Содержание

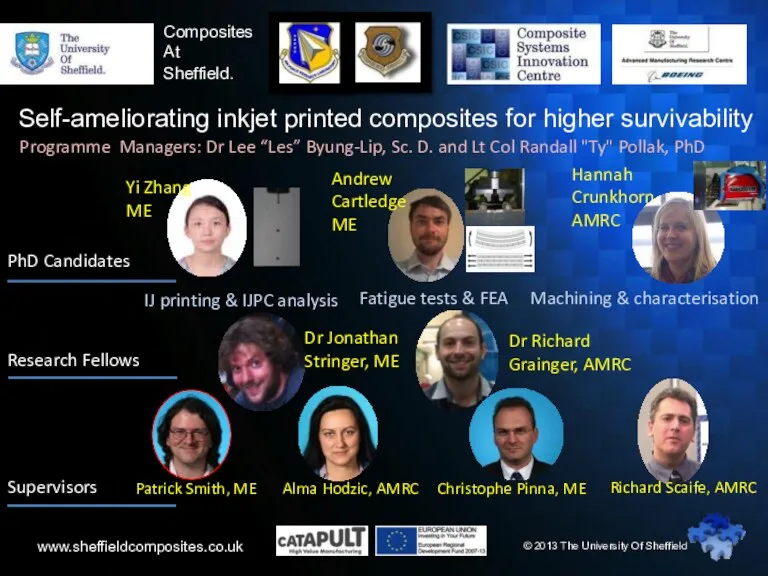

- 2. Self-ameliorating inkjet printed composites for higher survivability www.sheffieldcomposites.co.uk Composites At Sheffield. © 2013 The University Of

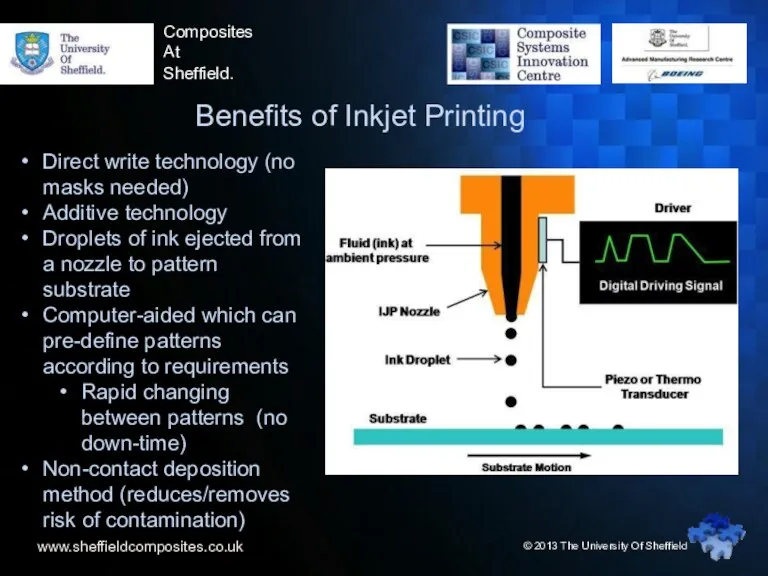

- 3. www.sheffieldcomposites.co.uk Composites At Sheffield. Benefits of Inkjet Printing Direct write technology (no masks needed) Additive technology

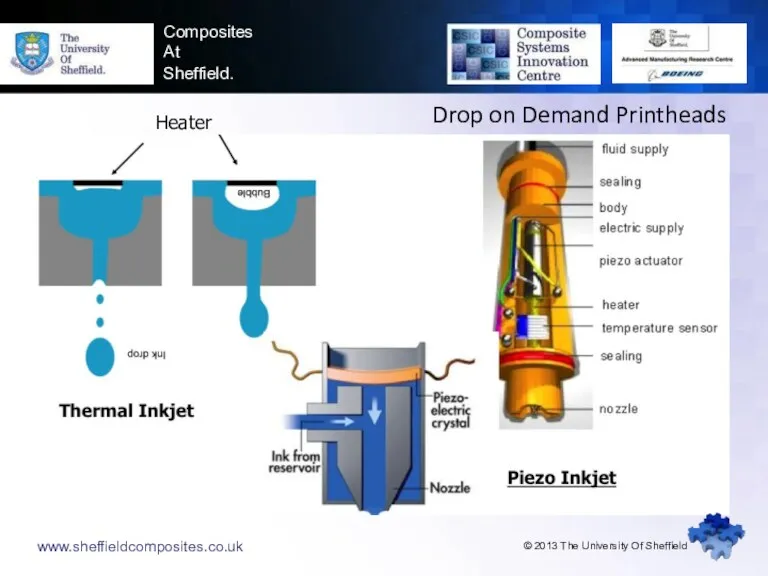

- 4. www.sheffieldcomposites.co.uk Composites At Sheffield. Drop on Demand Printheads Heater © 2013 The University Of Sheffield

