Содержание

- 2. GS-BW6025A 12000KW光纤激光切割机 ◆Wide Cutting Applications Applied in carbon steel, stainless steel, alloy steel and other metal

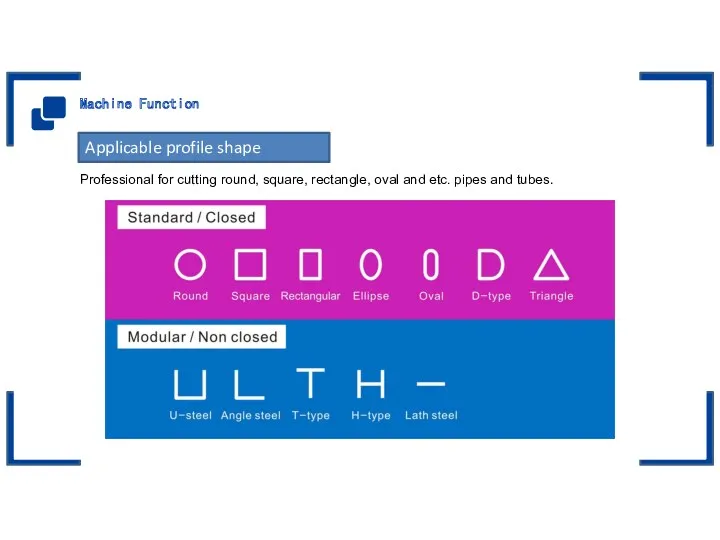

- 3. Applicable profile shape Machine Function Professional for cutting round, square, rectangle, oval and etc. pipes and

- 4. Applicable profile shape Machine Function Application industry

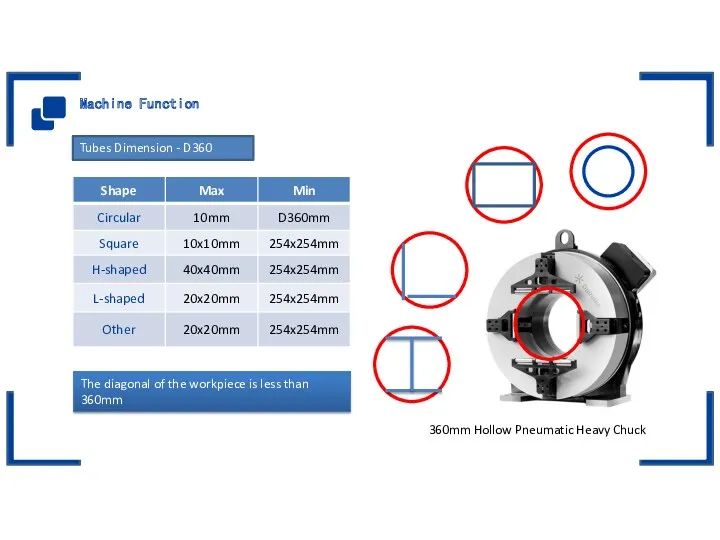

- 5. Applicable profile shape Machine Function Tubes Dimension - D360 The diagonal of the workpiece is less

