

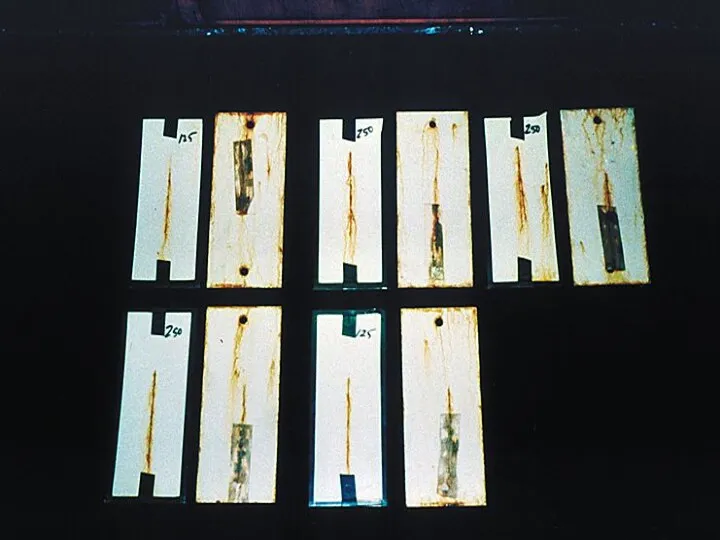

Pretreatment Tests

Water Break Free

Adhesion Test

Coating Weight

Humidity Test

Salt Spray Test

Слайд 31

Слайд 32

Слайд 33

Слайд 34

Слайд 35

Слайд 36

Слайд 37

Слайд 38

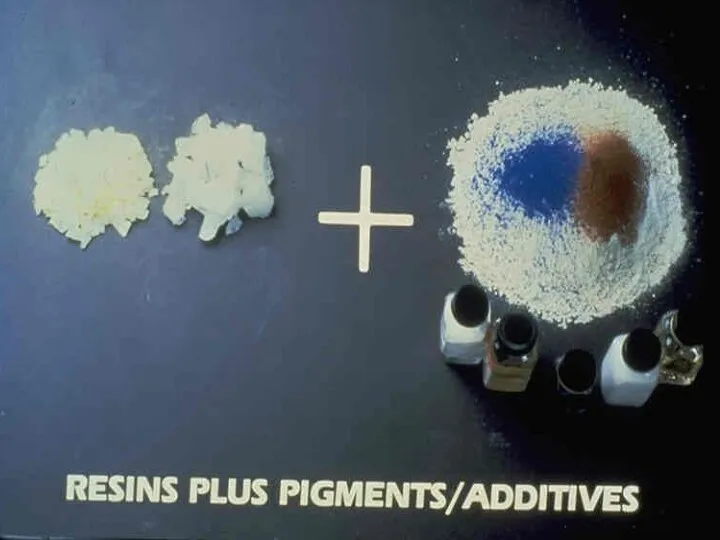

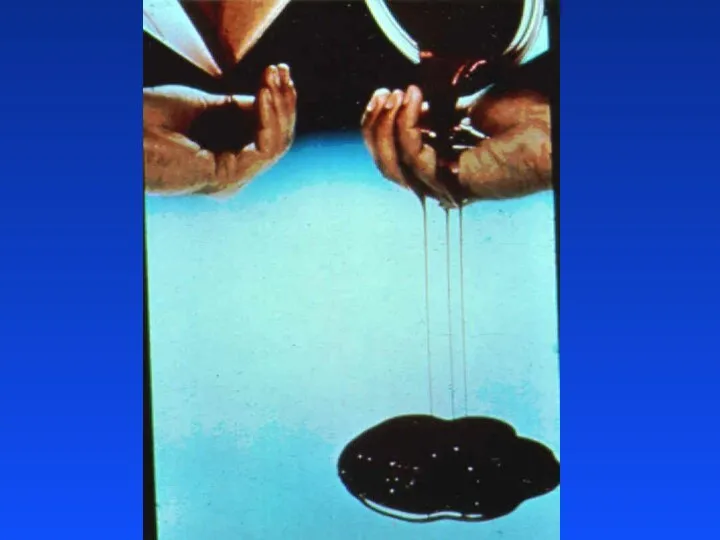

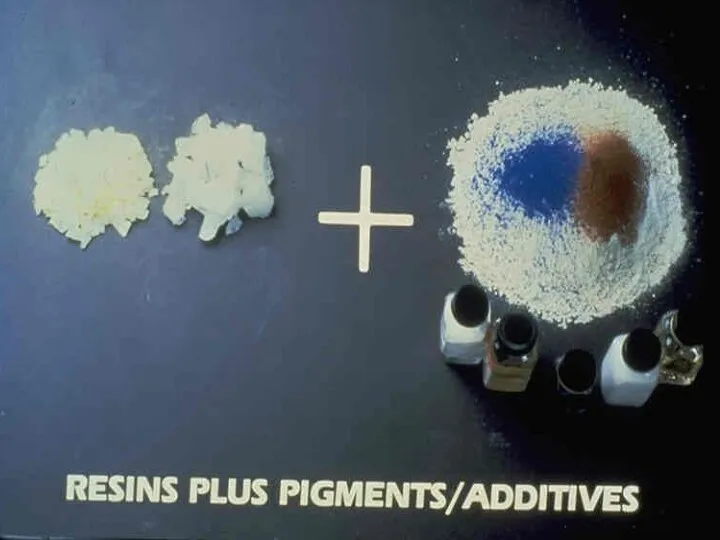

Powder Material Components

Resins

Pigments

Cure Agents

Flow Agents

Additives

Слайд 39

Слайд 40

Слайд 41

Слайд 42

Слайд 43

Two Types of Powder Materials

Thermoplastic

do not chemically react during cure

Thermoset

chemically react

during cure

Слайд 44

Thermoplastic Resins

Nylon

Polyethylene & Polypropylene

Polyvinyl Chloride (PVC)

Polyester

Poly(Vinylidene Fluoride)(PVFD)

