Содержание

- 2. Rover 20 Numerically Controlled Machining Centre For handicraft production it grants a wide product range with

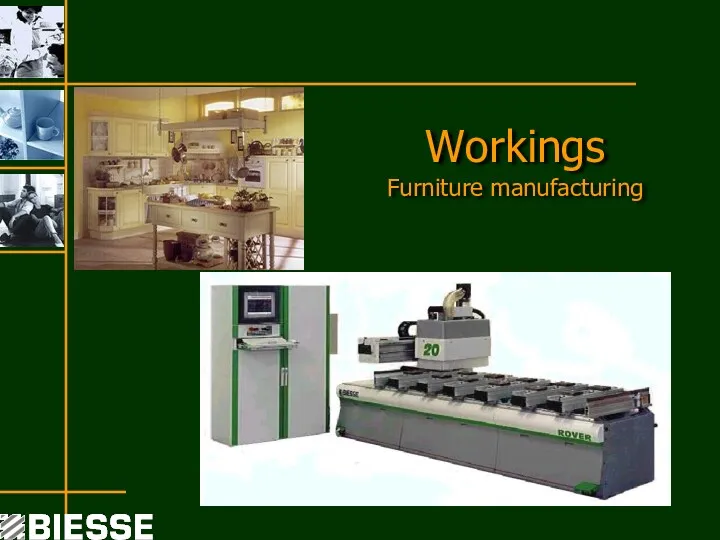

- 3. Workings Furniture manufacturing

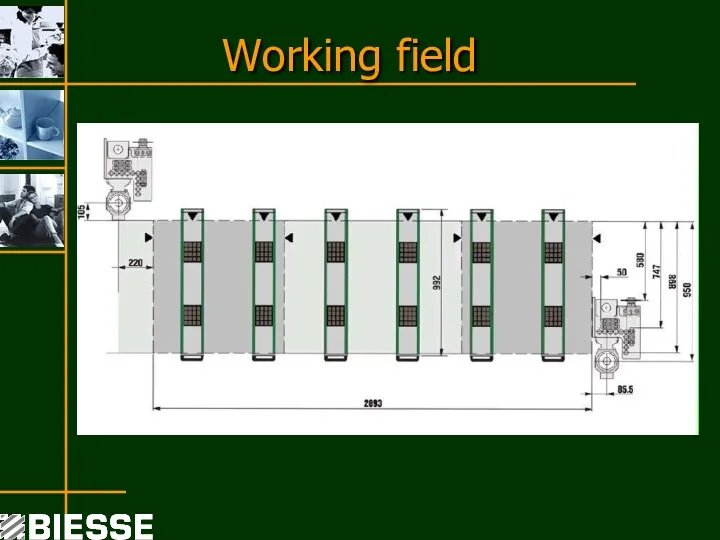

- 4. Working field

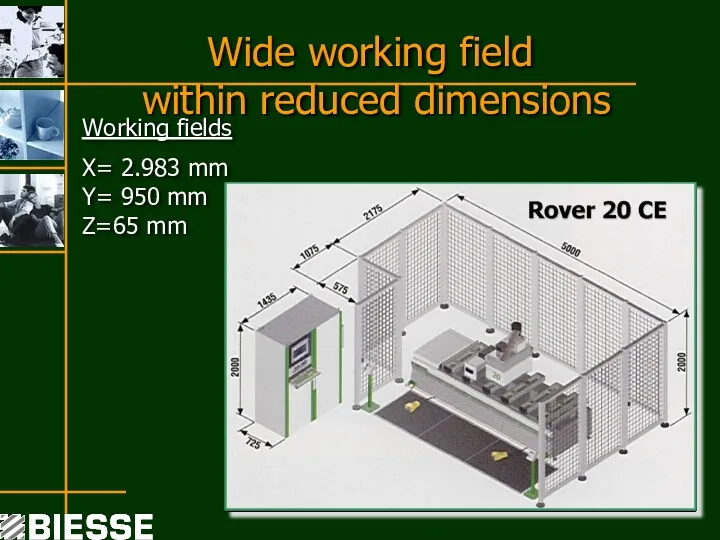

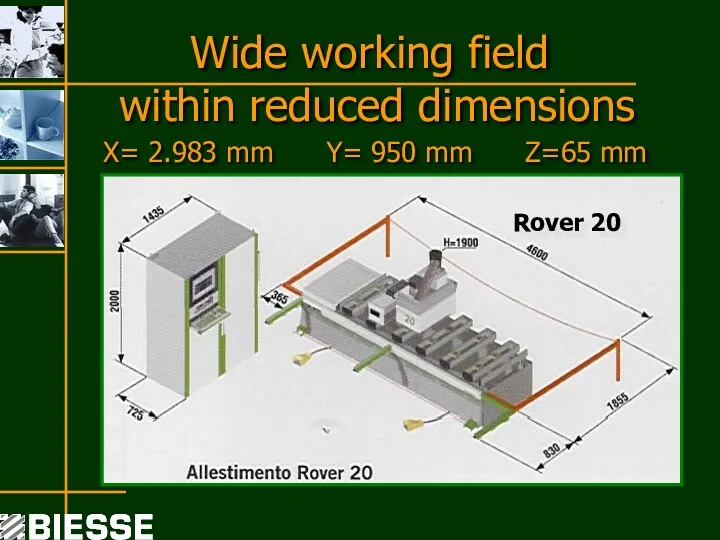

