Содержание

- 2. Factors that affect the rate of corrosion Temperature Oxygen Humidity Chemical Salts Chemicals and airborne gases

- 3. How to avoid (or control) Corrosion? Material Selection! Remember – environment key. Look at potential pH

- 4. How to avoid (or control) Corrosion? Pitting/Crevice: Watch for stagnate water/ electrolyte. Use gaskets Use good

- 5. How to avoid (or control) Corrosion? Consider organic coating (paint, ceramic, chrome, etc.) – DANGER IF

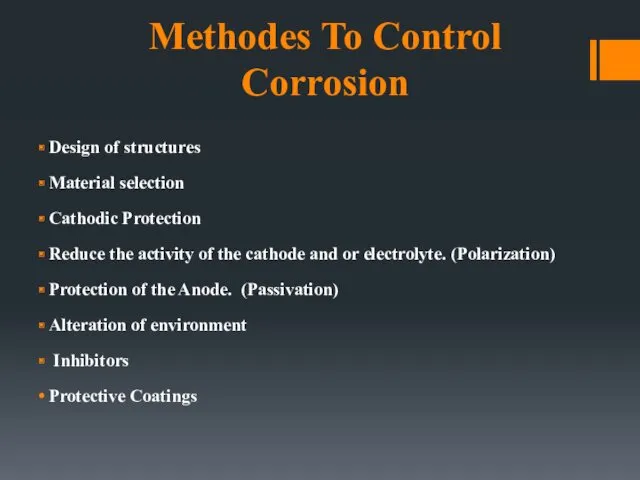

- 6. Methodes To Control Corrosion Design of structures Material selection Cathodic Protection Reduce the activity of the