Слайд 45

Thermoset Powders

Epoxies

Urethane Polyesters

TGIC Polyesters

Hybrids

Acrylics

Слайд 46

POWDER APPLICATION METHODS

Fluidized Bed Dip

Electrostatic Spray

Слайд 47

Fluidized Bed Dip

Preheated Part is Dipped into Fluidized Powder; Powder Gels

on Hot Surface

Used for Application of Thermoplastic Materials

Слайд 48

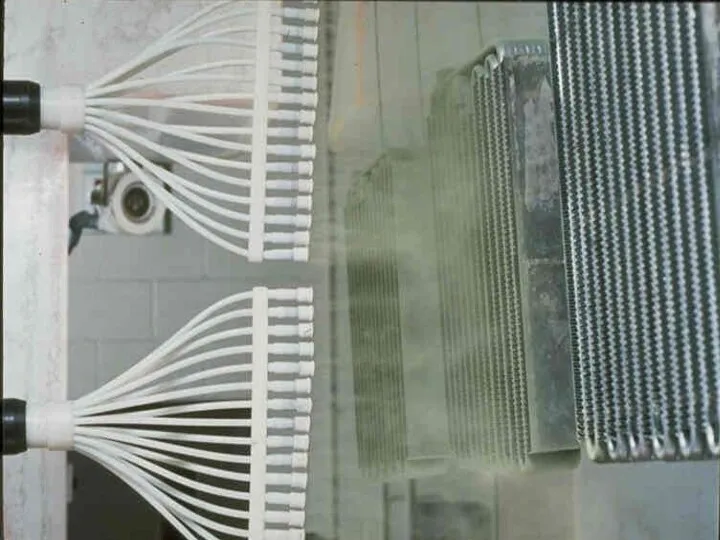

Electrostatic Spray

Charged Powder Material is Sprayed onto Grounded Part

Parts are Subjected

to High Temperature to Crosslink

Used for Application of Thermoset and Sometimes Thermoplastic Materials

Слайд 49

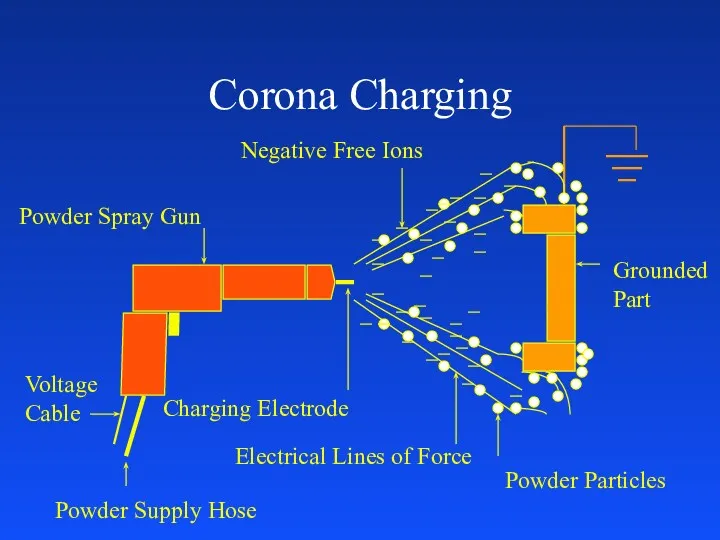

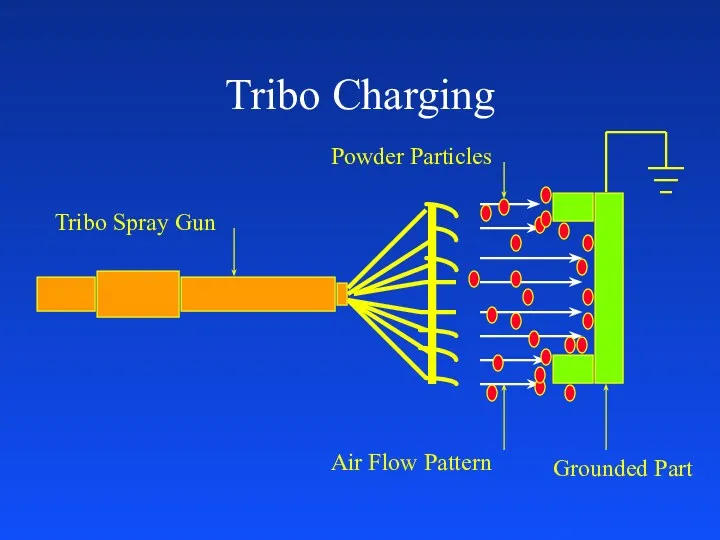

Charging Methods for Electrostatic Spray

Corona Charging

Uses High Voltage & an Electrode

Tribo Charging

Uses Frictional Contact With the Gun Interior Wall

Слайд 50

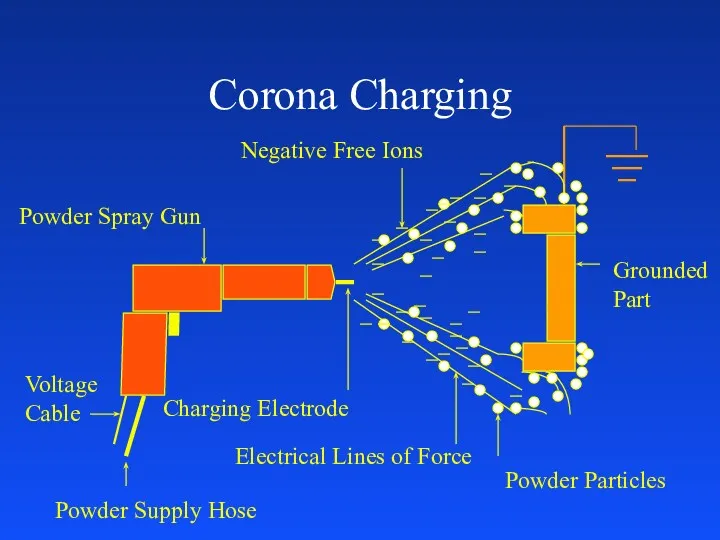

Corona Charging

Grounded

Part

Negative Free Ions

Voltage

Cable

Powder Supply Hose

Слайд 51

Слайд 52

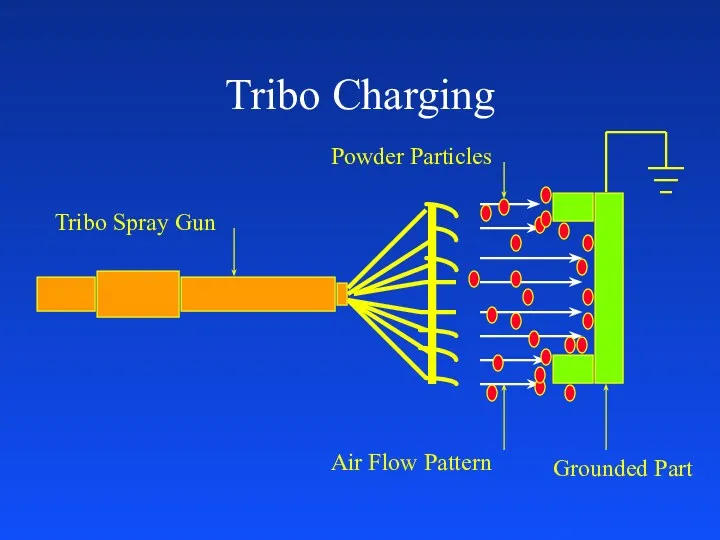

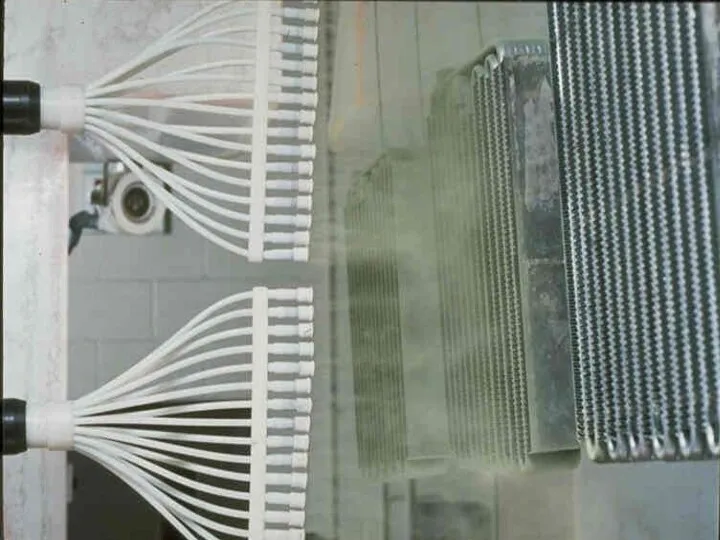

Tribo Charging

Tribo Spray Gun

Air Flow Pattern

Grounded Part

Powder Particles

Слайд 53

Слайд 54

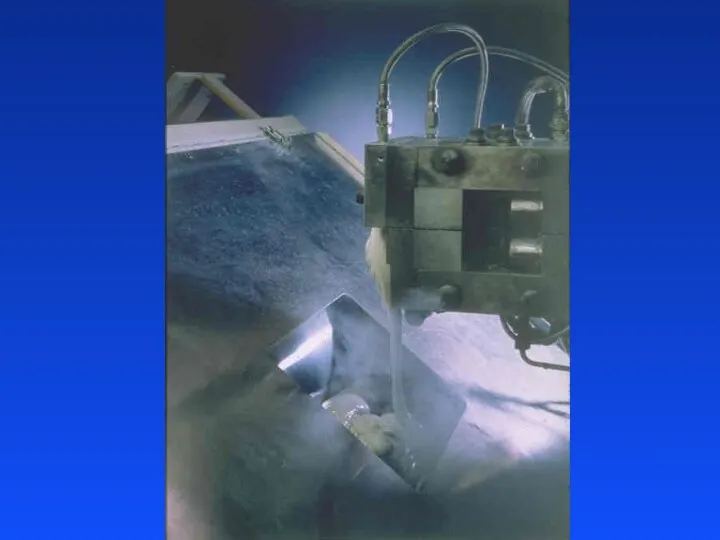

The Powder Delivery System

Fluid Bed Hopper

Powder Pump

Powder Hose

Spray Gun