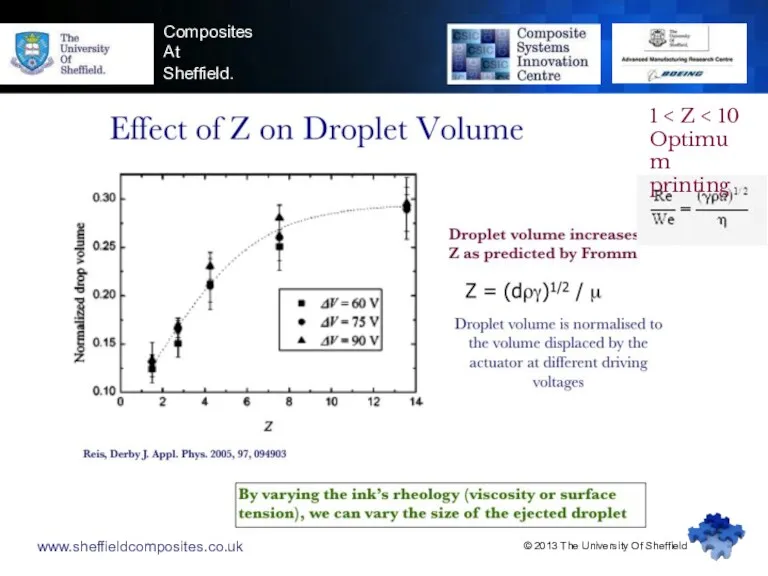

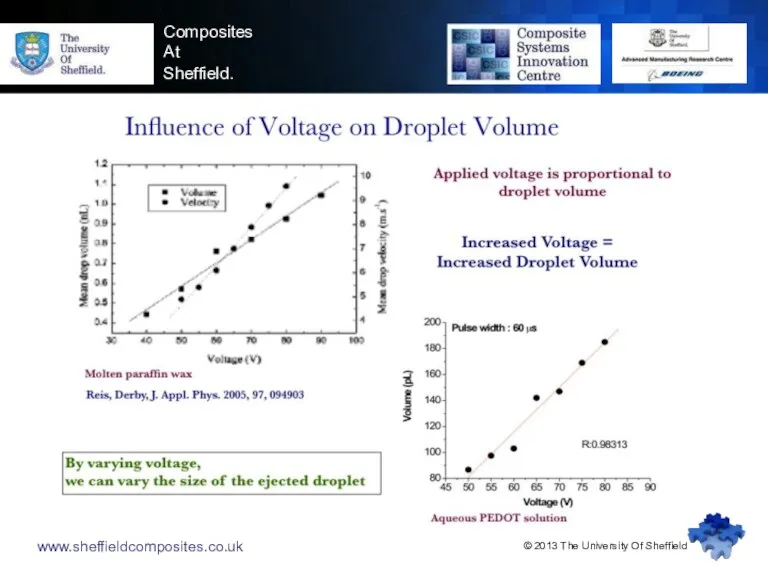

- 5. www.sheffieldcomposites.co.uk Composites At Sheffield. © 2013 The University Of Sheffield 1 Optimum printing

- 6. www.sheffieldcomposites.co.uk Composites At Sheffield. © 2013 The University Of Sheffield

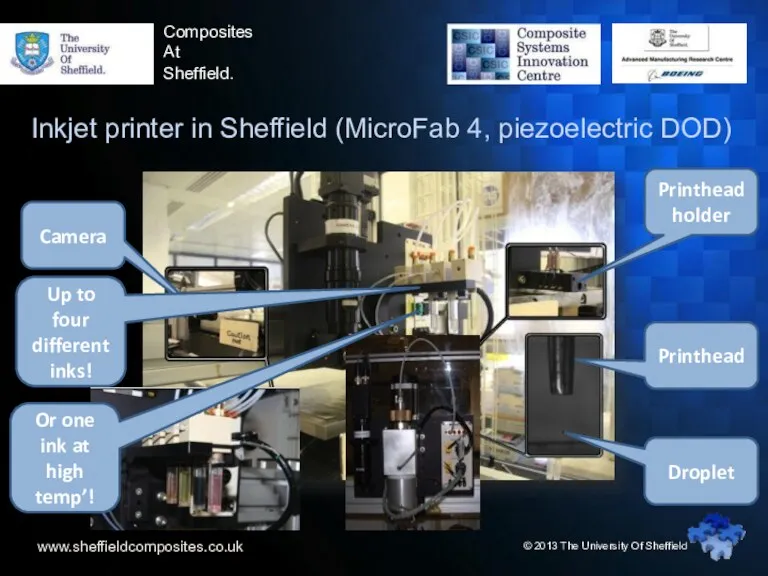

- 7. www.sheffieldcomposites.co.uk Composites At Sheffield. Inkjet printer in Sheffield (MicroFab 4, piezoelectric DOD) Up to four different

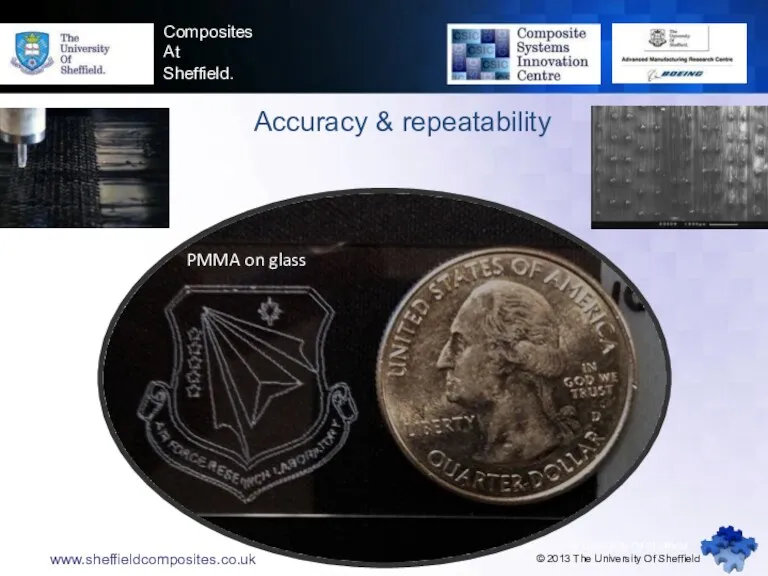

- 8. www.sheffieldcomposites.co.uk Accuracy & repeatability © 2013 The University Of Sheffield Composites At Sheffield. www.sheffieldcomposites.co.uk © 2013

