Содержание

- 2. Hydraulic Filtration Training Содержание Гидравлика, введение. Загрязнение, причины и последствия. Типы и источники возникновения загрязнений. Стандарты

- 3. Hydraulic Filtration Training Фильтрация, обучение#1 Гидравлика, Введение

- 4. Hydraulic Filtration Training Гидравлика. Введение “гидравлические жидкости” Главное задача гидроприводов –передача механической энергии через трансформацию в

- 5. Hydraulic Filtration Training Фильтрация, обучение#1 Загрязнения Причины/следствия + Типы и источники возникновения загрязнений

- 6. Hydraulic Filtration Training Типы загрязнений В анализируемых нами гидросистемах, существуют три типа загрязнений: Твёрдые (пыль и

- 7. Hydraulic Filtration Training Загрязнения Причины/следствия Статистические исследования проведённые Др. Рабинович из (Massachusset Institute of Technology) Бостон,

- 8. Hydraulic Filtration Training “Твёрдые” Загрязнения Твёрдые загрязнения (частицы) в гидравлической жидкости могут быть условно квалифицированы по

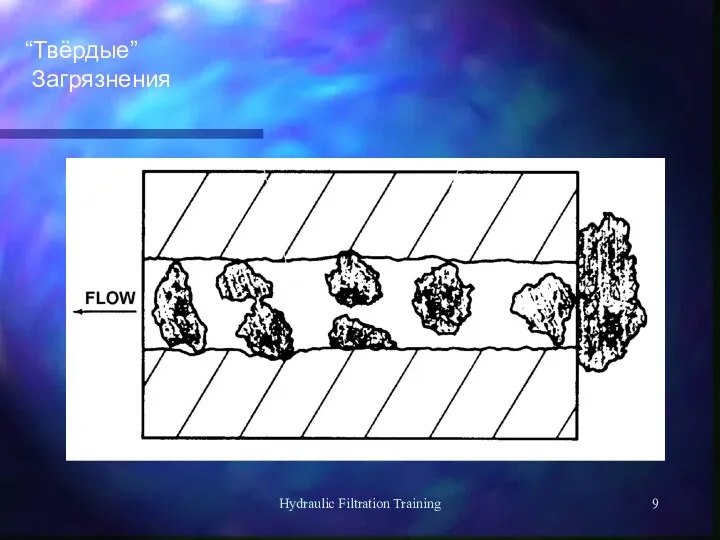

- 9. Hydraulic Filtration Training “Твёрдые” Загрязнения

- 10. Hydraulic Filtration Training “Твёрдые” Загрязнения “Катастрофический” выход из строя происходит когда в зазоры между движущимися компонентами

- 11. Hydraulic Filtration Training “Абразивный” выход из строя, происходит когда в зазоры между движущимися компонентами гидроузлов попадают

- 12. Hydraulic Filtration Training “Твёрдые” Загрязнения “Износ” происходит когда в зазоры между движущимися компонентами гидроузлов попадают частицы

- 13. Hydraulic Filtration Training “Твёрдые” Загрязнения/последствия Падение эффективности производства. Увеличение затрат на запасные части. Увеличение затрат на

- 14. Hydraulic Filtration Training “Твёрдые” Загрязнения/последствия поршень/ изношенный башмак Изношенный поршень Изношенный распределительный золотник аксиально поршневого насоса.

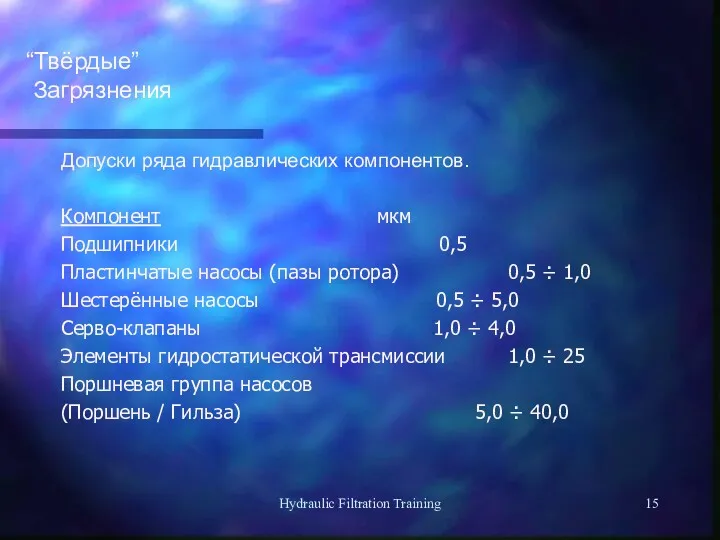

- 15. Hydraulic Filtration Training “Твёрдые” Загрязнения Допуски ряда гидравлических компонентов. Компонент мкм Подшипники 0,5 Пластинчатые насосы (пазы

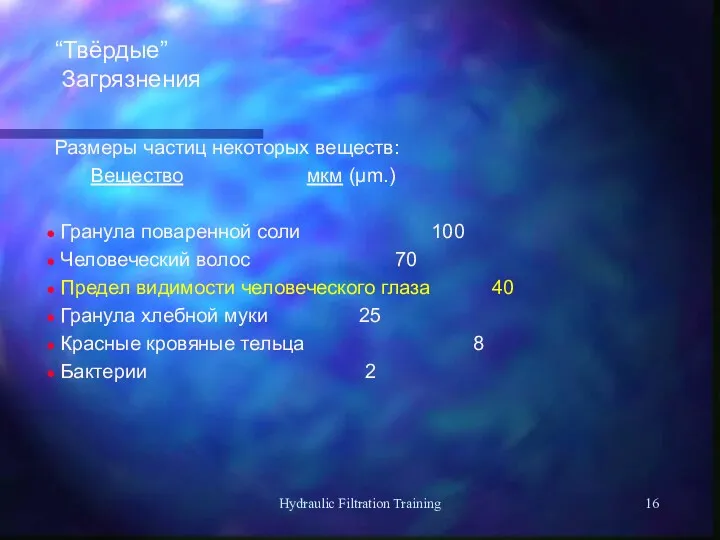

- 16. Hydraulic Filtration Training “Твёрдые” Загрязнения Размеры частиц некоторых веществ: Вещество мкм (μm.) Гранула поваренной соли 100

- 17. Hydraulic Filtration Training “Твёрдые” Загрязнения Примерная классификация Твёрдые частицы Кремний (пыль). Углерод (сварка). Металлические частицы (продукты

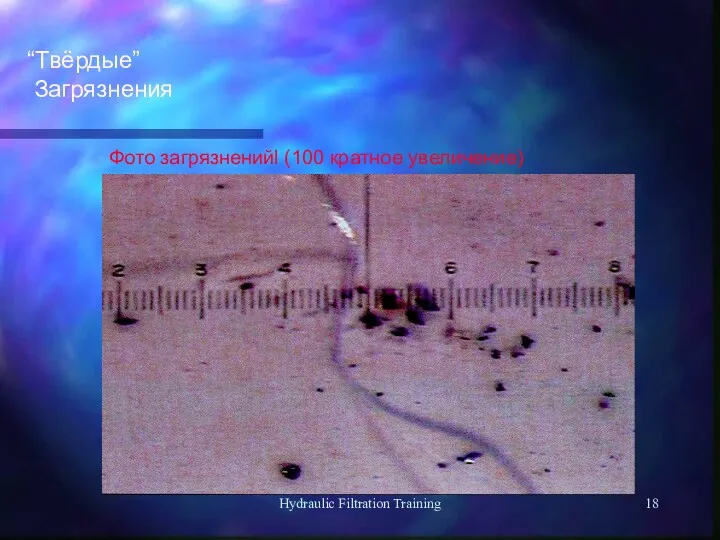

- 18. Hydraulic Filtration Training “Твёрдые” Загрязнения Фото загрязненийl (100 кратное увеличение)

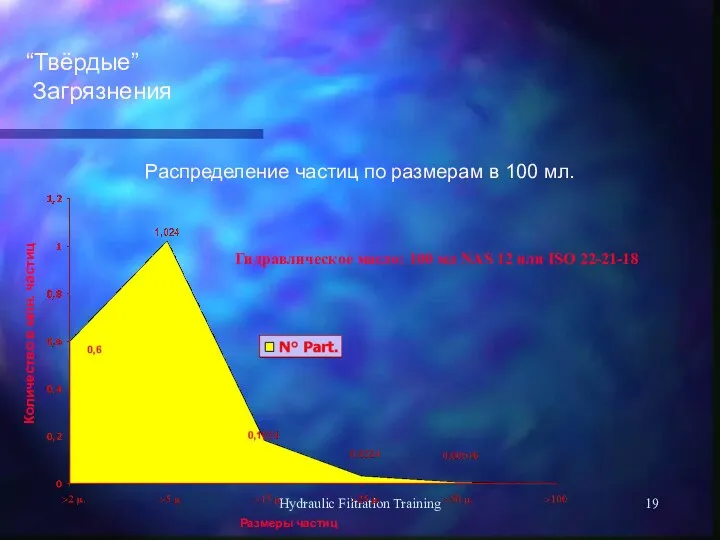

- 19. Hydraulic Filtration Training “Твёрдые” Загрязнения Распределение частиц по размерам в 100 мл. Количество в млн. частиц

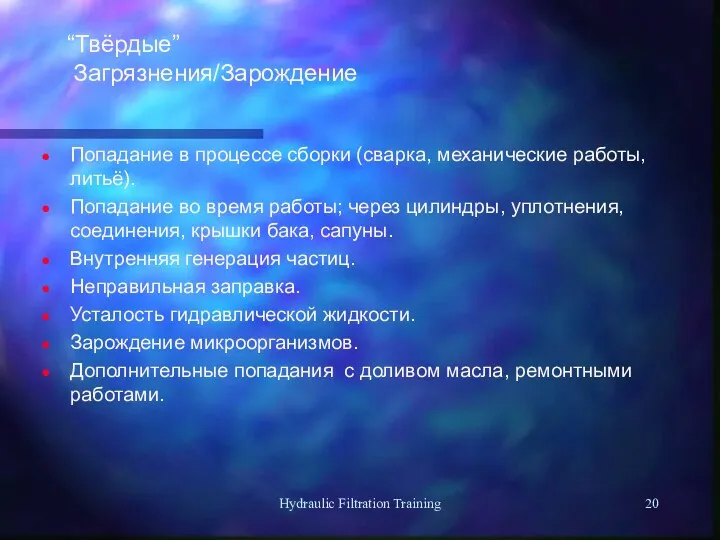

- 20. Hydraulic Filtration Training “Твёрдые” Загрязнения/Зарождение Попадание в процессе сборки (сварка, механические работы, литьё). Попадание во время

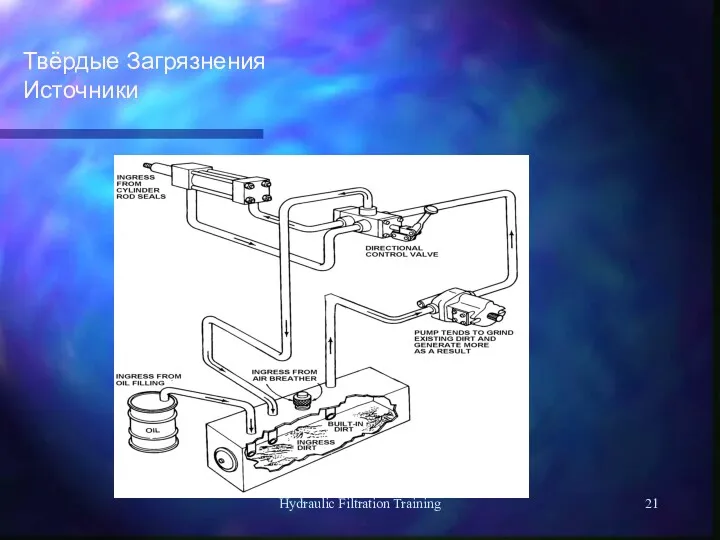

- 21. Hydraulic Filtration Training Твёрдые Загрязнения Источники

- 22. Hydraulic Filtration Training Интенсивность поступления загрязнений Количество частиц* Мобильная техника 108 - 1010 в мин. Производственные