Слайд 55

Compressed Air Supply

+380F Dew Point or Lower

Less than 0.1 PPM of

Oil

No Particle Greater than 0.3 Micron

Слайд 56

The Corona Charging System

Voltage Supply

High Voltage Generator

Voltage Cable

Electrode

Слайд 57

Pneumatic Controls

Fluidizing Air

Powder Supply Air

Atomizing Air

Cleansing or Shaping Air

Слайд 58

Слайд 59

Delivery Pressure & Transfer Efficiency

Powder Charges Better at Lower Pressure

Transfer Efficiency

is Higher at Lower Pressure

Слайд 60

Voltage Control

80 to 100 KV

Used for Most Surfaces

Lower Voltage

Used for Faraday

Cage Areas & Recoats

Слайд 61

Transfer Efficiency Variables

Nozzle Type

Powder Delivery Rate

Gun Position

Grounding

The Powder Material

System Maintenance &

Control

Слайд 62

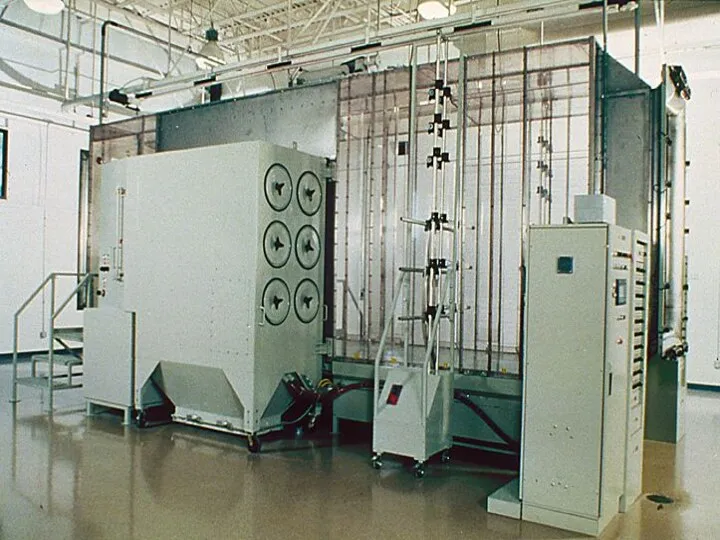

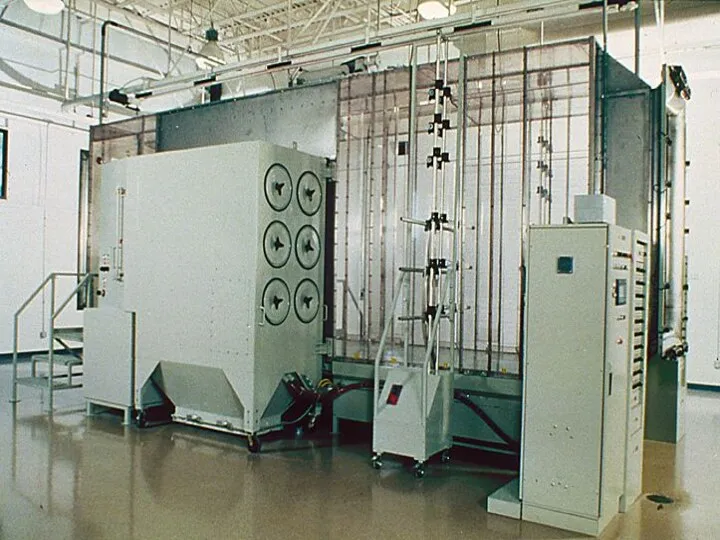

BOOTHS & RECOVERY SYSTEMS

Booth is Used to Enclose Process & Contain

Overspray

Recovery System is Used to Capture Overspray

Слайд 63

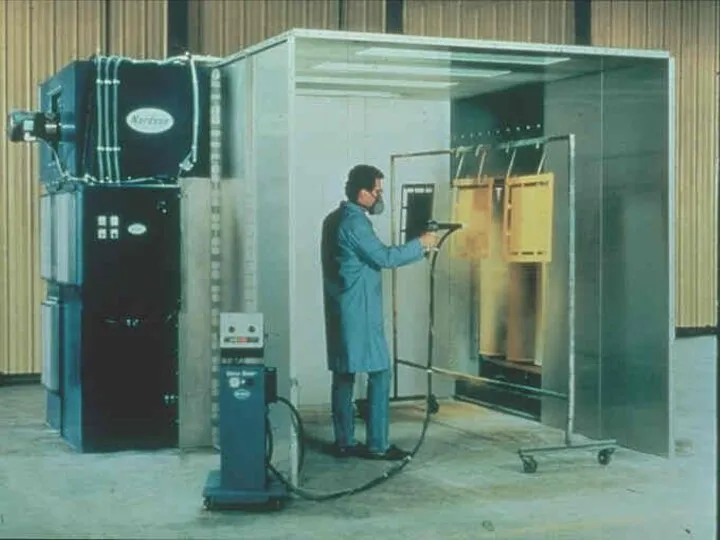

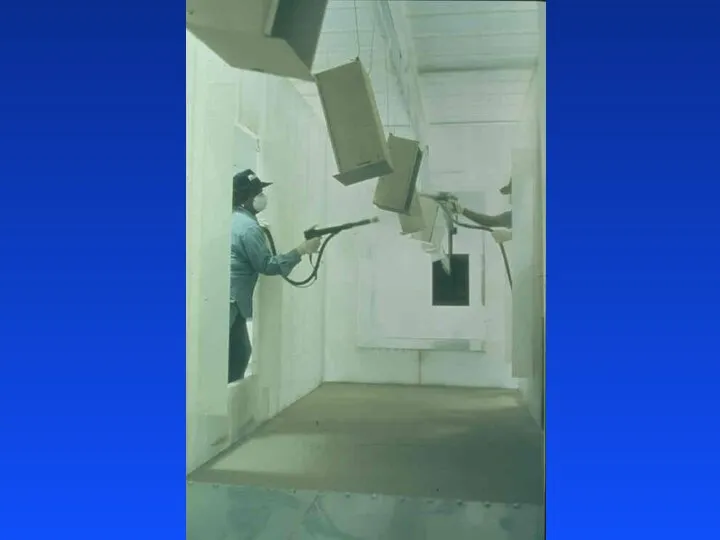

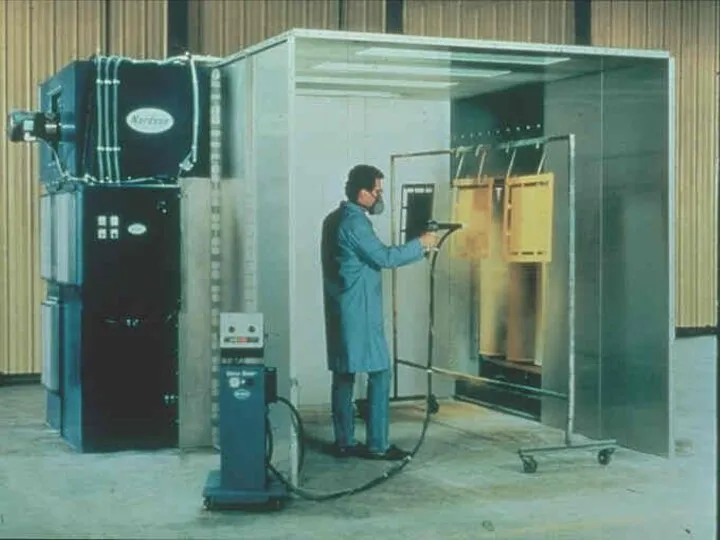

Types of Booths

Batch Booths

Conveyorized Systems

Слайд 64

Слайд 65

Слайд 66

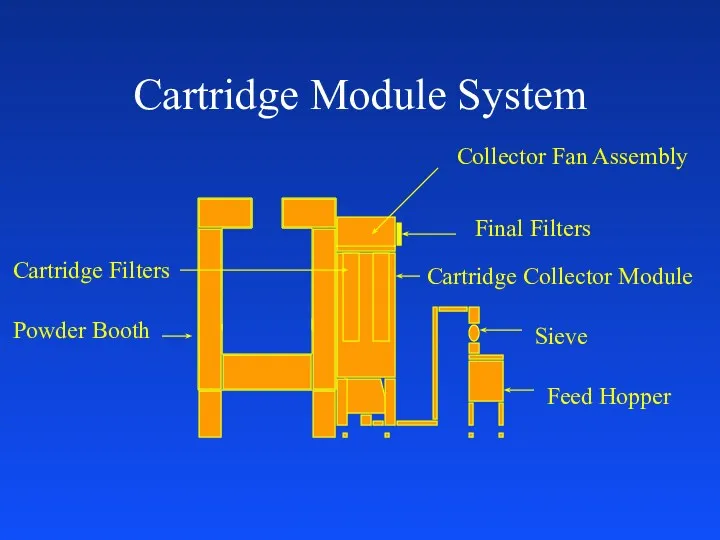

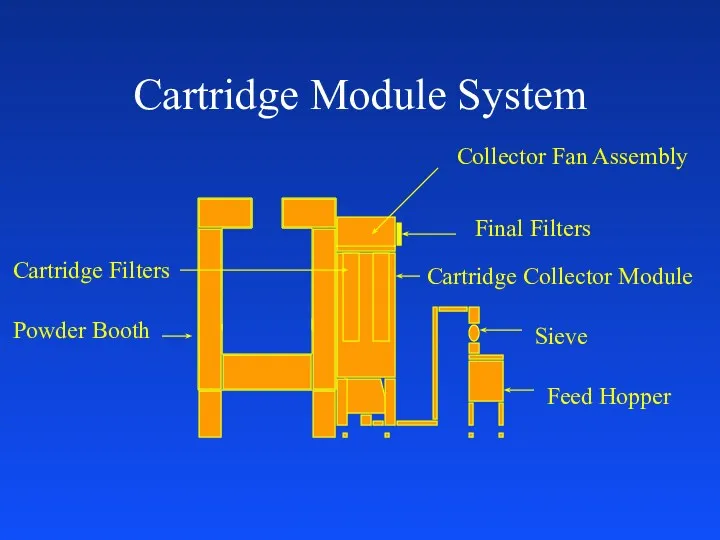

Two Common Types of Recovery Equipment