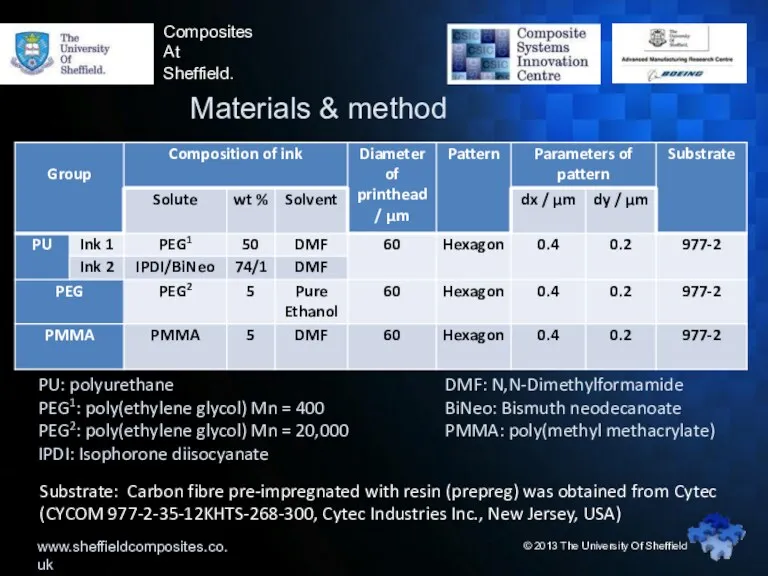

- 9. www.sheffieldcomposites.co.uk Composites At Sheffield. Materials & method © 2013 The University Of Sheffield PU: polyurethane PEG1:

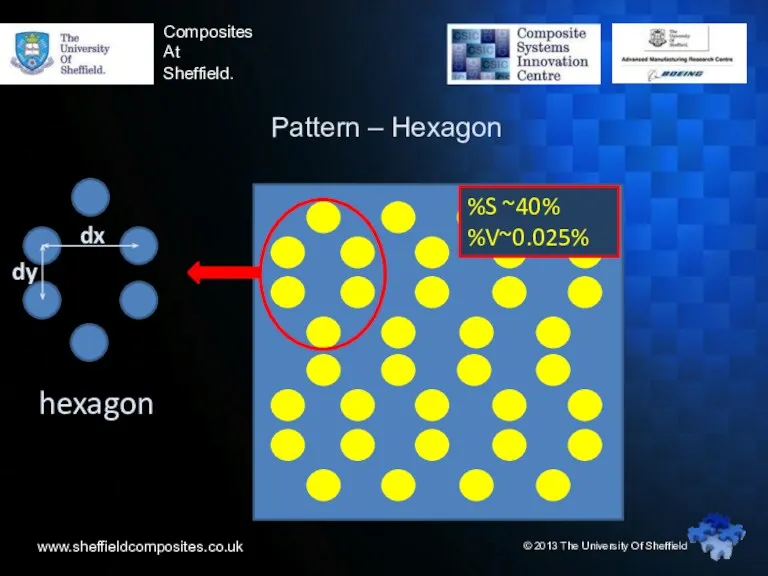

- 10. www.sheffieldcomposites.co.uk Composites At Sheffield. Pattern – Hexagon hexagon © 2013 The University Of Sheffield %S ~40%

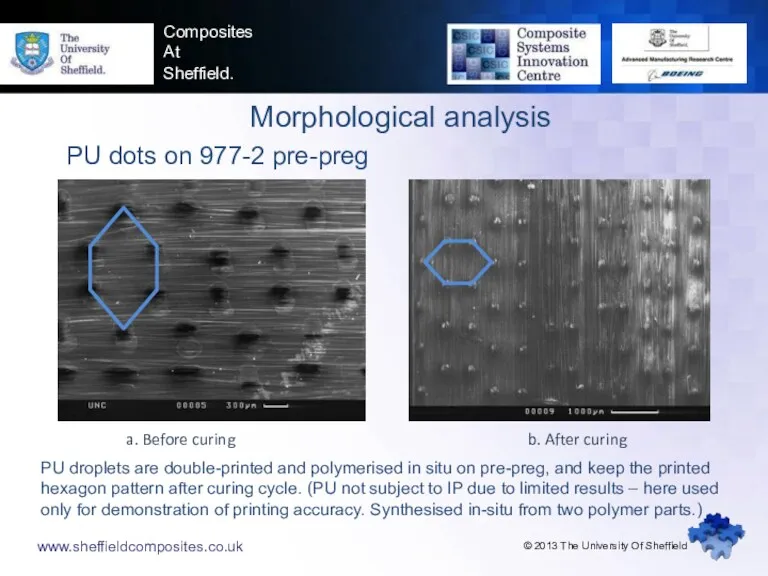

- 11. www.sheffieldcomposites.co.uk Composites At Sheffield. Morphological analysis PU dots on 977-2 pre-preg a. Before curing b. After