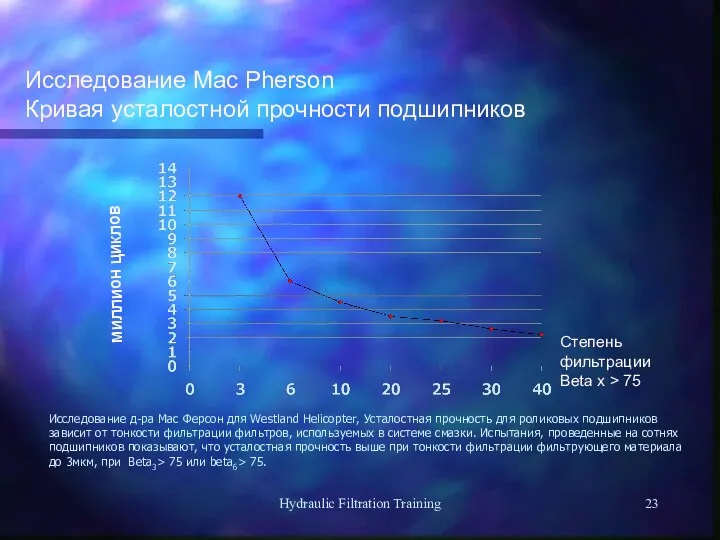

- 23. Hydraulic Filtration Training Исследование Mac Pherson Кривая усталостной прочности подшипников миллион циклов Степень фильтрации Beta x

- 24. Hydraulic Filtration Training Основные стандарты определения класса чистоты ISO 4406 - 1999 MTD. ISO 4406 -

- 25. Hydraulic Filtration Training Существуют несколько методов анализа Исследования пятна (калиброванная мембрана + микроскоп). Метод: анализ “затемнения

- 26. Hydraulic Filtration Training Обучение Чистота рабочей жидкости Классификация

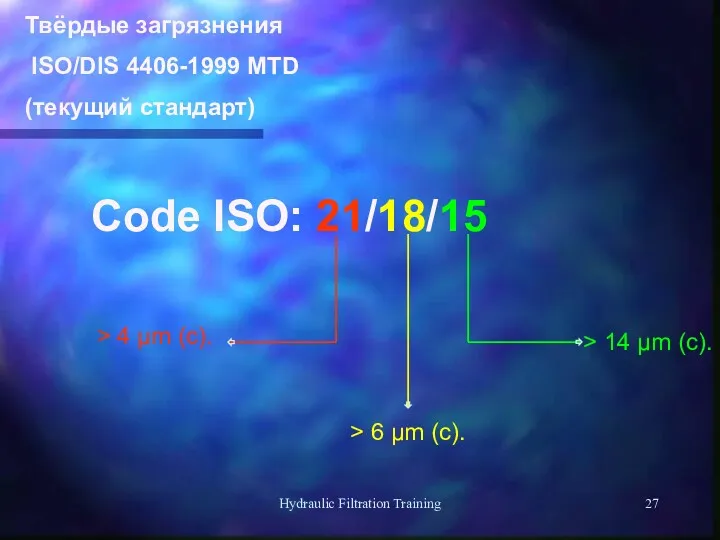

- 27. Hydraulic Filtration Training Code ISO: 21/18/15 Твёрдые загрязнения ISO/DIS 4406-1999 MTD (текущий стандарт)

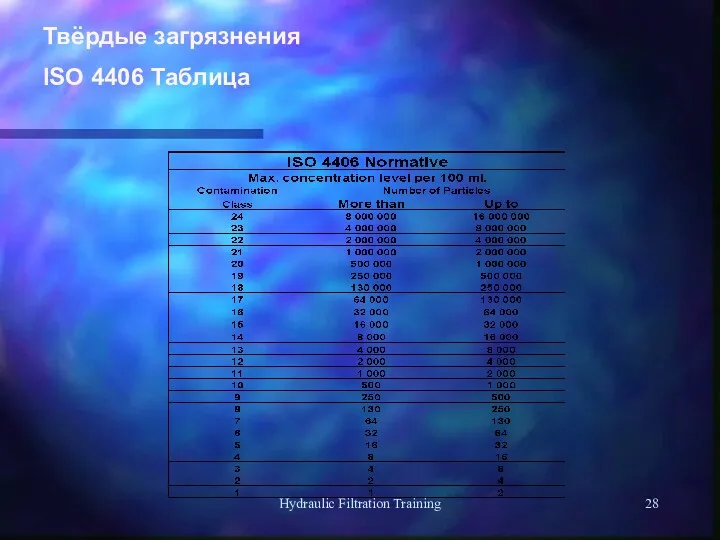

- 28. Hydraulic Filtration Training Твёрдые загрязнения ISO 4406 Таблица

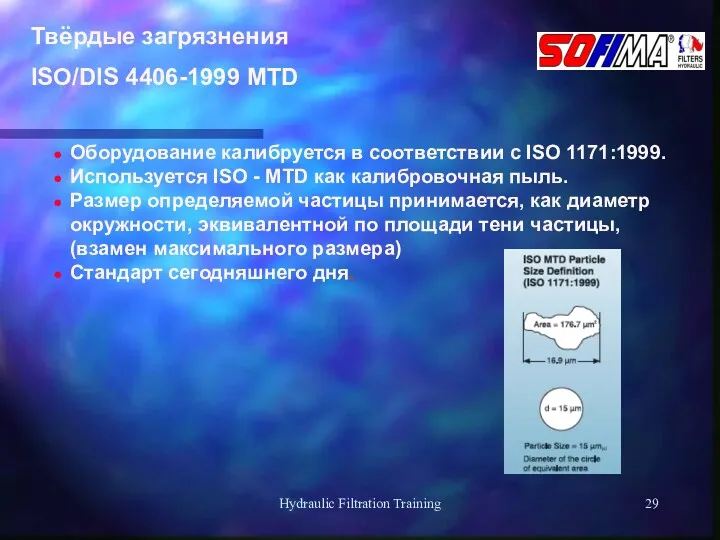

- 29. Hydraulic Filtration Training Оборудование калибруется в соответствии с ISO 1171:1999. Используется ISO - MTD как калибровочная

- 30. Hydraulic Filtration Training Используется старая классификация (бывшая просто 4406). – количество частиц на 100 мл. Те

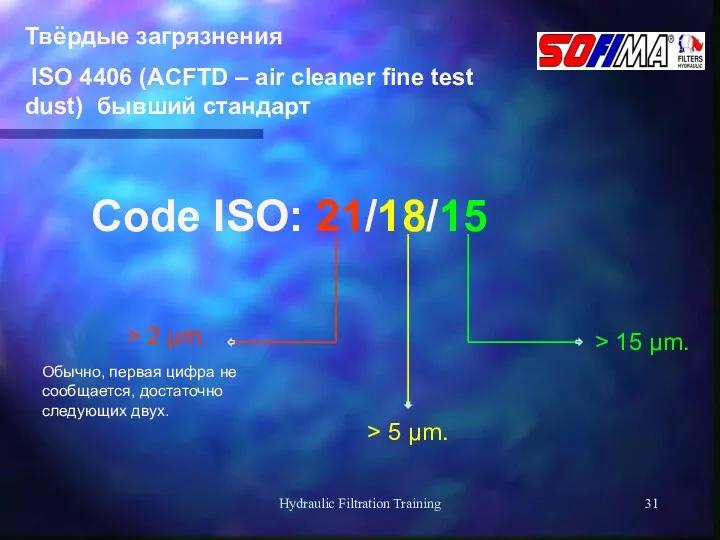

- 31. Hydraulic Filtration Training Code ISO: 21/18/15 Обычно, первая цифра не сообщается, достаточно следующих двух. Твёрдые загрязнения

- 32. Hydraulic Filtration Training Оборудование калибруется в соответствии с ISO 4402. Выбирается пыль ACFTD как калибровочная пыль

- 33. Hydraulic Filtration Training Используется старая классификация (бывшая просто 4406). – количество частиц на 100 мл. Те

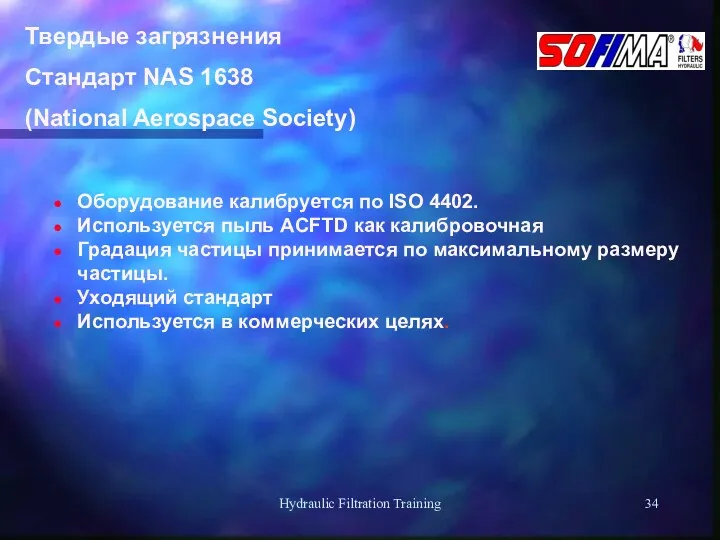

- 34. Hydraulic Filtration Training Оборудование калибруется по ISO 4402. Используется пыль ACFTD как калибровочная Градация частицы принимается

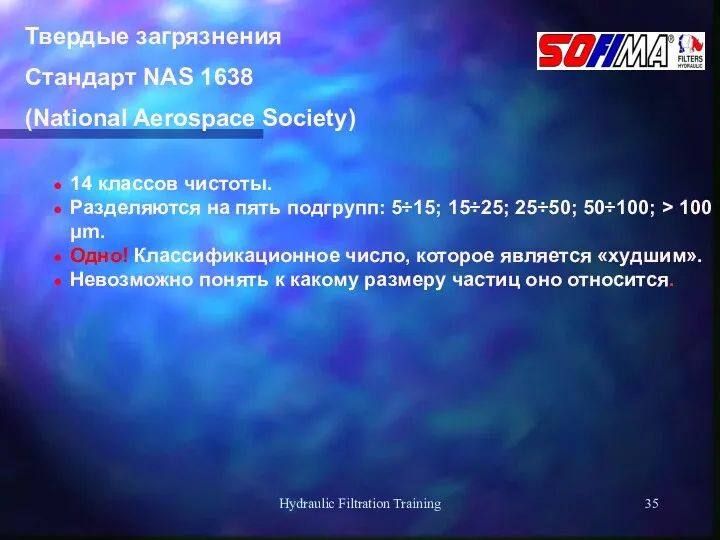

- 35. Hydraulic Filtration Training 14 классов чистоты. Разделяются на пять подгрупп: 5÷15; 15÷25; 25÷50; 50÷100; > 100

- 36. Hydraulic Filtration Training Code NAS 1638 = 10 Что значит класс 10? К какой размерной подгруппе

- 37. Hydraulic Filtration Training Твердые загрязнения Стандарт NAS 1638 (National Aerospace Society)

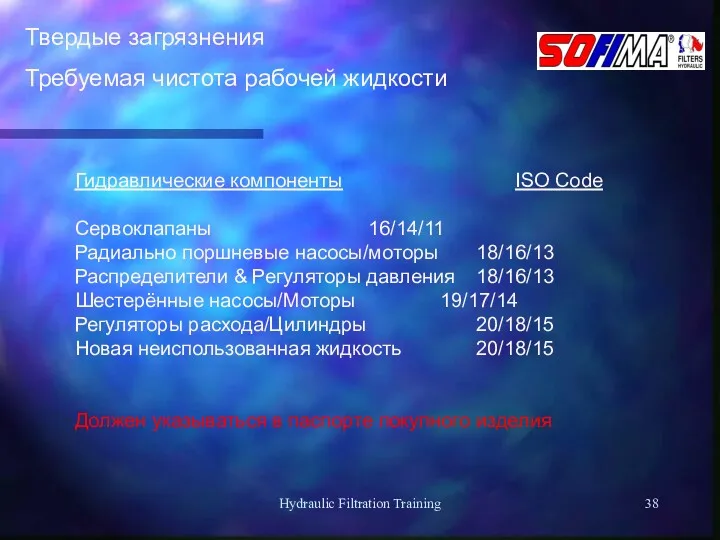

- 38. Hydraulic Filtration Training Твердые загрязнения Требуемая чистота рабочей жидкости Гидравлические компоненты ISO Code Сервоклапаны 16/14/11 Радиально