- 5. Wide working field within reduced dimensions Working fields X= 2.983 mm Y= 950 mm Z=65 mm

- 6. Wide working field within reduced dimensions X= 2.983 mm Y= 950 mm Z=65 mm Rover 20

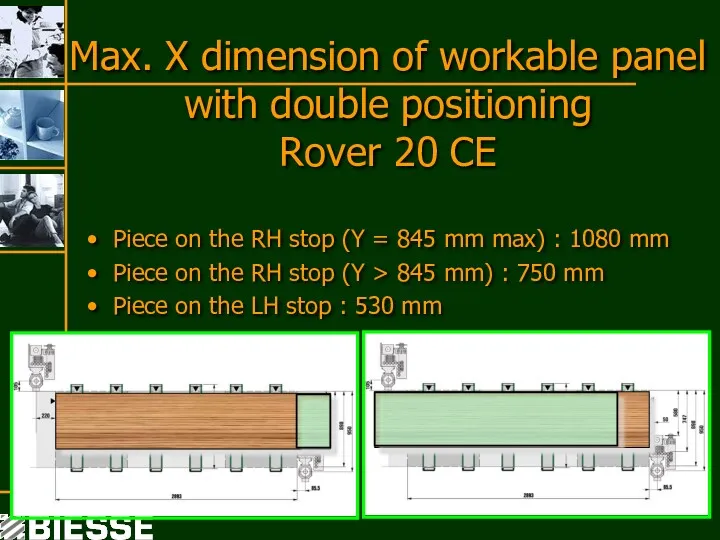

- 7. Max. X dimension of workable panel with double positioning Rover 20 CE Piece on the RH