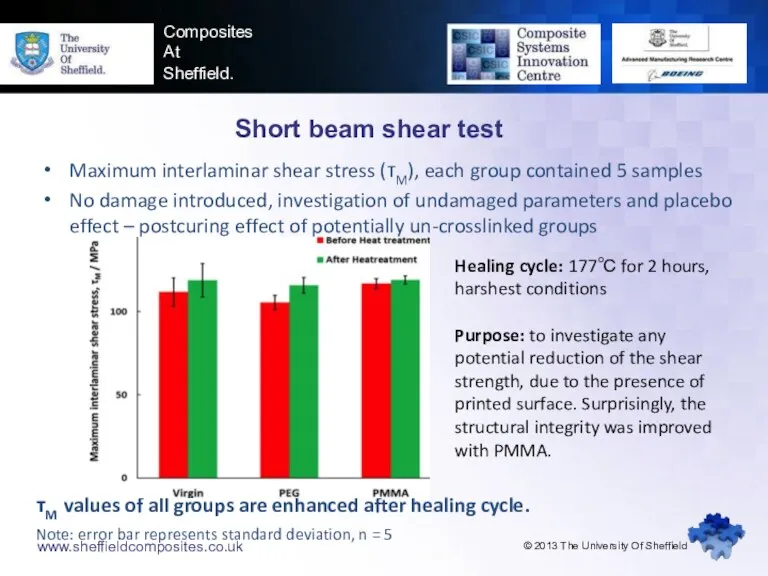

- 12. www.sheffieldcomposites.co.uk Composites At Sheffield. Short beam shear test Maximum interlaminar shear stress (τM), each group contained

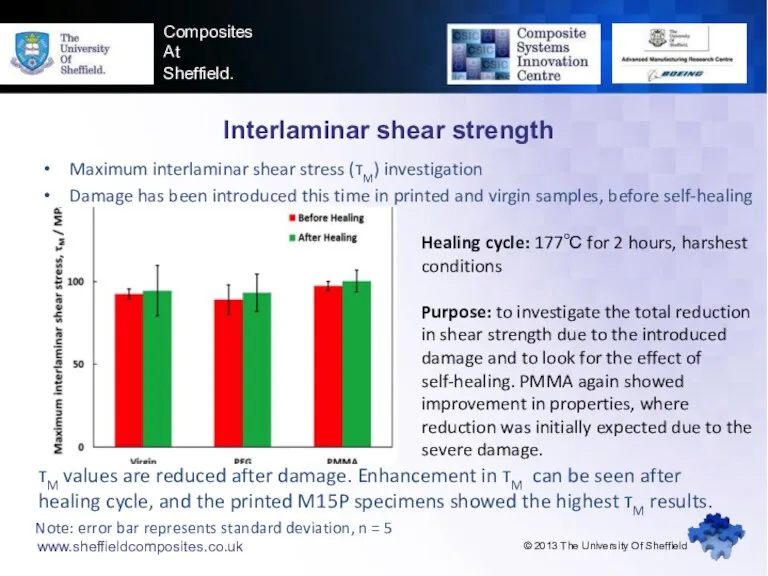

- 13. www.sheffieldcomposites.co.uk Composites At Sheffield. Interlaminar shear strength Maximum interlaminar shear stress (τM) investigation Damage has been

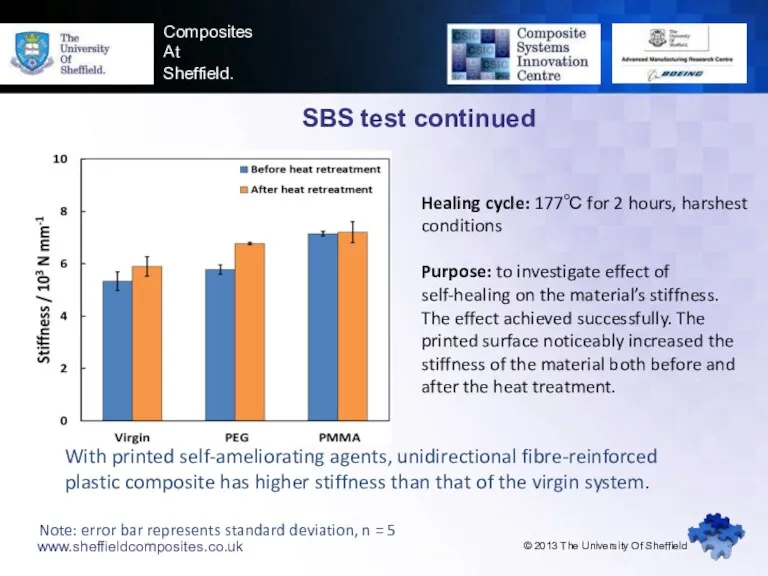

- 14. www.sheffieldcomposites.co.uk Composites At Sheffield. SBS test continued With printed self-ameliorating agents, unidirectional fibre-reinforced plastic composite has

- 15. www.sheffieldcomposites.co.uk Composites At Sheffield. Mode I interlaminar fracture toughness (GIC) test The fracture toughness, obtained by