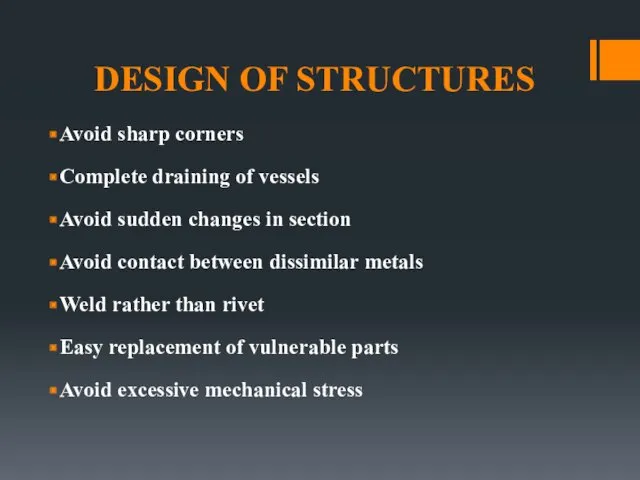

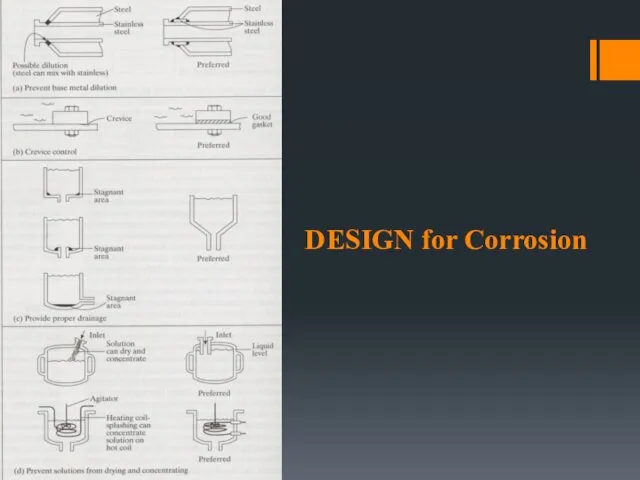

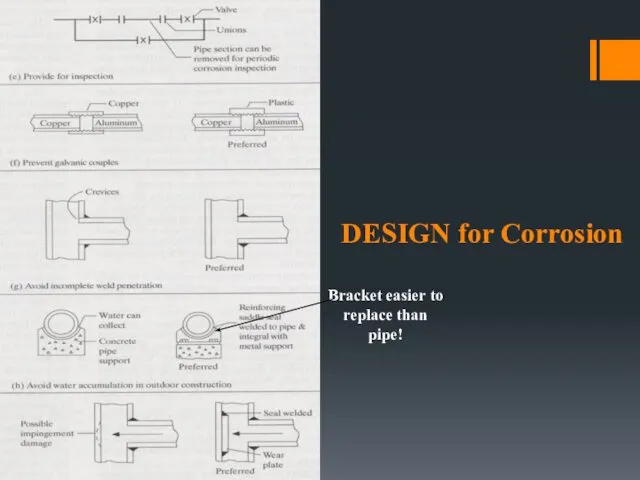

- 7. DESIGN OF STRUCTURES Avoid sharp corners Complete draining of vessels Avoid sudden changes in section Avoid

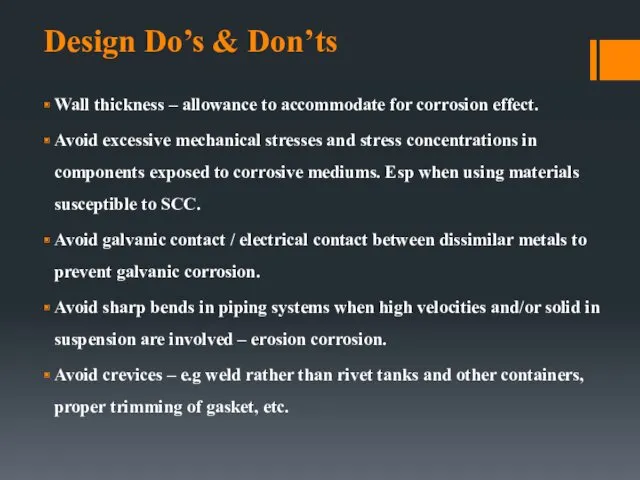

- 8. Design Do’s & Don’ts Wall thickness – allowance to accommodate for corrosion effect. Avoid excessive mechanical

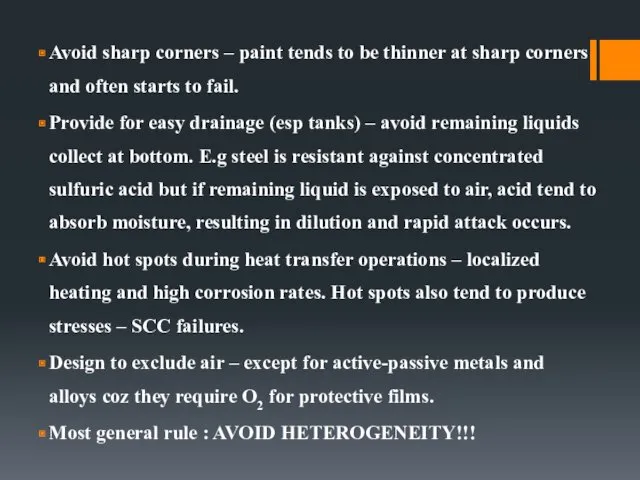

- 9. Avoid sharp corners – paint tends to be thinner at sharp corners and often starts to

- 10. DESIGN for Corrosion

- 11. DESIGN for Corrosion Bracket easier to replace than pipe!