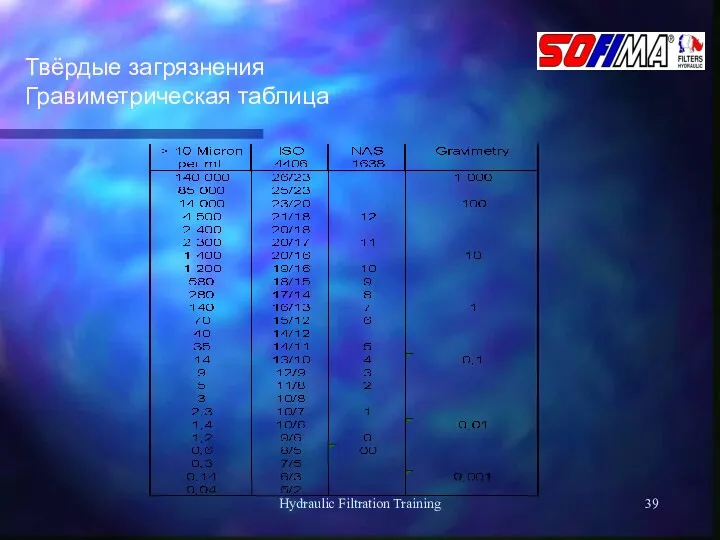

- 39. Hydraulic Filtration Training Твёрдые загрязнения Гравиметрическая таблица

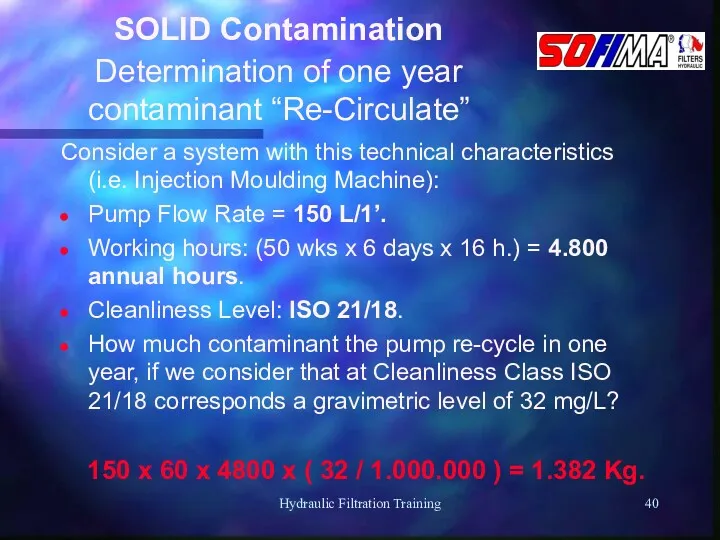

- 40. Hydraulic Filtration Training SOLID Contamination Determination of one year contaminant “Re-Circulate” Consider a system with this

- 41. Hydraulic Filtration Training Filtration Training #1 Filter Media Types and Filtration Degree

- 42. Hydraulic Filtration Training SOLID Contamination Filter Media Filter Media Classification “Surface” filter Media. Wire mesh. Membrane

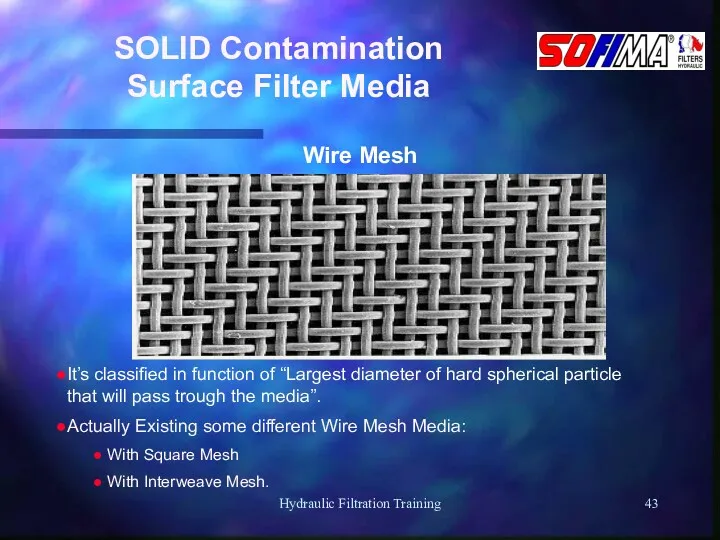

- 43. Hydraulic Filtration Training SOLID Contamination Surface Filter Media Wire Mesh It’s classified in function of “Largest

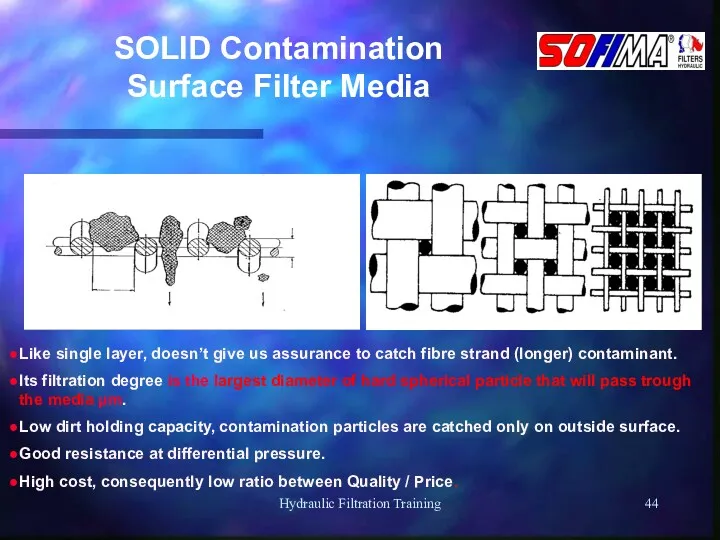

- 44. Hydraulic Filtration Training SOLID Contamination Surface Filter Media Like single layer, doesn’t give us assurance to

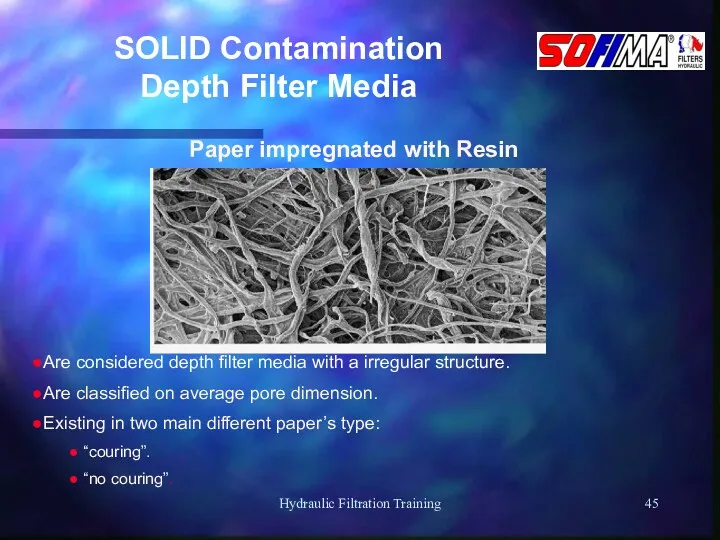

- 45. Hydraulic Filtration Training SOLID Contamination Depth Filter Media Paper impregnated with Resin Are considered depth filter

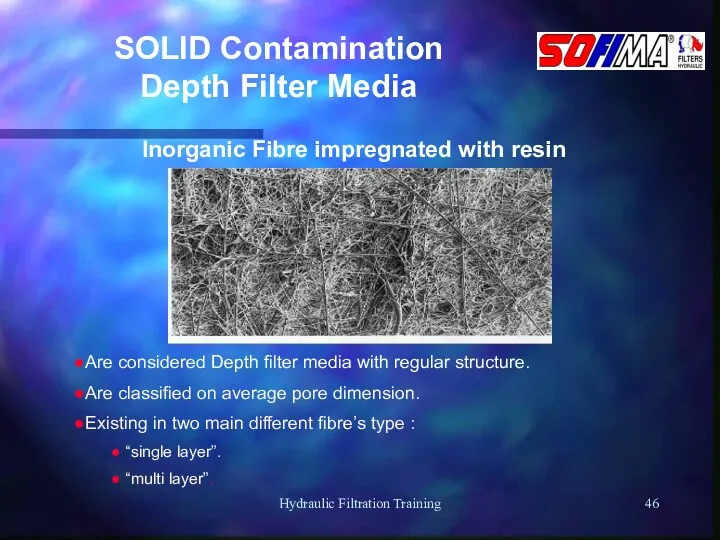

- 46. Hydraulic Filtration Training SOLID Contamination Depth Filter Media Inorganic Fibre impregnated with resin Are considered Depth

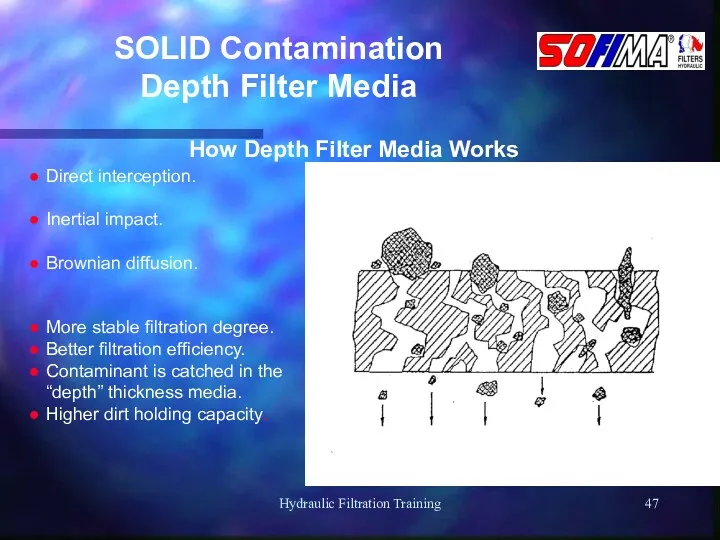

- 47. Hydraulic Filtration Training SOLID Contamination Depth Filter Media How Depth Filter Media Works Direct interception. Inertial

- 48. Hydraulic Filtration Training SOLID Contamination Depth Filter Media How Depth Filter Media are classified NOMINAL filtration

- 49. Hydraulic Filtration Training SOLID Contamination βeta Ratio βeta ratio, is the ratio existing between the number

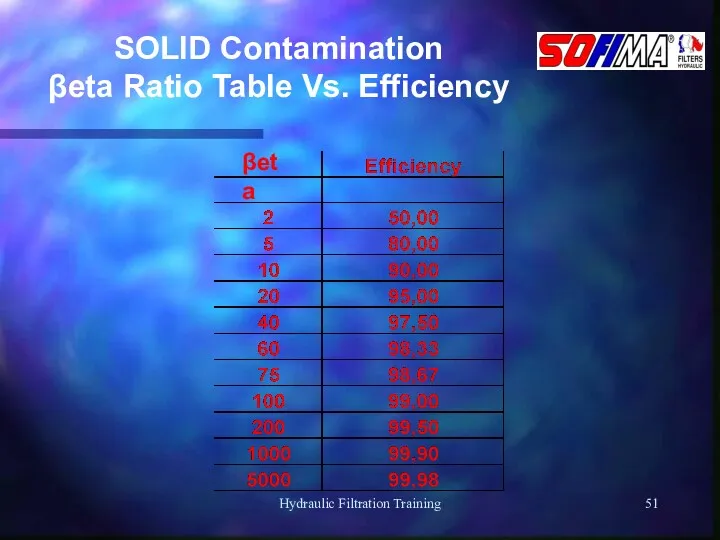

- 50. Hydraulic Filtration Training SOLID Contamination βeta Ratio vs. Efficiency βeta ratio number alone means very little,

- 51. Hydraulic Filtration Training SOLID Contamination βeta Ratio Table Vs. Efficiency