Cyclone System

Cartridge Module System

Слайд 67

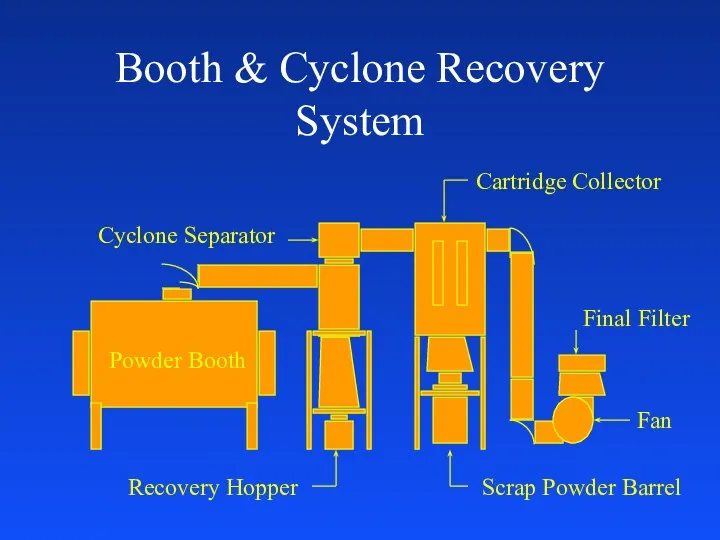

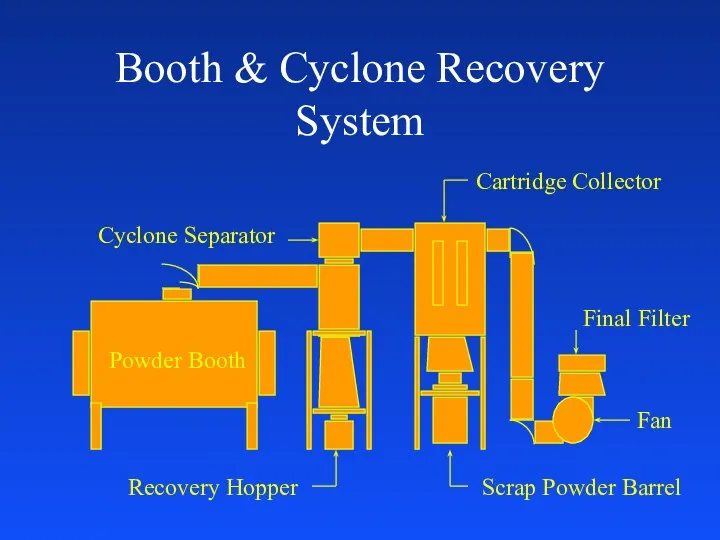

Booth & Cyclone Recovery System

Cyclone Separator

Cartridge Collector

Recovery Hopper

Scrap Powder Barrel

Final Filter

Fan

Слайд 68

Слайд 69

Слайд 70

Слайд 71

Слайд 72

Слайд 73

Spray to Waste

Short Runs of Various Colors

Faster Color Change Time

Higher

Material Cost

Слайд 74

Reclaiming Powder for Reuse

Collect Overspray for Reuse

Long Runs of the Same

Color

Mix Reclaim & Virgin Material Consistantly

Слайд 75

CURING, TESTING, QUALITY CONTROL & PACKAGING

Слайд 76

Powder Coating Cure Cycle

Enters the Oven Dry

Melts & Flows From Heat

Gels

& Chemically Crosslinks

Exits the Oven as a Hard Film

Слайд 77

Cure Methods

Convection

Infrared

Слайд 78

Convection Oven

Hot Air is Used to Heat Substrate

Heated Substrate Conducts Heat

to Coating

Temperature is Held for Specific Length of Time to Reach Full Cure

Слайд 79

Слайд 80

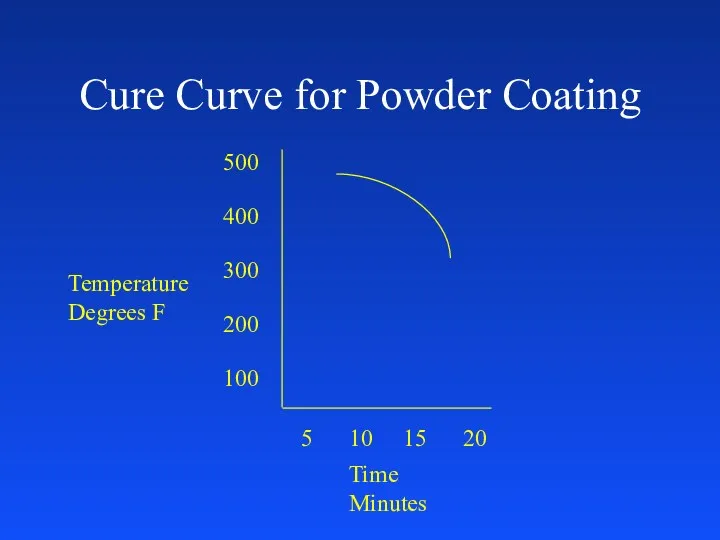

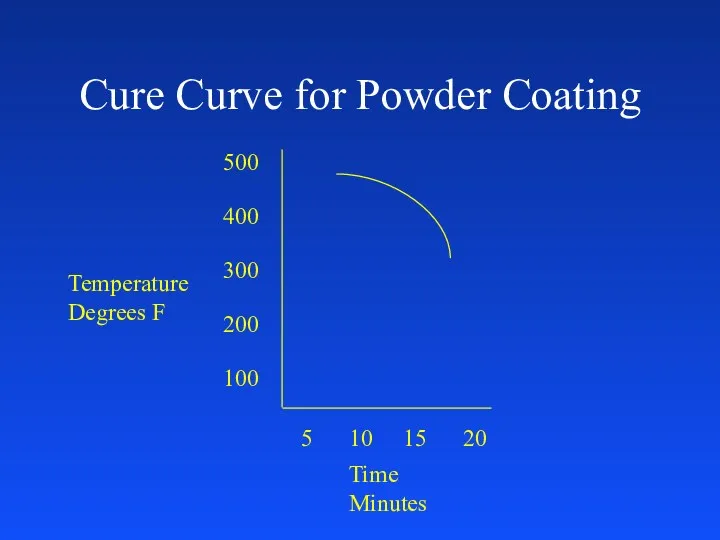

Cure Curve for Powder Coating

Time

Minutes

100

200

300

400

5

10

15

20

500

Temperature

Degrees F

Слайд 81

Infrared Cure

Energy is Emitted & Directed to Part

Energy Absorbed into Coating