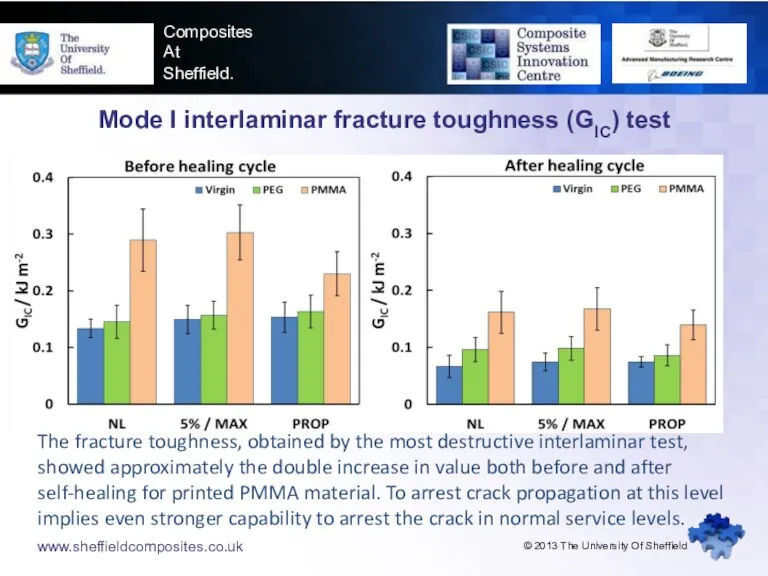

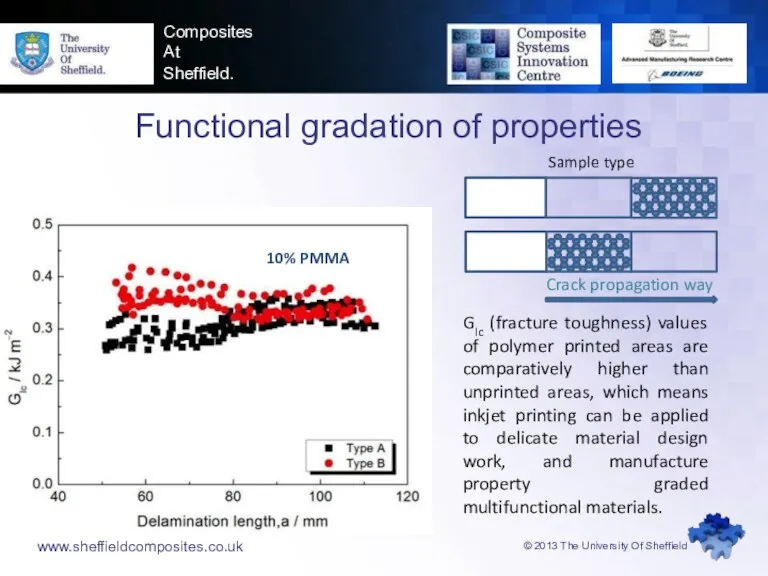

- 16. www.sheffieldcomposites.co.uk © 2013 The University Of Sheffield Composites At Sheffield. GIc (fracture toughness) values of polymer

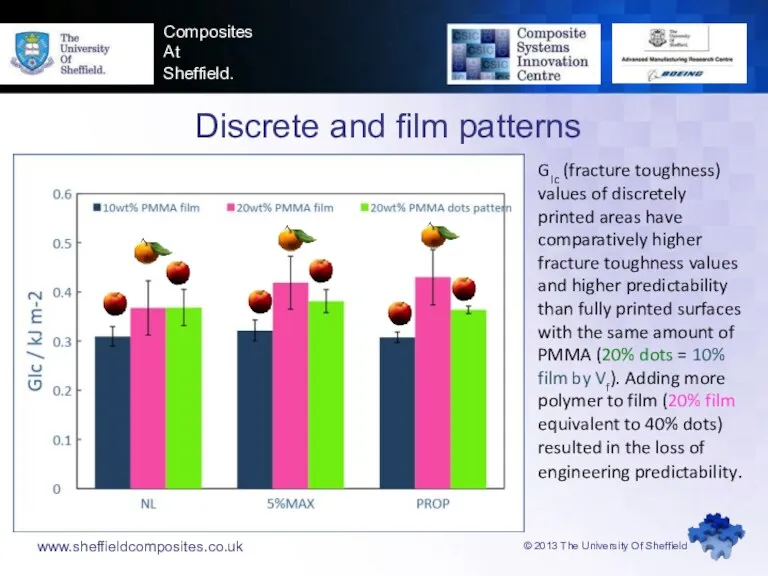

- 17. www.sheffieldcomposites.co.uk © 2013 The University Of Sheffield Composites At Sheffield. GIc (fracture toughness) values of discretely

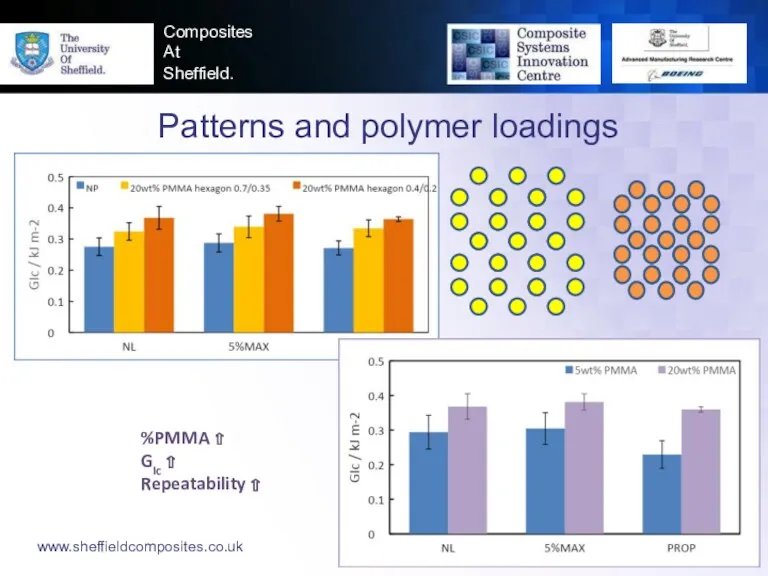

- 18. www.sheffieldcomposites.co.uk © 2013 The University Of Sheffield Composites At Sheffield. Patterns and polymer loadings %PMMA ⇧