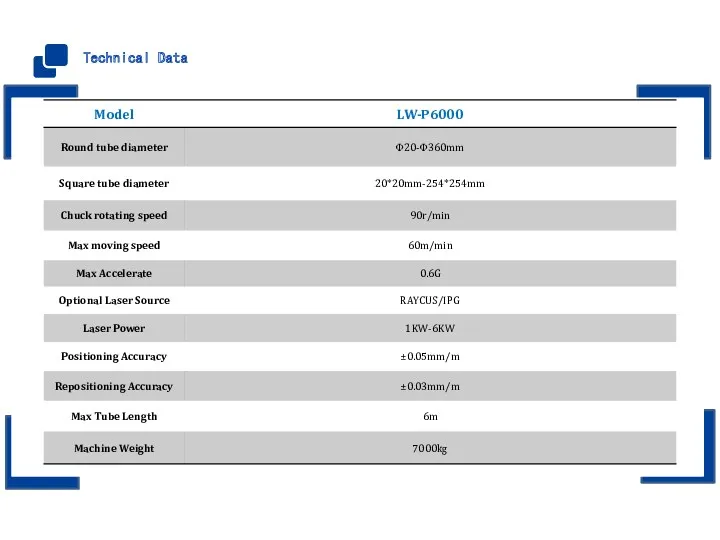

- 6. GS-BW6025A 12000KW光纤激光切割机 Technical Data

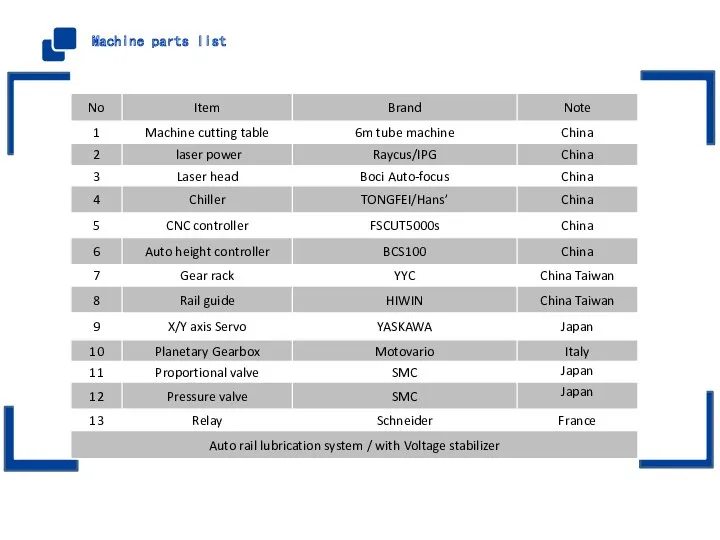

- 7. GS-BW6025A 12000KW光纤激光切割机 Machine parts list

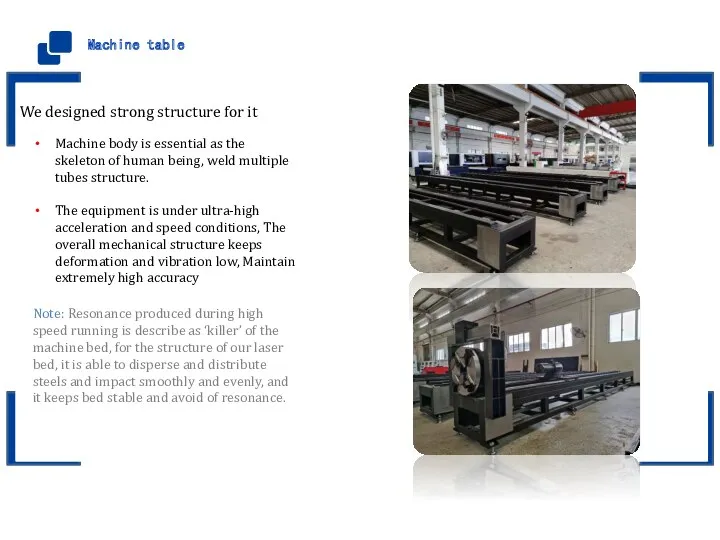

- 8. We designed strong structure for it 08 Machine body is essential as the skeleton of human

- 9. Product Introduction Datum Plane milling is vital for installation & running accuracy of motion parts, Lonwill

- 10. Product Introduction In strict accordance with the mechanical installation standards and requirements, ensure that each part

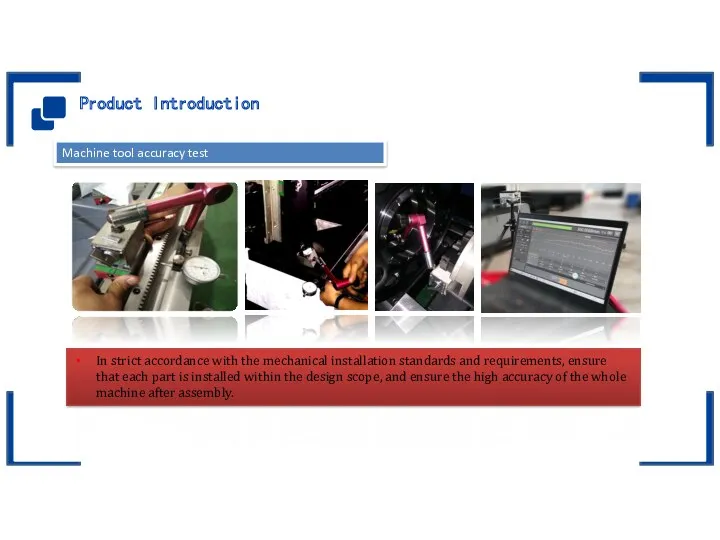

- 11. Product Introduction Boci Laser Head

- 12. 1 CNC clamping system High-precision position control and torque control CNC Self-centering chuck, position monitoring in