& Part Surface Causes Quick Crosslinking

Слайд 82

Слайд 83

Convection Cure

Advantages

More Flexible for Part Mass & Surface Variety With Little

Required Adjustment

More Consistent Outcome with a Broader Range of Process Control Variables

Limitations

Requires More Space

Longer Cycle Time

Слайд 84

Infrared Cure

Advantages

Faster Cure Cycle

Limitations

Dependent on Line-of-Sight

Less Flexible for Part Mass &

Surface Variety With More Adjustment Required

Слайд 85

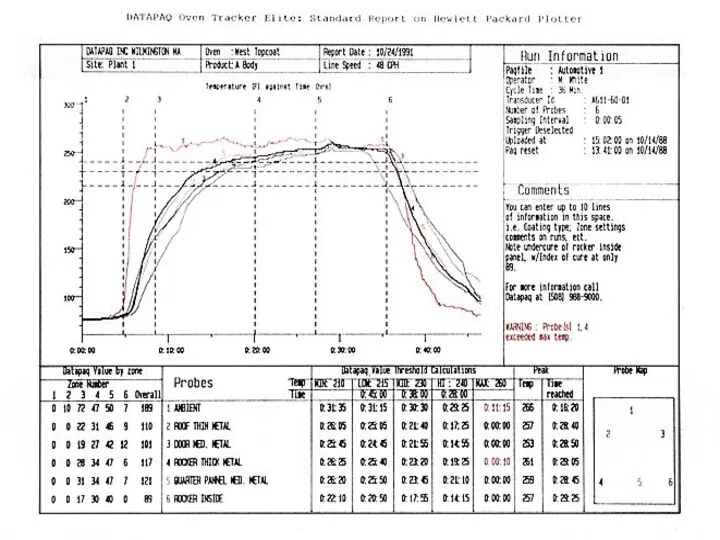

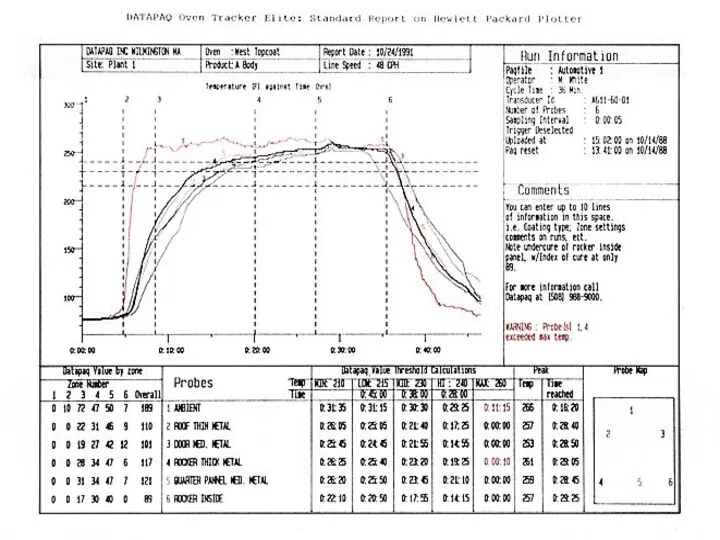

Testing & Quality Control

Test Oven for Temperature Uniformity

Test Washer Chemistry

Test Finished

Film Properties

Слайд 86

Слайд 87

Слайд 88

Finished Film Tests

Color & Gloss

Film Thickness

Adhesion

Pencil Hardness

Impact Resistance

Chemical Rub Test

Слайд 89

Packaging

Protect the Surface After Coating

Keep Good Records of Packed Product

Control the

Volume per Skid

Take Account of any Special Costs

Слайд 90

Packaging Materials

Boxes

Paper

Foam

Plastic Bags

Cardboard Dividers

Shrink Wrap

Banding

Слайд 91

Types of Packaging

Bulk Containers

Layer Packing

Layer Packing with Wrap

Weave Packing

Cell Packing

Stacking

Слайд 92

OPERATIONS -

MATERIALS HANDLING, PROCESS CONTROL, TRACKING & RECORDING