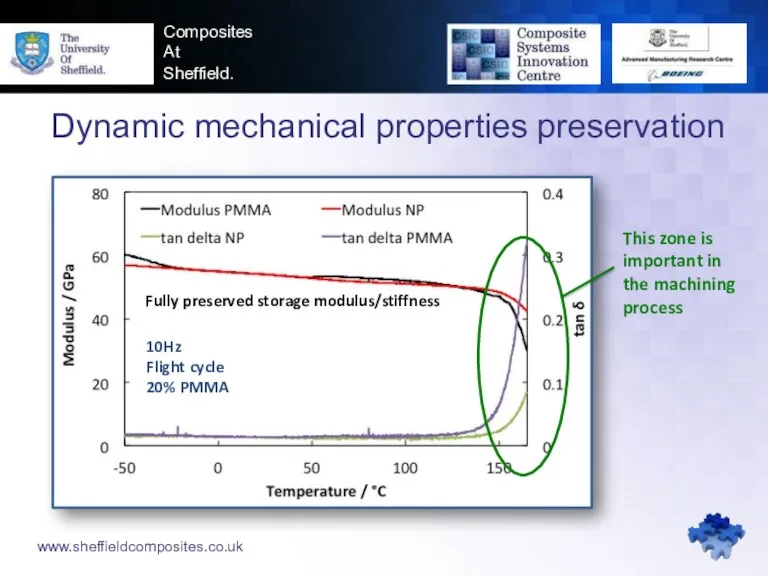

- 19. www.sheffieldcomposites.co.uk Composites At Sheffield. Dynamic mechanical properties preservation 10Hz Flight cycle 20% PMMA This zone is

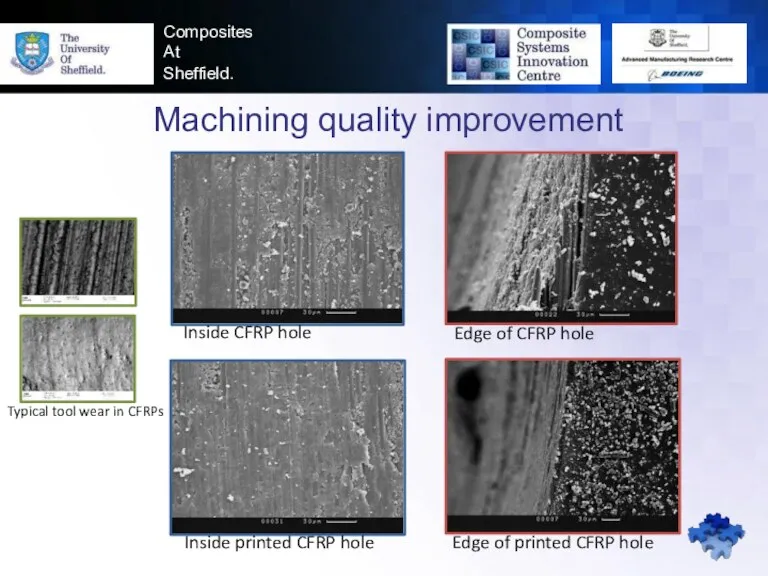

- 20. Composites At Sheffield. Machining quality improvement Inside CFRP hole Edge of CFRP hole Inside printed CFRP

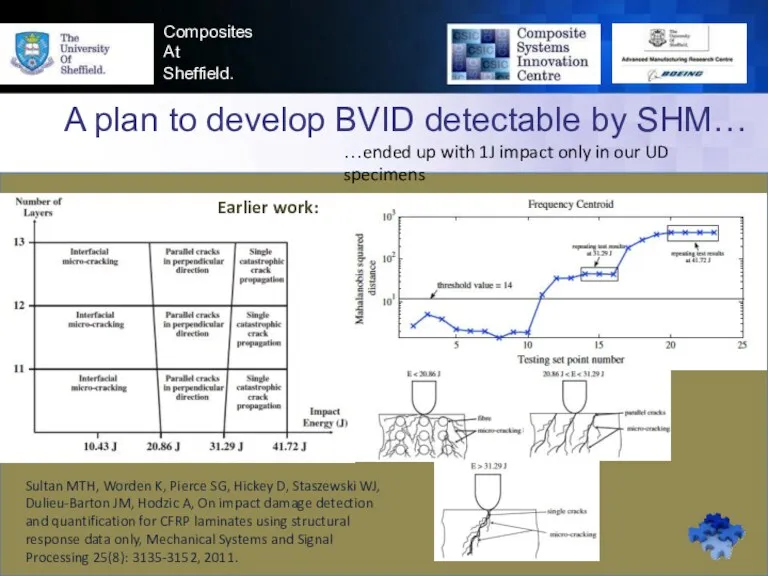

- 21. Composites At Sheffield. A plan to develop BVID detectable by SHM… Sultan MTH, Worden K, Pierce