- 14. Material Selection

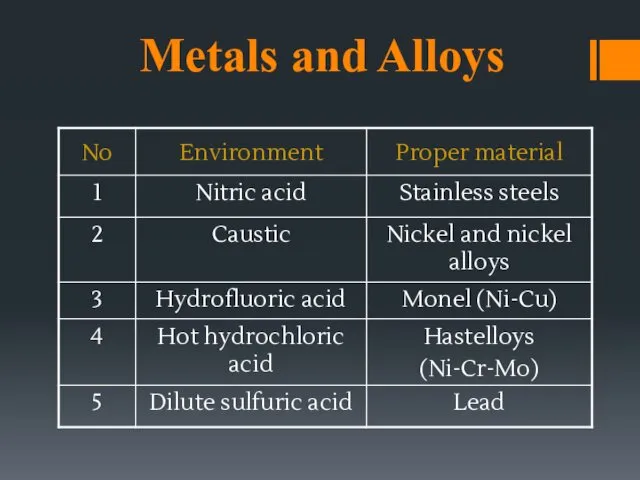

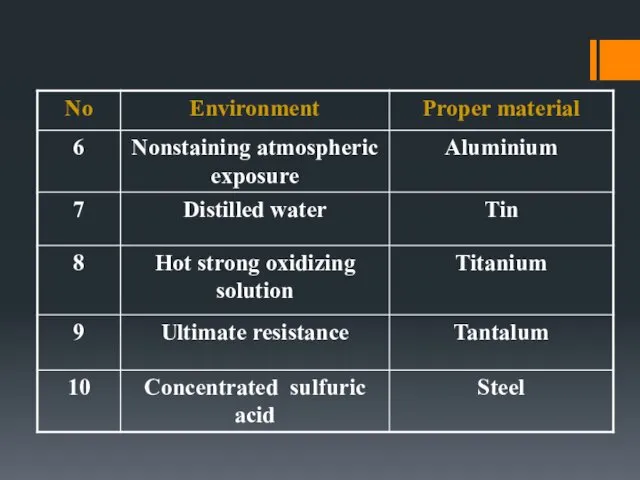

- 15. MATERIAL SELECTION (selection of proper material for a particular corrosive service) Metallic : [metal and alloy]

- 16. IMPROVEMENTS OF MATERIALS Purification of metals: Al , Zr Making more noble, e.g. Pt in Ti

- 17. Material Selection - Galvanic Series [Seawater at 77⁰ F.] Magnesium Zinc Aluminum Mild Steel Cast Iron

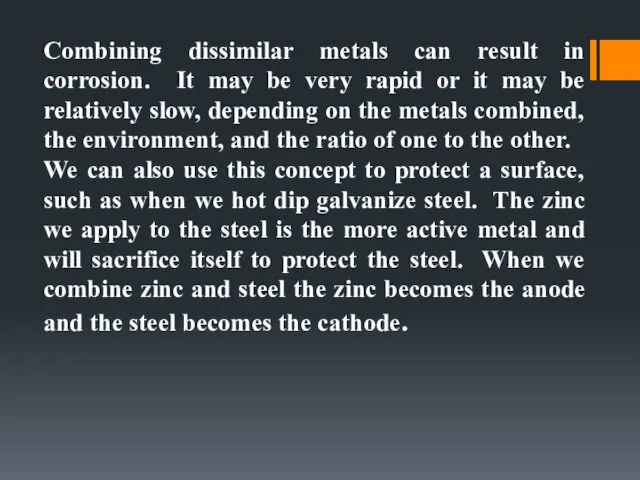

- 18. Combining dissimilar metals can result in corrosion. It may be very rapid or it may be

- 19. Metals and Alloys

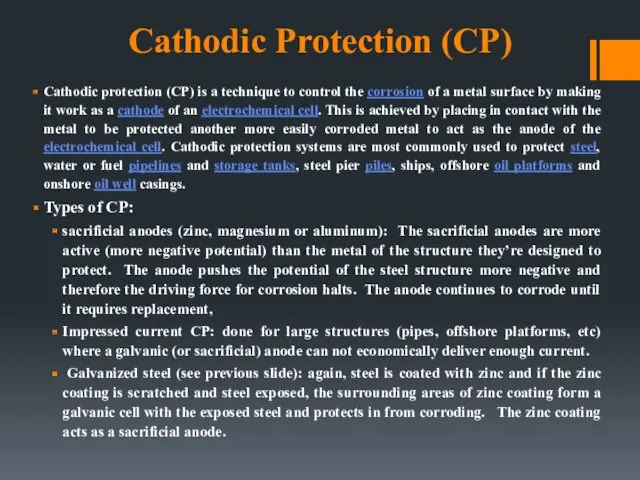

- 21. Cathodic Protection (CP) Cathodic protection (CP) is a technique to control the corrosion of a metal