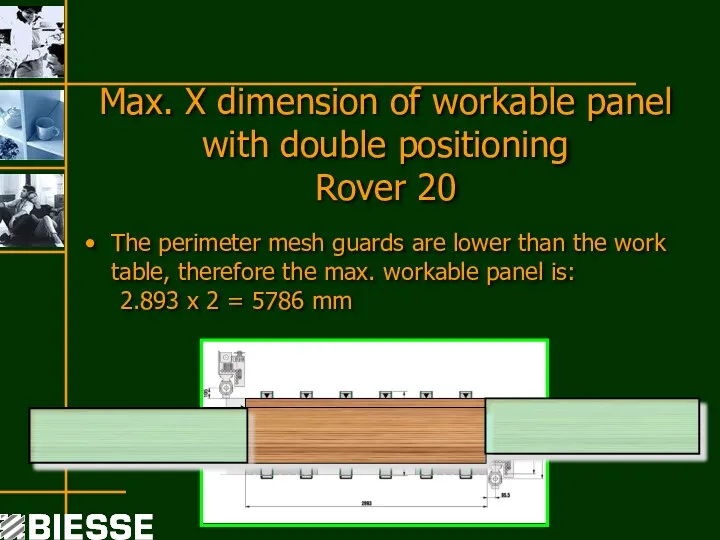

- 8. Max. X dimension of workable panel with double positioning Rover 20 The perimeter mesh guards are

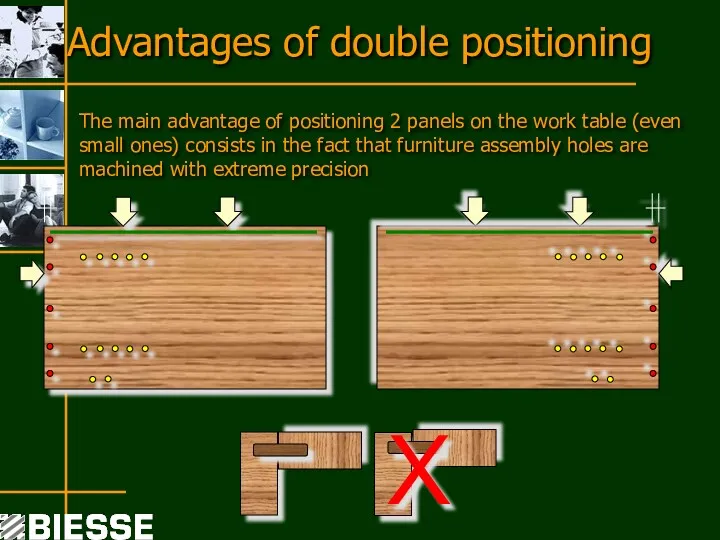

- 9. Advantages of double positioning The main advantage of positioning 2 panels on the work table (even

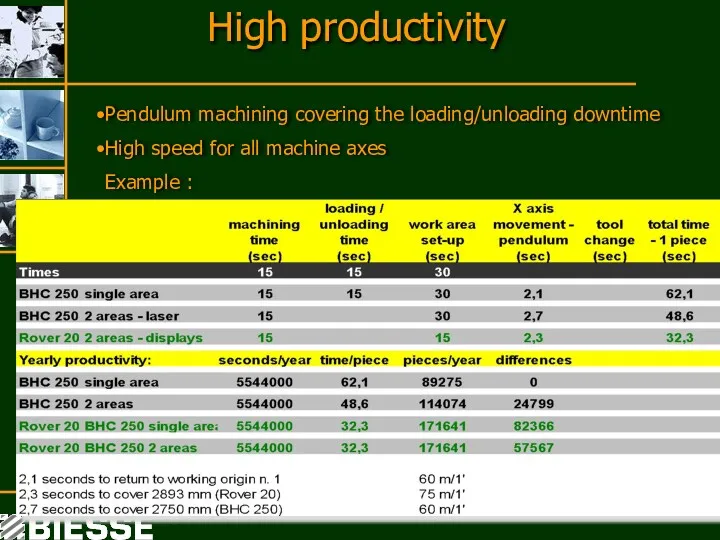

- 10. High productivity Pendulum machining covering the loading/unloading downtime High speed for all machine axes Example :