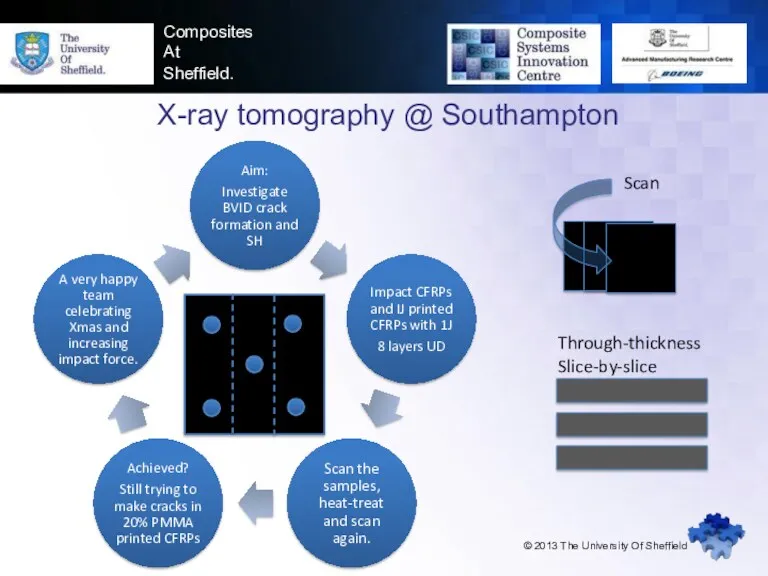

- 22. Composites At Sheffield. X-ray tomography @ Southampton © 2013 The University Of Sheffield Scan Through-thickness Slice-by-slice

- 23. Composites At Sheffield. X-ray tomography @ Southampton © 2013 The University Of Sheffield System: Custom design

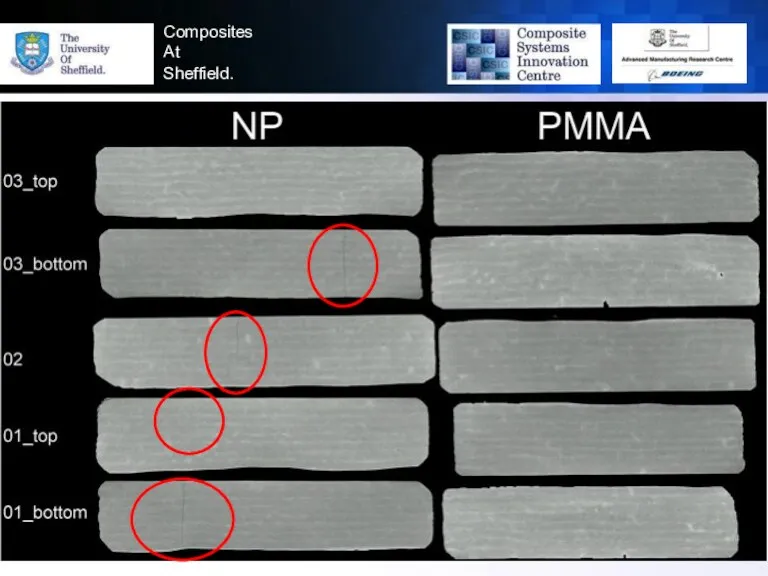

- 24. Composites At Sheffield.

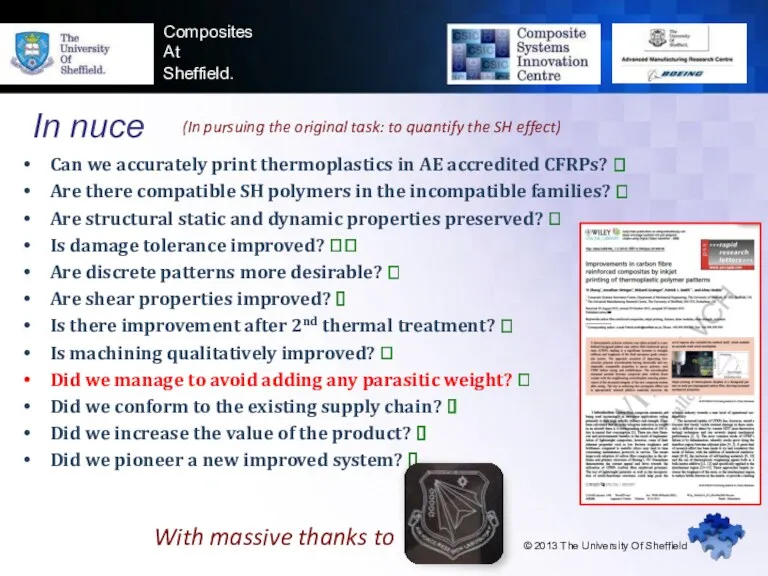

- 25. Composites At Sheffield. In nuce © 2013 The University Of Sheffield Can we accurately print thermoplastics

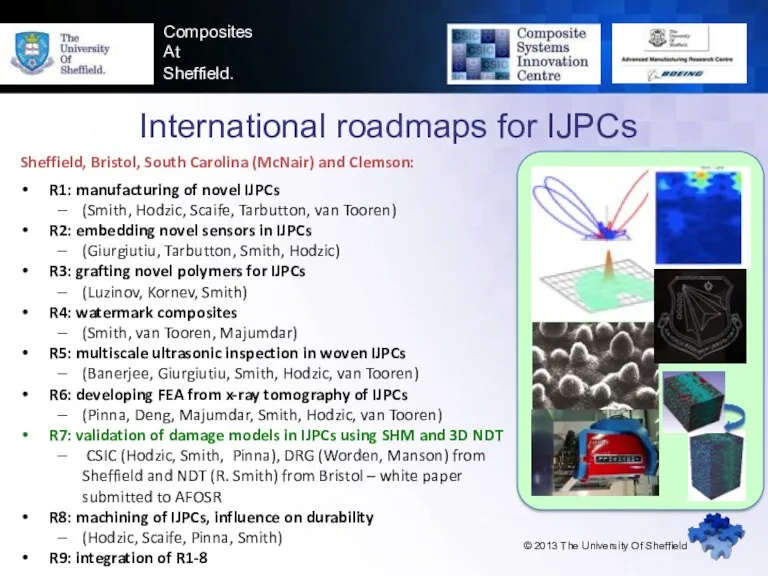

- 26. Composites At Sheffield. International roadmaps for IJPCs © 2013 The University Of Sheffield Sheffield, Bristol, South

- 27. Innovation and Research Manufacture/Characterization/Certification Center for Mechanics, Materials, and Non-Destructive Evaluation Laboratory for Active Materials and

- 29. Скачать презентацию

Шаблон курсового проекта

Шаблон курсового проекта Использование ИКТ в образовательном пространстве ДОУ

Использование ИКТ в образовательном пространстве ДОУ Тема: Здоровый образ жизни.