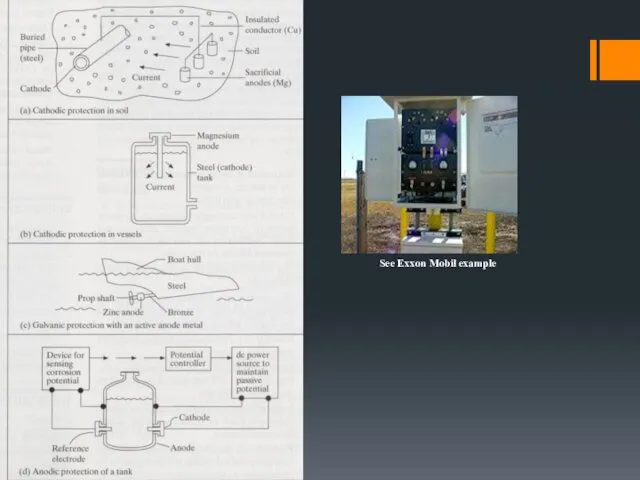

- 22. CATHODIC & ANODIC PROTECTION Cathodic protection: Make the structure more cathodic by Use of sacrificial anodes

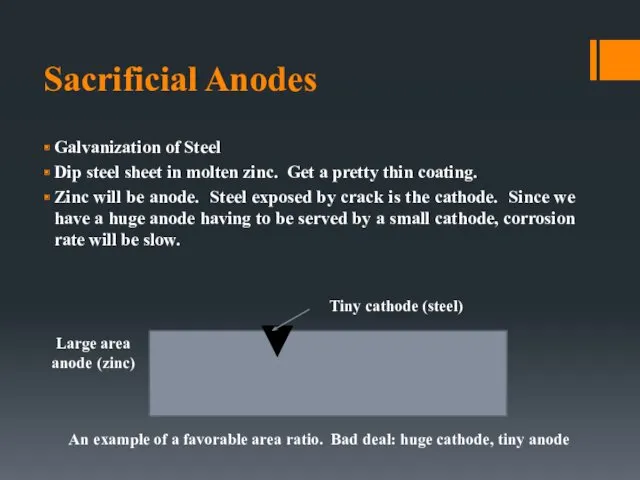

- 23. Sacrificial Anodes Galvanization of Steel Dip steel sheet in molten zinc. Get a pretty thin coating.

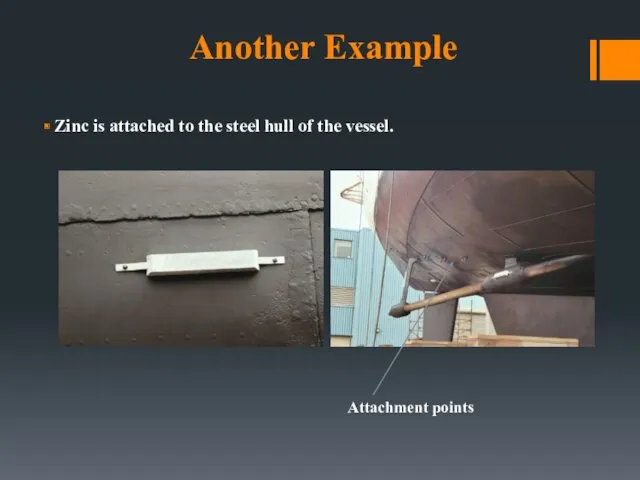

- 24. Another Example Zinc is attached to the steel hull of the vessel. Attachment points