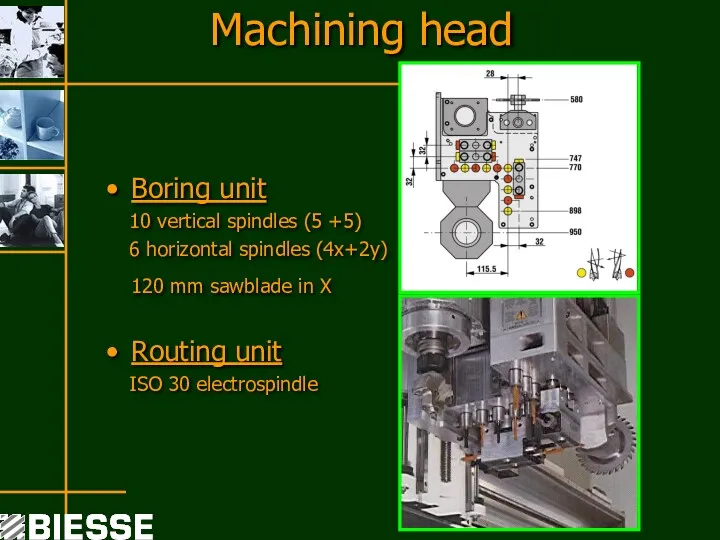

- 11. Machining head Boring unit 10 vertical spindles (5 +5) 6 horizontal spindles (4x+2y) 120 mm sawblade

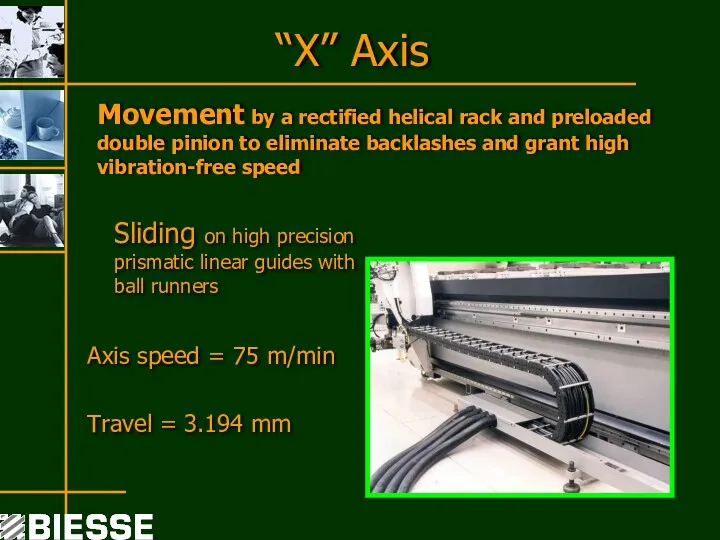

- 12. “X” Axis Sliding on high precision prismatic linear guides with ball runners Axis speed = 75

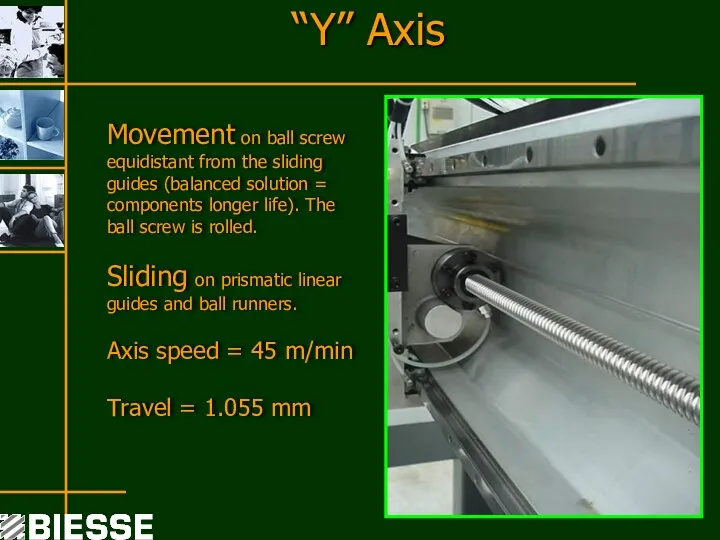

- 13. “Y” Axis Movement on ball screw equidistant from the sliding guides (balanced solution = components longer

- 14. “Z” Axis Movement on ball screw Sliding on linear guides and ball runners. The optimal weight