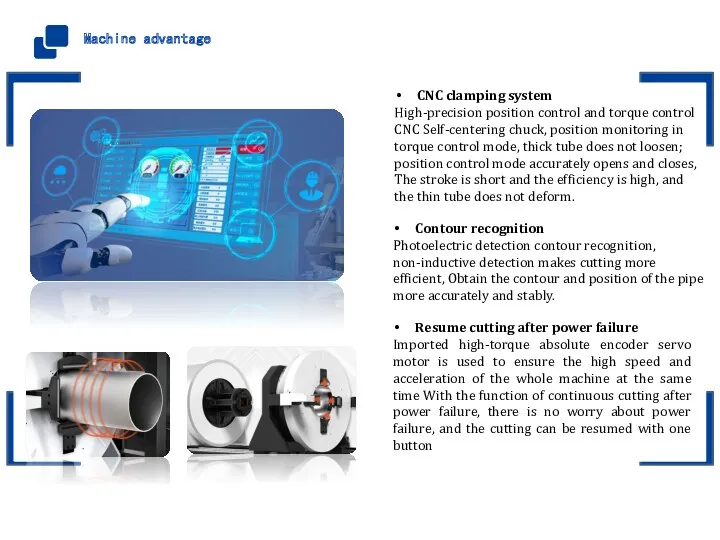

- 13. 1 Anti-carton Precise guide rail, slipping without jam 2 All-in-one design Integral built-in drive, accurate and

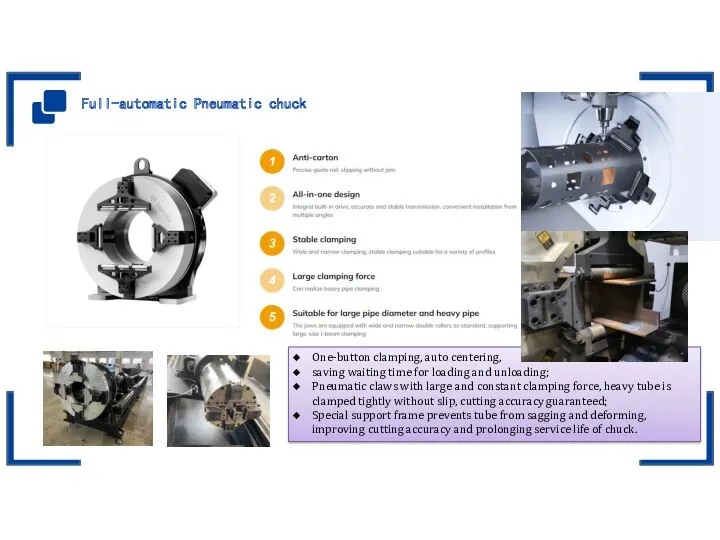

- 14. More Stable and Scratch-resistant It has tube follow-up support and righting device. It supports avoids tube

- 15. Product Introduction Professional tube cutting CNC Controller Specially developed for tube cutting controller. Tube deviation detection,

- 16. IPG Photonics is the world leader in fiber laser technology, enabling greater precision, higher productivity and