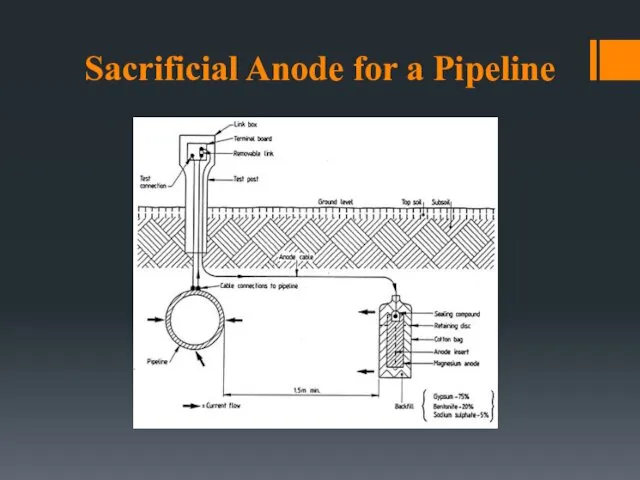

- 26. Sacrificial Anode for a Pipeline

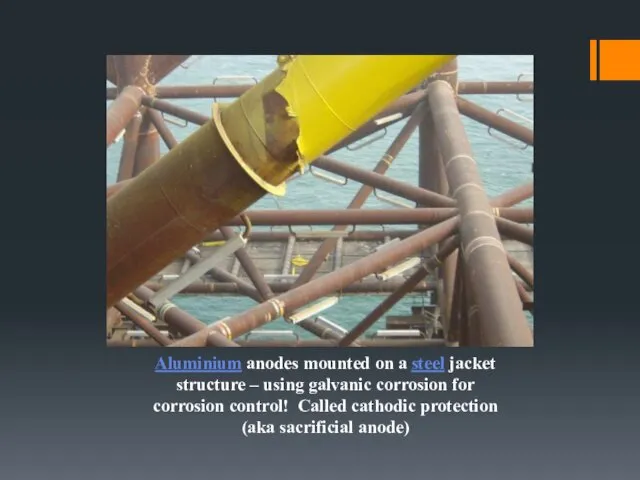

- 27. Aluminium anodes mounted on a steel jacket structure – using galvanic corrosion for corrosion control! Called

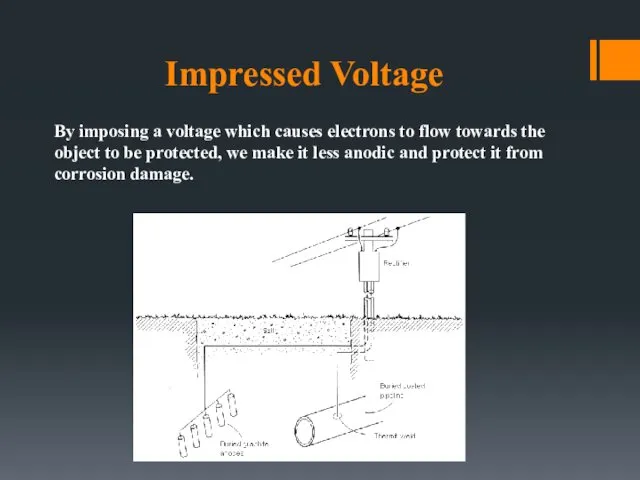

- 28. Impressed Voltage By imposing a voltage which causes electrons to flow towards the object to be

- 30. See Exxon Mobil example

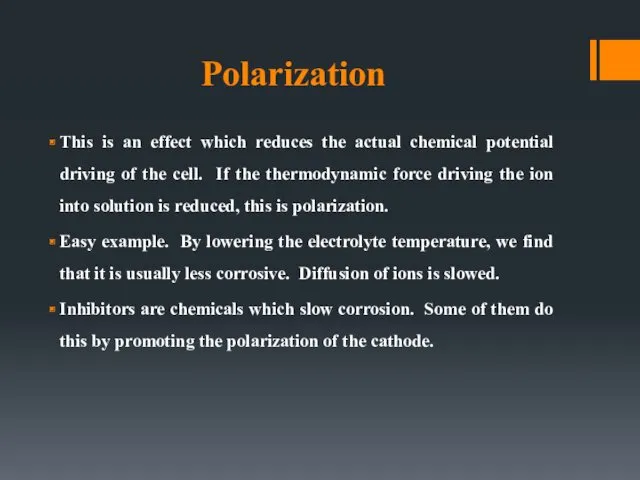

- 31. Polarization This is an effect which reduces the actual chemical potential driving of the cell. If

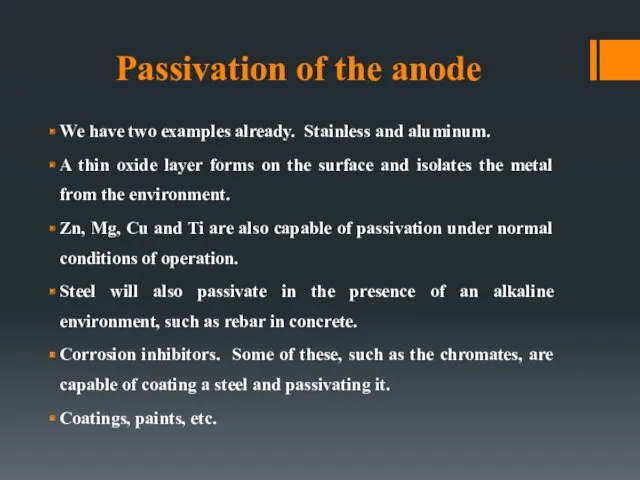

- 32. Passivation of the anode We have two examples already. Stainless and aluminum. A thin oxide layer