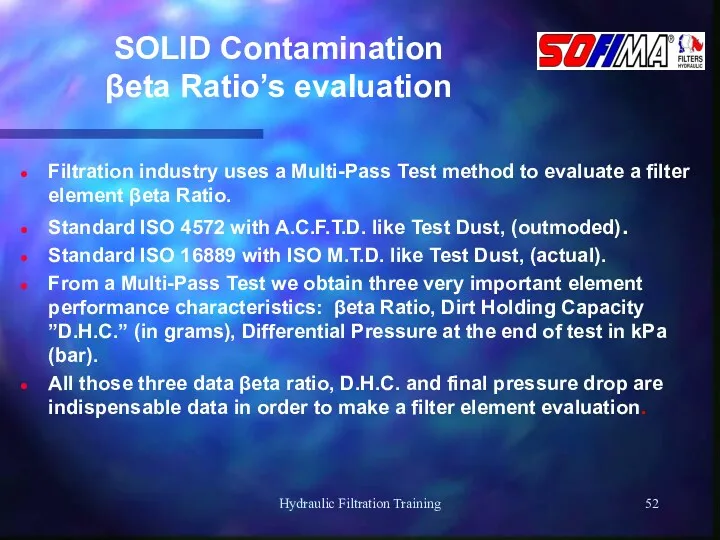

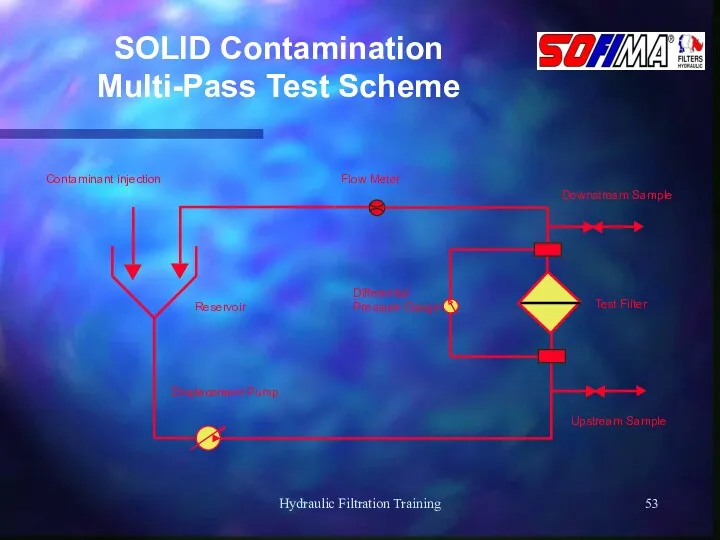

- 52. Hydraulic Filtration Training SOLID Contamination βeta Ratio’s evaluation Filtration industry uses a Multi-Pass Test method to

- 53. Hydraulic Filtration Training SOLID Contamination Multi-Pass Test Scheme

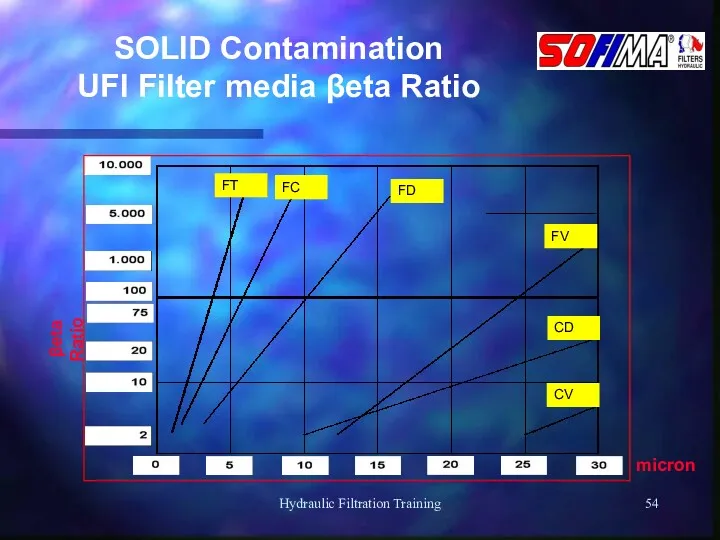

- 54. Hydraulic Filtration Training SOLID Contamination UFI Filter media βeta Ratio βeta Ratio micron FT FC FD

- 55. Hydraulic Filtration Training SOLID Contamination βeta Ratio variation βeta ratio is a measure (data) obtained in

- 56. Hydraulic Filtration Training Filtration Training #1 Right Filter Element / Media Selection

- 57. Hydraulic Filtration Training SOLID Contamination Filter Media Selection One method to select right filter media was

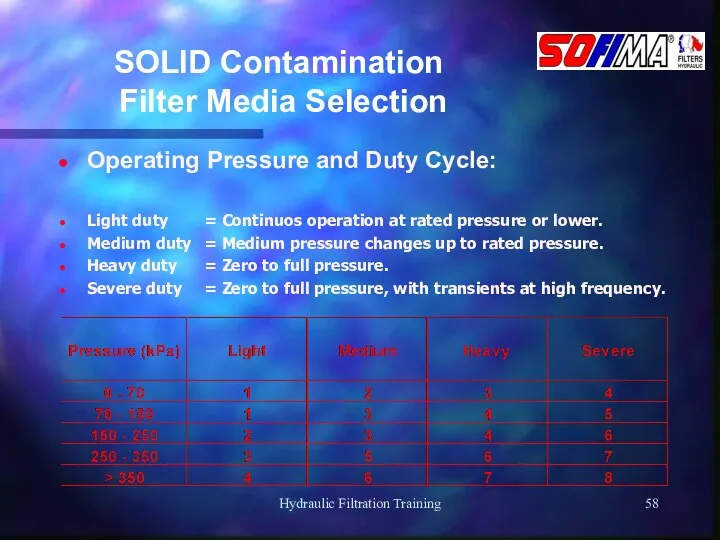

- 58. Hydraulic Filtration Training SOLID Contamination Filter Media Selection Operating Pressure and Duty Cycle: Light duty =

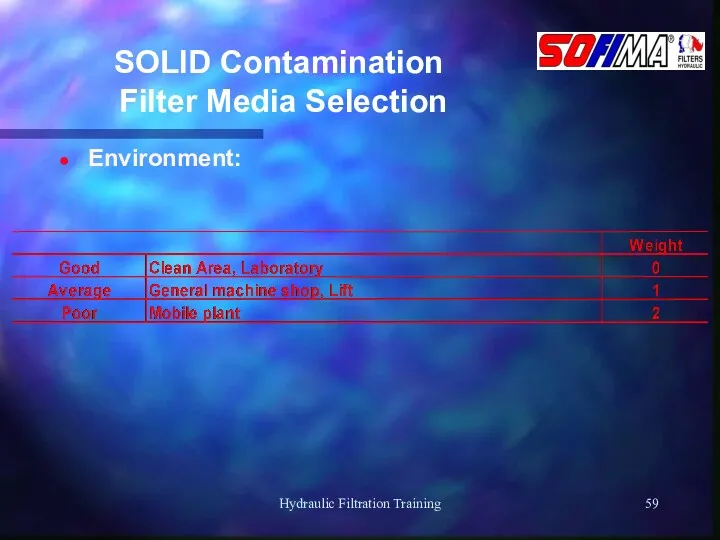

- 59. Hydraulic Filtration Training SOLID Contamination Filter Media Selection Environment:

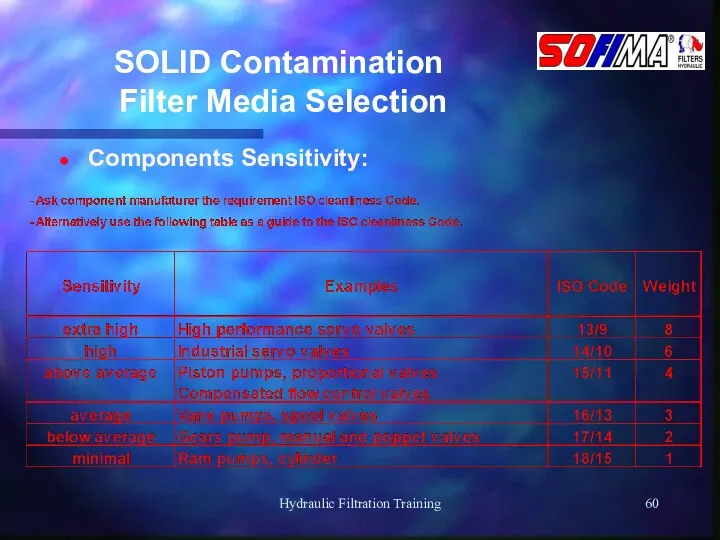

- 60. Hydraulic Filtration Training SOLID Contamination Filter Media Selection Components Sensitivity:

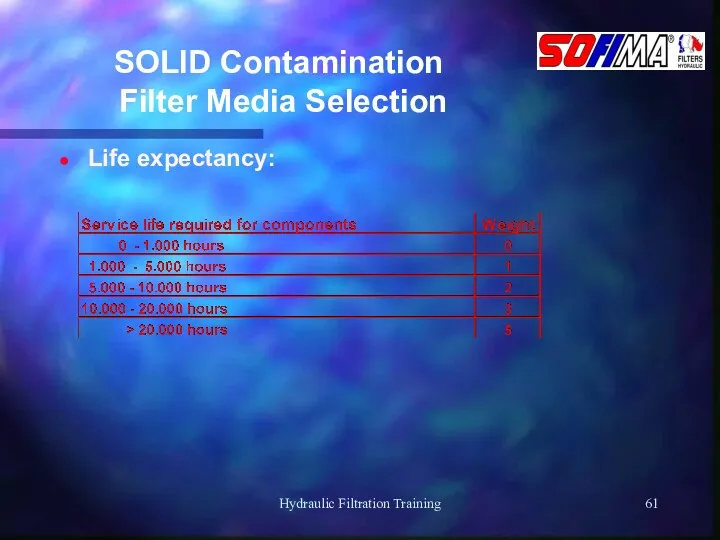

- 61. Hydraulic Filtration Training SOLID Contamination Filter Media Selection Life expectancy:

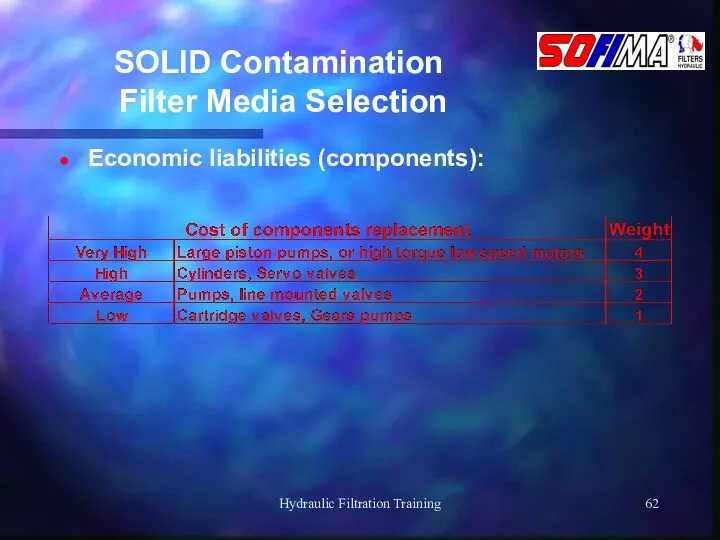

- 62. Hydraulic Filtration Training SOLID Contamination Filter Media Selection Economic liabilities (components):

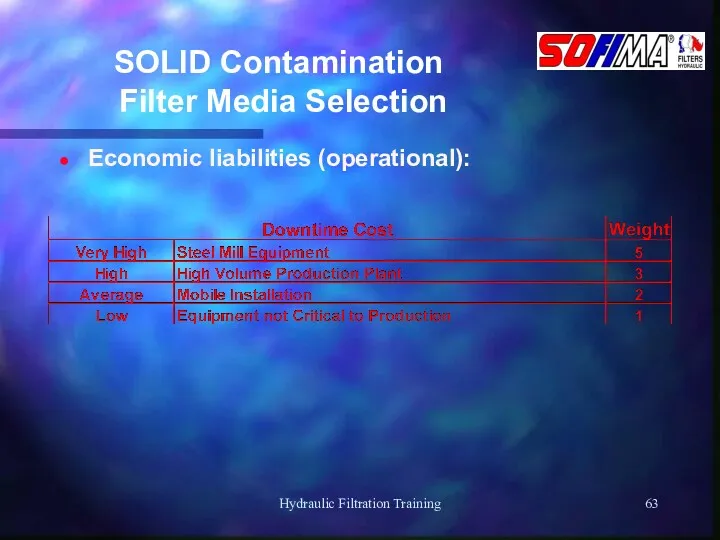

- 63. Hydraulic Filtration Training SOLID Contamination Filter Media Selection Economic liabilities (operational):