- 17. Cutting Samples Photos

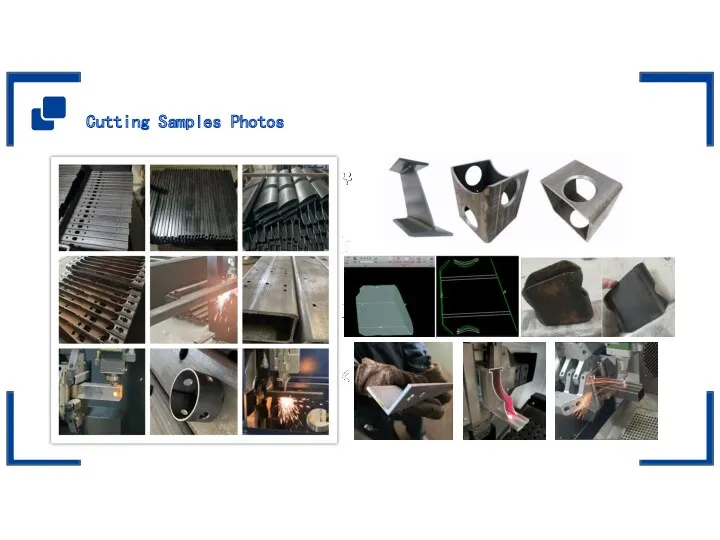

- 18. Product Introduction

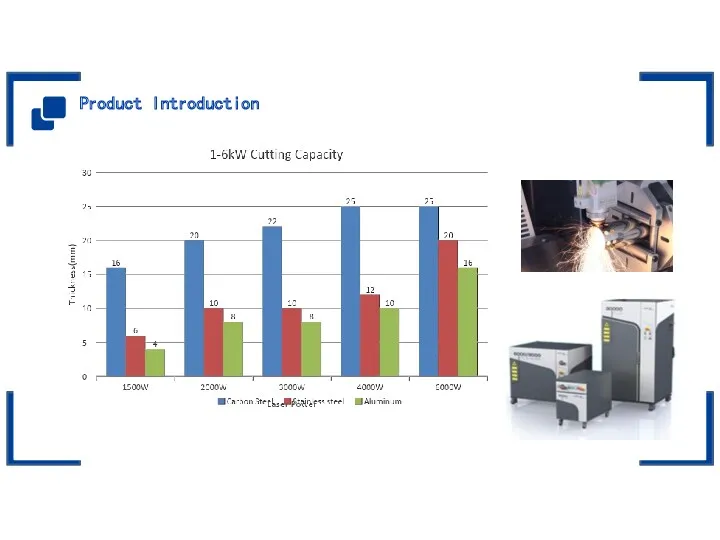

- 19. a、验收标准 Packing and Shipping

- 20. a、验收标准 After-Sale Service Warranty period: From the acceptance qualified date, the warranty period will be one

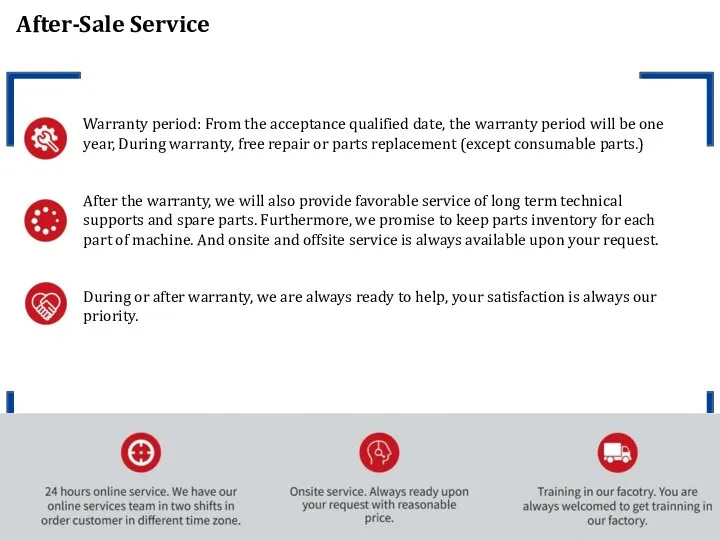

- 22. Скачать презентацию

Проект: Использование ЦОР по предупреждению и коррекции оптической дисграфии у младших школьников .