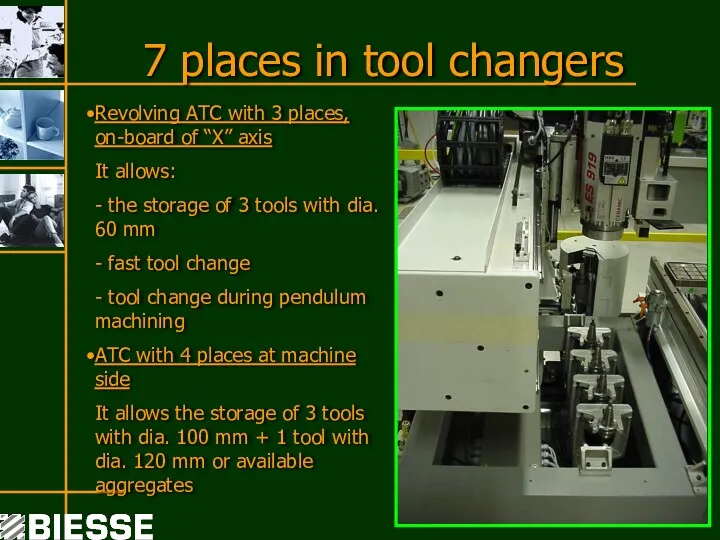

- 15. 7 places in tool changers Revolving ATC with 3 places, on-board of “X” axis It allows:

- 16. Fast and safe tool change The machine is equipped with sensors to avoid collisions, constantly checking:

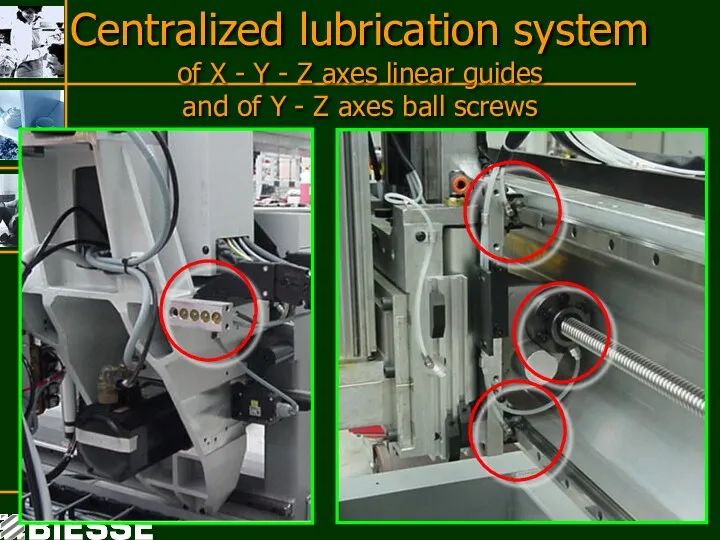

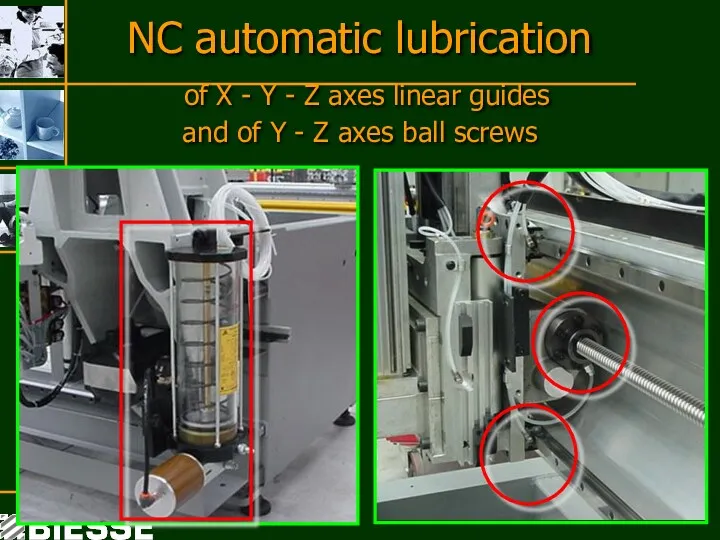

- 17. Centralized lubrication system of X - Y - Z axes linear guides and of Y -

- 18. NC automatic lubrication of X - Y - Z axes linear guides and of Y -

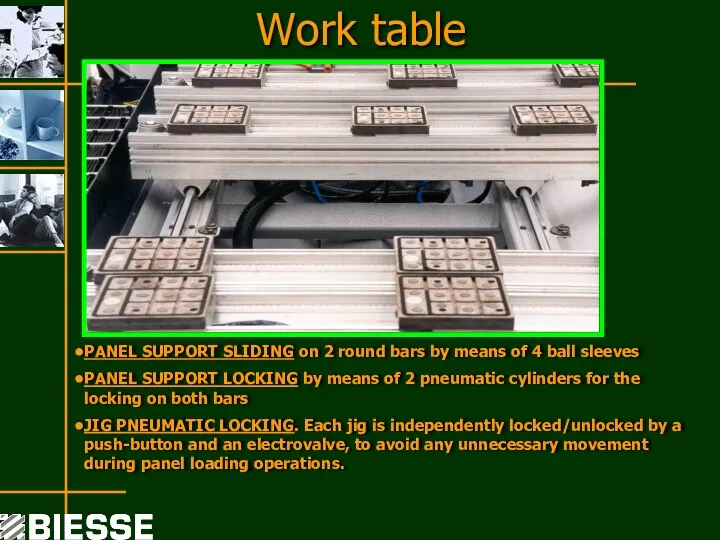

- 19. Work table PANEL SUPPORT SLIDING on 2 round bars by means of 4 ball sleeves PANEL

- 20. Read-outs on the panel supports The quick set-up of the work area is granted by: -

- 21. Fully equipped standard machine 6 panel supports with a supporting surface of 915 mm 12 pneumatic

- 22. Fully equipped standard machine 7 kW electrospindle (9 Hp) ISO 30 7,5 kW inverter Boring unit

- 24. Скачать презентацию

Современный православный монастырь как центр духовного просвещения молодежи

Современный православный монастырь как центр духовного просвещения молодежи Я - гражданин и патриот России!

Я - гражданин и патриот России! Игра-тренажёр Помоги освободить принцессу. Счёт в пределах 10 +2, -2

Игра-тренажёр Помоги освободить принцессу. Счёт в пределах 10 +2, -2 Классный час.

Классный час. Чтобы учение было в радость

Чтобы учение было в радость Суффиксы -ова- и -ыва-

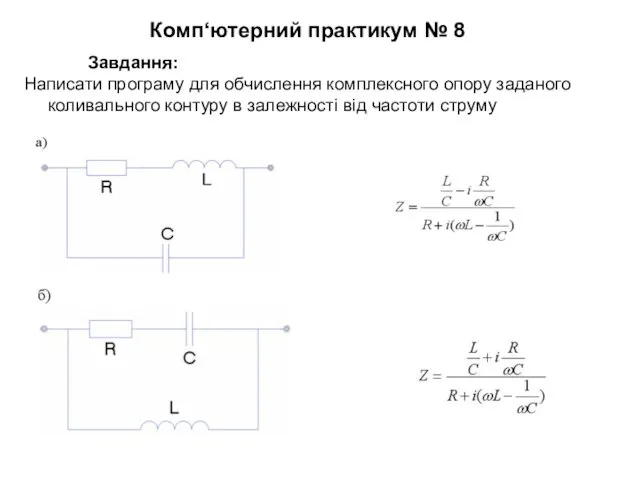

Суффиксы -ова- и -ыва- обчислення комплексного опору заданого коливального контуру в залежності від частоти струму

обчислення комплексного опору заданого коливального контуру в залежності від частоти струму Модуляция. Способы и типы модуляции

Модуляция. Способы и типы модуляции Особенности размещения приемного отделения

Особенности размещения приемного отделения Презентация к занятию по познавательному развитию для детей дошкольного возраста (подготовительная группа). Тема: Недаром помнит вся Россия про день Бородина!