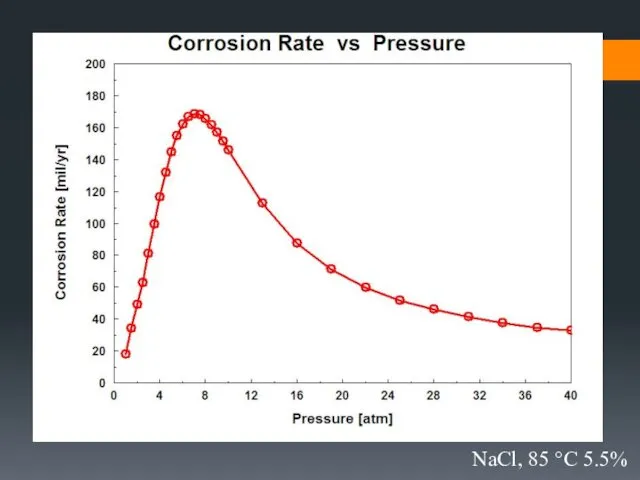

- 33. Effect of environmental parameters on the rate of corrosion

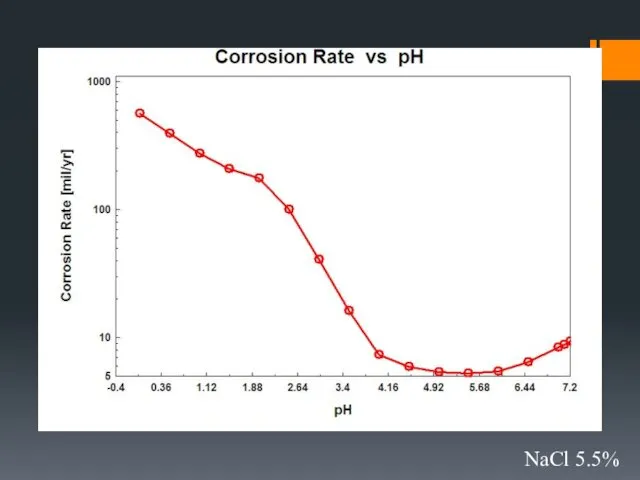

- 34. 5.5% NaCl

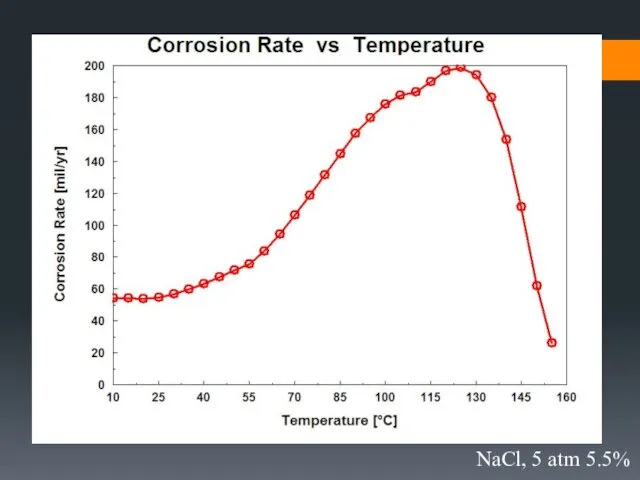

- 35. 5.5% NaCl, 5 atm

- 36. 5.5% NaCl, 85 °C

- 37. 5.5% NaCl, 10 °C, 15 atm

- 38. Alternation of Environment Lower temperature and velocity Remove oxygen/oxidizers Change concentration Add Inhibitors Adsorption type, e.g.