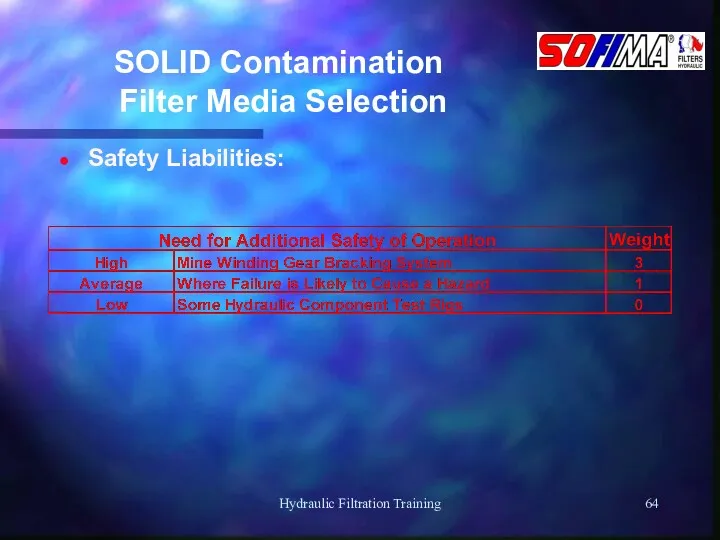

- 64. Hydraulic Filtration Training SOLID Contamination Filter Media Selection Safety Liabilities:

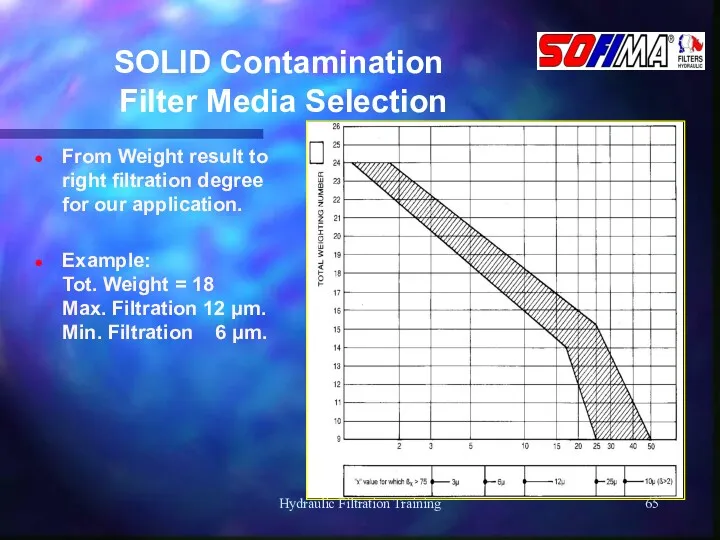

- 65. Hydraulic Filtration Training SOLID Contamination Filter Media Selection From Weight result to right filtration degree for

- 66. Hydraulic Filtration Training Filtration Training #1 Filter Element’s “LIFE”

- 67. Hydraulic Filtration Training SOLID Contamination Filter Element’s Life It is related to : D.H.C. value. Contaminant

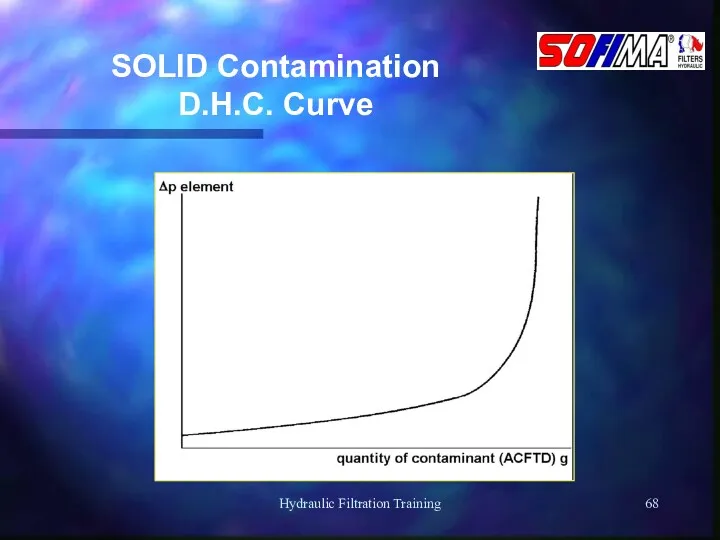

- 68. Hydraulic Filtration Training SOLID Contamination D.H.C. Curve

- 69. Hydraulic Filtration Training SOLID Contamination How to prevent or limit it Wash and protect all components

- 70. Hydraulic Filtration Training SOLID Contamination How to remove it Use the appropriate filtration system in function

- 71. Hydraulic Filtration Training Filtration Training #1 “LIQUID” Contamination

- 72. Hydraulic Filtration Training “LIQUID” Contamination About 10 - 20% of failure in hydraulic system is due

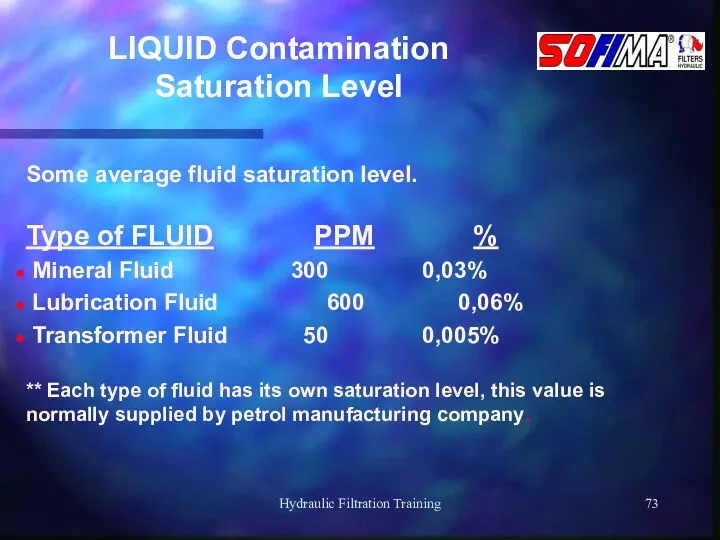

- 73. Hydraulic Filtration Training LIQUID Contamination Saturation Level Some average fluid saturation level. Type of FLUID PPM

- 74. Hydraulic Filtration Training LIQUID Contamination Damage Effects Corrosion of metal surface. Accelerated abrasive wear. Bearings

- 75. Hydraulic Filtration Training LIQUID Contamination Visual Effects How to recognise a fluid contaminated by water: It’s

- 76. Hydraulic Filtration Training LIQUID Contamination Analysis Method - Counting Actually existing two different analysis and counting

- 77. Hydraulic Filtration Training LIQUID Contamination Contamination Sources Like for Solid contamination there are “Contamination Sources” also

- 78. Hydraulic Filtration Training LIQUID Contamination How to prevent or limit it Replace frequently cylinder’s seals. Guarantee

- 79. Hydraulic Filtration Training LIQUID Contamination How to remove it Actually existing three methods to remove water

- 80. Hydraulic Filtration Training Filtration Training #1 “AIR” Contamination

- 81. Hydraulic Filtration Training AIR Contamination We can find Air contamination in three different status FREE Air:

- 82. Hydraulic Filtration Training AIR Contamination Damages Effects Loss of transmitted power. Reduced pump output (air

- 83. Hydraulic Filtration Training AIR Contamination Contamination Sources As for Solid & Liquid contaminant, also for the

- 84. Hydraulic Filtration Training AIR Contamination How to prevent and limit it Reservoir pressurisation. System air bleeds.

- 85. Hydraulic Filtration Training AIR Contamination How to remove it Actually there are not any specific method

- 86. Hydraulic Filtration Training AIR Contaminant Analysis Method - Counting Existing three methods to analyse and count

- 87. Hydraulic Filtration Training Filtration Training #1 FILTERS Insertion points

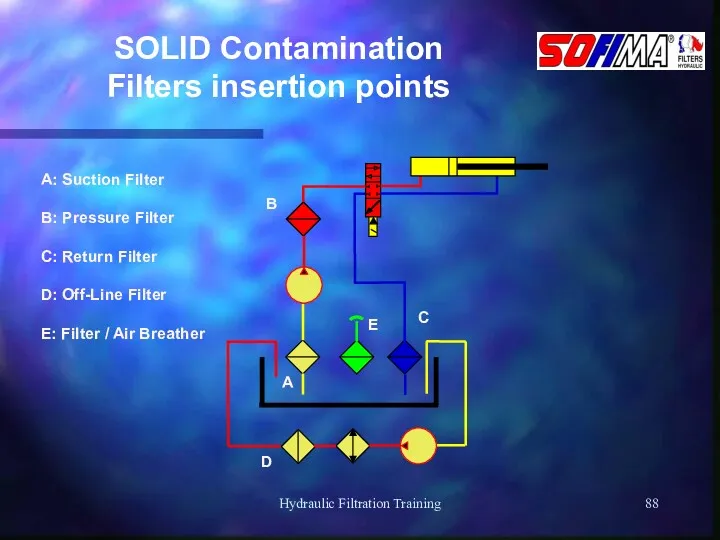

- 88. Hydraulic Filtration Training SOLID Contamination Filters insertion points A B C D E A: Suction Filter

- 89. Hydraulic Filtration Training Filters Insertion Points Suction Filters Types: immersed in the reservoir. Sub-immersed, on reservoir’s

- 90. Hydraulic Filtration Training Suction Filters Advantage & Disadvantage Advantage Last possibility to protect the pump. Easy

- 91. Hydraulic Filtration Training Suction Filters Calculation’s parameters Max. allowable Δp with clean filter = 10 kPa

- 92. Hydraulic Filtration Training Filters Insertion Points Pressure Filters Types: Low, Medium, High pressure. Line mounting. Manifold

- 93. Hydraulic Filtration Training Pressure Filters Advantage & Disadvantage Advantage Protect all components downstream the pump. It

- 94. Hydraulic Filtration Training Pressure Filters Calculation’s parameters Max. allowable Δp with clean filter = 100 kPa

- 95. Hydraulic Filtration Training Filters Insertion Point Return Filters Types: Tank Top mounting. In Line mounting, outside

- 96. Hydraulic Filtration Training Return Filters Advantage & Disadvantage Advantage Capture all built in and system’s generated

- 97. Hydraulic Filtration Training Return Filters Calculation Parameters Max. allowable Δp at clean filter = 50 kPa

- 98. Hydraulic Filtration Training Filters Insertion Points Off-Line Filters Types: Tank Top mounting. In Line mounting, outside

- 99. Hydraulic Filtration Training Off-Line Filters Advantage & Disadvantage Advantage It’s normally combined with a cooler system.

- 100. Hydraulic Filtration Training OFF - LINE Filters Calculation Parameters Max. allowable Δp at clean filter ≤

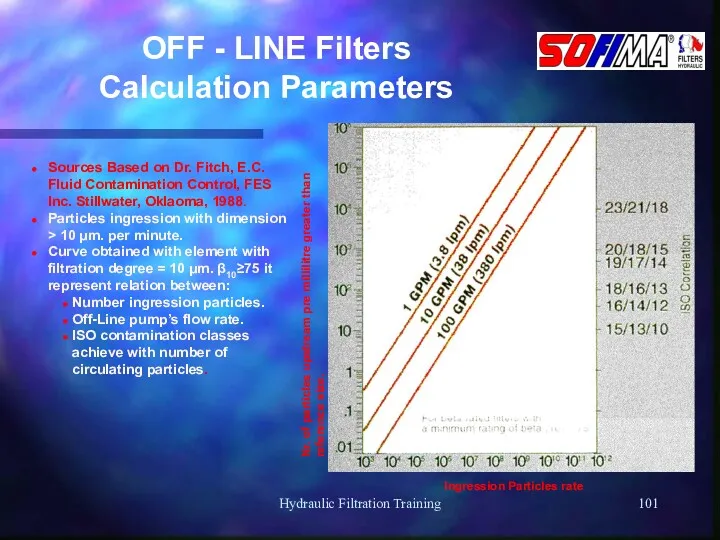

- 101. Hydraulic Filtration Training OFF - LINE Filters Calculation Parameters Sources Based on Dr. Fitch, E.C. Fluid

- 102. Hydraulic Filtration Training Filters Insertion Points Filters - Air Breathers Types: Dry, to remove solid contaminant.

