Содержание

- 2. Name: Ostap Syrotych. Location: Hoghiz Cement Plant, CRH Romania. Plant Manager: Dan Sima. Assignment term: 08

- 3. 11-11-2018 Ostap Syrotych Contents 1. Safety activities, tasks and experience – slides 4-5 2. Work in

- 4. 11-11-2018 Ostap Syrotych Daily safety inspections during Winter Overhaul as a part of inspection team; inspections

- 5. 11-11-2018 Ostap Syrotych Noticed and learnt a lot from Romanian engineers and workers behaviour and practices

- 6. 11-11-2018 Ostap Syrotych 1. Ball Mills inspections (Raw Mill and Cement Mills); calculating ball charge. 2.

- 7. 11-11-2018 Ostap Syrotych 6. False air measurements and investigations (Preheater Tower, Raw Mill , Coal Mill)

- 8. 11-11-2018 Ostap Syrotych 10. Inspections at the Winter Overhaul (Raw Materials Area,Raw Mill Area, Preheater Tower

- 9. 11-11-2018 Ostap Syrotych 1. Developed my knowledge and skills in process which were on basic level

- 10. 11-11-2018 Ostap Syrotych 1. False air measurements for the Coal Mill. 2. Preheater Tower and Kiln

- 11. 11-11-2018 Ostap Syrotych 1. KIMA SmartFill System calibration for 3 Ball Cement Mills (all three with

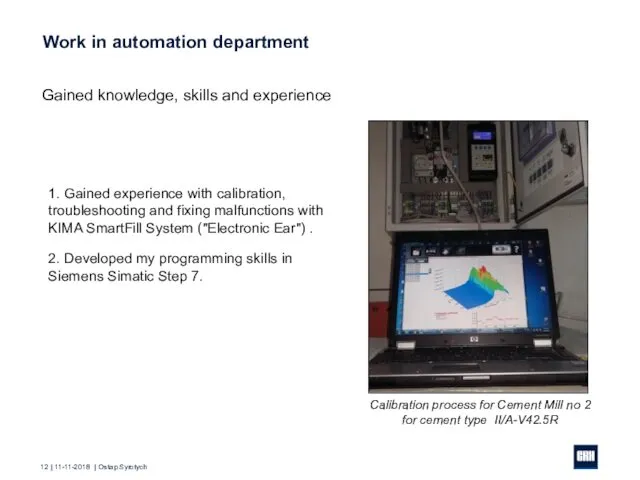

- 12. 11-11-2018 Ostap Syrotych 1. Gained experience with calibration, troubleshooting and fixing malfunctions with KIMA SmartFill System

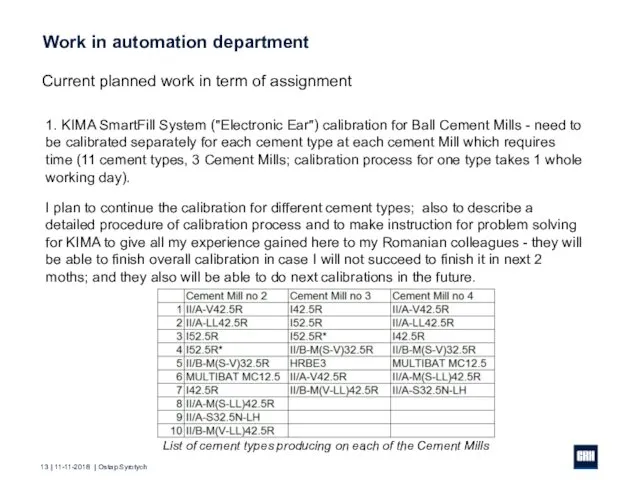

- 13. 11-11-2018 Ostap Syrotych 1. KIMA SmartFill System ("Electronic Ear") calibration for Ball Cement Mills - need

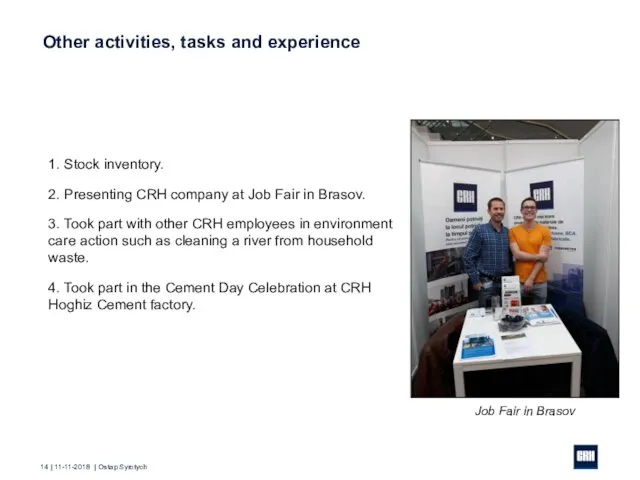

- 14. 11-11-2018 Ostap Syrotych 1. Stock inventory. 2. Presenting CRH company at Job Fair in Brasov. 3.