- 39. Alteration of Environment Typical changes in medium are : Lowering temperature – but there are cases

- 40. Removing oxygen or oxidizers – e.g vacuum treatment, inert gas sparging, or thru the use of

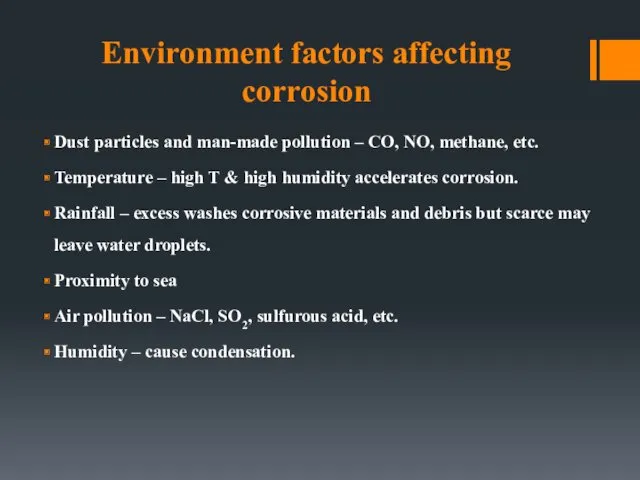

- 41. Environment factors affecting corrosion Dust particles and man-made pollution – CO, NO, methane, etc. Temperature –

- 42. Inhibitors Inhibitors are materials that may be injected into the system . They plate out on

- 43. They are sometimes injected into the water stream that may be used for the surface preparation

- 45. Скачать презентацию

![Material Selection - Galvanic Series [Seawater at 77⁰ F.] Magnesium](/_ipx/f_webp&q_80&fit_contain&s_1440x1080/imagesDir/jpg/3519/slide-16.jpg)

Педагогика: анализ основных теоретических аспектов

Педагогика: анализ основных теоретических аспектов Любимый уголок моей республики

Любимый уголок моей республики Электроизмерительные приборы. 8 класс

Электроизмерительные приборы. 8 класс Highway construction

Highway construction Завершальний етап ліквідації поліомієліту. Перехід до бОПВ

Завершальний етап ліквідації поліомієліту. Перехід до бОПВ Профессия - стропальщик

Профессия - стропальщик Деревенское подворье: Стиль кантри в ландшафтном дизайне.

Деревенское подворье: Стиль кантри в ландшафтном дизайне. Аналоговый датчик линии

Аналоговый датчик линии Проект Фабрика загадок Диск

Проект Фабрика загадок Диск Холецистит у детей

Холецистит у детей Сигналы ограждения на железнодорожном транспорте

Сигналы ограждения на железнодорожном транспорте Столяр

Столяр Василий Андреевич Жуковский (1783-1852)

Василий Андреевич Жуковский (1783-1852) Родительское собрание на тему: Безопасность детей в Интернете

Родительское собрание на тему: Безопасность детей в Интернете Право на образование

Право на образование Учет взносов и отчислений на обязательное социальное медицинское страхование (ОСМС)

Учет взносов и отчислений на обязательное социальное медицинское страхование (ОСМС) Магия в первобытной культуре. Виды, приемы, механизмы

Магия в первобытной культуре. Виды, приемы, механизмы Построение образовательного пространства детей младшего дошкольного возраста в игровой деятельности

Построение образовательного пространства детей младшего дошкольного возраста в игровой деятельности Знаки препинания в сложном предложении

Знаки препинания в сложном предложении Фрезерование. Выбор торцевых фрез

Фрезерование. Выбор торцевых фрез Скрининговые тесты в диагностике состояния системы гемостаза

Скрининговые тесты в диагностике состояния системы гемостаза ГК Стронг. Гипсостружечная плита

ГК Стронг. Гипсостружечная плита Словарь-презентация терминов по морфологии. Именные части речи

Словарь-презентация терминов по морфологии. Именные части речи Шаблон презентации проекта

Шаблон презентации проекта Стихи собственного сочинения учащихся 3 класса Диск

Стихи собственного сочинения учащихся 3 класса Диск Талисманы Олимпиад

Талисманы Олимпиад Формирование чувства цвета у детей дошкольного возраста

Формирование чувства цвета у детей дошкольного возраста Климат Южной Америки.

Климат Южной Америки.