- 103. Hydraulic Filtration Training Filtration Training #1 Function’s scheme of a FILTER and FILTER ELEMENT

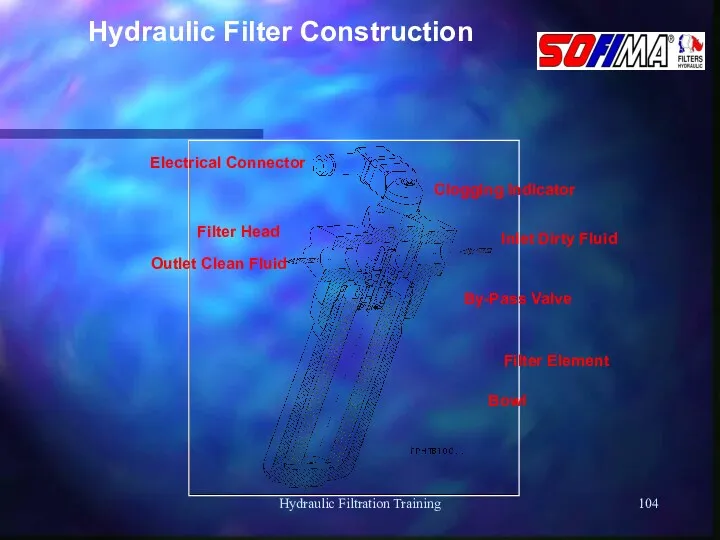

- 104. Hydraulic Filtration Training Hydraulic Filter Construction

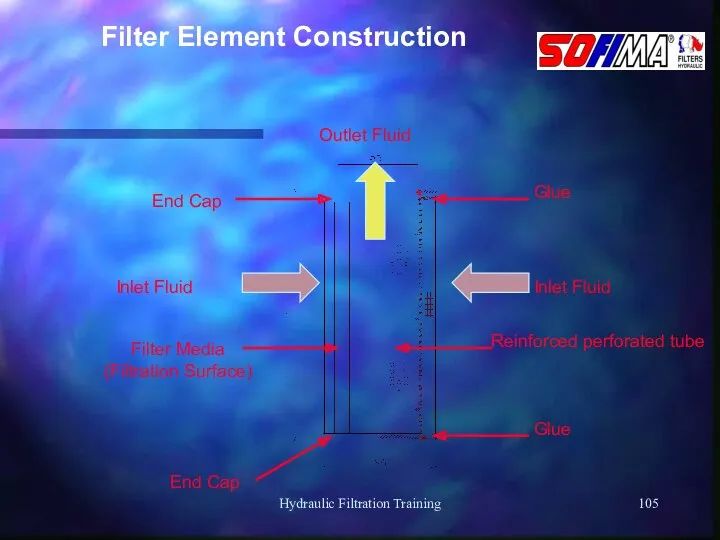

- 105. Hydraulic Filtration Training Filter Element Construction Glue Glue Reinforced perforated tube End Cap Filter Media (Filtration

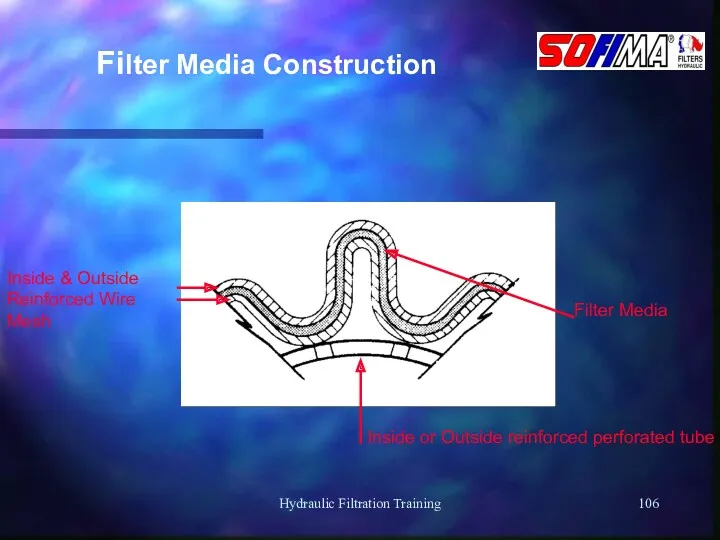

- 106. Hydraulic Filtration Training Filter Media Construction

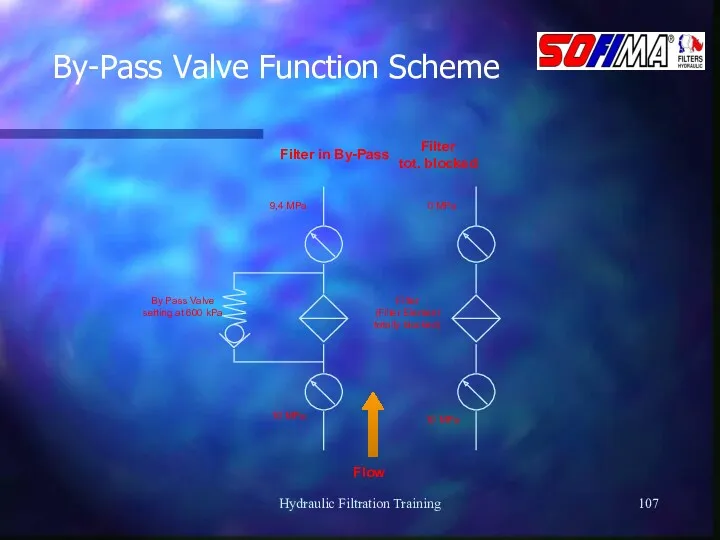

- 107. Hydraulic Filtration Training By-Pass Valve Function Scheme

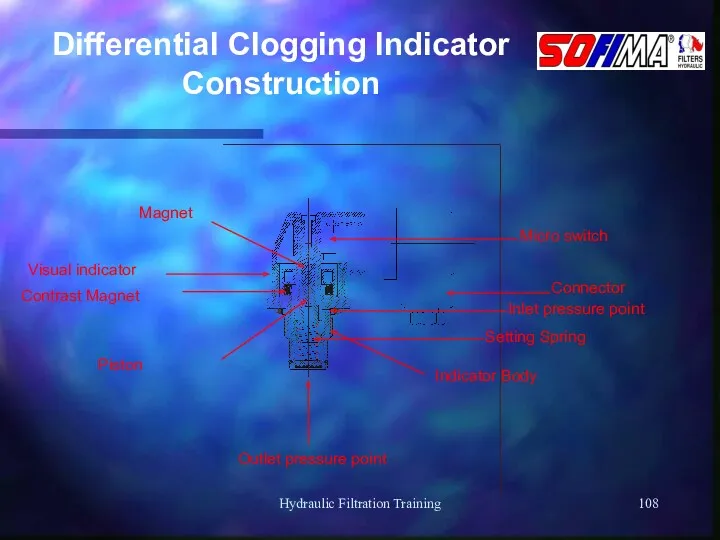

- 108. Hydraulic Filtration Training Differential Clogging Indicator Construction

- 109. Hydraulic Filtration Training Filtration Training #1 Filter’s Application & Products Analysis

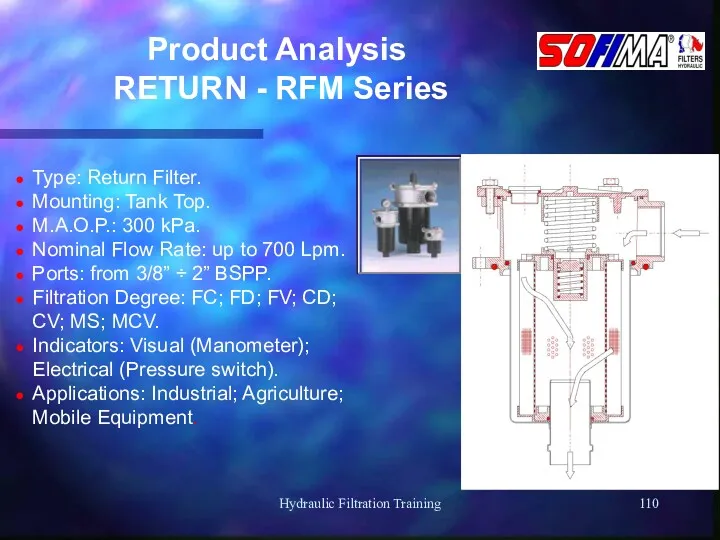

- 110. Hydraulic Filtration Training Product Analysis RETURN - RFM Series Type: Return Filter. Mounting: Tank Top. M.A.O.P.:

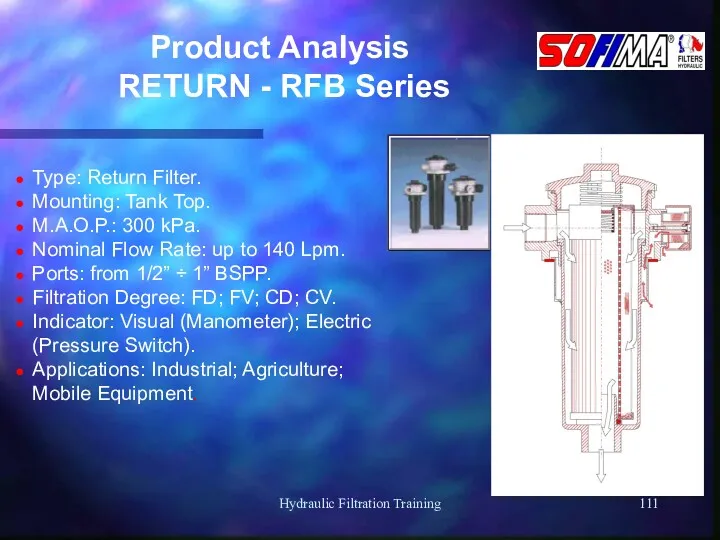

- 111. Hydraulic Filtration Training Product Analysis RETURN - RFB Series Type: Return Filter. Mounting: Tank Top. M.A.O.P.:

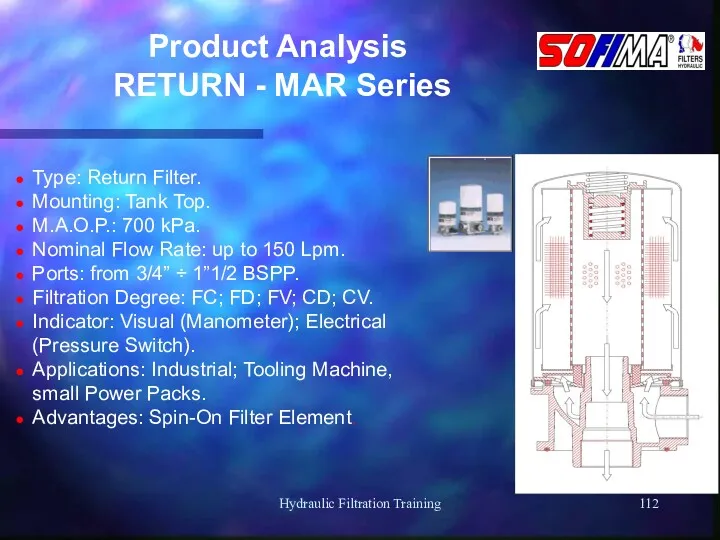

- 112. Hydraulic Filtration Training Product Analysis RETURN - MAR Series Type: Return Filter. Mounting: Tank Top. M.A.O.P.:

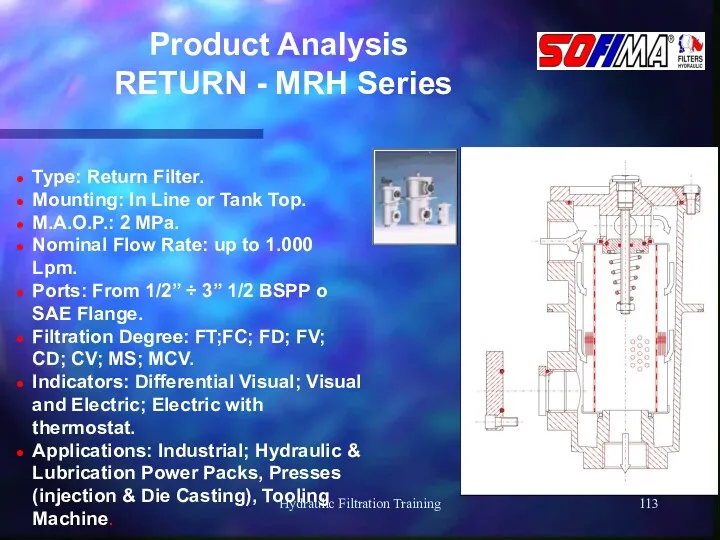

- 113. Hydraulic Filtration Training Product Analysis RETURN - MRH Series Type: Return Filter. Mounting: In Line or