- 16. Скачать презентацию

Исследование органов пищеварения

Исследование органов пищеварения Господарсько-договірні зобов’язання. Господарсько-правова відповідальність

Господарсько-договірні зобов’язання. Господарсько-правова відповідальність Мотив тоски и одиночества в стихотворении М.Ю.Лермонтова Тучи. 6 класс

Мотив тоски и одиночества в стихотворении М.Ю.Лермонтова Тучи. 6 класс Роснефть сегодня. Стратегические инициативы в области социального развития

Роснефть сегодня. Стратегические инициативы в области социального развития Организация предприятия общественного питания на примере ресторана KFC в г. Омске

Организация предприятия общественного питания на примере ресторана KFC в г. Омске Оригами из модулей

Оригами из модулей Объемные фигуры. Изготовление изделий из полосок.

Объемные фигуры. Изготовление изделий из полосок. Эксперимент на уроке биологии

Эксперимент на уроке биологии Использование голосового помощника Маруся на уроках математики в 5 классе

Использование голосового помощника Маруся на уроках математики в 5 классе Бухгалтерский учет договоров аренды отдельными некредитными финансовыми организациями. Глава 13

Бухгалтерский учет договоров аренды отдельными некредитными финансовыми организациями. Глава 13 20231022_dif._podhod

20231022_dif._podhod Татар теле. 2 сыйныф. Изложение. “Үрдәк”.

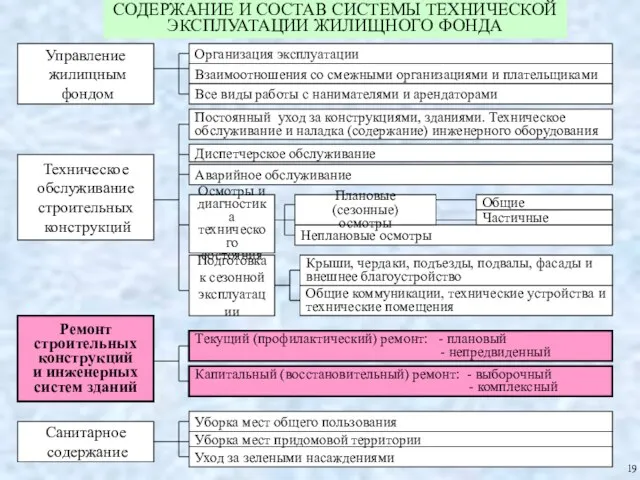

Татар теле. 2 сыйныф. Изложение. “Үрдәк”. Основные положения по организации и производству ремонтно-строительных работ

Основные положения по организации и производству ремонтно-строительных работ Передача информации

Передача информации Дифференциальная диагностика болезни Паркинсона с мультисистемной атрофией

Дифференциальная диагностика болезни Паркинсона с мультисистемной атрофией Проект Проблема использования народного творчества для духовного и творческого развития личности

Проект Проблема использования народного творчества для духовного и творческого развития личности Питание и пищеварение

Питание и пищеварение Способы образования поверхностей двоякой кривизны. Схемы поверхностей вращения и переноса

Способы образования поверхностей двоякой кривизны. Схемы поверхностей вращения и переноса гражданское право

гражданское право Использование дидактической игры для развития речи детей раннего возраста

Использование дидактической игры для развития речи детей раннего возраста Здоровьесбережение на уроках русского языка и литературы

Здоровьесбережение на уроках русского языка и литературы Графические ошибки детей 6-7 лет

Графические ошибки детей 6-7 лет Презентация к программе доп.образования в ДОУ Занимательный английских

Презентация к программе доп.образования в ДОУ Занимательный английских Композитор Модест Петрович Мусоргский

Композитор Модест Петрович Мусоргский Рабочая документация на новые модели одежды

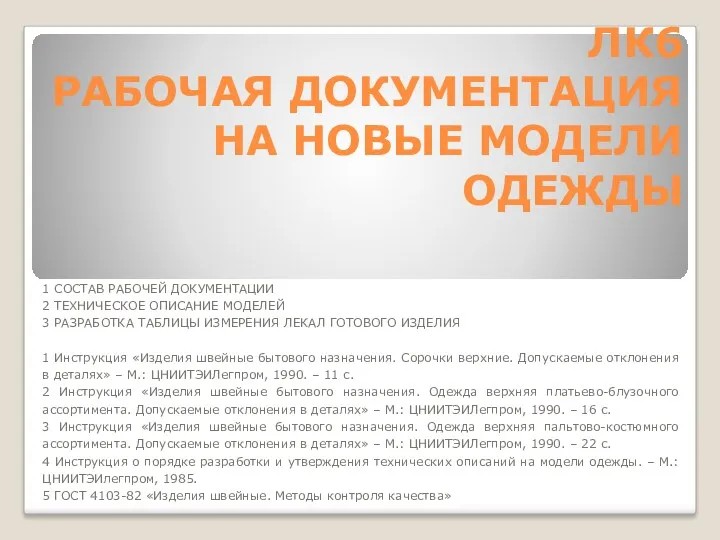

Рабочая документация на новые модели одежды Классицизм в русском искусстве

Классицизм в русском искусстве Тестирование на предмет раннего выявления незаконного потребления наркотических средств и психотропных веществ (для родителей)

Тестирование на предмет раннего выявления незаконного потребления наркотических средств и психотропных веществ (для родителей) Жертвенна праця для спасіння душі. Андрей Шептицький

Жертвенна праця для спасіння душі. Андрей Шептицький