Слайд 93

Material Handling

Purchasing Materials

Storage of Materials

Inventory Control

Material Supply

Слайд 94

Powder Purchasing Considerations

Purchase Just Enough to Support Production

Avoid Long-Term Storage

Слайд 95

Powder Storage

Maintain Temperature as Low as Possible

Below 800 F Preferred

Maintain Humidity

as Low as Possible

Below 60%Preferred

Do Not Stack More Than 3 Boxes High

First in, First out

Слайд 96

Powder Supply

Sieve or Screen all Powder

Precondition Powder by Fluidizing

Mix Enough Virgin

Material with Reclaim To Remain Efficient

50/50 Typical

Close Up Containers in Storage

Слайд 97

Pretreatment Chemicals

Additions to Washer

Manual or Automatic

Handling

Use Proper Safety Precautions

Storage

Indoors, Dry

Conditions

Слайд 98

PROCESS CONTROL

Application Control

System Monitoring & Maintenance

Слайд 99

System Monitoring & Maintenance

Training to Maintain Worker Skills

Proper Management of Raw

Materials

Housekeeping & Control of the Environment

Maintenance of the Equipment

Слайд 100

Equipment Maintenance

Spray Washer - titrate solutions, clean nozzles, clean screens

Dry-off Oven

- keep oven clean

Application Equipment - keep clean, replace worn parts

Cure Oven - keep oven clean

Слайд 101

Equipment Maintenance (Continued)