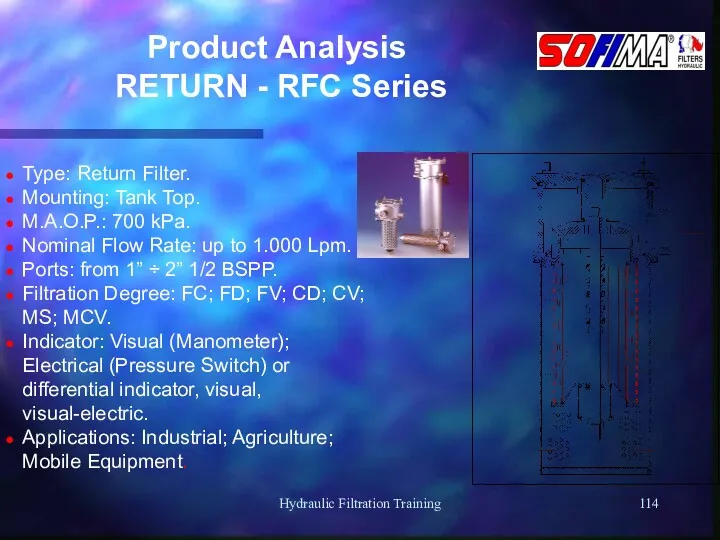

- 114. Hydraulic Filtration Training Product Analysis RETURN - RFC Series Type: Return Filter. Mounting: Tank Top. M.A.O.P.:

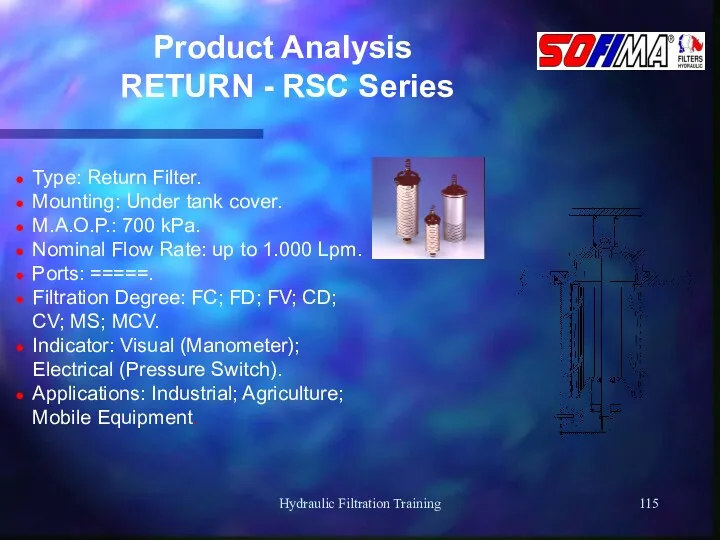

- 115. Hydraulic Filtration Training Product Analysis RETURN - RSC Series Type: Return Filter. Mounting: Under tank cover.

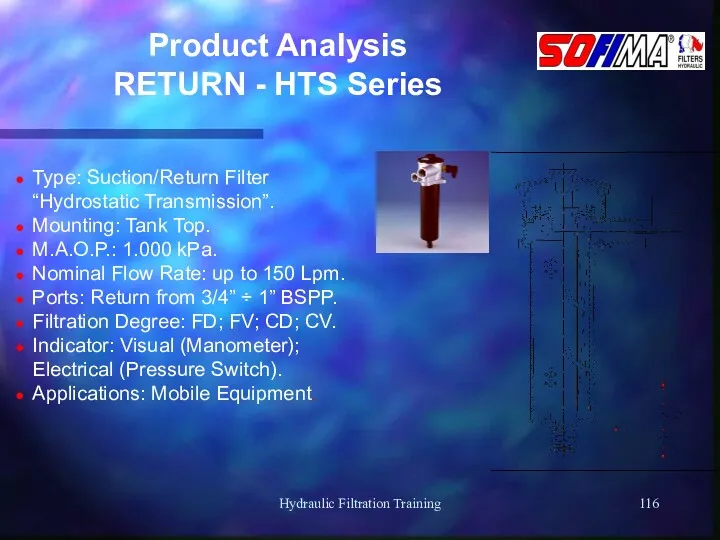

- 116. Hydraulic Filtration Training Product Analysis RETURN - HTS Series Type: Suction/Return Filter “Hydrostatic Transmission”. Mounting: Tank

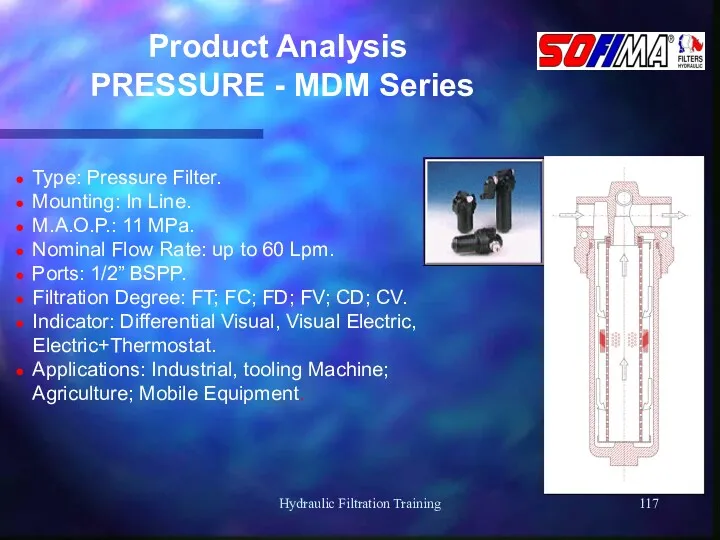

- 117. Hydraulic Filtration Training Product Analysis PRESSURE - MDM Series Type: Pressure Filter. Mounting: In Line. M.A.O.P.:

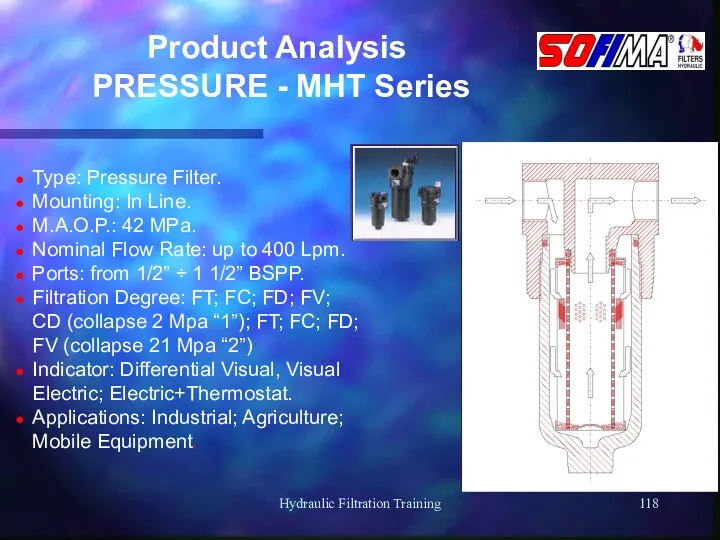

- 118. Hydraulic Filtration Training Product Analysis PRESSURE - MHT Series Type: Pressure Filter. Mounting: In Line. M.A.O.P.:

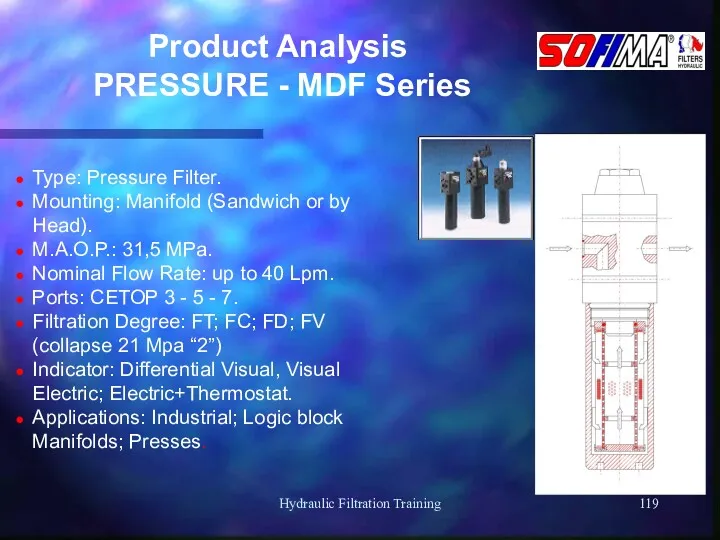

- 119. Hydraulic Filtration Training Product Analysis PRESSURE - MDF Series Type: Pressure Filter. Mounting: Manifold (Sandwich or

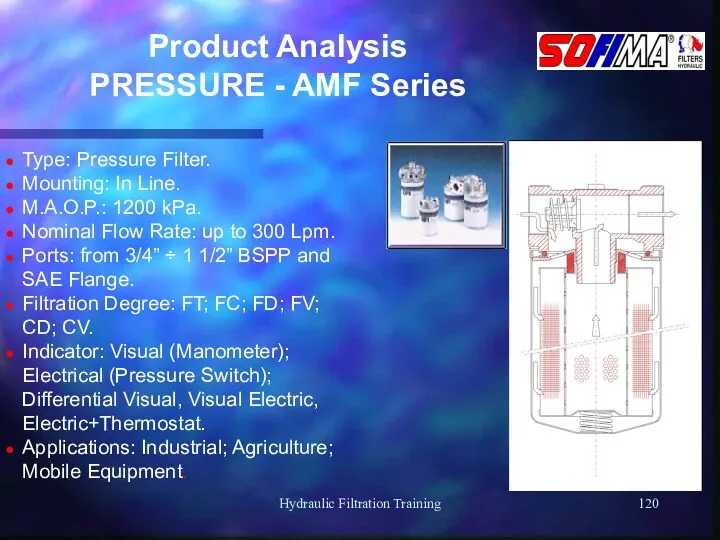

- 120. Hydraulic Filtration Training Product Analysis PRESSURE - AMF Series Type: Pressure Filter. Mounting: In Line. M.A.O.P.:

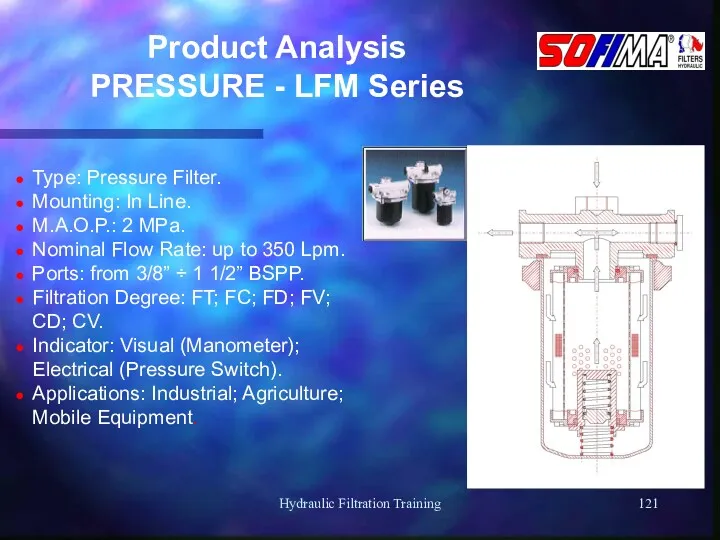

- 121. Hydraulic Filtration Training Product Analysis PRESSURE - LFM Series Type: Pressure Filter. Mounting: In Line. M.A.O.P.:

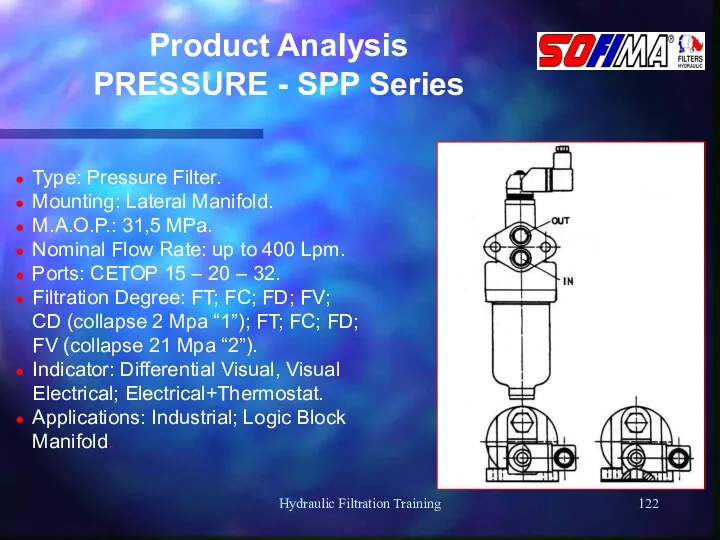

- 122. Hydraulic Filtration Training Product Analysis PRESSURE - SPP Series Type: Pressure Filter. Mounting: Lateral Manifold. M.A.O.P.:

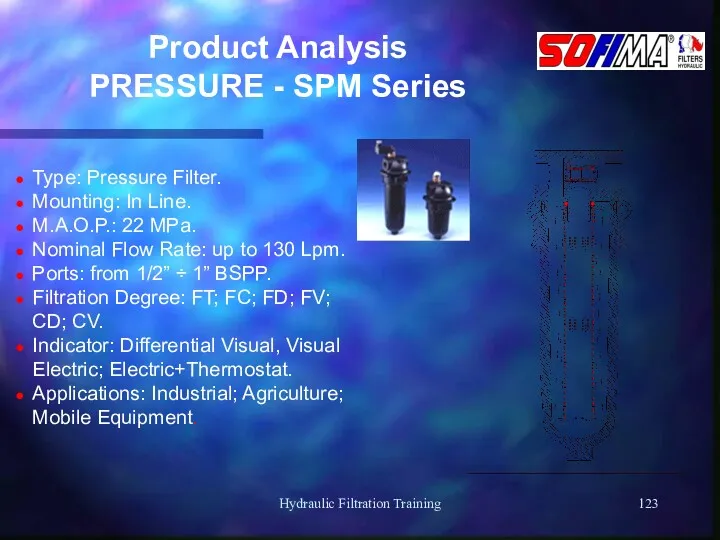

- 123. Hydraulic Filtration Training Product Analysis PRESSURE - SPM Series Type: Pressure Filter. Mounting: In Line. M.A.O.P.:

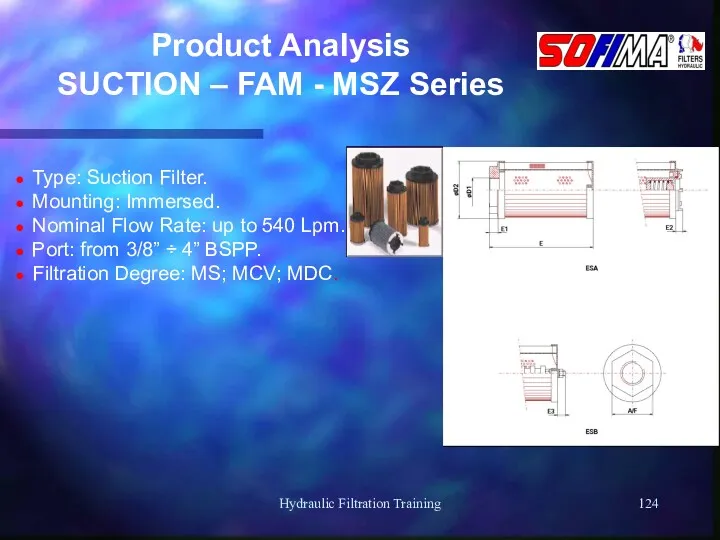

- 124. Hydraulic Filtration Training Product Analysis SUCTION – FAM - MSZ Series Type: Suction Filter. Mounting: Immersed.

- 125. Hydraulic Filtration Training Product Analysis SUCTION - FSB Series Type: Suction Filter. Mounting: Sub-Level at Wall.

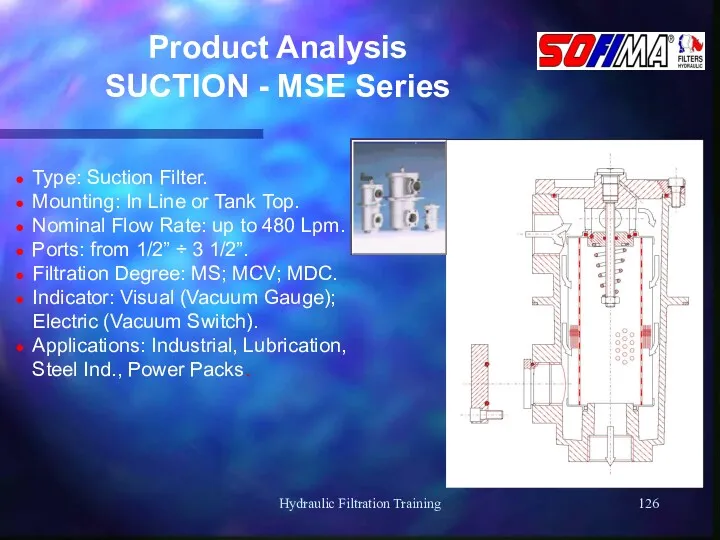

- 126. Hydraulic Filtration Training Product Analysis SUCTION - MSE Series Type: Suction Filter. Mounting: In Line or

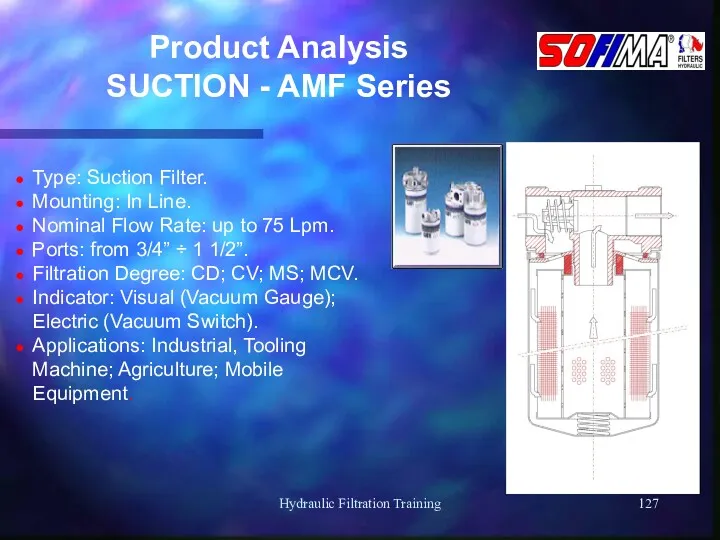

- 127. Hydraulic Filtration Training Product Analysis SUCTION - AMF Series Type: Suction Filter. Mounting: In Line. Nominal

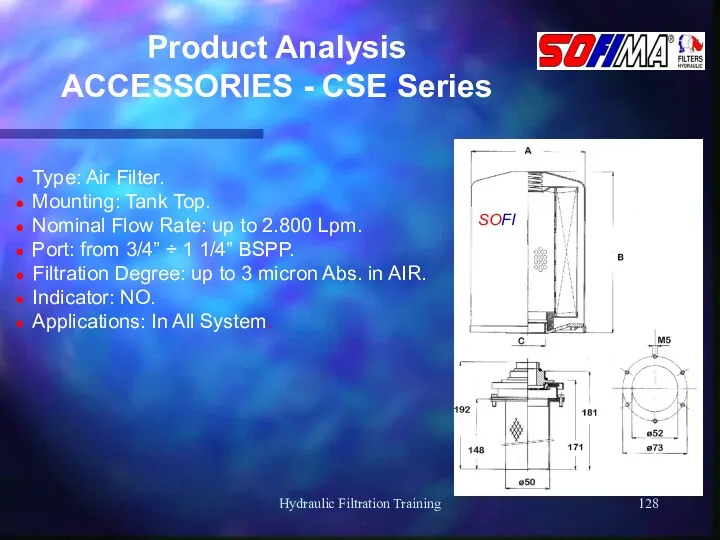

- 128. Hydraulic Filtration Training Product Analysis ACCESSORIES - CSE Series Type: Air Filter. Mounting: Tank Top. Nominal

- 129. Hydraulic Filtration Training Filtration Training #1 Fluid Analysis

- 130. Hydraulic Filtration Training Fluids Analysis Analysis Types Analysis Types Physique: Patch Test (Sample Membrane); contaminant’s type

- 131. Hydraulic Filtration Training Fluids Analysis Analysis Types Analysis Types Chemical: Viscosity; determine the fluid’s viscosity grade

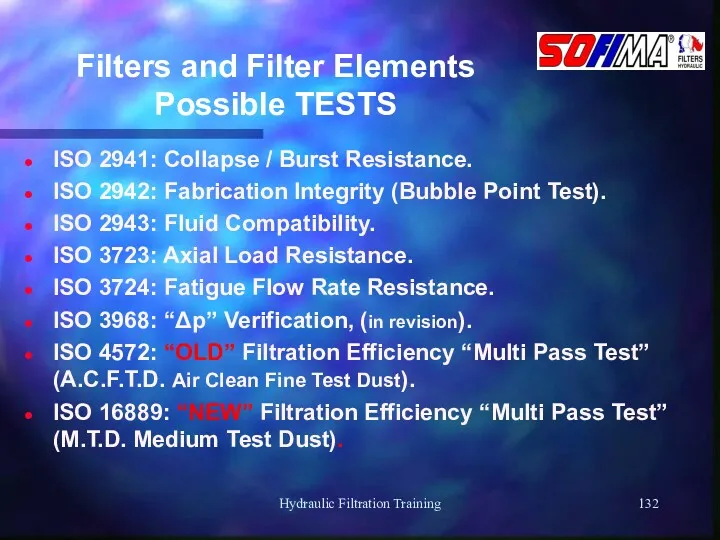

- 132. Hydraulic Filtration Training Filters and Filter Elements Possible TESTS ISO 2941: Collapse / Burst Resistance. ISO

- 134. Скачать презентацию

Акция Истории спасенных животных

Акция Истории спасенных животных Экспертные модели бизнес-процессов. Экспертные сравнения

Экспертные модели бизнес-процессов. Экспертные сравнения Презентация Герои минувшей войны.

Презентация Герои минувшей войны. Школьные службы примирения как форма профилактики преступлений и правонарушений

Школьные службы примирения как форма профилактики преступлений и правонарушений Фото. Айсберг

Фото. Айсберг Система функционирования и особенности суда в РФ

Система функционирования и особенности суда в РФ Отечественная война 1812 года

Отечественная война 1812 года Презентация по географии на тему : Мой знак зодиака

Презентация по географии на тему : Мой знак зодиака Россия в первой половине ХIХ века

Россия в первой половине ХIХ века Библиотека Высшего медицинского колледжа

Библиотека Высшего медицинского колледжа Ванюков пешінің бай штейндеріндегі сульфидті мыс концентраттарын балқытуды зерттеу

Ванюков пешінің бай штейндеріндегі сульфидті мыс концентраттарын балқытуды зерттеу Сталь. Классификация сталей

Сталь. Классификация сталей Христианство: католицизм, православие и протестантизм

Христианство: католицизм, православие и протестантизм Обработка символьной информации в TurboPascal (задачи, часть 1)

Обработка символьной информации в TurboPascal (задачи, часть 1) Легенды старого Кенигсберга

Легенды старого Кенигсберга Вторичные дистонии

Вторичные дистонии Организаторы военной экономики

Организаторы военной экономики Электробезопасность. Пожаровзрывобезопасность. Механические опасности

Электробезопасность. Пожаровзрывобезопасность. Механические опасности Способы получения металлов

Способы получения металлов Діни ағымдардың қоғамға кері әсері

Діни ағымдардың қоғамға кері әсері Проектная работа Семейные традиции

Проектная работа Семейные традиции Горожане и их образ жизни

Горожане и их образ жизни Иван Сергеевич Тургенев Записки охотника

Иван Сергеевич Тургенев Записки охотника Открытка ко дню матери

Открытка ко дню матери Вимоги до науково-педагогічного працівника

Вимоги до науково-педагогічного працівника Базовая аппаратная конфигурация персонального компьютера

Базовая аппаратная конфигурация персонального компьютера Жизнь и быт городских жителей России 19-го века

Жизнь и быт городских жителей России 19-го века Tovar-moddiy zaxiralar hisobi

Tovar-moddiy zaxiralar hisobi