Тема: Здоровый образ жизни. Волоховой

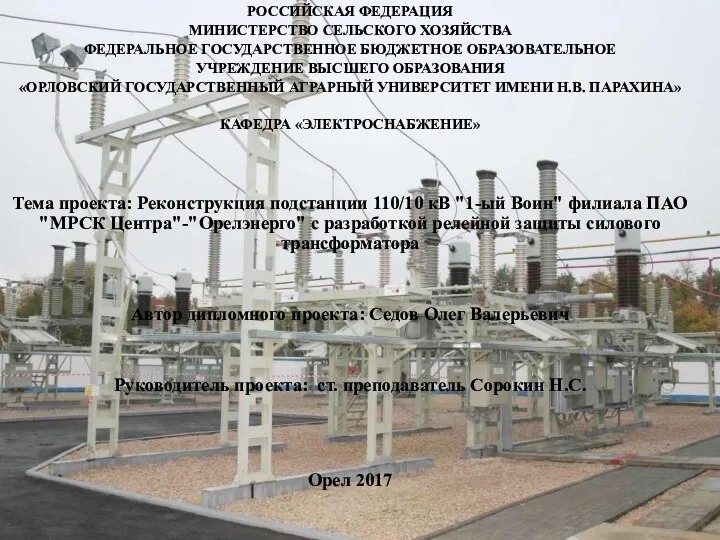

Волоховой Реконструкция подстанции 110/10 кВ с разработкой релейной защиты силового трансформатора

Реконструкция подстанции 110/10 кВ с разработкой релейной защиты силового трансформатора Программа по внеурочной деятельности пректного направления Мой родной край

Программа по внеурочной деятельности пректного направления Мой родной край Презентация Виды работы с текстом учебника географии

Презентация Виды работы с текстом учебника географии Лучевая диагностика туберкулеза органов дыхания

Лучевая диагностика туберкулеза органов дыхания Презентация Механизм взаимодействия учителя-логопеда с педагогом-психологом и социальным педагогом в рамках деятельности ПМПконсилиума общеобразовательной организации

Презентация Механизм взаимодействия учителя-логопеда с педагогом-психологом и социальным педагогом в рамках деятельности ПМПконсилиума общеобразовательной организации Презентация к уроку 70 лет со дня освобождения Кубани от фашистских захватчиков

Презентация к уроку 70 лет со дня освобождения Кубани от фашистских захватчиков презентация к уроку Географическое положение Африки

презентация к уроку Географическое положение Африки Первоклассник

Первоклассник Под знаком двойной розы. Англия при Тюдорах

Под знаком двойной розы. Англия при Тюдорах презентацияАзбука нравственности

презентацияАзбука нравственности Вторая Мировая война. Тихоокеанский фронт

Вторая Мировая война. Тихоокеанский фронт Рождение протестантизма православия

Рождение протестантизма православия Витамин В-12. Дефицитная анемия

Витамин В-12. Дефицитная анемия Природные зоны Австралии

Природные зоны Австралии Сити-фермер - профессия будущего

Сити-фермер - профессия будущего Зажимные устройства технологической оснастки и их расчёт

Зажимные устройства технологической оснастки и их расчёт Химический состав клетки. (9 класс)

Химический состав клетки. (9 класс) бизнес план

бизнес план Саул. Царственные задатки и непослушание, гордость, зависть

Саул. Царственные задатки и непослушание, гордость, зависть Центральная и осевая симметрии презентации по геометрии для 8АВ

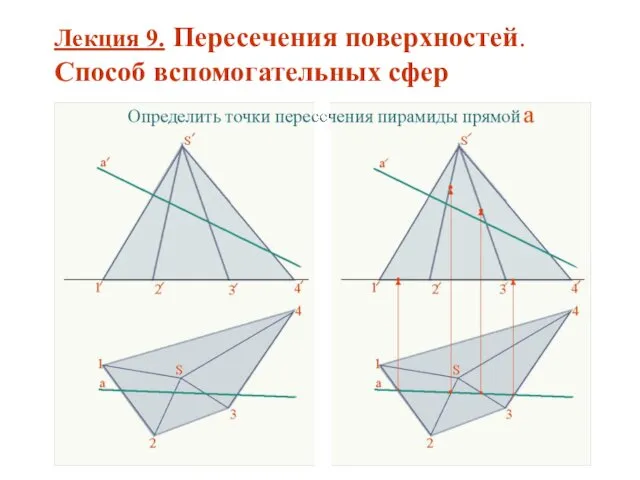

Центральная и осевая симметрии презентации по геометрии для 8АВ Пересечения поверхностей. Способ вспомогательных сфер. (Лекция 9)

Пересечения поверхностей. Способ вспомогательных сфер. (Лекция 9) Атлас педагогических идей

Атлас педагогических идей Слесарное дело. Тест

Слесарное дело. Тест Век медный, бронзовый, железный. Презентация к уроку химии 9 класс.

Век медный, бронзовый, железный. Презентация к уроку химии 9 класс.