Booth & Recovery System - keep clean, check filters,

clean sieve

Conveyor - keep clean, lubricate

Racks & Hangers - keep contacts & frame clean & in good repair

Слайд 102

TRACKING & RECORDING COATING JOBS

Control of Inventory From Arrival to Shipment

Work

in Process Records

Слайд 103

Receiving

Enter into Inventory

Notify Customer of Mistakes

Store in Consistent Location

Isolate

one Batch from Others

Слайд 104

Processing

Verify Proper Count When Loading

Separate & Count Rejects

Maintain Counts With Progress

raw parts

coated, not inspected

ready for shipment

rejects

Слайд 105

Rework

Schedule for Quick Turn-around

Maintain Status Report

Count Parts that Cannot be Salvaged

Слайд 106

Status

Be Able to Inform Customer on Progress

parts raw

parts coated

parts ready for

shipment

parts to be reworked

parts that have flaws that cannot be fixed

Слайд 107

SAFETY ISSUES, OSHA, & ENVIRONMENTAL CONCERNS

Слайд 108

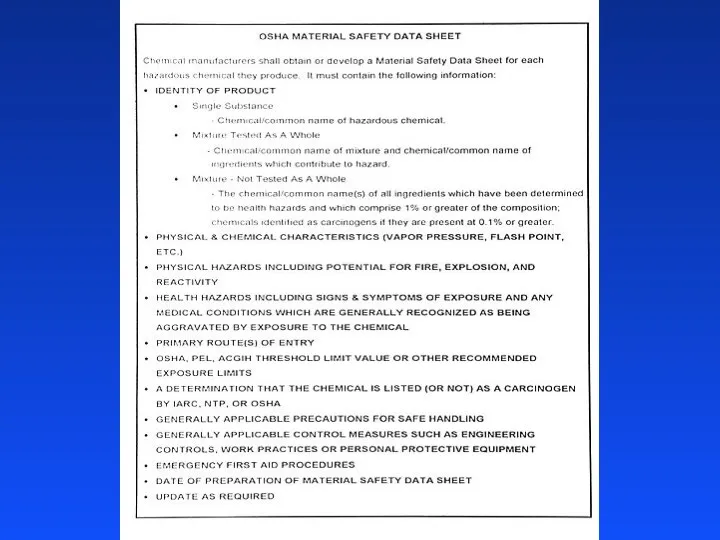

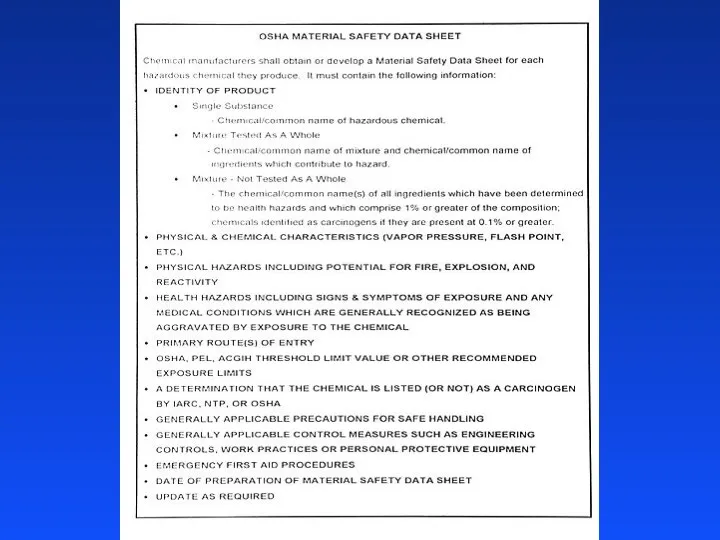

Handling of Powder Coatings

Read the MSDS

Avoid Excess Skin Exposure

Wear the

Proper Respiratory Equipment

Wear the Proper Clothing & Eyewear

Слайд 109

Слайд 110

Слайд 111

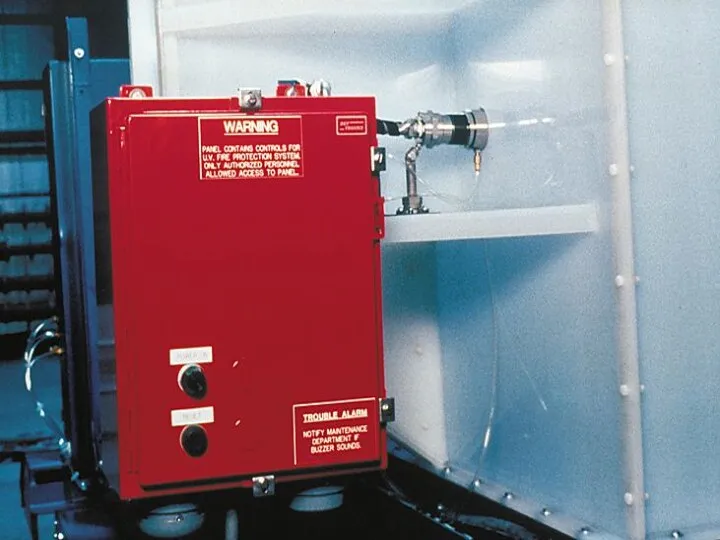

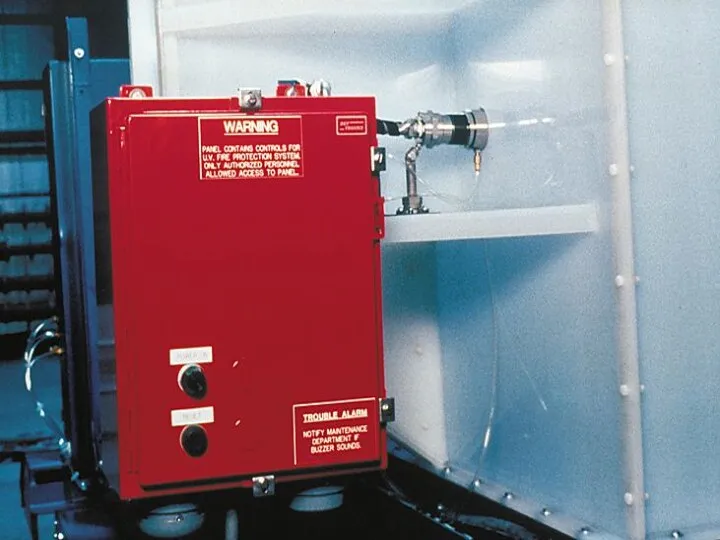

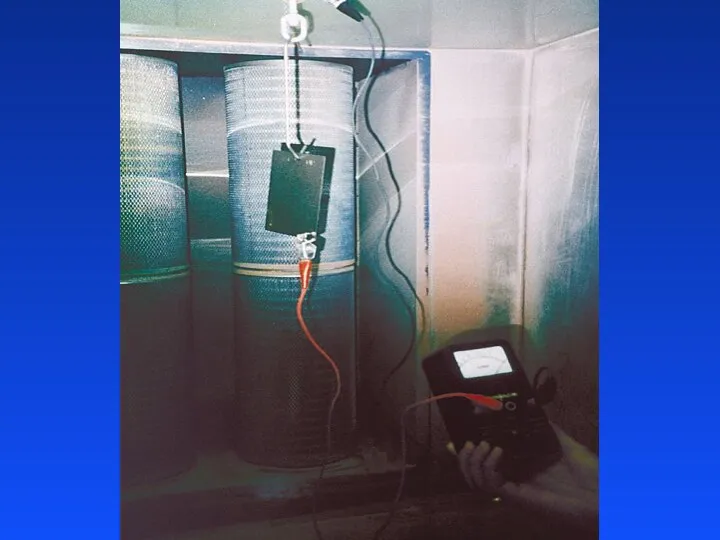

Fire Risk

Maintain Safe Concentration Level of Powder

Eliminate Sources of Ignition

Maintain

Good Ground of Everything in the System

Maintain Good Ground Through Racks

Слайд 112

Слайд 113

Слайд 114

Pretreatment Chemicals

Read MSDS

Avoid Skin Contact

Wear the Recommended Safety Clothing

Maintain Good

Ventilation

Слайд 115

High Temperature Environments

Limit Access

Never Enter Washer or Oven During Operation

Disconnect Power

Before Entering

Use Good Lighting When Entering

Wear a Hard Hat in Areas Where it is Necessary to Stoop

Know the Hazards Inside the Equipment

Слайд 116

Методология научного познания

Методология научного познания Технология формирования интонационной стороны речи

Технология формирования интонационной стороны речи Презентация к уроку математики 5 класс (Никольский С.М. идр.)