Презентация к занятию по познавательному развитию для детей дошкольного возраста (подготовительная группа). Тема: Недаром помнит вся Россия про день Бородина! Презентация опыта работы: Биоадекватная методика - средство развития познавательной активности дошкольников с ОВЗ

Презентация опыта работы: Биоадекватная методика - средство развития познавательной активности дошкольников с ОВЗ Робототехника. Компоненты роботов

Робототехника. Компоненты роботов Илья Сергеевич Глазунов

Илья Сергеевич Глазунов Размещение и миграции населения мира. Анимированный тест. 10-11 класс

Размещение и миграции населения мира. Анимированный тест. 10-11 класс Информационная Безопасность Компьютерных Систем (IBKS). Высшая Школа Кибербезопасности

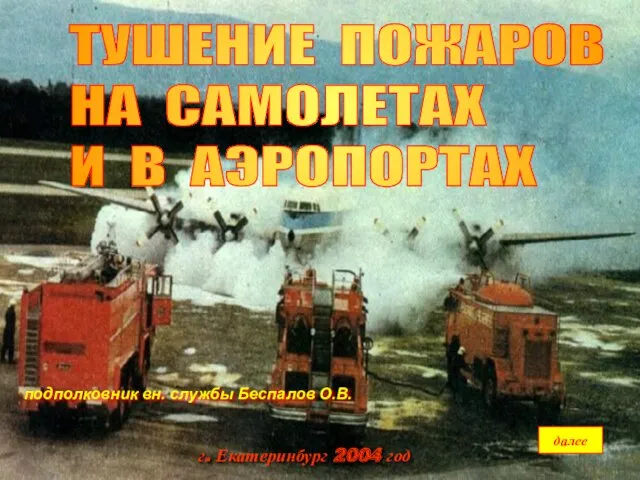

Информационная Безопасность Компьютерных Систем (IBKS). Высшая Школа Кибербезопасности Тушение пожаров на самолётах и в аэропортах

Тушение пожаров на самолётах и в аэропортах Проектирование и оценка технологической эффективности проведения гидравлического разрыва пласта

Проектирование и оценка технологической эффективности проведения гидравлического разрыва пласта Получение, собирание и распознавание кислорода. Практическая работа №4

Получение, собирание и распознавание кислорода. Практическая работа №4 Реклама в печатных СМИ. Структура рекламного объявления

Реклама в печатных СМИ. Структура рекламного объявления Презентация Лесостепи и степи России

Презентация Лесостепи и степи России шаблон для создания теста

шаблон для создания теста Натуральные волокна

Натуральные волокна Лекции 8-9. Публичное выступление

Лекции 8-9. Публичное выступление Язык и логика. Интегрированный урок русского языка, математики и информатики

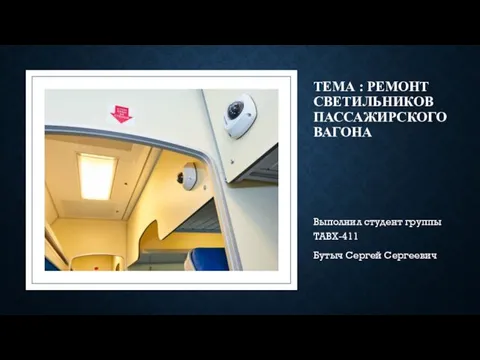

Язык и логика. Интегрированный урок русского языка, математики и информатики презентация Бутыч

презентация Бутыч история одежды

история одежды Ни дня без смеха

Ни дня без смеха Рациональная добыча атлантической трески

Рациональная добыча атлантической трески