Проект: Использование ЦОР по предупреждению и коррекции оптической дисграфии у младших школьников . Электроэнергетика России

Электроэнергетика России пищевые добавки

пищевые добавки Понятие - наука

Понятие - наука Всероссийская метапредметная олимпиада по ФГОС “Новые знания” для учащихся 2-4 классов

Всероссийская метапредметная олимпиада по ФГОС “Новые знания” для учащихся 2-4 классов Сайт Салона красоты Al’Paco

Сайт Салона красоты Al’Paco Профессия - стропальщик

Профессия - стропальщик Предраковые заболевания слизистой оболочки полости рта и красной каймы губ

Предраковые заболевания слизистой оболочки полости рта и красной каймы губ Страны Юго-Восточной Азии. Индонезия

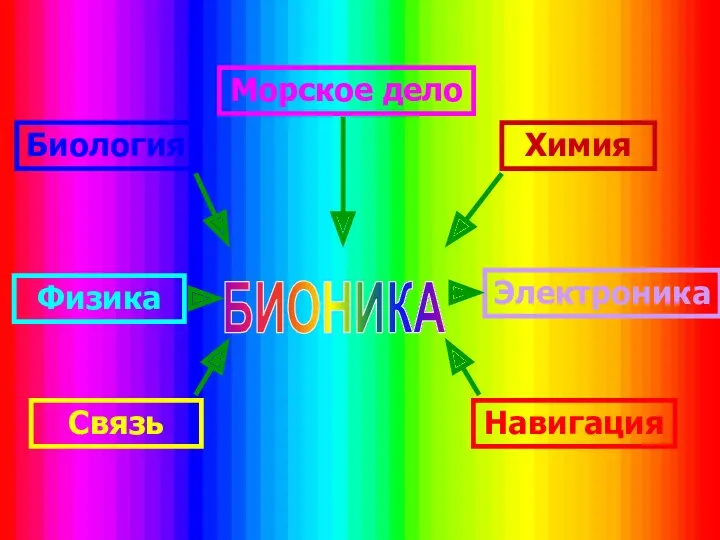

Страны Юго-Восточной Азии. Индонезия Презентация НАУКА БИОНИКА

Презентация НАУКА БИОНИКА Презентация к уроку Высотная поясность

Презентация к уроку Высотная поясность Кадровое дело

Кадровое дело American horror story

American horror story Классификация видов информационных технологий. Лекция 2

Классификация видов информационных технологий. Лекция 2 Моя мама

Моя мама Спутниковое ТВ. Для агентского канала

Спутниковое ТВ. Для агентского канала Клиника дизартрий

Клиника дизартрий Новый Закон об образовании

Новый Закон об образовании Методическая работа по развитию речи в дошкольном образовательном учреждении на диагностической основе

Методическая работа по развитию речи в дошкольном образовательном учреждении на диагностической основе Формование батонов

Формование батонов Правила учащихся лицея

Правила учащихся лицея Презентация о школьном музее

Презентация о школьном музее Диоды с переменной емкостью

Диоды с переменной емкостью Медицина во время Первой Мировой Войны

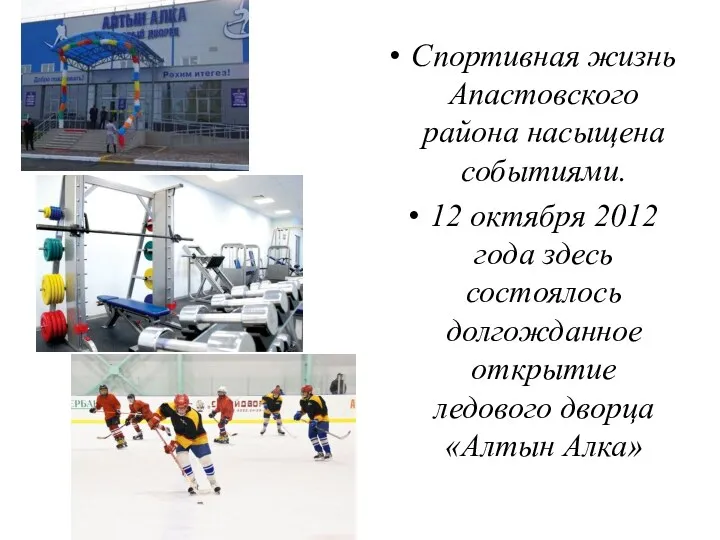

Медицина во время Первой Мировой Войны Моя малая родина 5

Моя малая родина 5 Электроэнергетика России

Электроэнергетика России Глазунов Илья Сергеевич

Глазунов Илья Сергеевич Физиология высшей нервной деятельности

Физиология высшей нервной деятельности