Презентация к уроку математики 5 класс (Никольский С.М. идр.) Курская Битва. Лето 1943 года

Курская Битва. Лето 1943 года Учебно-методическое пособие. Игры на развитие фонематического анализа и синтеза.

Учебно-методическое пособие. Игры на развитие фонематического анализа и синтеза. Ферменты. Структура и функция. Классификация и номенклатура

Ферменты. Структура и функция. Классификация и номенклатура Терминальные состояния. Основы современной реанимации

Терминальные состояния. Основы современной реанимации Инфинитив и -ing форма

Инфинитив и -ing форма портфолио Диск Диск Диск Диск Диск Диск Диск

портфолио Диск Диск Диск Диск Диск Диск Диск Устройства ввода-вывода

Устройства ввода-вывода Вибраторы. Машины для уплотнения бетонной смеси

Вибраторы. Машины для уплотнения бетонной смеси Сергей Александрович Есенин (1895-1925)

Сергей Александрович Есенин (1895-1925) Презентация по теме Северный Кавказ (9 класс)

Презентация по теме Северный Кавказ (9 класс) Вся жизнь - страна детства

Вся жизнь - страна детства Тауартану – тауарлардың тұтынушылық қасиеттерін зерттейтін ғылыми пәнтауартану ғылым ретінде xvі ғ. Ортасында қалыптасты

Тауартану – тауарлардың тұтынушылық қасиеттерін зерттейтін ғылыми пәнтауартану ғылым ретінде xvі ғ. Ортасында қалыптасты Types of Bulbs

Types of Bulbs презентация Игра как педагогическая технология

презентация Игра как педагогическая технология Дезинфекция

Дезинфекция Адаптация студентов к обучению в медицинском вузе

Адаптация студентов к обучению в медицинском вузе Вместе победим туберкулез

Вместе победим туберкулез Простой компас

Простой компас Школа критики Полярного дня. Есенин vs Слава КПСС

Школа критики Полярного дня. Есенин vs Слава КПСС 20230923_biologiya_nauka_5_kl

20230923_biologiya_nauka_5_kl Зенкерование. Развертывание

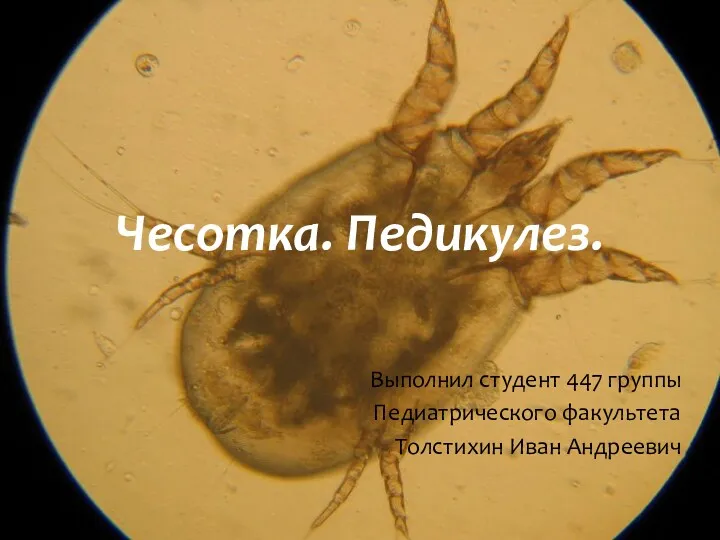

Зенкерование. Развертывание Чесотка. Педикулез

Чесотка. Педикулез Алгебра предикатов

Алгебра предикатов Сборник заданий по математике для начальной школы

Сборник заданий по математике для начальной школы Сжатое изложение. Приёмы компрессии текста

Сжатое изложение. Приёмы компрессии текста